Full-automatic tobacco baling machine

A fully automatic, packing machine technology, applied in packaging and other directions, can solve problems such as waste of manpower, achieve the effects of improving work efficiency, high degree of automation, and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

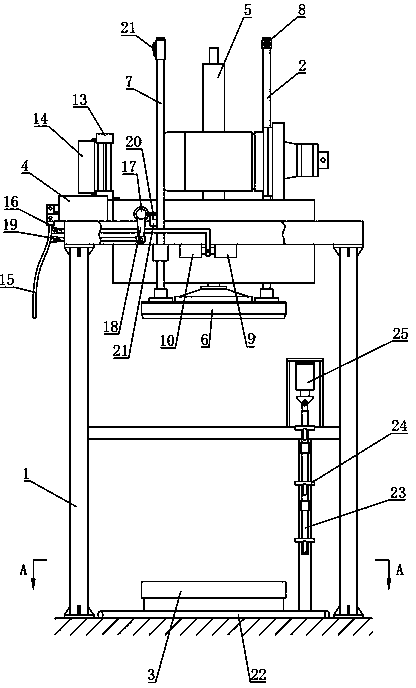

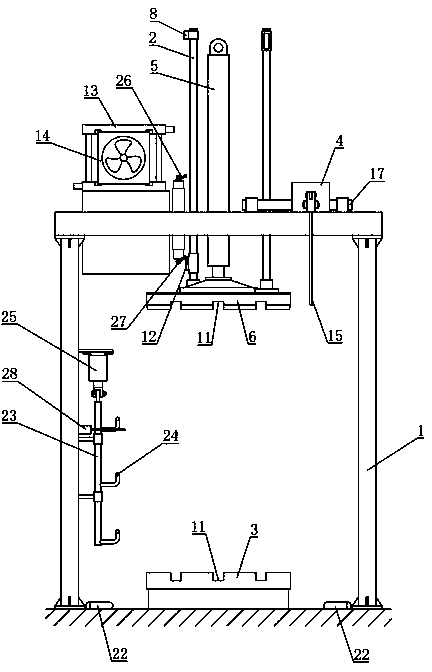

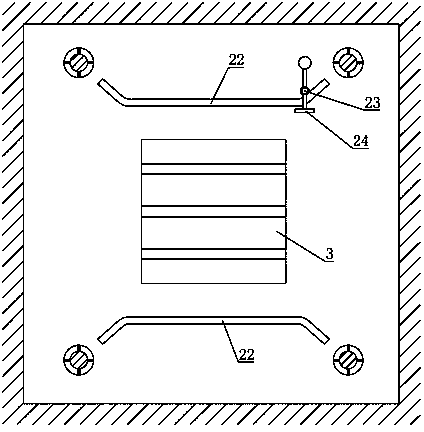

[0021] Such as figure 1 , figure 2 , image 3Shown, this full-automatic tobacco leaf packing machine comprises the portal frame 1 that is fixed on the ground. The bottom of the portal frame 1 is provided with a passage for packing boxes to enter in it along the front and rear directions. A lower pressing plate 3 fixed on the ground is provided in the channel. The upper part of the gantry 1 is provided with a hydraulic cylinder 5 controlled by a reversing valve 4 , and the bottom of the piston rod of the hydraulic cylinder 5 is equipped with an upper pressing plate 6 corresponding to the lower pressing plate 3 . The upper pressing plate 6 and the lower pressing plate 3 are respectively provided with a plurality of grooves 11 for placing binding ropes, and the grooves 11 on the upper pressing plate 6 and the lower pressing plate 3 are correspondingly arranged. When in use, the binding rope can be pre-placed in the groove 11 to facilitate bundling. The reversing valve 4 com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com