Floating support device

A floating support and floating spring technology, which is applied to grinding machines, metal processing equipment, grinding/polishing equipment, etc., can solve problems such as low production efficiency, heavy dust environmental pollution, and unfavorable health of workers, so as to achieve high production efficiency and improve The effect of the polished effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

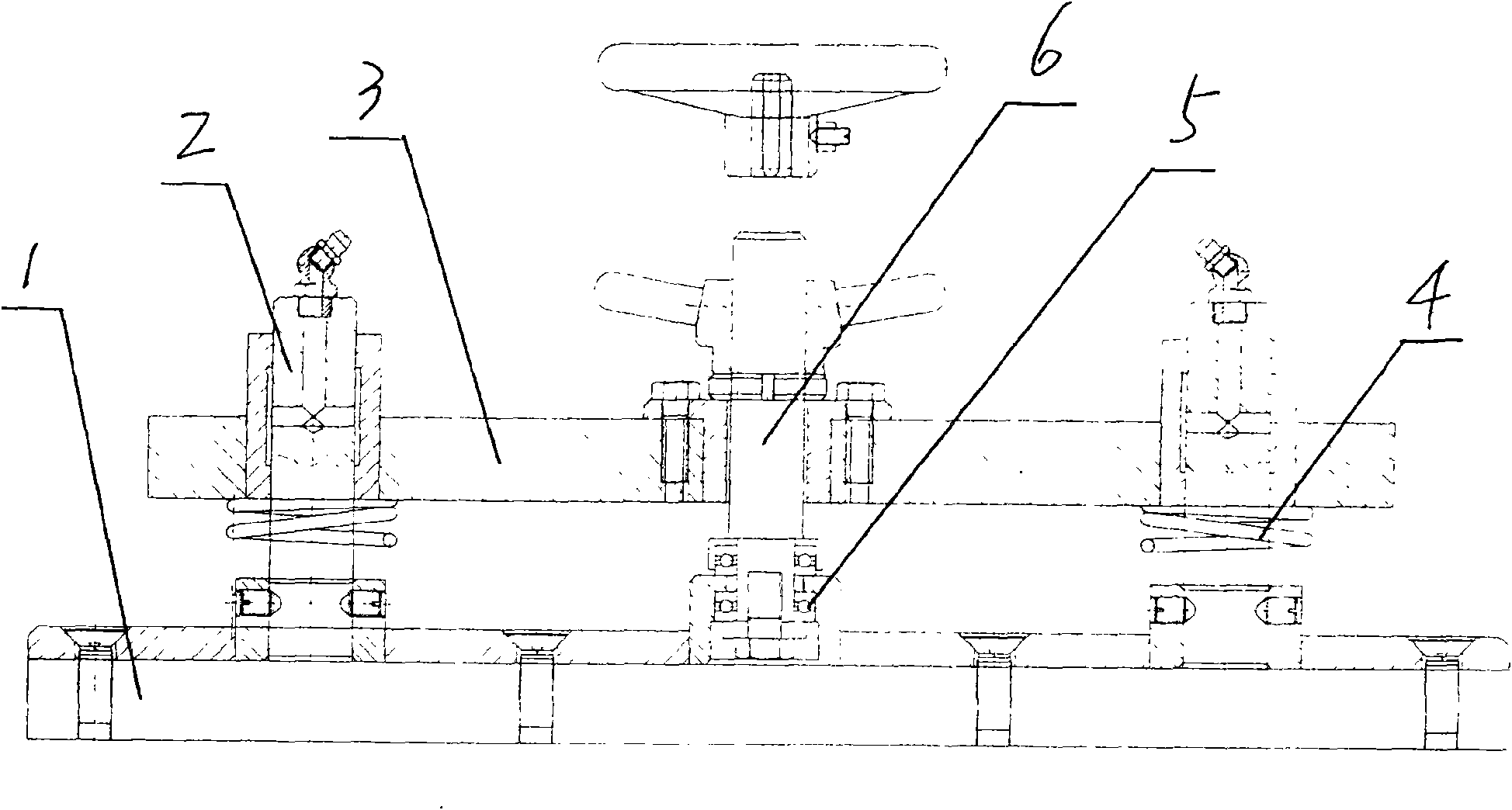

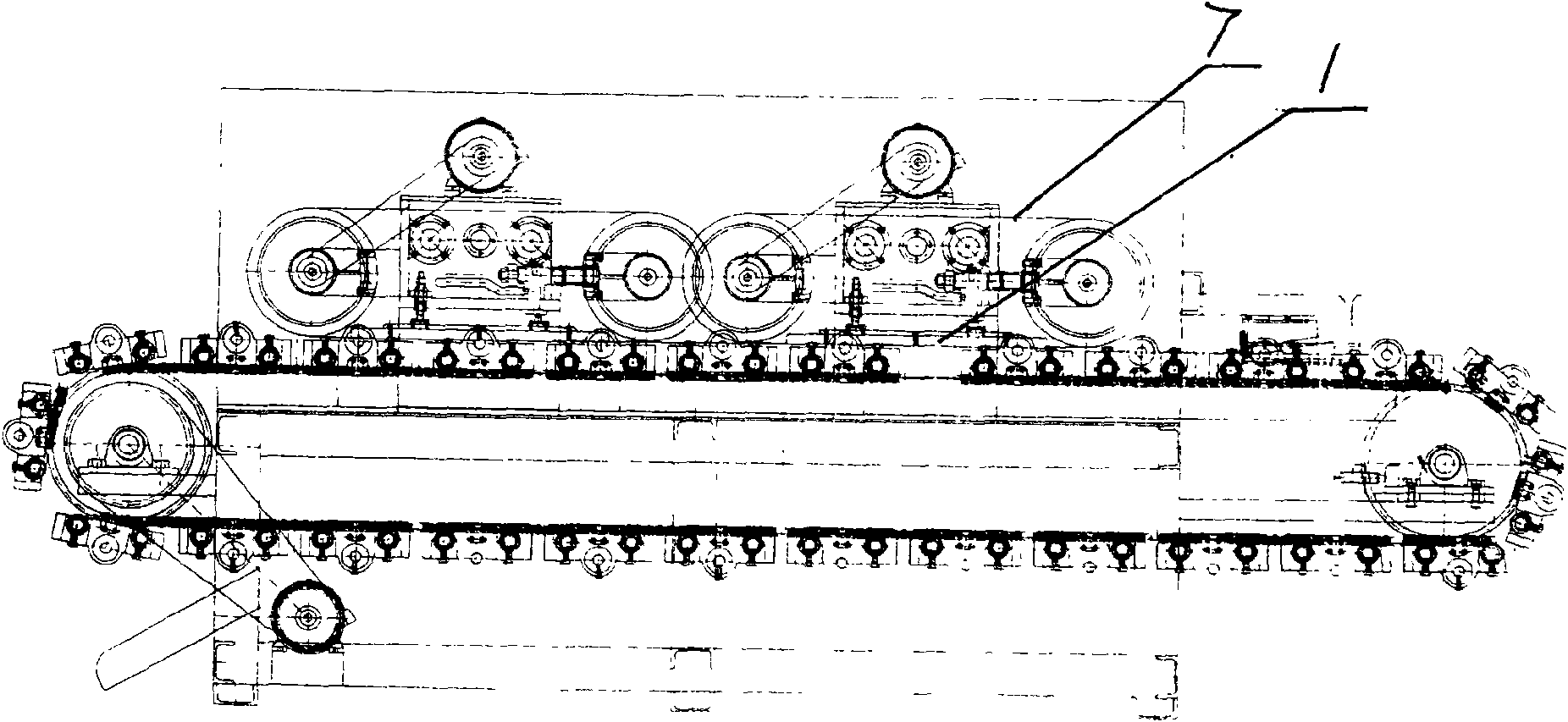

[0007] refer to figure 1 , figure 2 . A floating support device, which is composed of a floating guide plate 1 fixed on the guide plate base; guide columns 2 are arranged on the front and rear ends of the guide plate base, and the upper end of the guide column 2 is located on the guide hole on the fixed support plate 3 to pass through. A floating spring 4 is arranged on the guide column between the plates; a thrust bearing 5 is arranged in the middle of the guide plate seat to connect the lower end of the screw mandrel 6, and a hand wheel is arranged at the upper end of the screw mandrel 6; the screw mandrel 6 is threadedly matched with the fixed support beam. During use, the fixed supporting plate is fixed on the support, so that the floating guide plate is close to the inner surface of the polishing abrasive belt 7 and gets final product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com