Hydraulic chain tensioner device

A tensioner, hydraulic technology, applied in the direction of transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of large chain noise, large transmission noise, heavy gear and other problems, and achieve smooth and high promotion of sprocket transmission. Value, compact layout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

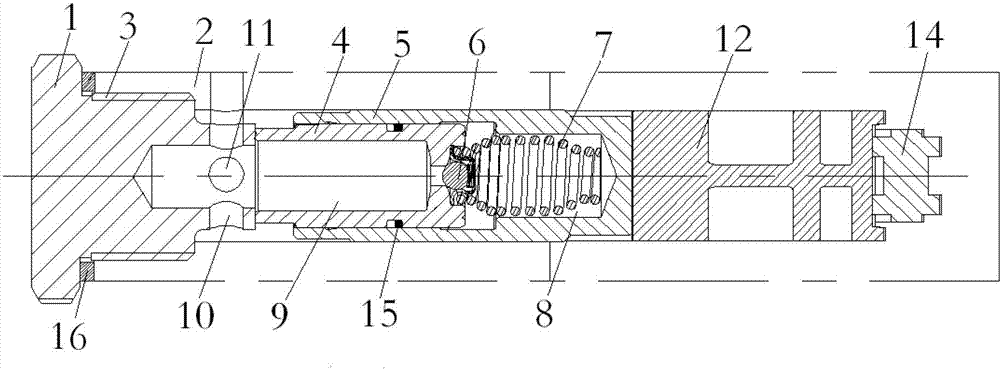

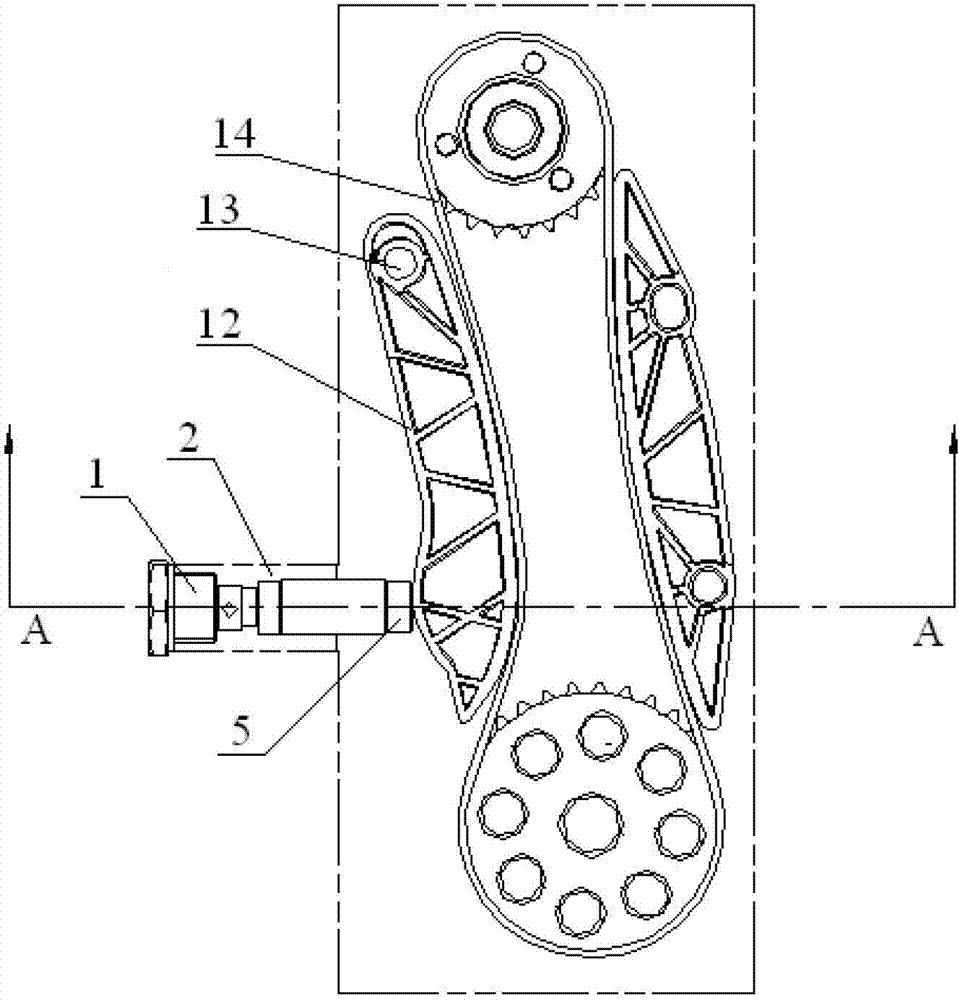

[0008] The principle and structure of the present invention will be further explained below with reference to the drawings and specific embodiments. Hydraulic chain tensioner device (such as figure 1 ), its structure is: tensioner fastening seat 1 and sprocket chamber 2 ( figure 1 The middle part) is fastened by the thread 3, and the foremost end of the tightening seat of the tensioner is close to the plunger 4, and the plunger is placed in the plunger sleeve 5. A check valve 6 and a return spring 7 are sequentially arranged between the plunger and the plunger sleeve, and the return spring is placed in the oil storage chamber 8 of the plunger sleeve. The oil cavity of the tightening seat of the tensioner is communicated with the plunger oil cavity 9, and the oil cavity of the tightening seat of the tensioner is provided with a horizontal oil passage 10 and a longitudinal oil passage 11. The guide plate 12 is in contact with the outer end of the plunger sleeve, and the guide pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com