Patents

Literature

108results about How to "Excellent thermoformability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

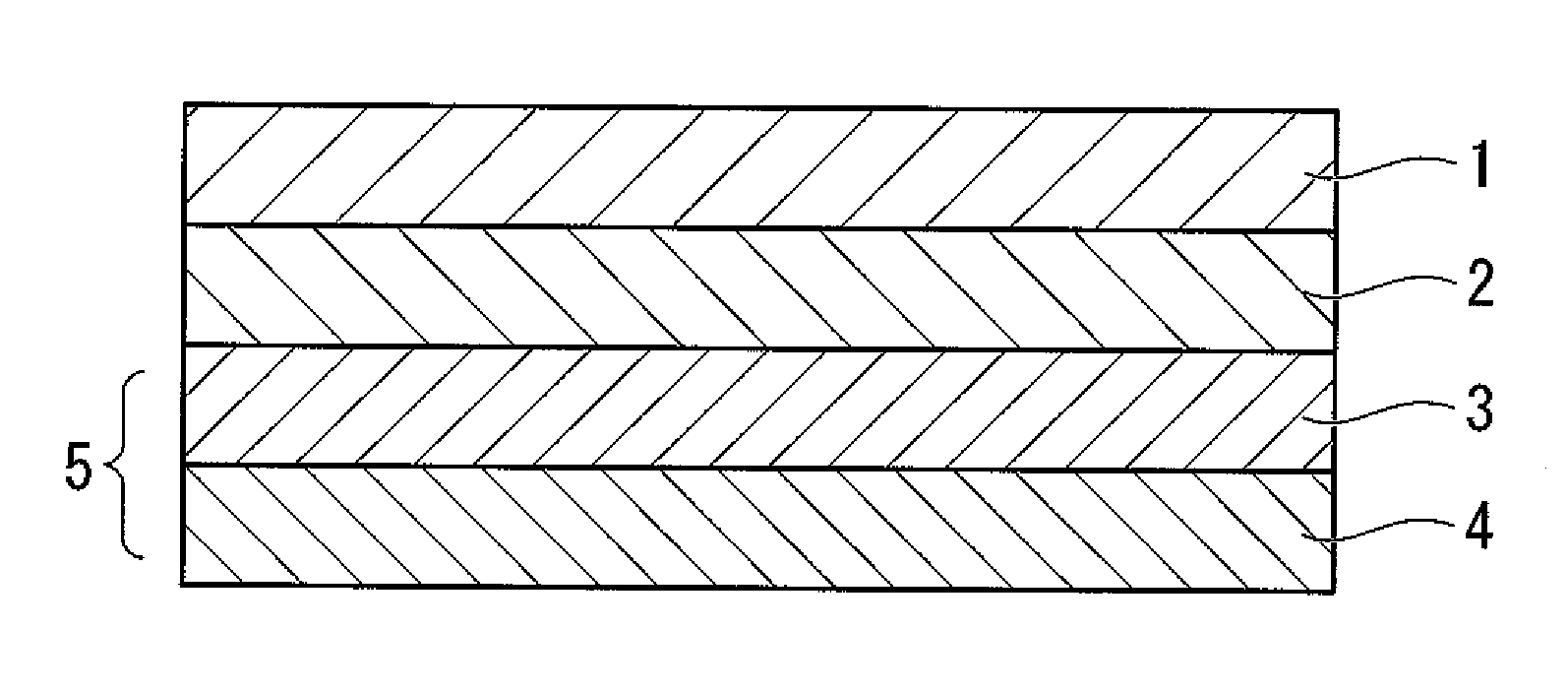

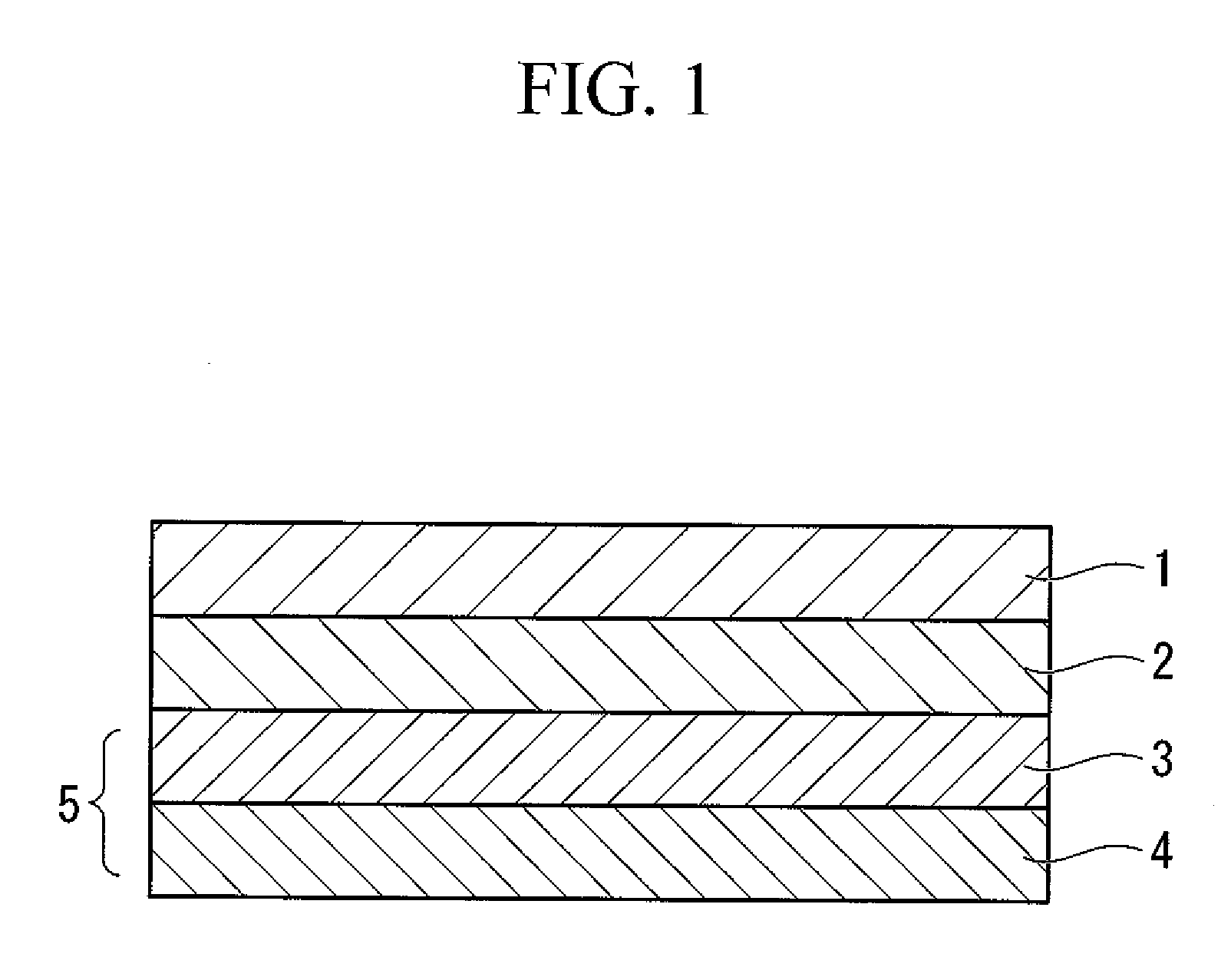

Multi-Layerd Polylactic Acid Resin Foamed Body And Multi-Layered Polylactic Acid Resin Foamed Molded Article

ActiveUS20100028654A1Improve heat resistanceHigh mechanical strengthSynthetic resin layered productsThin material handlingHeat fluxHeat resistance

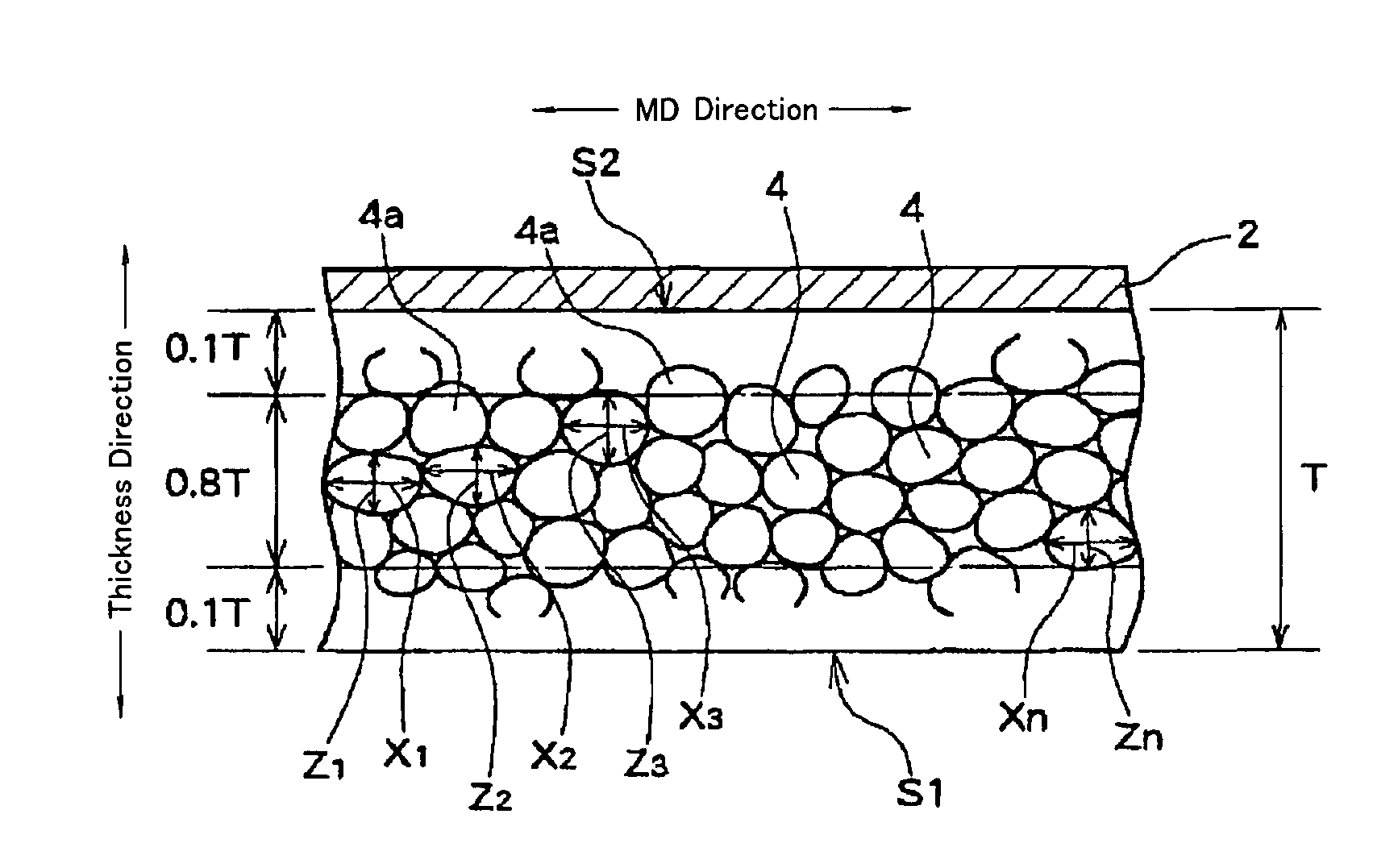

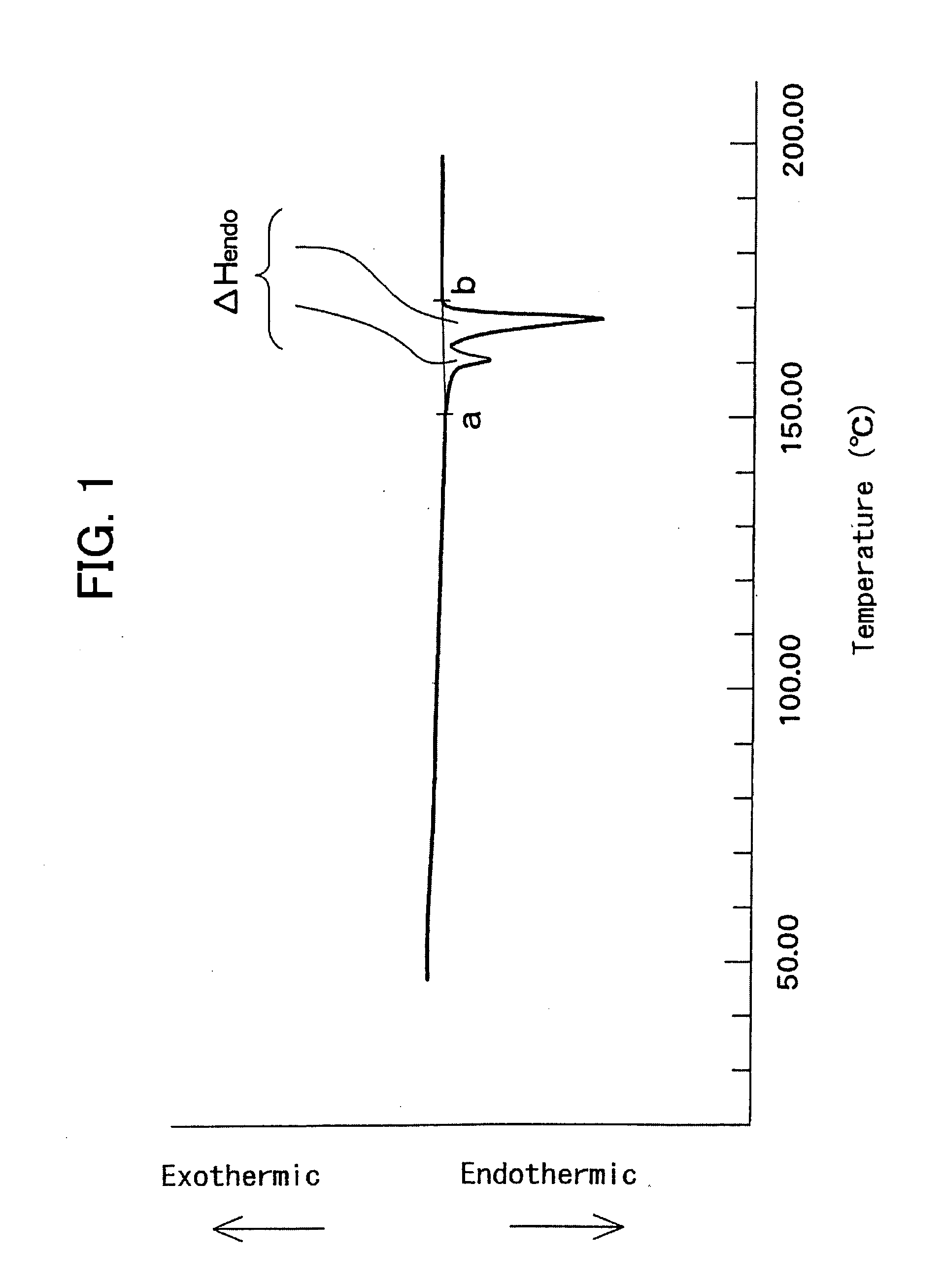

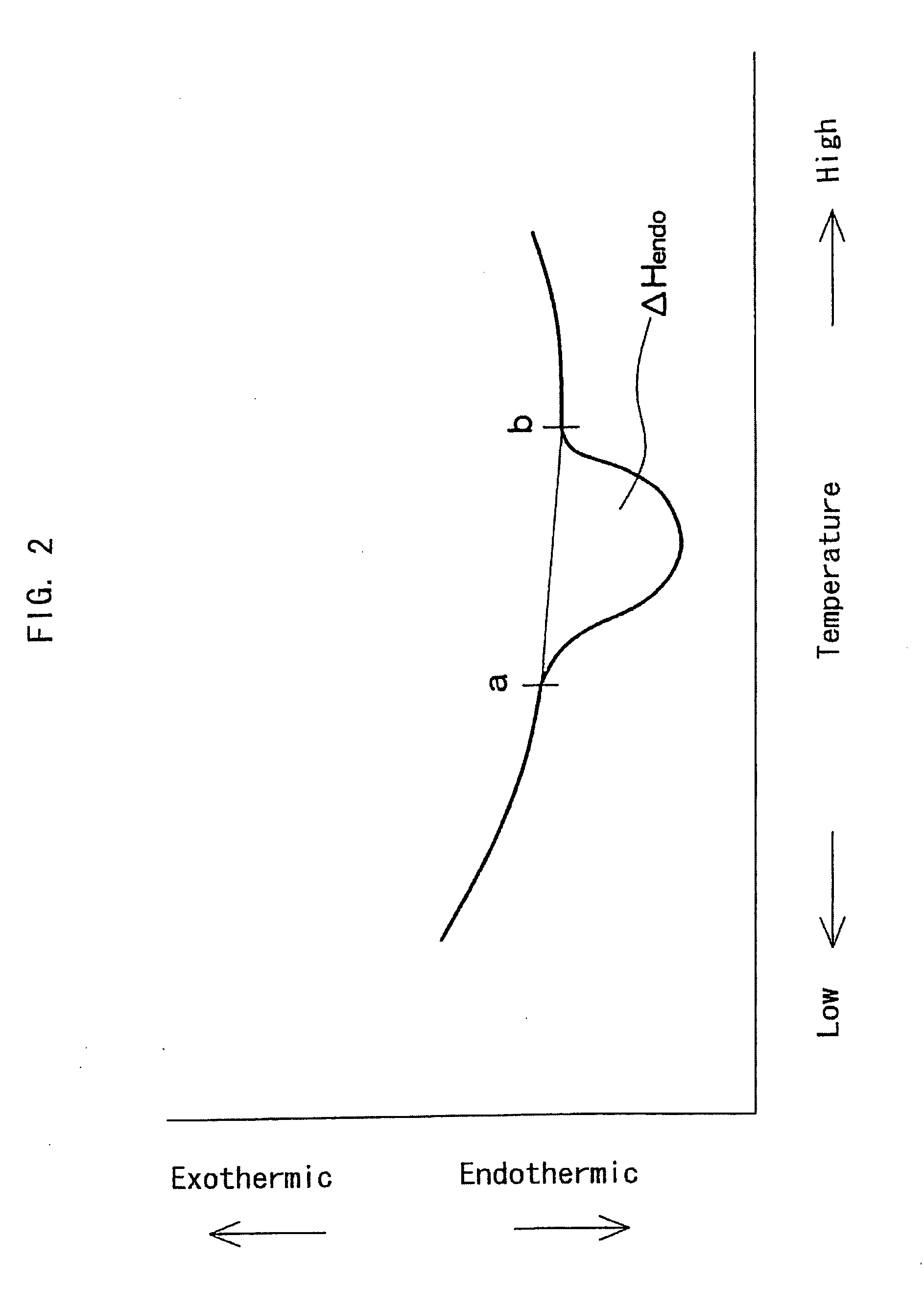

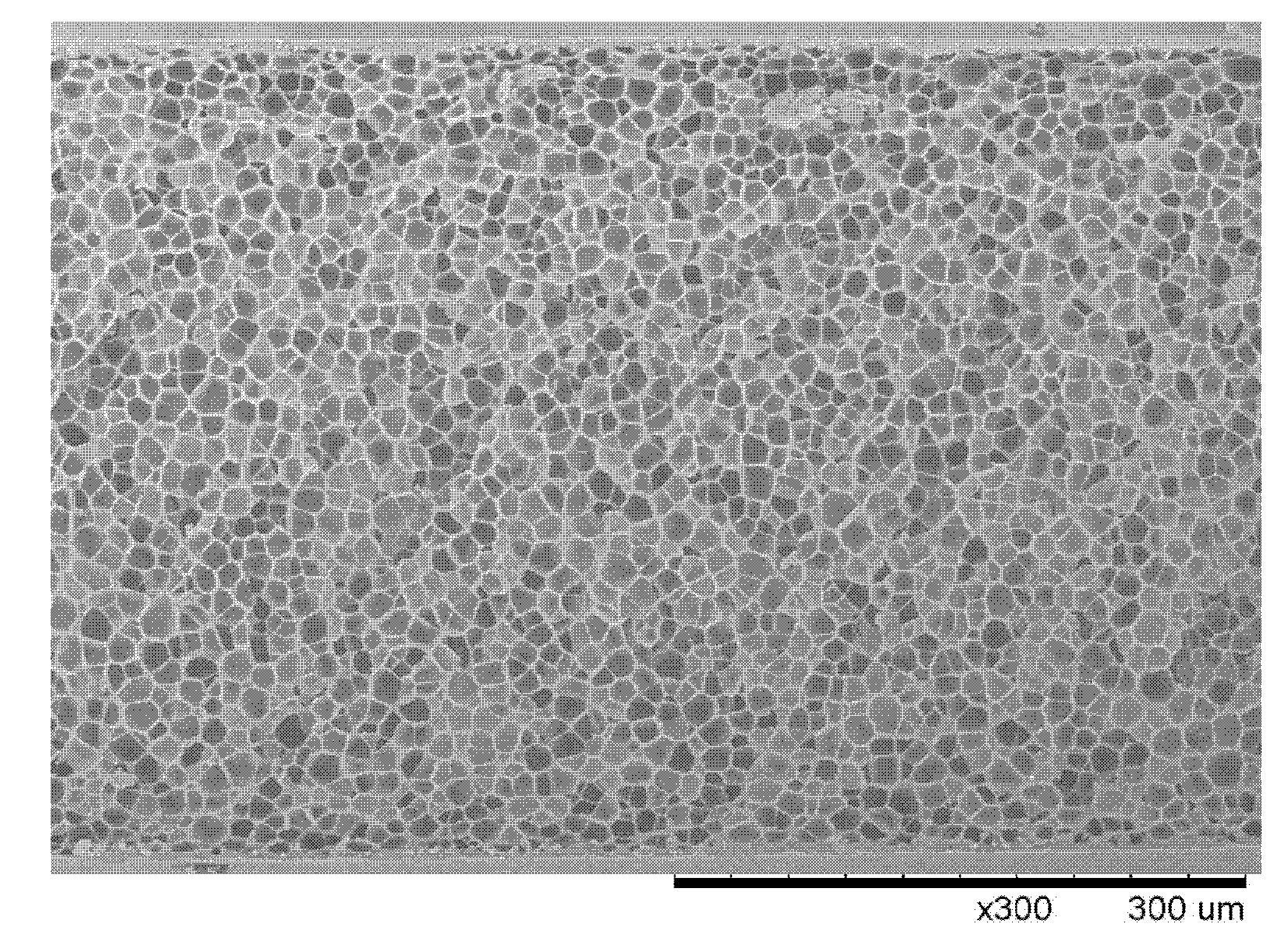

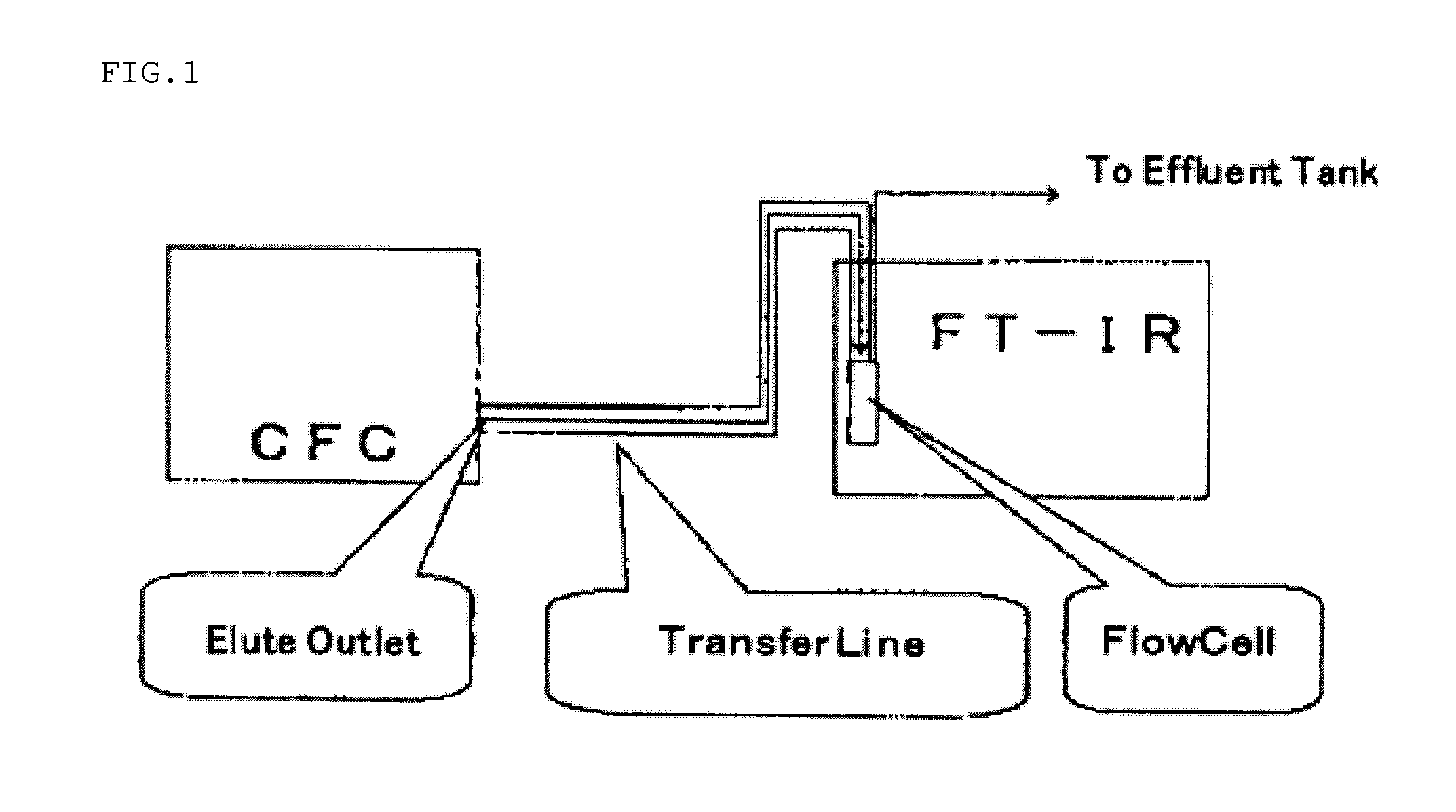

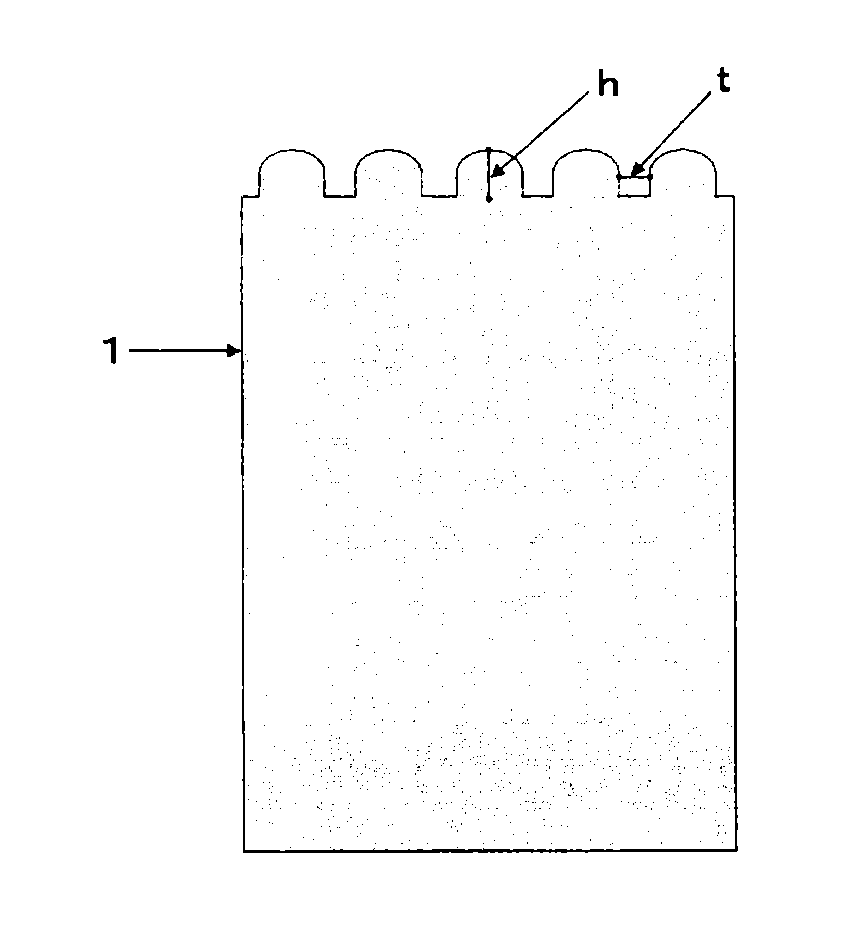

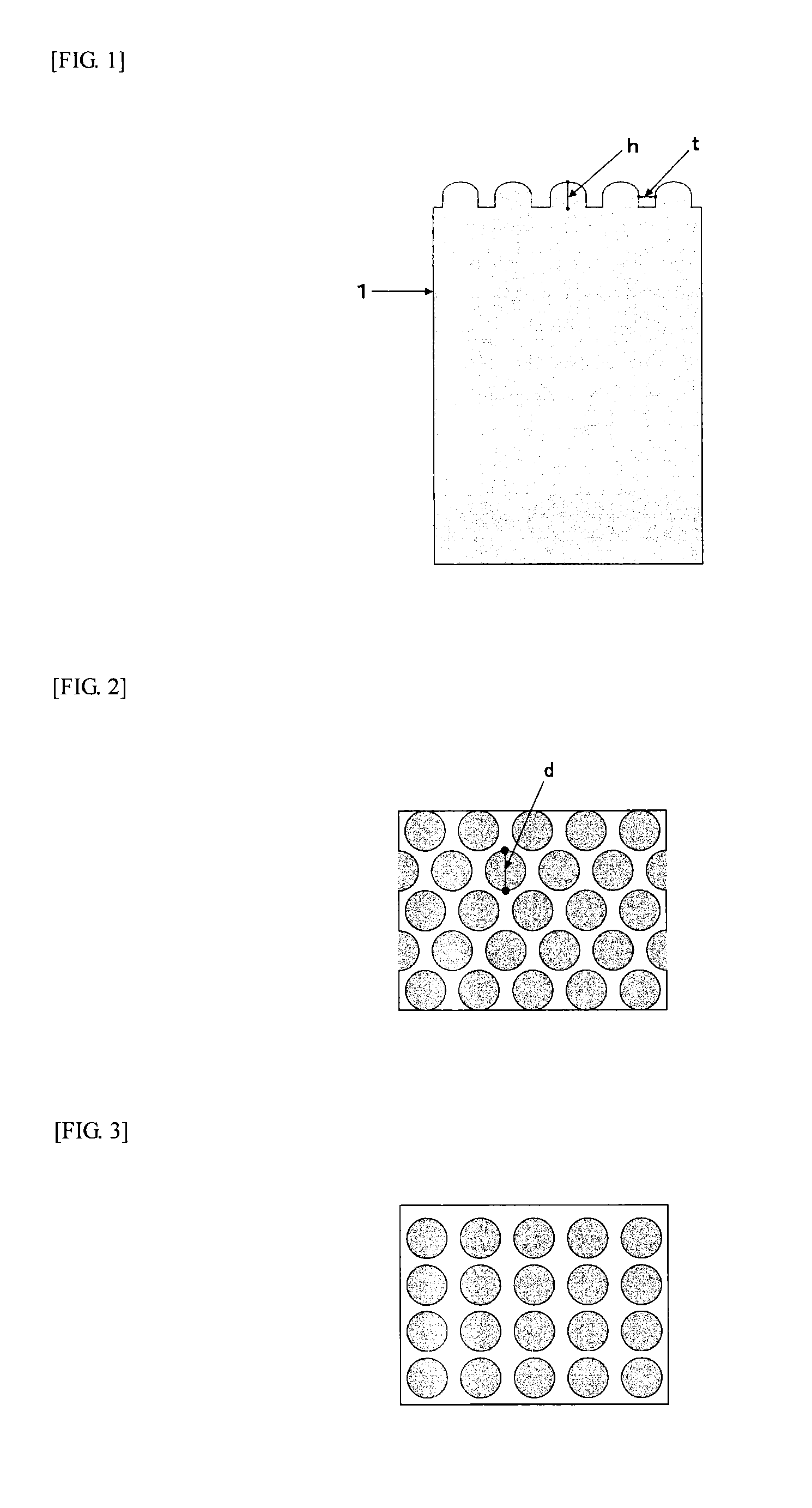

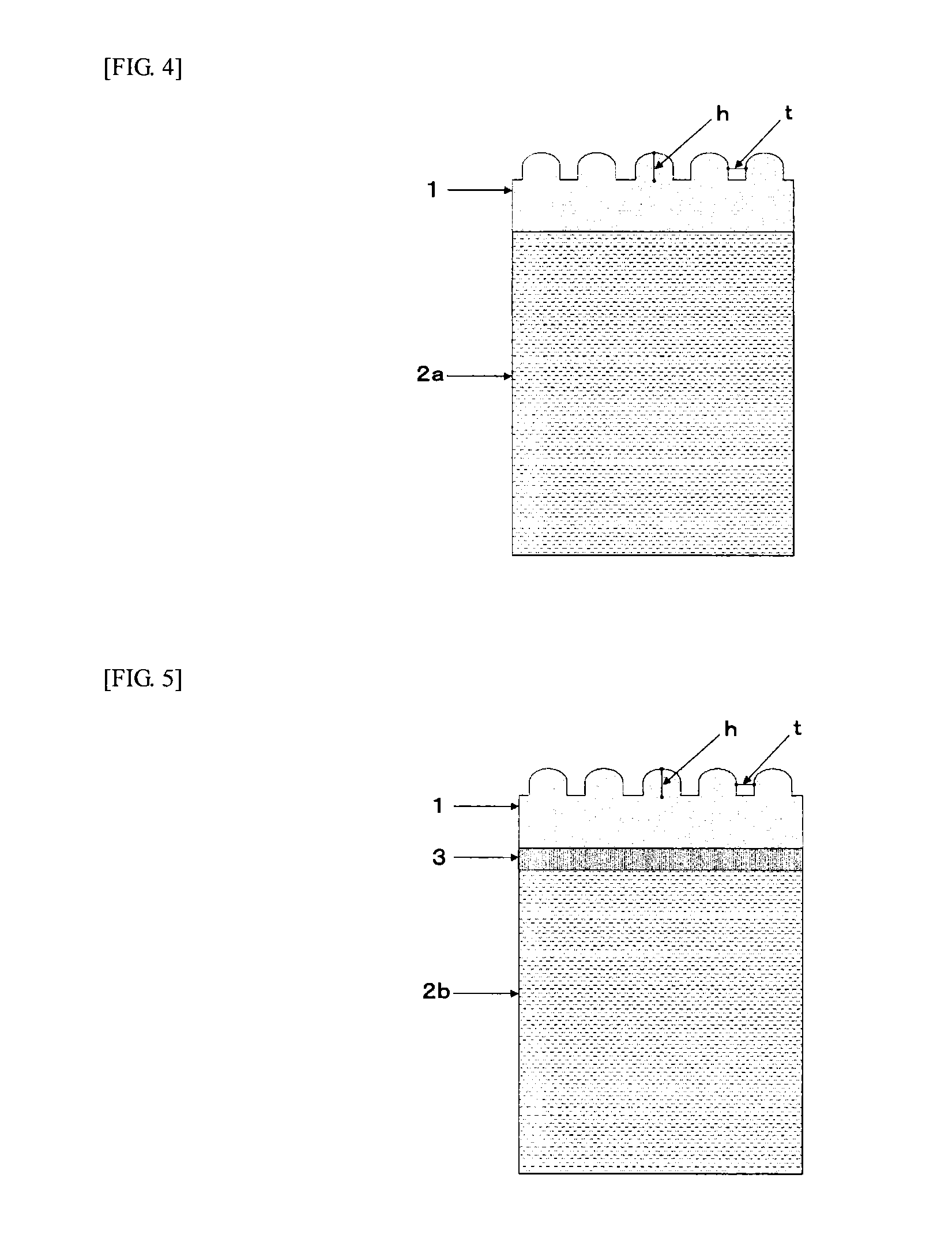

An object of the present invention is to provide a multi-layered polylactic acid resin foamed body of a crystalline polylactic acid resin which has good appearance and excellent mechanical strength such as bending strength and compressive strength and which is capable of being imparted with excellent heat resistance, and to provide a multi-layered polylactic acid resin foamed molded article having excellent appearance, heat resistance and mechanical strength.The multi-layered polylactic acid resin foamed body of the present invention is a laminate having a polylactic acid resin foamed layer and a thermoplastic resin layer provided at least one side of the foamed layer, wherein the foamed layer has a cell shape satisfying specific conditions, wherein the difference (ΔHendo:2° C. / min−ΔHexo:2° C. / min) between an endothermic calorific value (ΔHendo:2° C. / min) and an exothermic calorific value (ΔHexo:2° C. / min) of the foamed layer as measured by heat flux differential scanning calorimetry at a heating rate of 2° C. / min is less than 40 J / g, and wherein the endothermic calorific value (ΔHendo:2° C. / min) is at least 10 J / g and the exothermic calorific value (ΔHexo:2° C. / min) is at least 3 J / g.

Owner:JSP CORP

Laminate sheet of polylactic acid-based resin and thermoformed plastic thereof

InactiveUS20090053489A1Excellent thermoformabilityIncrease resistanceFlexible coversWrappersPolymer chemistryPolylactic acid

The laminate sheet of polylactic acid-based resin of the present invention is a laminate sheet comprising Layer A and Layer B consisting of polylactic acid-based resin composition and both of said Layer A and said Layer B contain a nucleating agent, and said Layer A and said Layer B contain said nucleating agent in a specific amount. The present invention makes it possible to obtain a thermoformed plastic excellent in heat resistance and transparency, and further, provides a laminate sheet of polylactic acid-based resin excellent in thermoformability.

Owner:TORAY IND INC

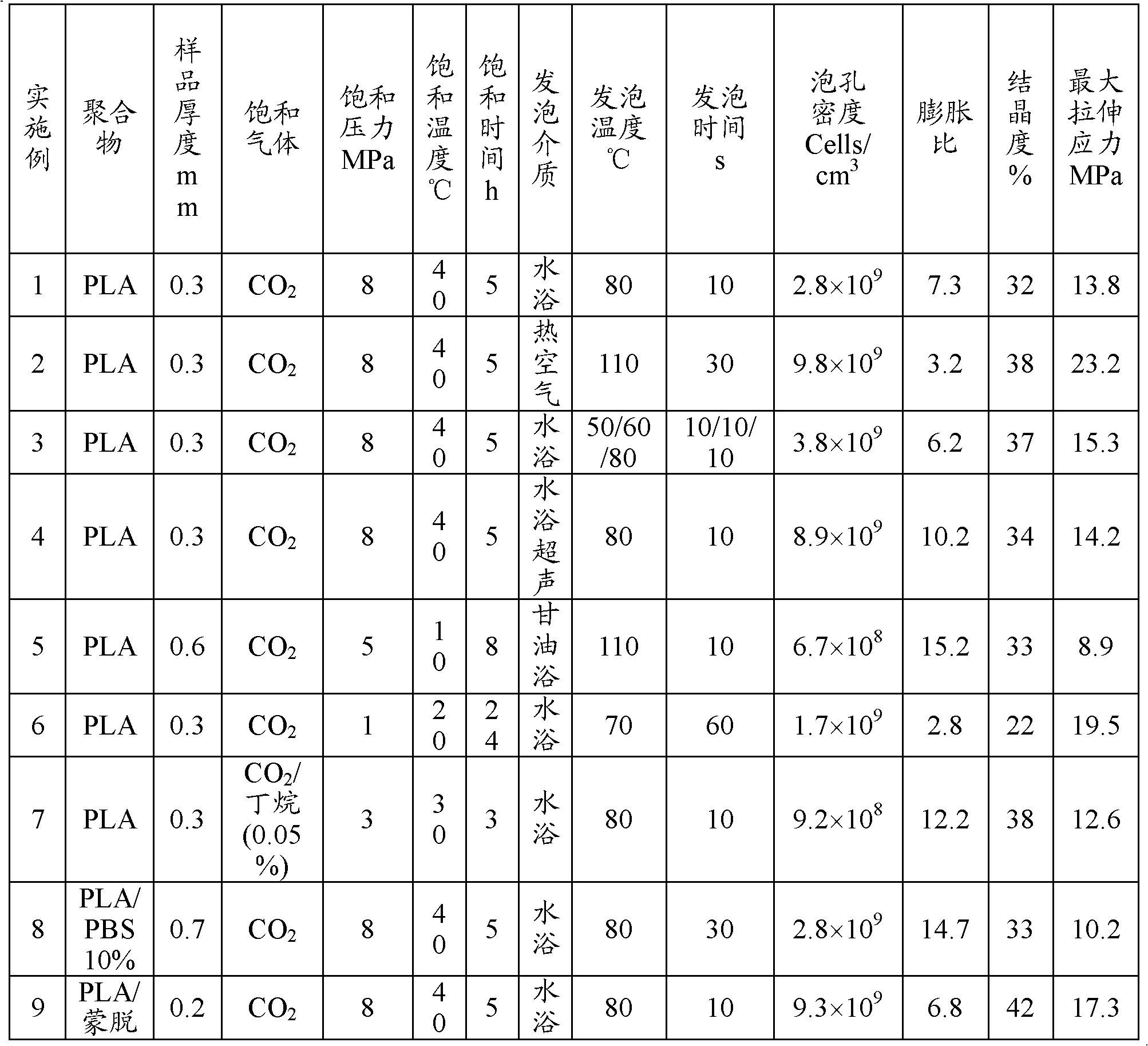

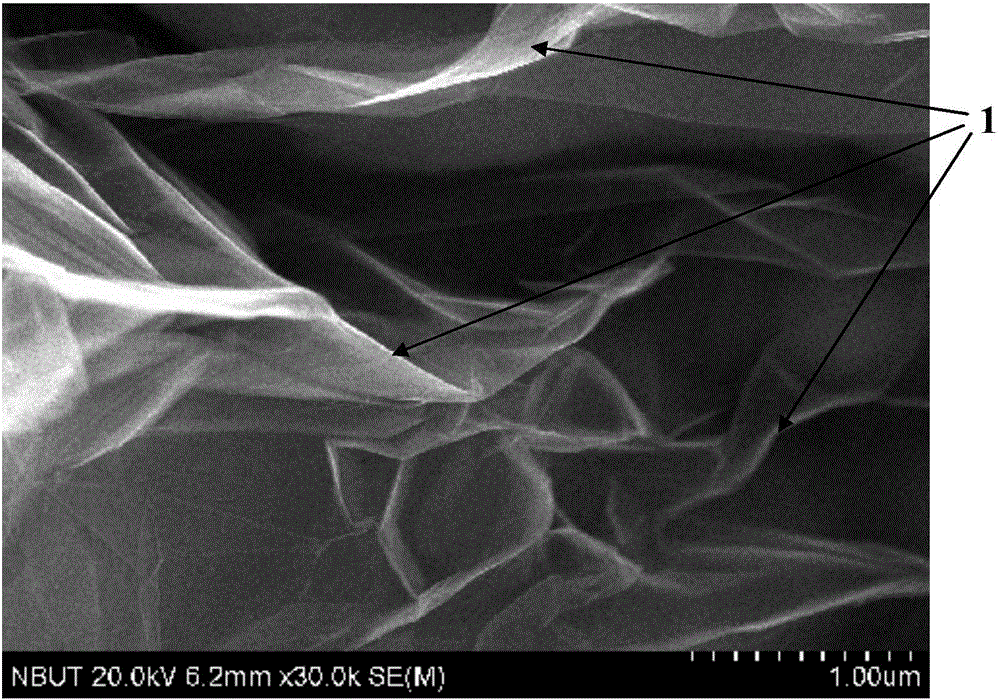

Preparation method of biodegradable polymer foamed sheet product

The invention discloses a preparation method of a biodegradable polymer foamed sheet product, comprising the following steps of: putting a polymer sheet into high-pressure fluid with the pressure of 0.5-10MPa to saturate the polymer sheet; then putting the saturated polymer sheet into a hot medium with the temperature of 40-140 DEG C for foaming for 2-300 seconds to obtain a polymer foamed sheet; and forming the polymer foamed sheet by heat treatment to obtain the biodegradable polymer foamed sheet product, wherein the polymer sheet is made of polylactic acid or the blend of polylactic acid and a polymer with an ester group or ether bond, and the thickness of the sheet is 0.1-2.0mm. The process disclosed by the invention is simple to operate, easy to control and favorable for industrial implementation, and the product has the advantages of bright and clean surface, light weight, uniform closed pore structure with the pore size of 5-50 micrometers, high tensile modulus and strength, excellent temperature tolerance and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

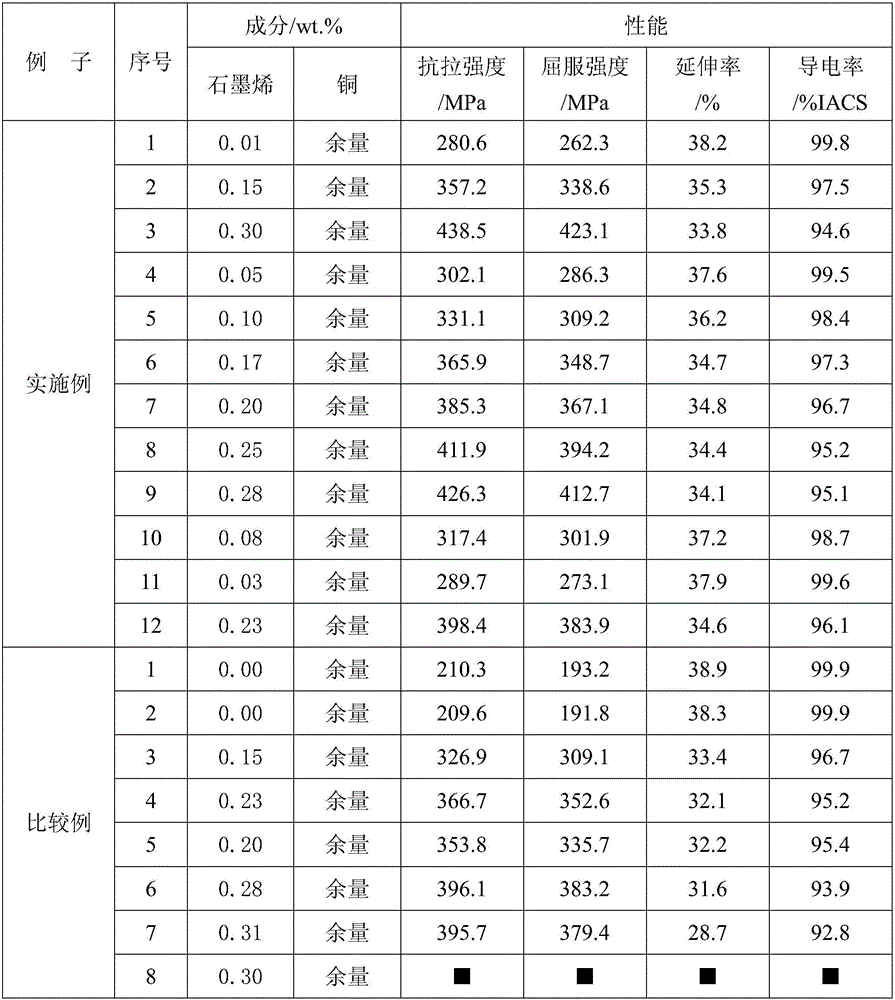

Copper-graphene composite material and preparation method thereof

ActiveCN105714139APrevent oxidationControllable distribution densityLead frameUltimate tensile strength

The invention relates to a copper-graphene composite material and a preparation method thereof. The copper-graphene composite material comprises graphene and copper, and is characterized in that the graphene is evenly distributed in a copper matrix in a sheet structure; distribution density of the graphene is 100 sheets per square centimeter to 3000 sheets per square centimeter; and preferably, the content of the graphene is 0.01 wt% to 0.30 wt%, and the balance is Cu. The copper-graphene composite material disclosed by the invention is prepared by adding the graphene into the copper; the copper matrix can be served as an electrical conduction main body to enable electrical conductivity of the composite material to be close to pure copper, and the graphene is served as a reinforcement phase, so that tensile strength performance and yield strength performance are both increased; therefore the copper-graphene composite material can be widely applied to the fields of consumer electronics, electrics, aeronautics and astronautics, high-speed rails, lead frames, electronic connector preparation; and the preparation method provided by the invention is suitable for industrial and scale production.

Owner:NINGBO POWERWAY ALLOY MATERIAL

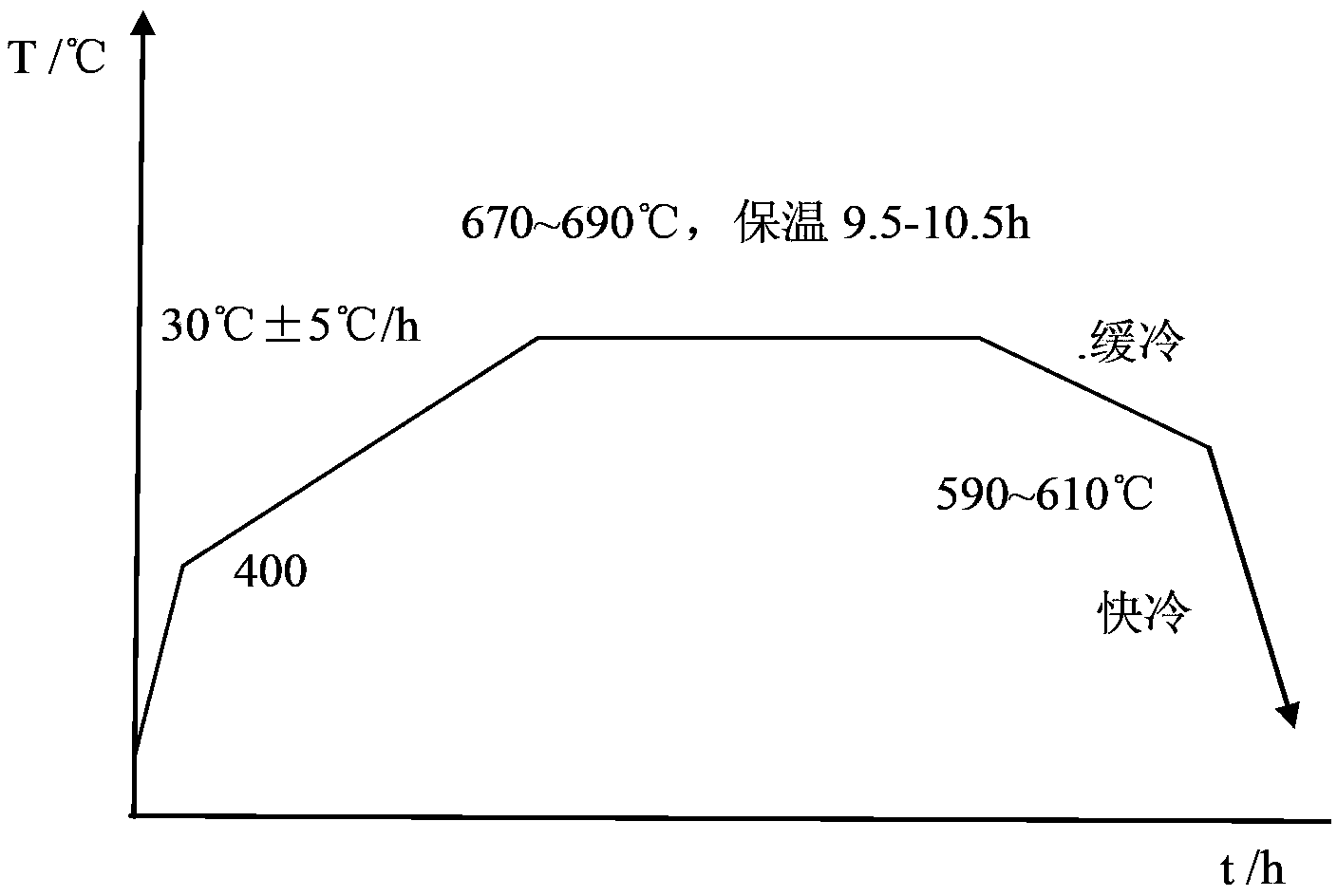

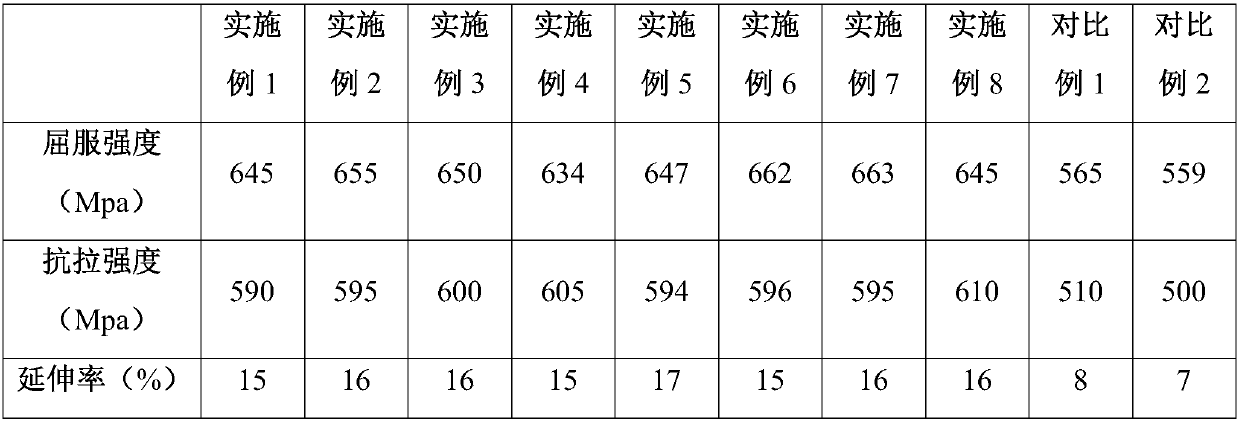

Cold-rolled hot-molded steel plate and production method thereof

The invention discloses a cold-rolled hot-molded steel plate. The cold-rolled hot-molded steel plate is produced from the following chemical components in percentage by weight: 0.22-0.25% of C, 1.20-1.40% of Mn, 0.20-0.30% of Si, less than or equal to 0.020% of P, less than or equal to 0.0030% of S, 0.10-0.30% of Cr, 0.020-0.050% of Ti, 0.025-0.060% of Alt, 0.0020-0.0040% of B, less than or equal to 0.006% of N and the balance of Fe. The invention further discloses a method for producing the cold-rolled hot-molded steel. The method comprises the following steps of: refining molten steel, and casting continuously to obtain a steel plate blank; carrying out hot rolling on the steel plate blank, and cooling the hot-rolled steel plate blank by laminar flow to obtain a hot-rolled coil; carrying out cold rolling on the hot-rolled coil to obtain a cold-rolled coil; and finally annealing the cold-rolled coil in a cover to obtain strip steel. By adjusting the chemical components and optimizing the hot rolling, cold rolling, cover-type annealing and flattening parameters, the high-strength hot-molded steel plate can be produced successfully. The high-strength hot-molded steel plate has good hot molding performance and low stamping wrinkling, cracking and retracting risks so that a molded part has high strength and safety factor.

Owner:SHOUGANG CORPORATION

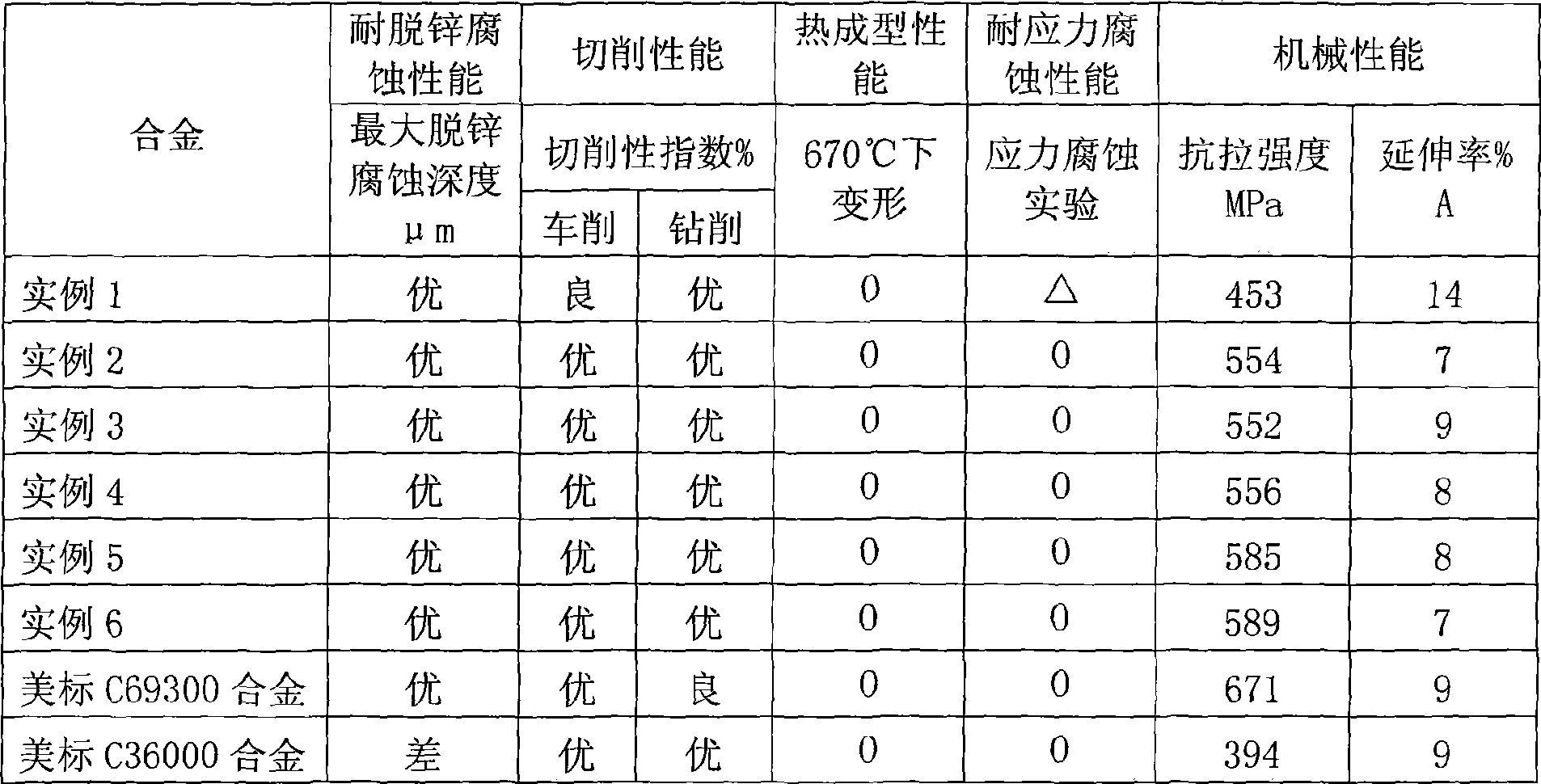

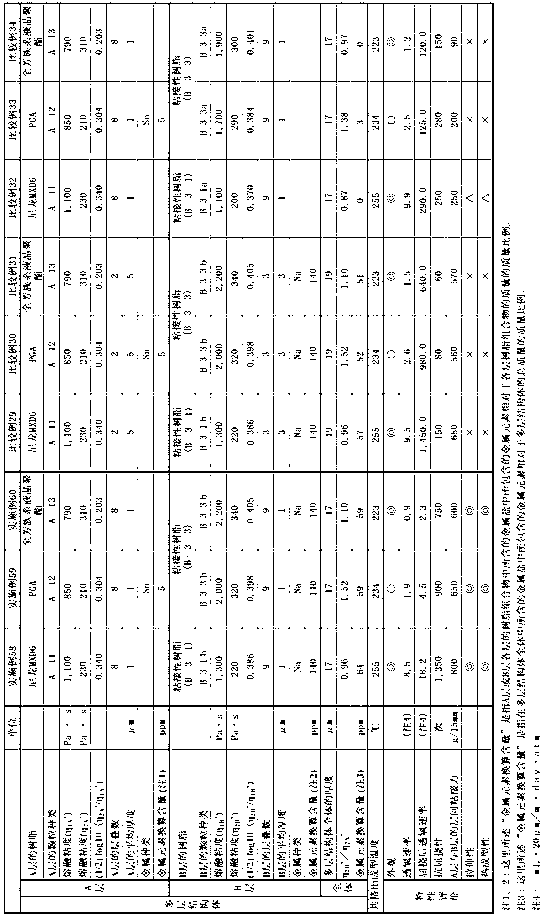

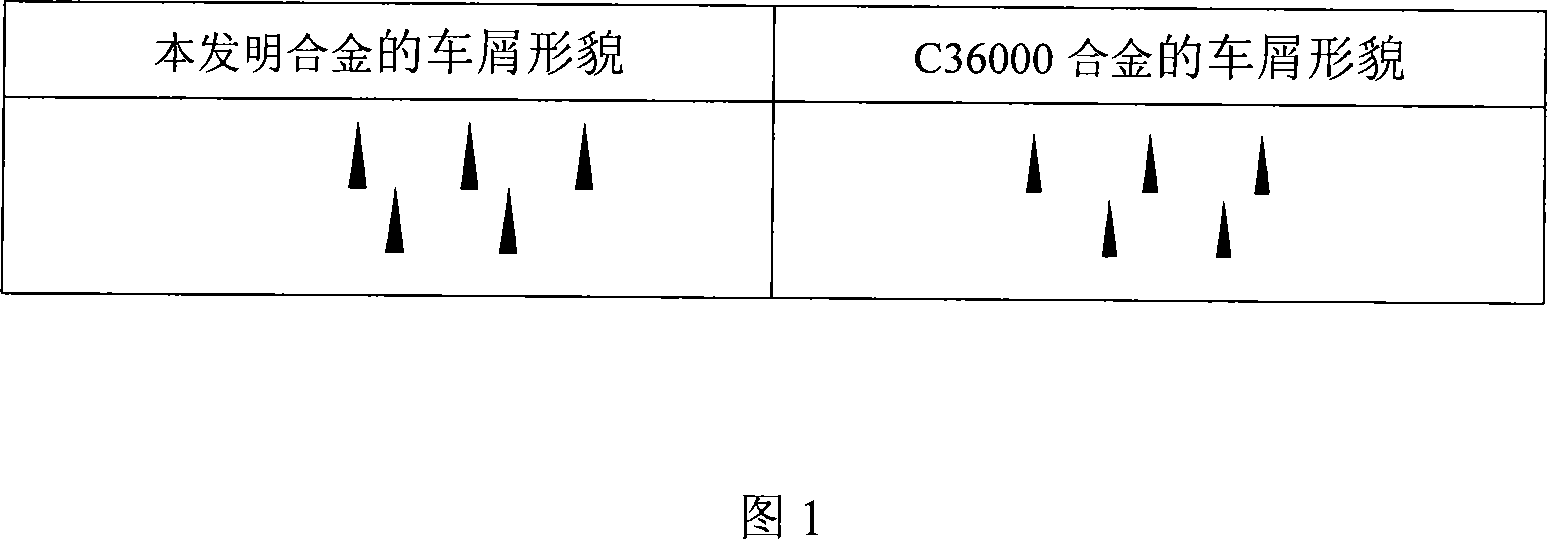

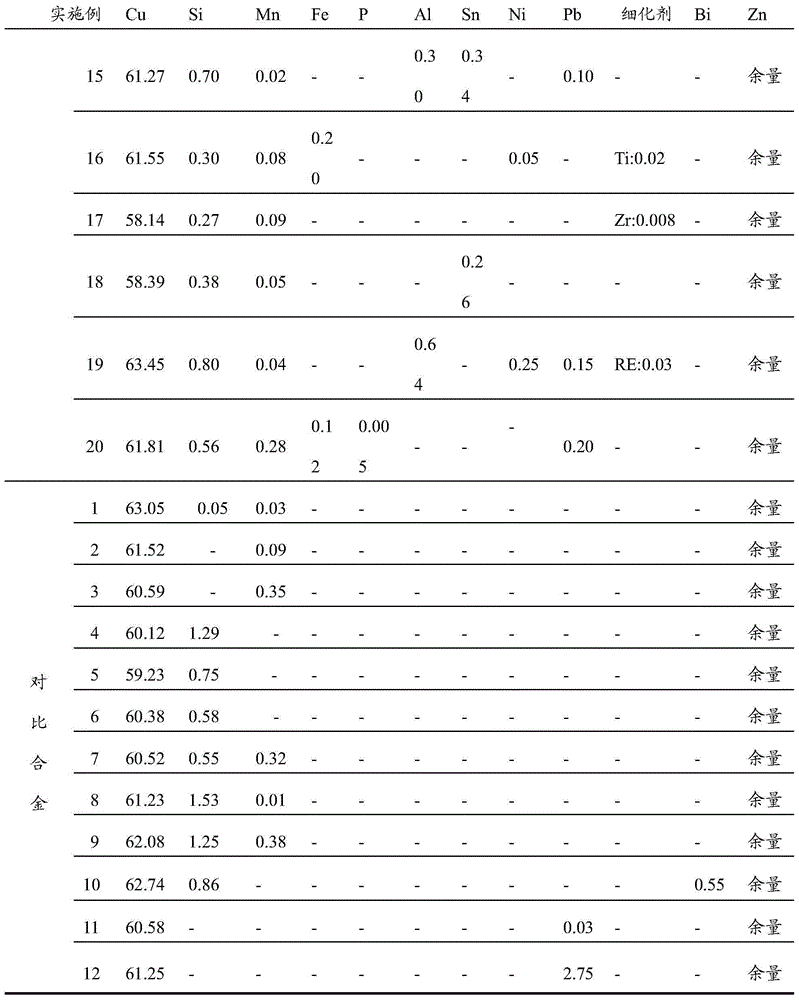

Leadless and free-cutting phosphorus-brass alloy and manufacturing method thereof

The invention provides a lead-free cutting-free alloy and a preparation method thereof. The components (weight percentage) of the alloy are: more than 97.0 but not equal to 99.5 of (copper + zinc), more than 35.0 of zinc, 0.4-1.6 of phosphor and 0.005-0.6 of at least two other elements selected from aluminum, silicon, antimony, stannum, lanthanon, titanium and boron, the balance being zinc and impurities, wherein, the zinc content is more than 35.0 (weight percentage). The invention also provides a preparation method for the lead-free cutting-free high phosphor brass alloy. The alloy of the invention has excellent machinability, castibility, welding property, dezincification corrosion resisting property, formability and mechanical property, and is particularly suitable for forged pieces and low-pressure cast castings needing cutting processing, grinding processing (polish), welding and plating, such as hydrants, valve bodies and bushings in a water supply system.

Owner:XIAMEN LAVIDA HI TECH MATERIAL CO LTD

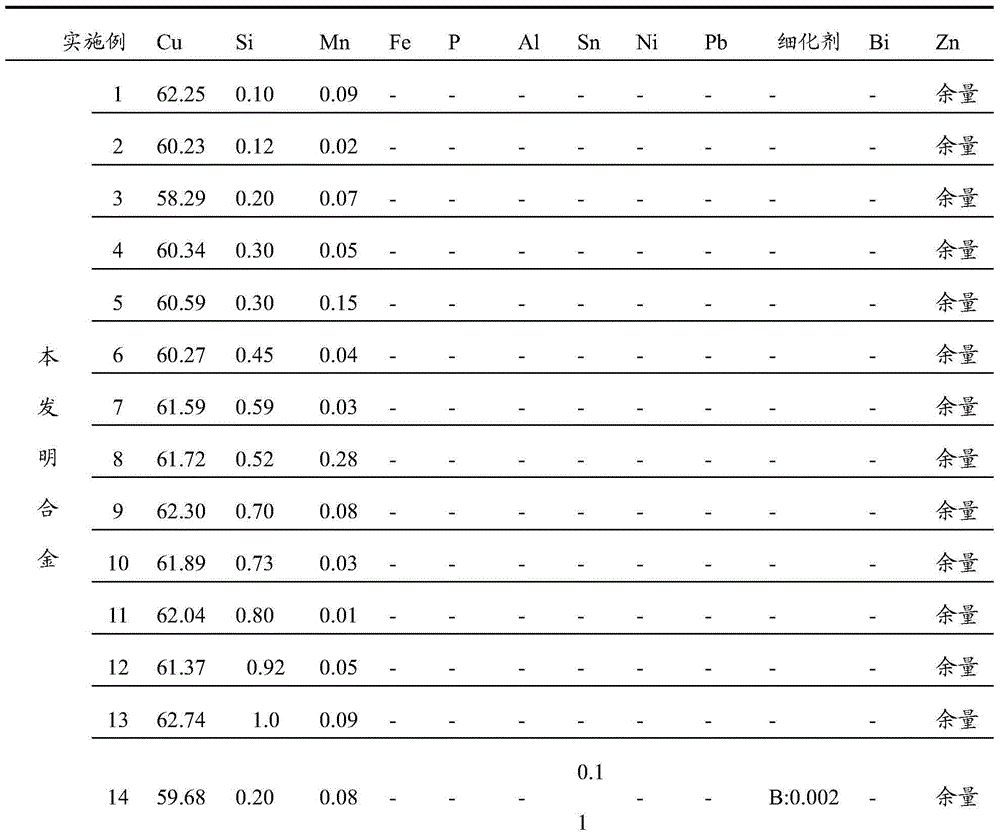

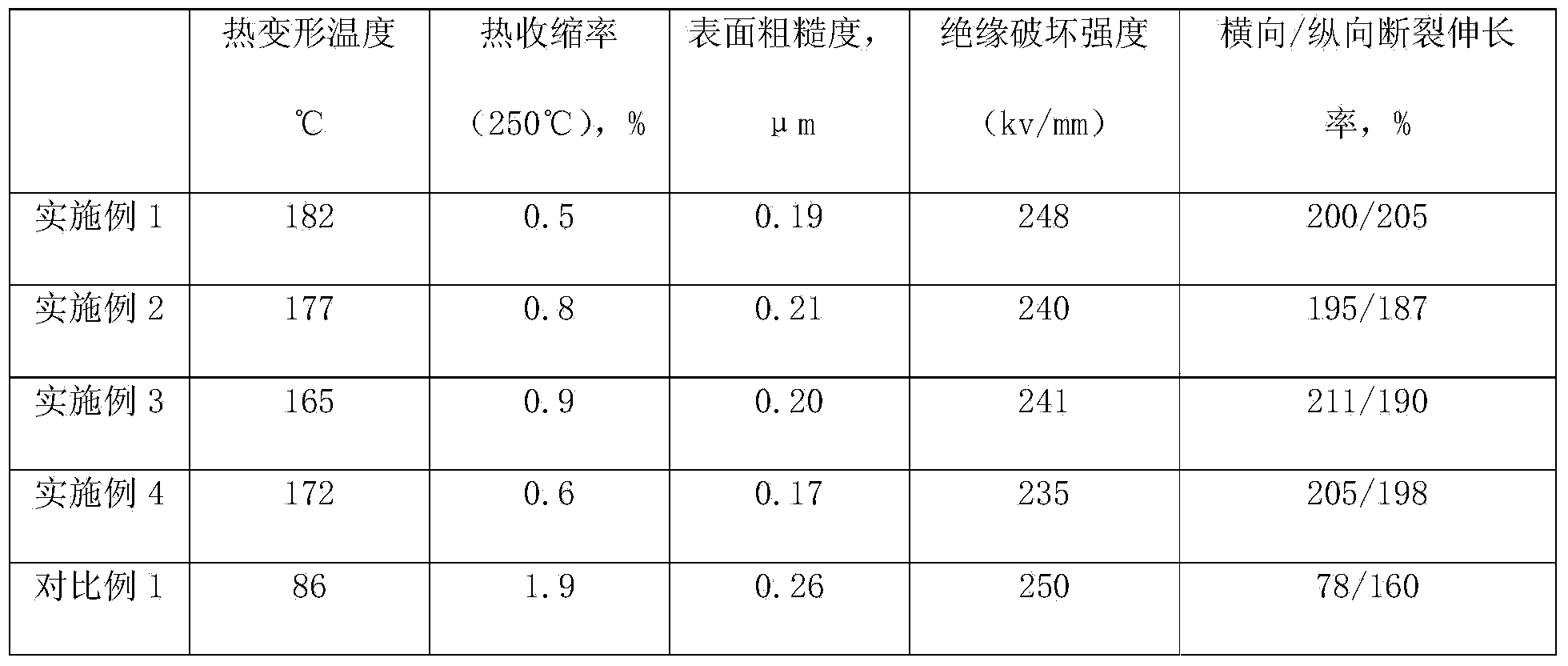

Easily-cut silicon brass alloy and preparation method thereof

ActiveCN101445885AExcellent machinabilityExcellent resistance to dezincificationManganeseStress relief

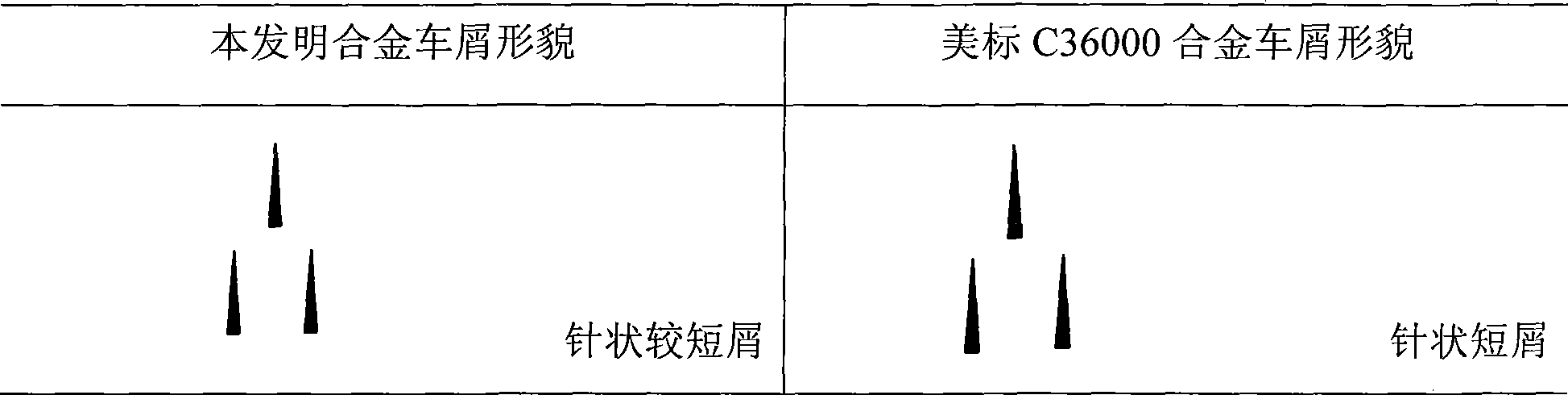

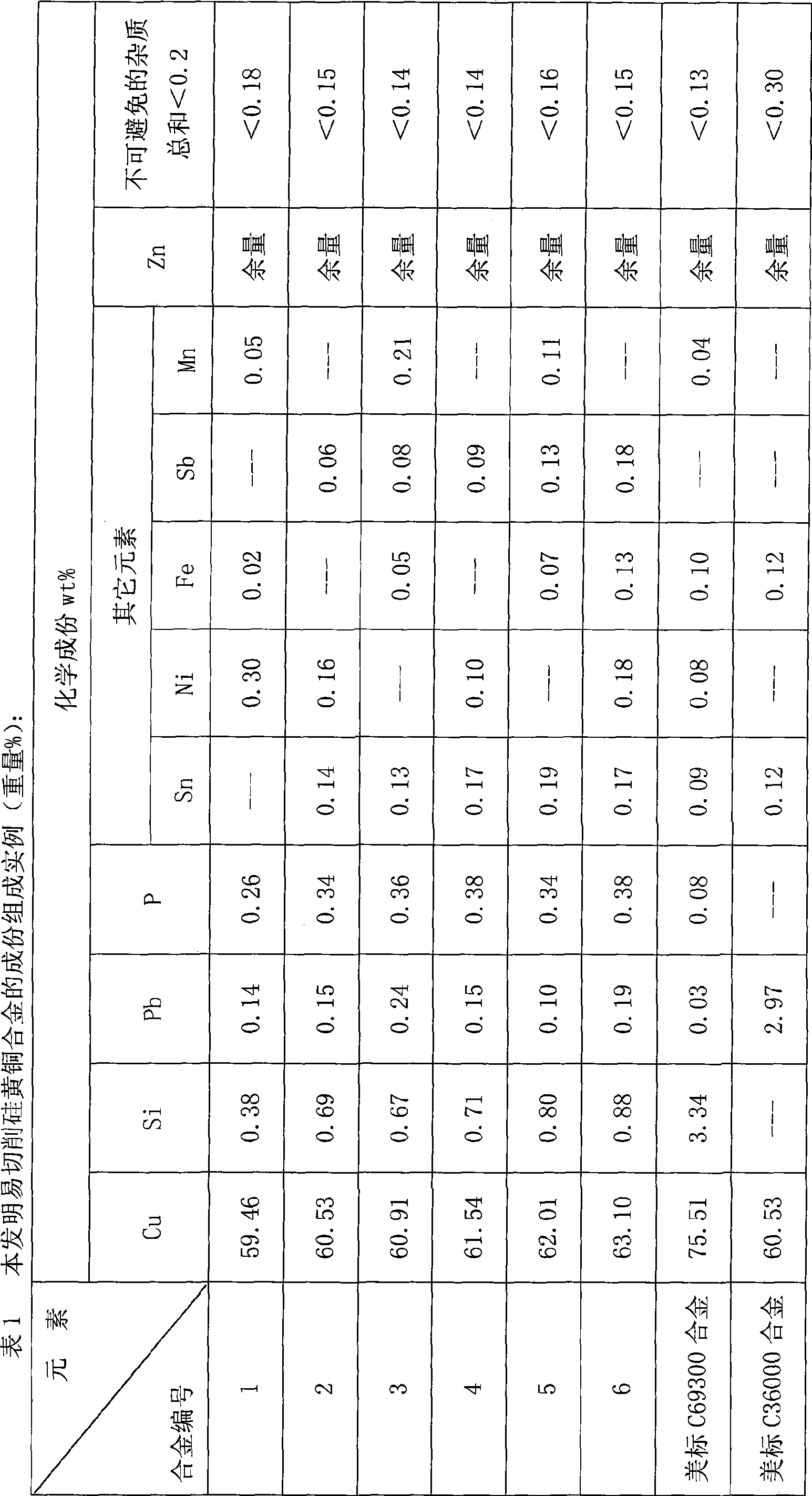

The invention discloses an easily-cut silicon brass alloy and a preparation method thereof. Chemical components of the silicon brass alloy include 59.2-63.5wt% of copper, 0.35-0.9wt% of silicon, 0.04-0.25wt% of lead and 0.22-0.38wt% of phosphor, other elements account for 0.005-1.1wt%, and the rest include zinc and inevitable impurities, wherein, the total amount of the copper, the zinc, the silicon, the lead and the phosphor is larger than 98.7wt%, and the other elements include at least one element selected from a group consisting of tin, nickel, iron, stibium and manganese. The preparation method is as follows: a method for alloying and for purifying and refining a covered and protected alterative scarfing cinder is adopted for smelting the easily-cut silicon brass alloy, then intermediate heat treatment is carried out at a temperature of 560-660 DEG C after coldworking with a working rate ranging from 4 percent to 25 percent, and a final finished product resulting from the working undergoes stress relief annealing at a low temperature of 380 DEG C. The invention has the advantage that the easily-cut silicon brass alloy has high tensile strength, excellent thermal formability, dezincing resistance, safe and sanitary performance and remarkable excellent cutting performance; meanwhile, the preparation process of the easily-cut silicon brass alloy is simple, the cost is low, and the easily-cut silicon brass alloy can be easily recycled.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Breathable packaging film having enhanced thermoformability

InactiveUS20060105166A1Excellent thermoformabilitySimple structureSynthetic resin layered productsDomestic containersPolyesterPolyolefin

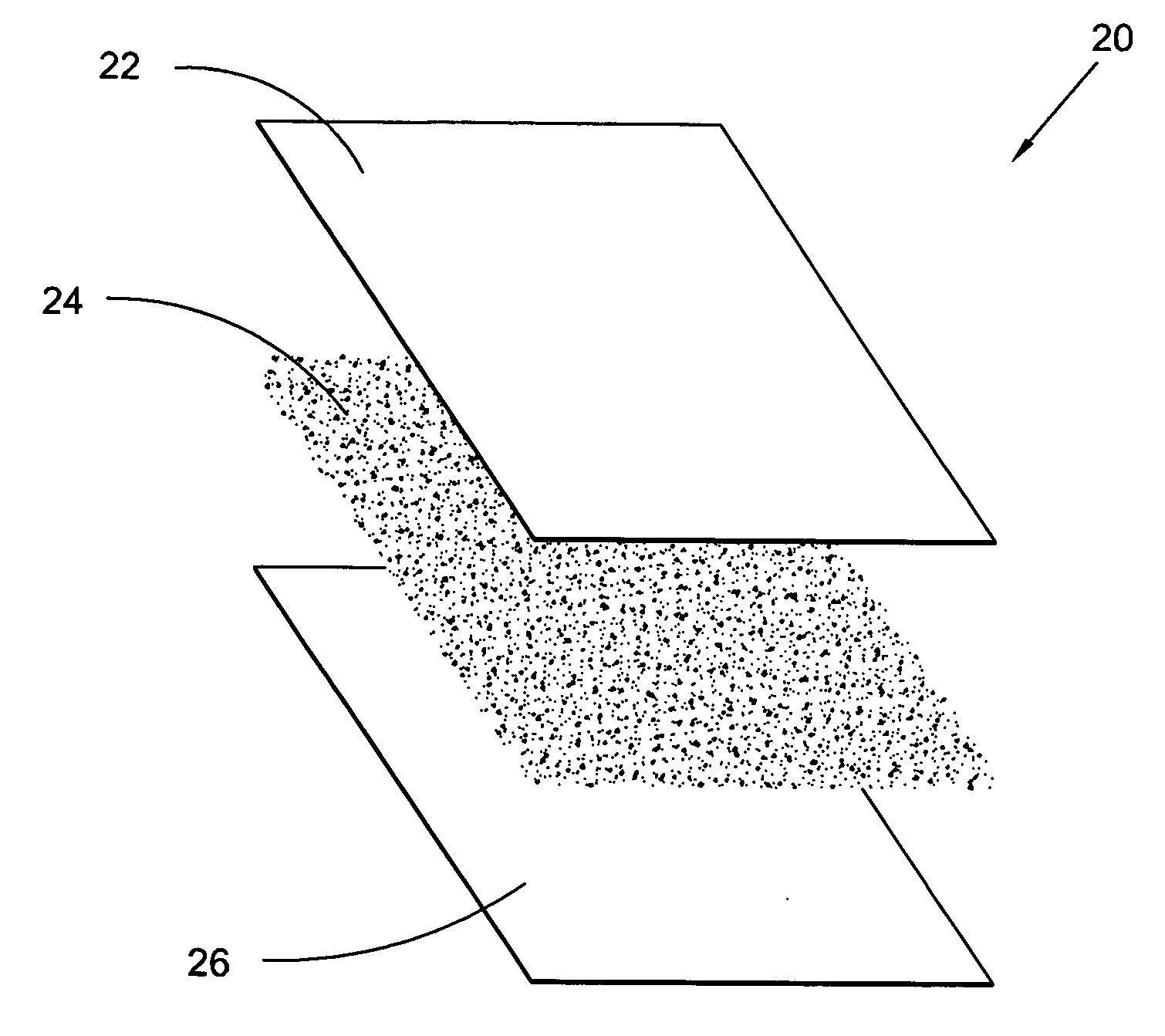

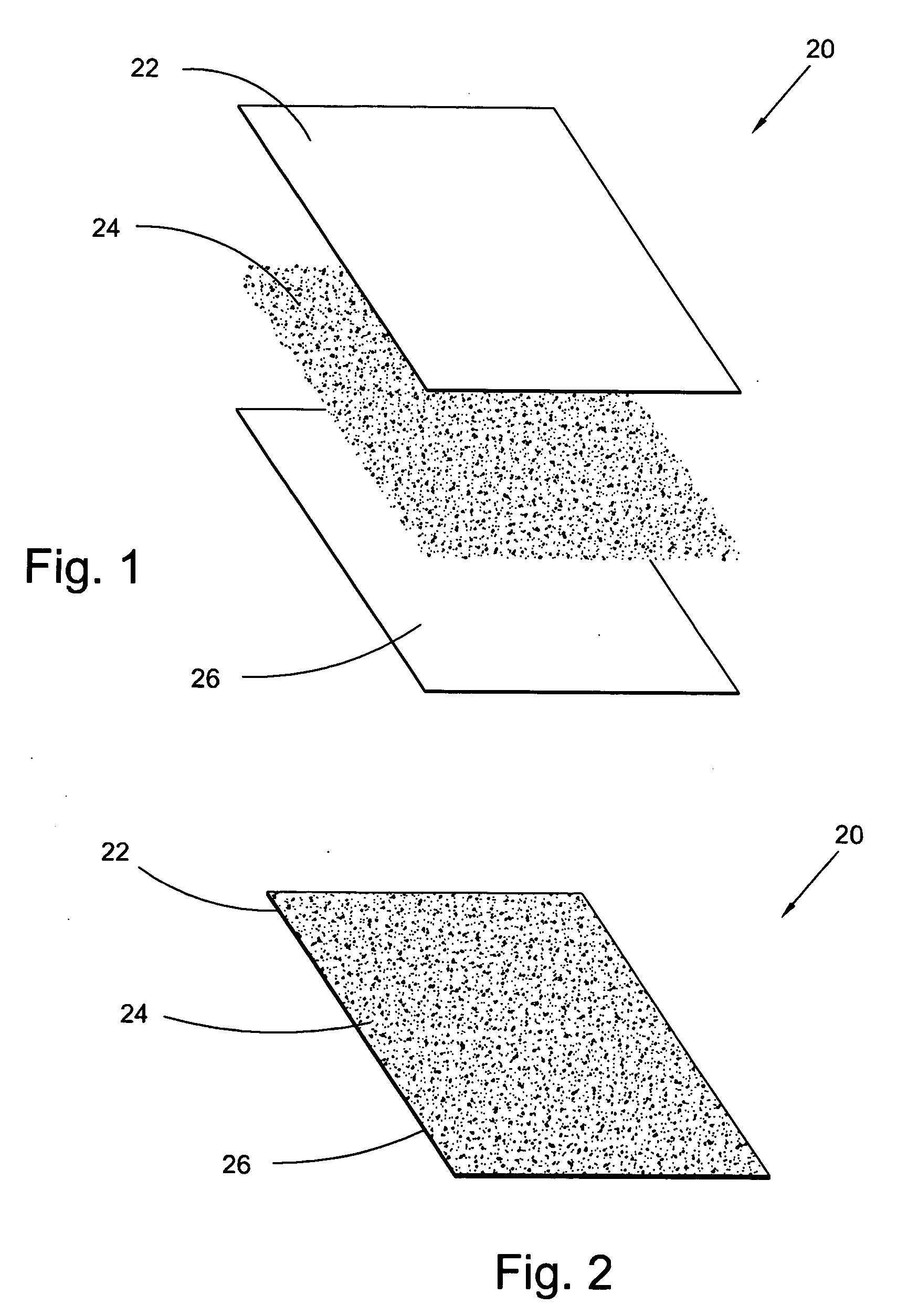

The present invention describes thermoformable coextruded film suitable for use in packaging applications having at least a first polymeric layer serving as an outermost exterior-film layer and comprising a cycloaliphatic polyester, an aromatic polyester or blends thereof; a second polymeric layer serving as a thermoforming-assist layer and comprising a polyolefin; and a third polymeric layer serving as an innermost exterior-film layer and comprising a heat-sealing polyolefinic material. The films of the present invention are oxygen-permeable in that they exhibit an oxygen transmission rate of between 2-1000 cm3 / 100 in2 / 24 h.atm.

Owner:BEMIS COMPANY INC

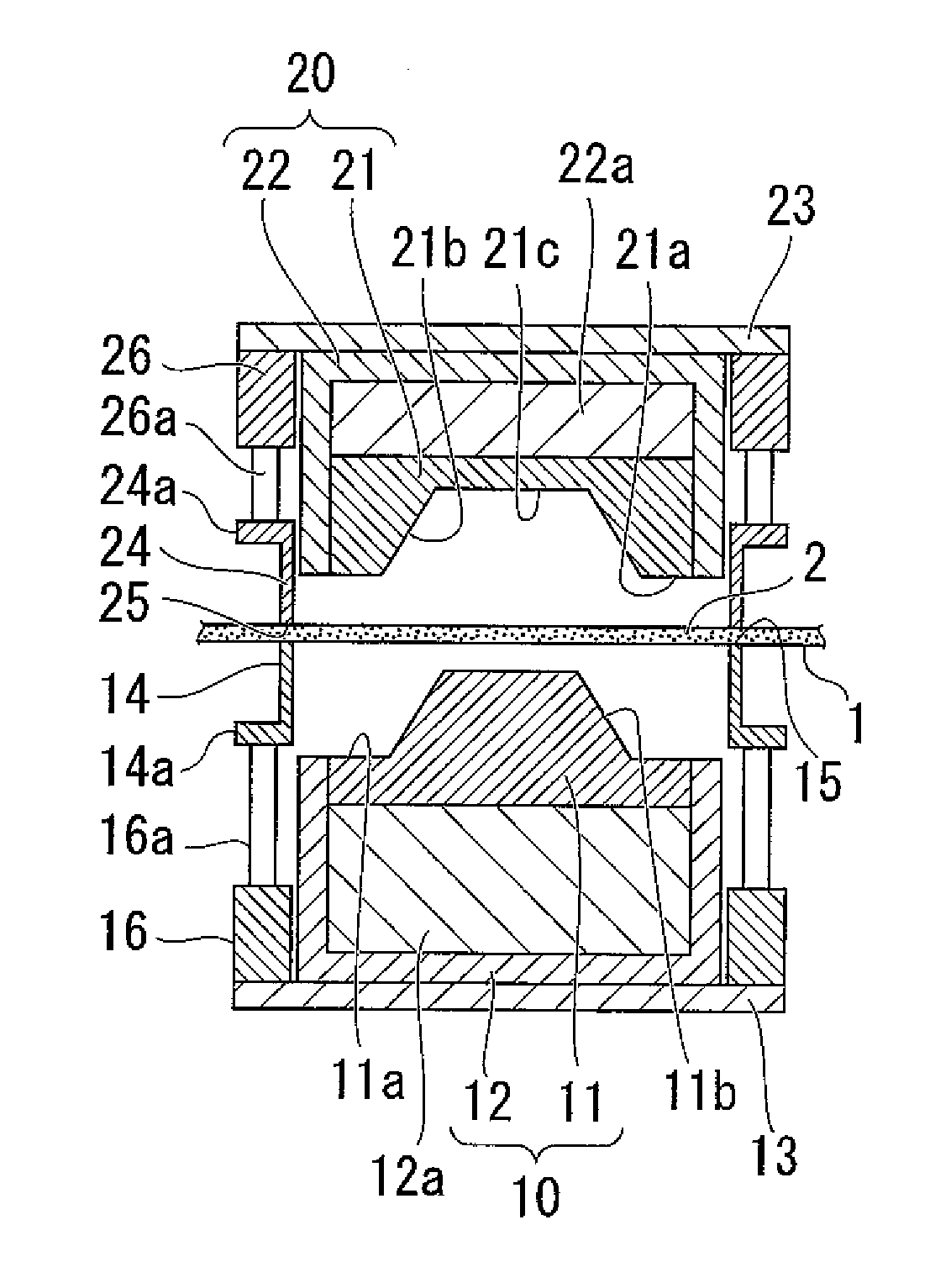

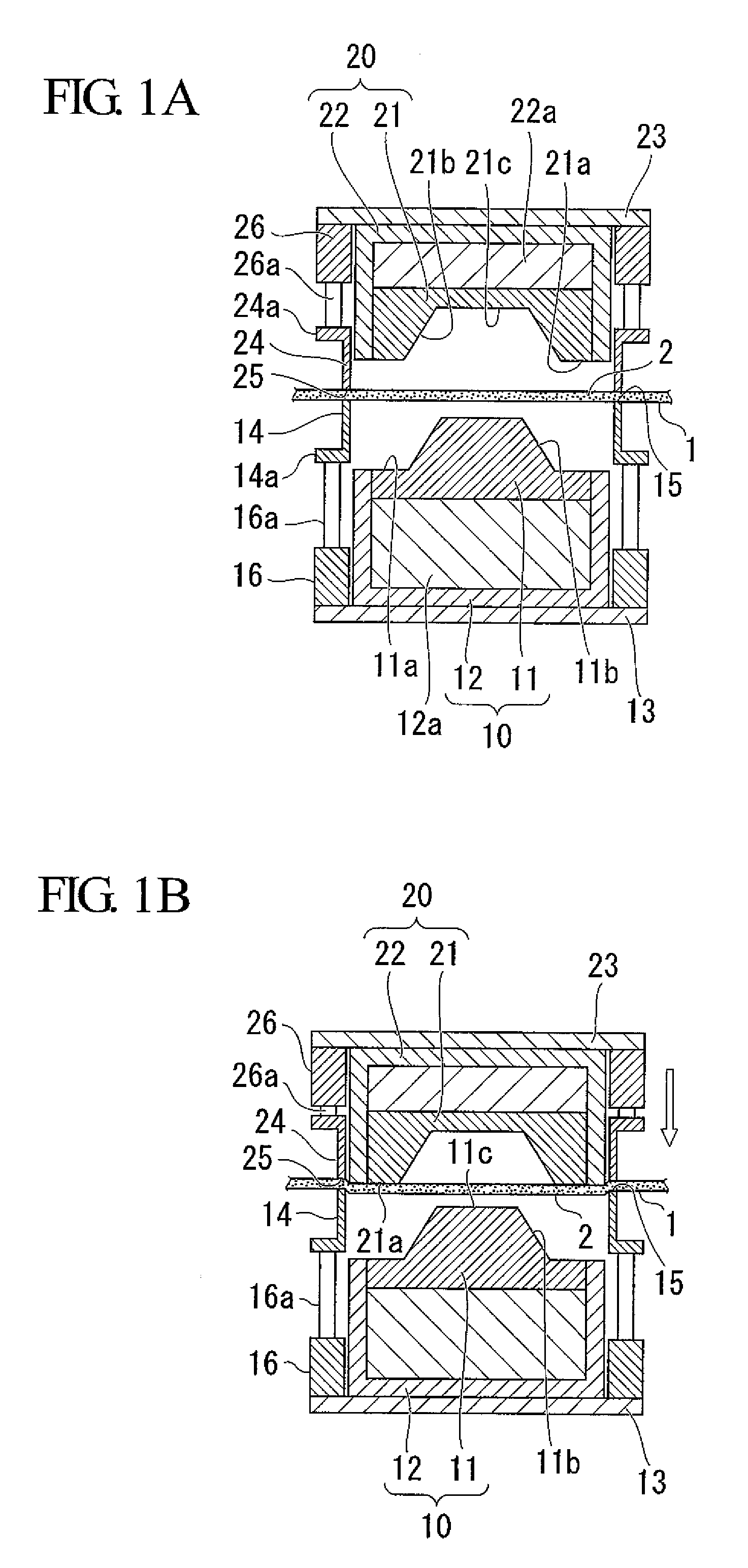

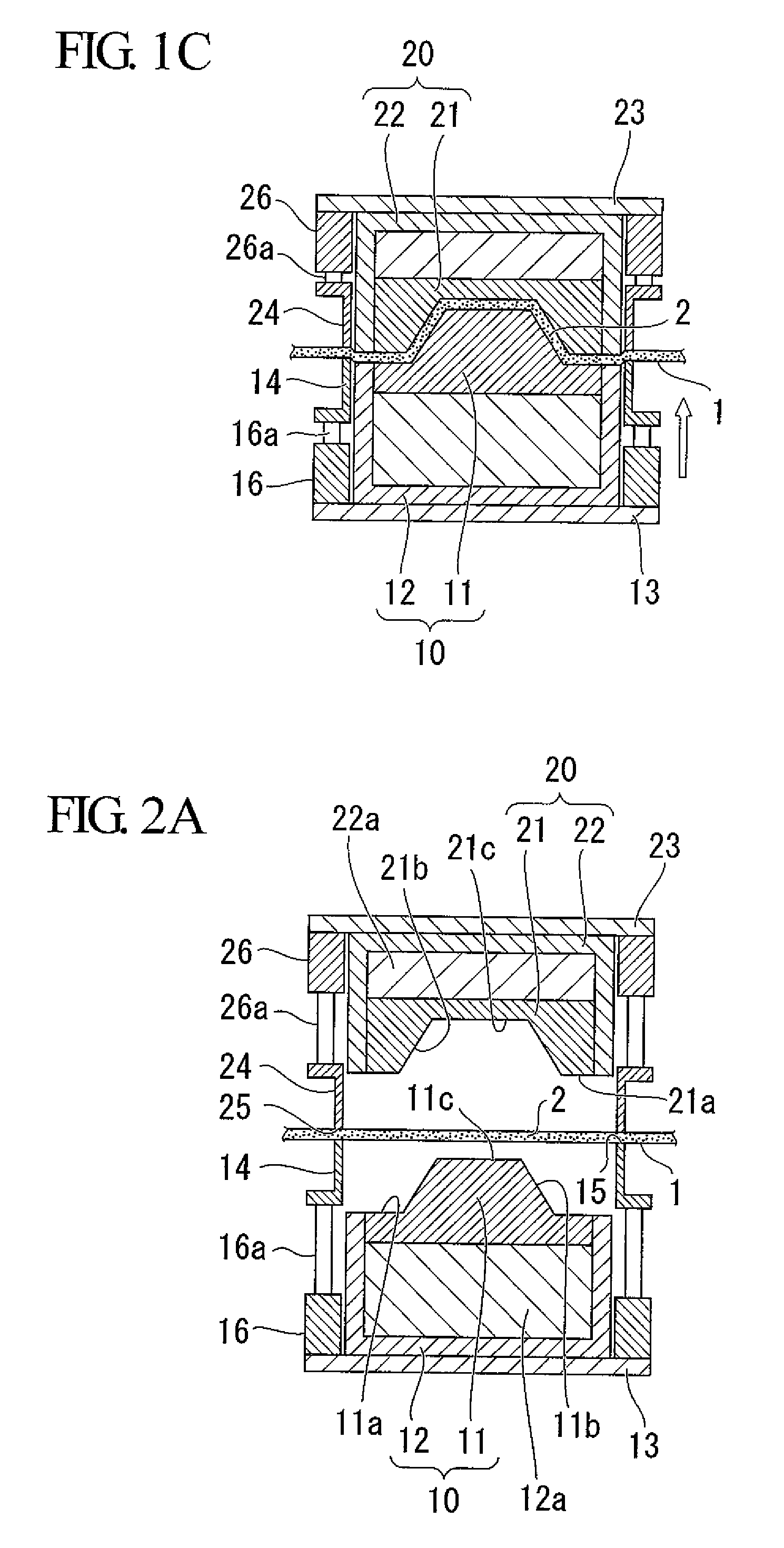

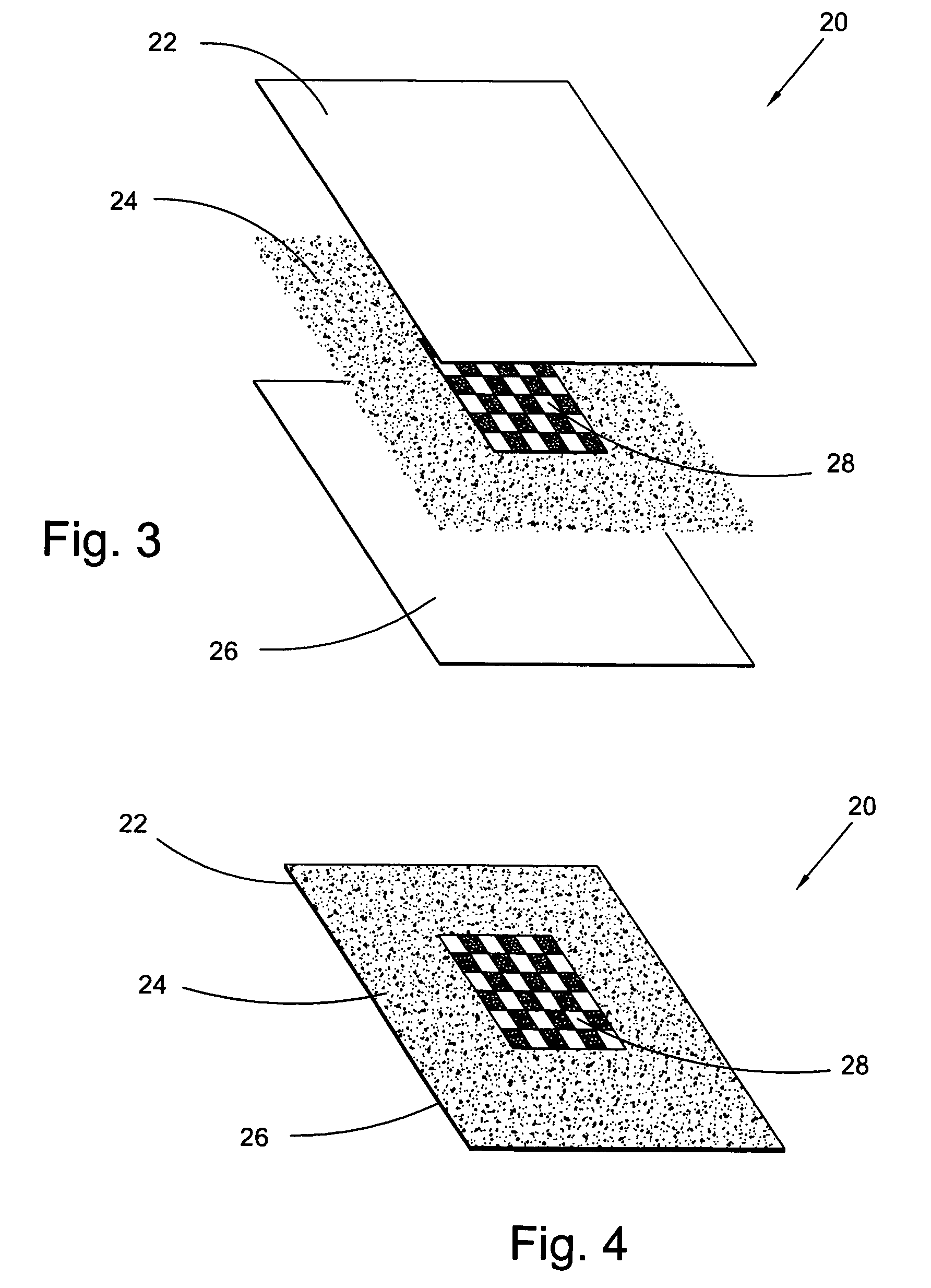

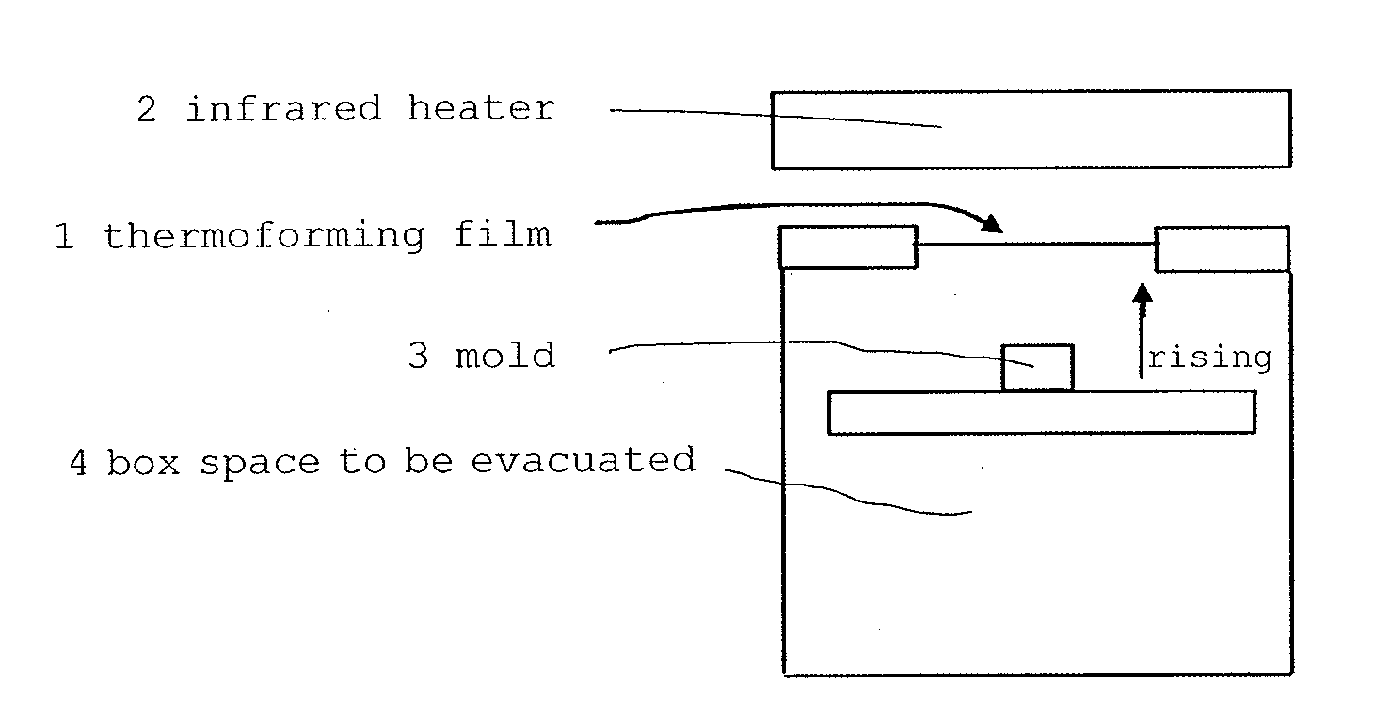

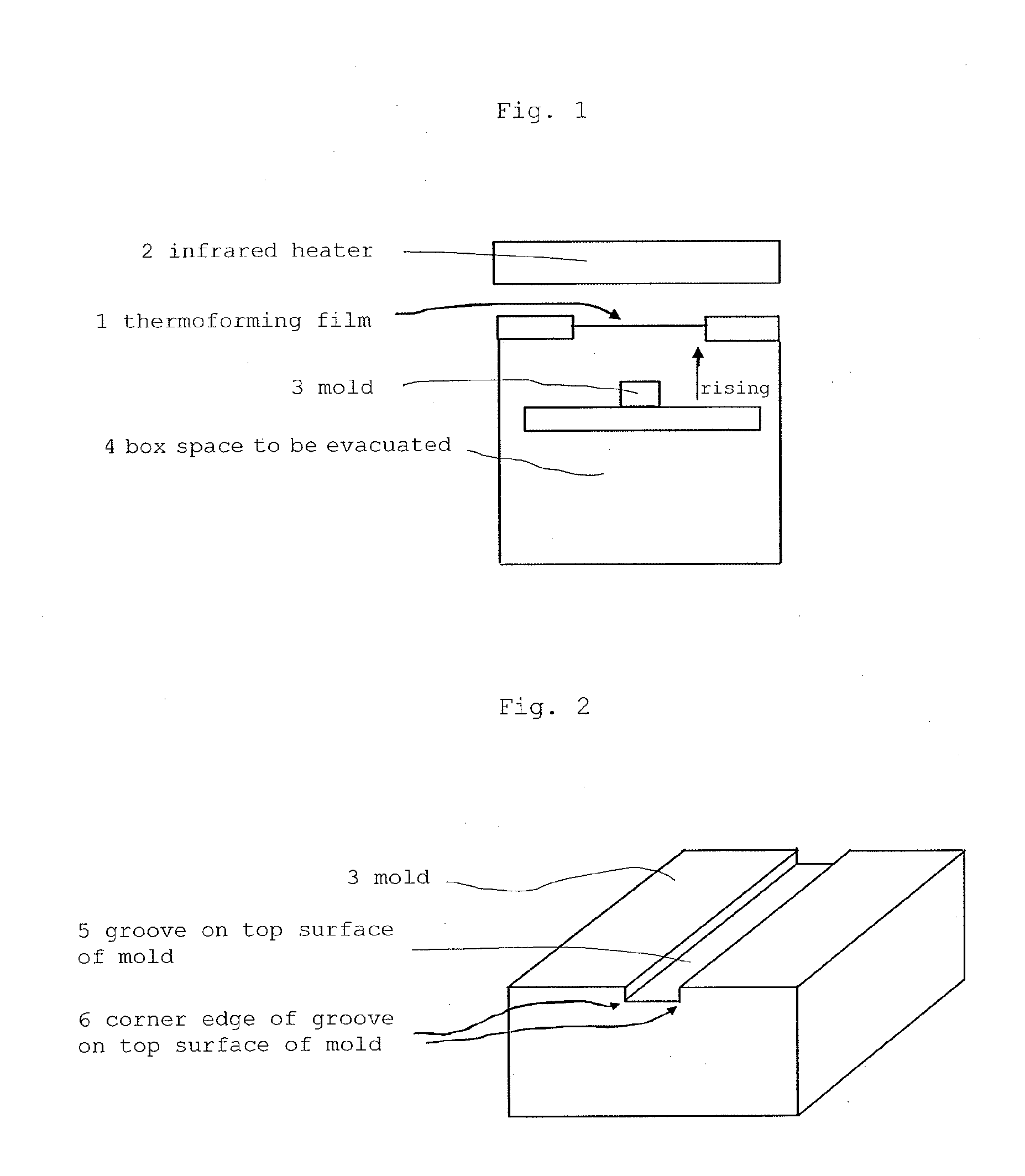

Thermoforming method for thermoforming sheet and thermoforming apparatus

InactiveUS20090039556A1Design property is not deterioratedNo wrinklesConfectioneryWood working apparatusThermoformingShell molding

The thermoforming method of the present invention is a method that includes thermoplasticizing a portion, including a part 2 which is molded with molds, of a thermoforming sheet 1 in which at least one or more thermoplastic resin layers (A) and a decorative layer (B) were laminated, at a temperature range of (Tg (A)−30)° C. to (Tg (A)+10)° C. with respect to the glass transition temperature (Tg (A)) of the thermoplastic resin layer (A); subsequently clamping by using a pair of frame clamps 14 and 24 both sides of a perimeter around the portion 2, which is molded with the molds, of the sheet 1; expanding the thermoplasticized portion between one mold and the frame clamps by pressing a portion of the one mold 20 onto one surface of the thermoplasticized portion; subsequently bringing the other mold 10 into contact with the thermoplasticized portion from the side opposite to the surface of the thermoplasticized portion that the one mold is in contact with; and mold-clamping the thermoplasticized portion with the one mold 10 and the other mold 20 to mold the thermoforming sheet. According to the present invention, forming at a low temperature in which the design properties can not be adversely affected can be achieved, and formed articles in which wrinkles or the like are not generated can be obtained.

Owner:DAINIPPON INK & CHEM INC

Lead-free easy-to-cut corrosion-resistant brass alloy with good thermoforming performance

The present invention provides a lead-free easy-to-cut corrosion-resistant brass alloy with good thermoforming performance. The brass alloy contains: 74.5-76.5 wt % of Cu, 3.0-3.5 wt % of Si, 0.11-0.2 wt % of Fe, 0.04-0.10% wt % of P, Zn and inevitable impurities. The alloy provided by the present invention has good cold-working and hot-working forming performance, and good dezincification corrosion-resistant and stress corrosion-resistant performance, applies to parts that require cutting and grinding forming in water-heating sanitaryware, electronic appliances, automobiles and the like, and especially applies to production and assembling of complex forging products for which stress is inconvenient to eliminate, such as water taps, values and the like.

Owner:XIAMEN LOTA INT CO LTD

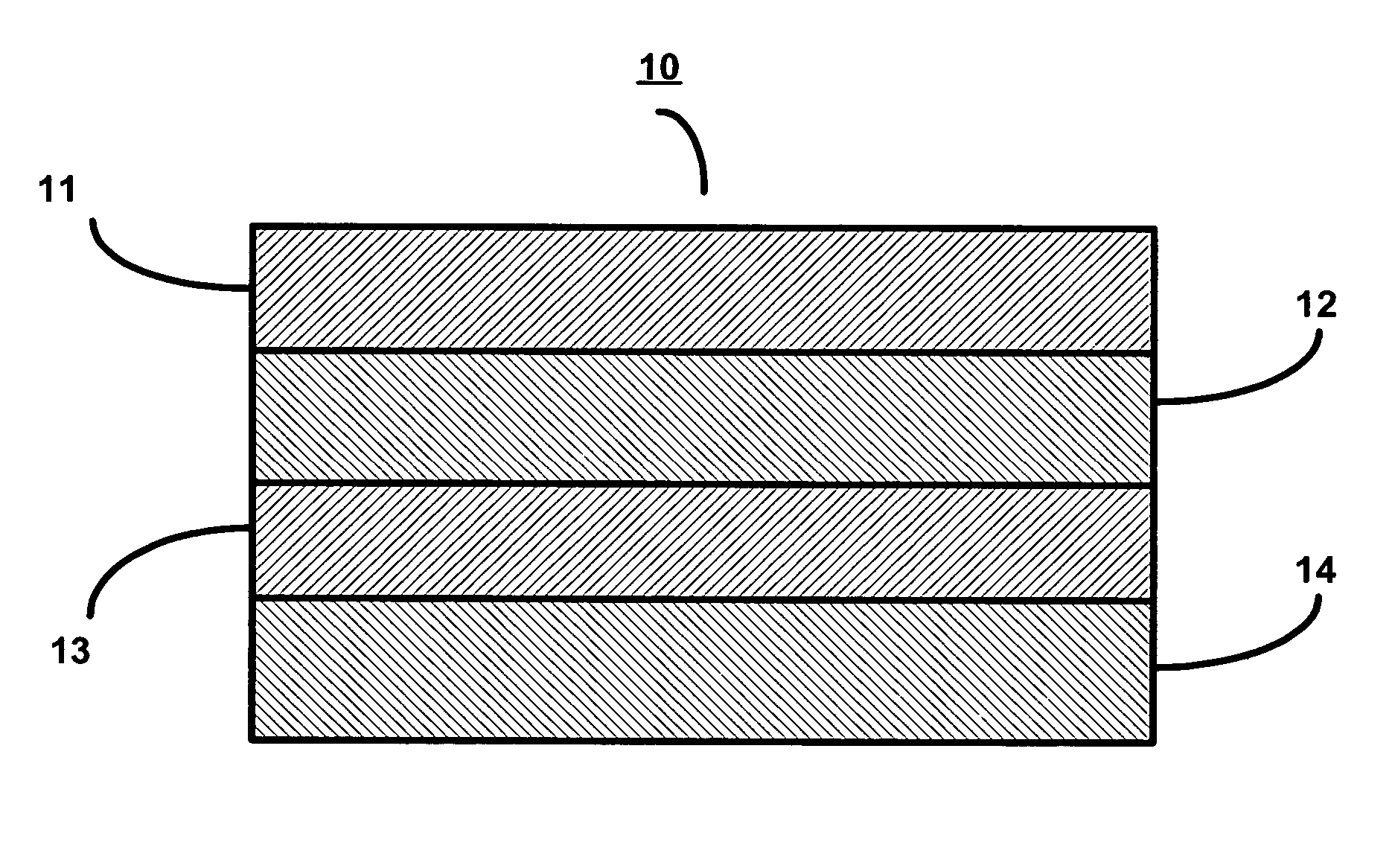

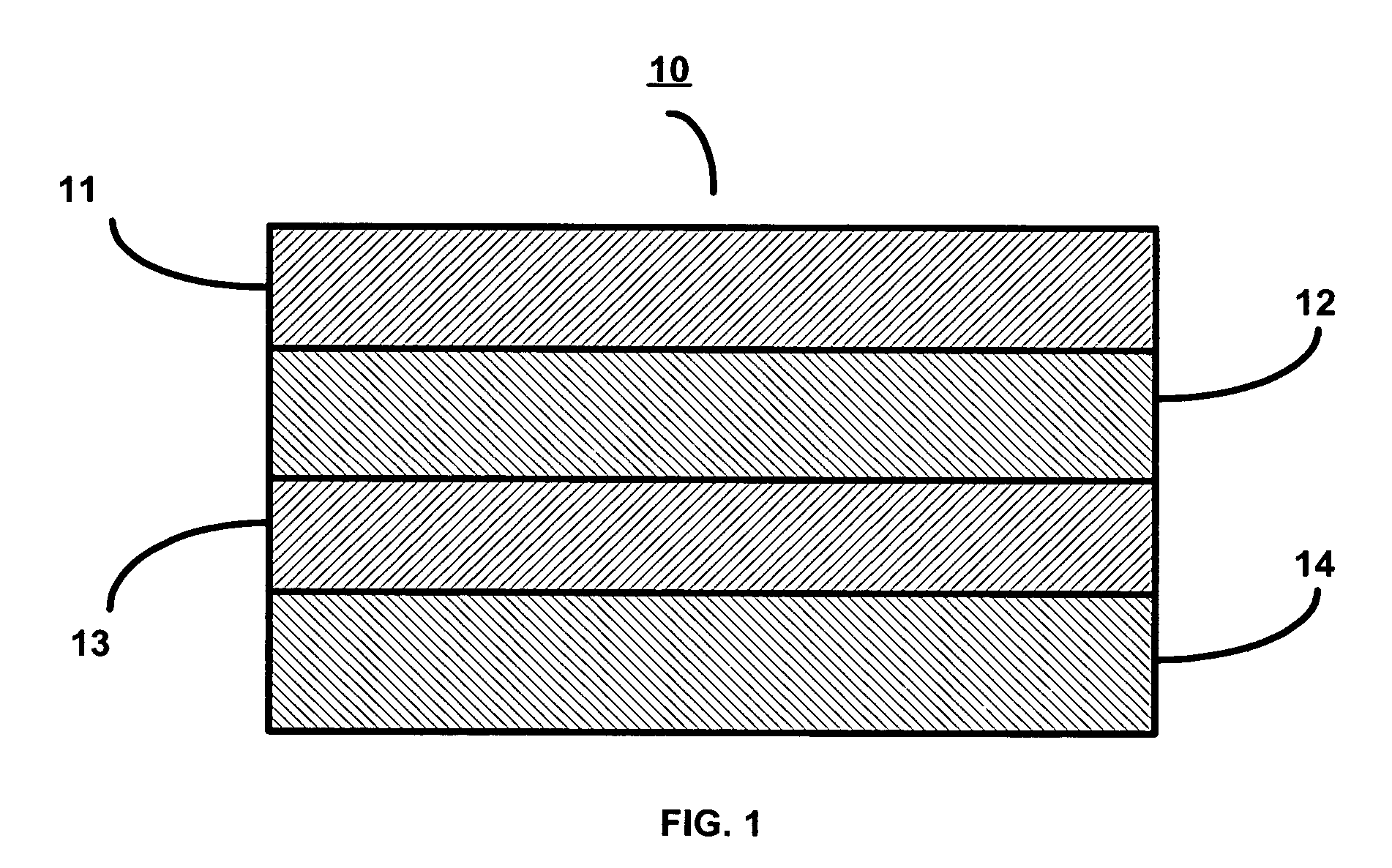

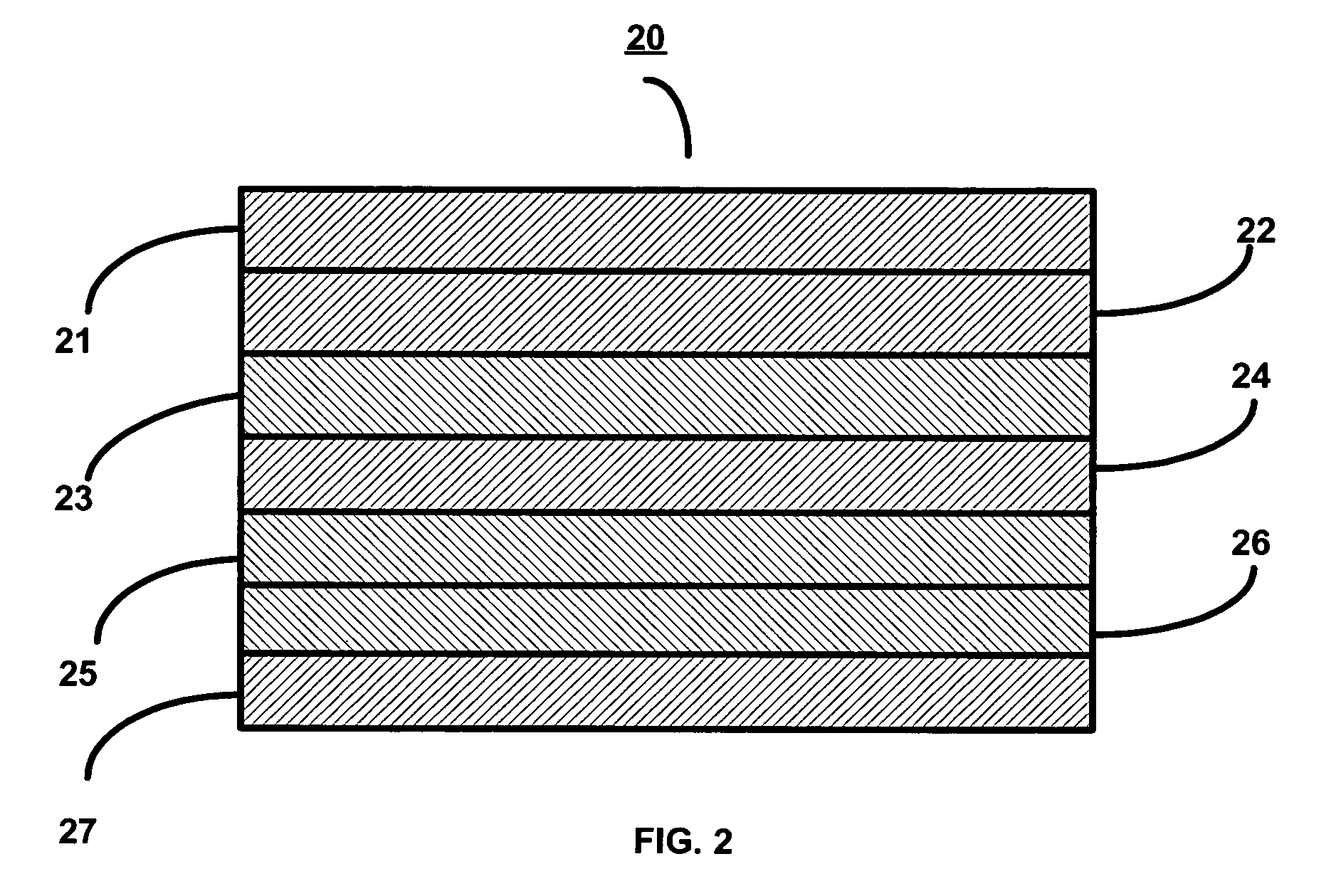

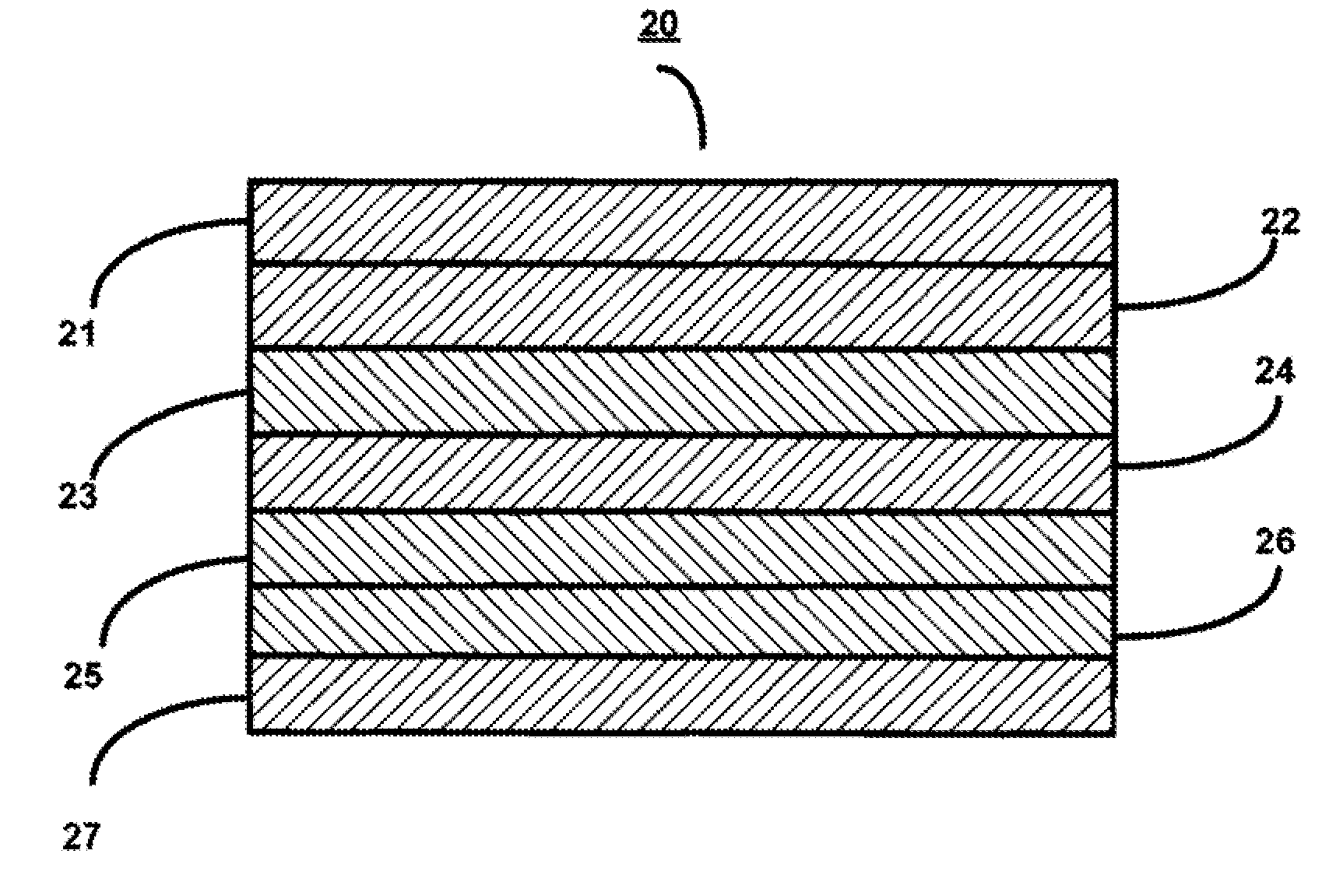

Multilayer structure and method for producing same

ActiveCN102712182AExcellent interlayer adhesionSuppression of manufacturing cost increaseSynthetic resin layered productsThin material handlingPolymer sciencePolymer chemistry

The disclosed multilayer structure provided with at least eight resin layers is characterized by: having, as resin layers, A layers comprising a resin composition containing a gas-barrier resin, and B layers comprising a resin composition containing a thermoplastic resin; containing a metal salt within at least one of the resin compositions of the adjacent A layers and B layers; the quantity of contained metal salt being at least 1 ppm and no more than 10,000 ppm in terms of the metallic element; and the interlayer adhesive force between the A layers and the B layers being at least 450 g / 15 mm. It is preferable that the A layers and B layers are layered in alternation. Furthermore, it is preferable for the average thickness of one layer of the A layers and / or the B layers to be at least 0.01 [mu]m and no more than 10 [mu]m.

Owner:KURARAY CO LTD

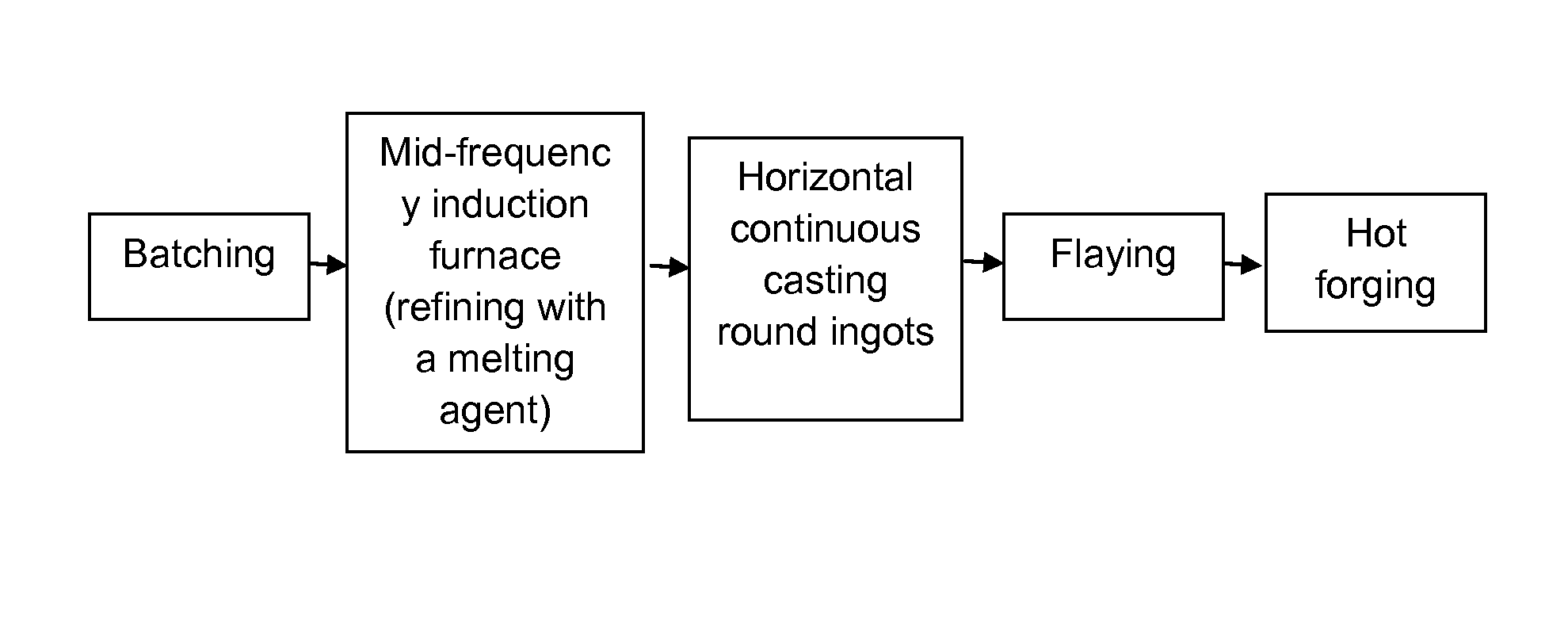

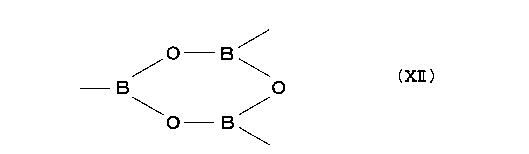

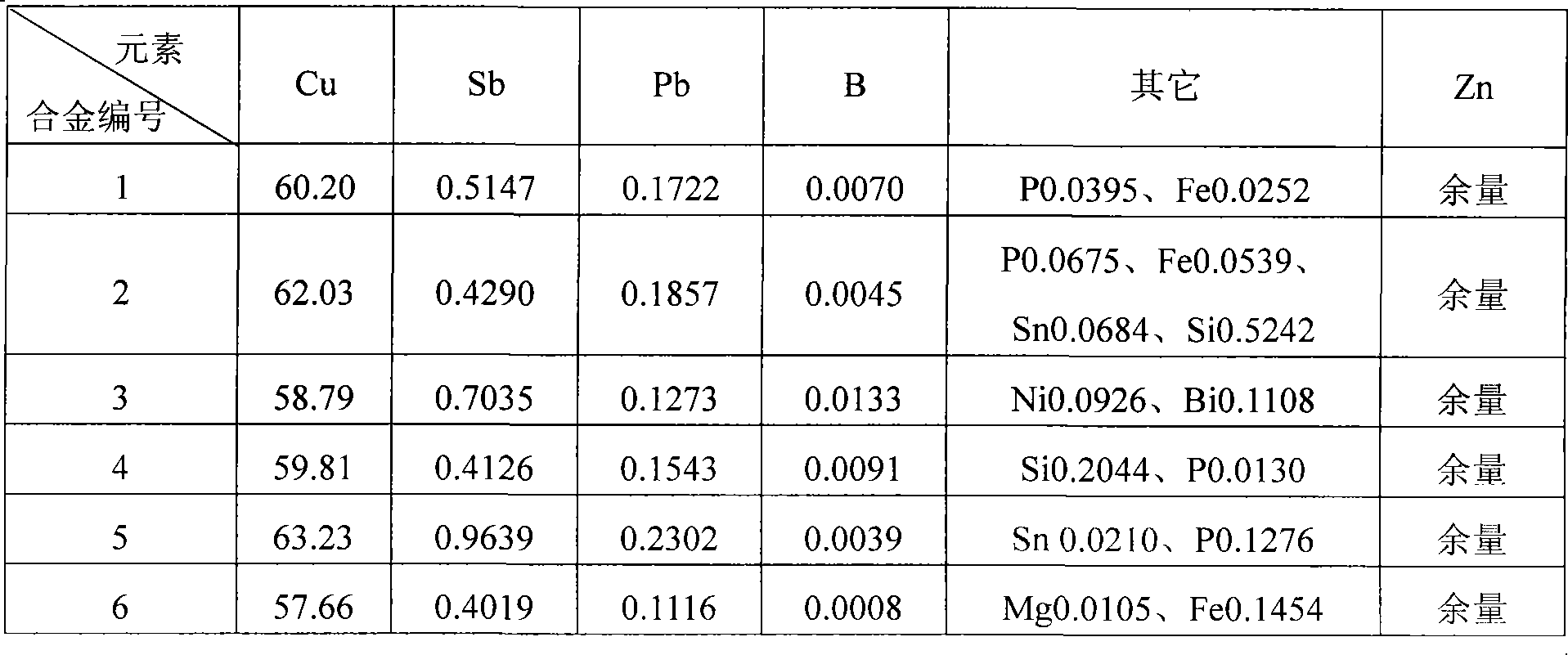

Low-lead-boron easy-cutting antimony brass alloy and method for manufacturing same

ActiveCN101113501AImprove mechanical propertiesExcellent thermoformabilityMechanical propertyImpurity

The invention discloses a low lead and boron easy-cutting antimony brass alloy and a preparation method thereof. The chemical components of the low lead brass alloy are that: 55-65wt percent of copper, 0.4-1.2wt percent of antimony, 0.1-0.3wt percent of lead, 0.0003-0.05 wt percent of boron, 0.05-1.5wt percent of other components, wherein, the other components comprise at least one of the elements of: magnesium, iron, tin, nickel, silicon, bismuth and phosphorus, the other elements are zinc and inevitable impurities. The production method is that: the low lead and boron easy-cutting antimony brass alloy is treated by an alloying treatment and is smelted by a cover protection method to ensure the metal antimony, boron to become intermetallic compound through fast solid solution in the melten brass; the bass casting ingots are made by continuous casting under 1020 DEG C; the bass casting is pressed under a large pressing ratio under the temperature between 680 DEG C and 750 DEG C, anneal in the middle thermal treatment is under 450-650 DEG C according to cold process conditions, when the temperature is below 400 DEG C, anneal for eliminating stress is made. The invention has the advantages that the products have good mechanical, thermoforming, corrosion resistance, polishing and electroplating performance, and successfully solves the problems of singularity of waste chips, recovery of variety of components and comprehensive utilization and recycling. The recovery can be singularity or be comprehensive such as comprehensive recovery of the waste chips of the Cu-Zn-Si system, Cu-Zn-Bi system and Cu-Zn-Sb system alloy. At the same time the lead and brass waste chips can also be partly recovered and utilized.

Owner:NINGBO POWERWAY ALLOY MATERIAL

Laminated sheet for thermoforming, formed product, injection-molded product, and method of producing the same

InactiveUS20090104441A1Excellent thermoformabilityImprove impact resistanceFilm/foil adhesivesSynthetic resin layered productsLinear low-density polyethyleneLow-density polyethylene

The object of the present invention is to provide a laminated sheet for thermoforming, including a thermoplastic resin film layer; a decoration layer; and a support base resin layer, wherein the thermoplastic resin film layer, the decoration layer, and the support base resin layer are sequentially laminated, and the support base resin layer contains one or more linear low density polyethylene layers. Also, the object of the resent invention is to provide a formed product obtained by thermoforming the laminated sheet, and a method of producing the same. Furthermore, the object of the present invention is to provide an injection-molded product obtained by loading an injection resin onto the backside of the molded product, and a method of producing the same.

Owner:DAINIPPON INK & CHEM INC

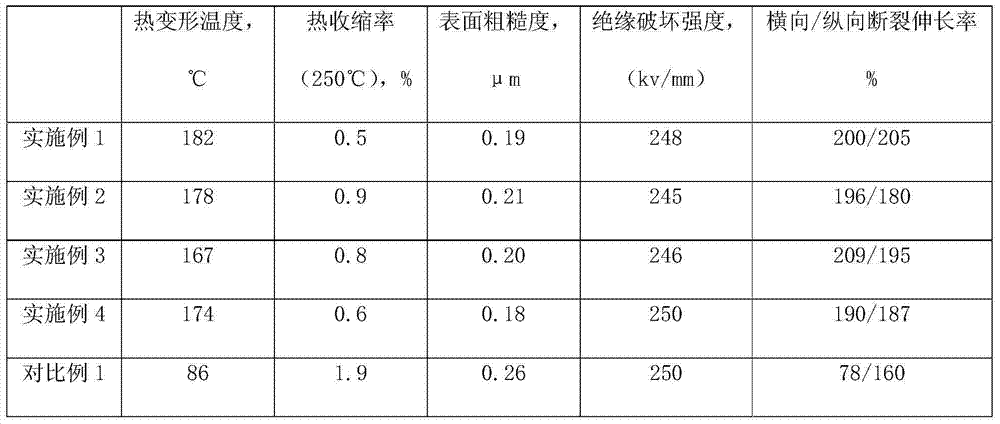

Preparation method of biaxially oriented polyphenylene sulfide composite film

The invention relates to the technical field of extraordinary film preparation, and especially relates to a preparation method of a biaxially oriented polyphenylene sulfide composite film with good toughness and excellent heat resistance. The preparation method comprises the steps of master batch preparation, sheet casting and stretching film formation. The biaxially oriented polyphenylene sulfide composite film prepared by adopting a technical scheme in the invention has the advantages of excellent heat resistance, excellent dimensional stability, excellent heat formability and excellent toughness, can be applied the fields of electric insulation materials or forming materials of motors, transformers and insulation cables, the field of circuit substrate materials, and the field of loudspeaker vibration plates for mobile phones.

Owner:常州钟恒新材料股份有限公司

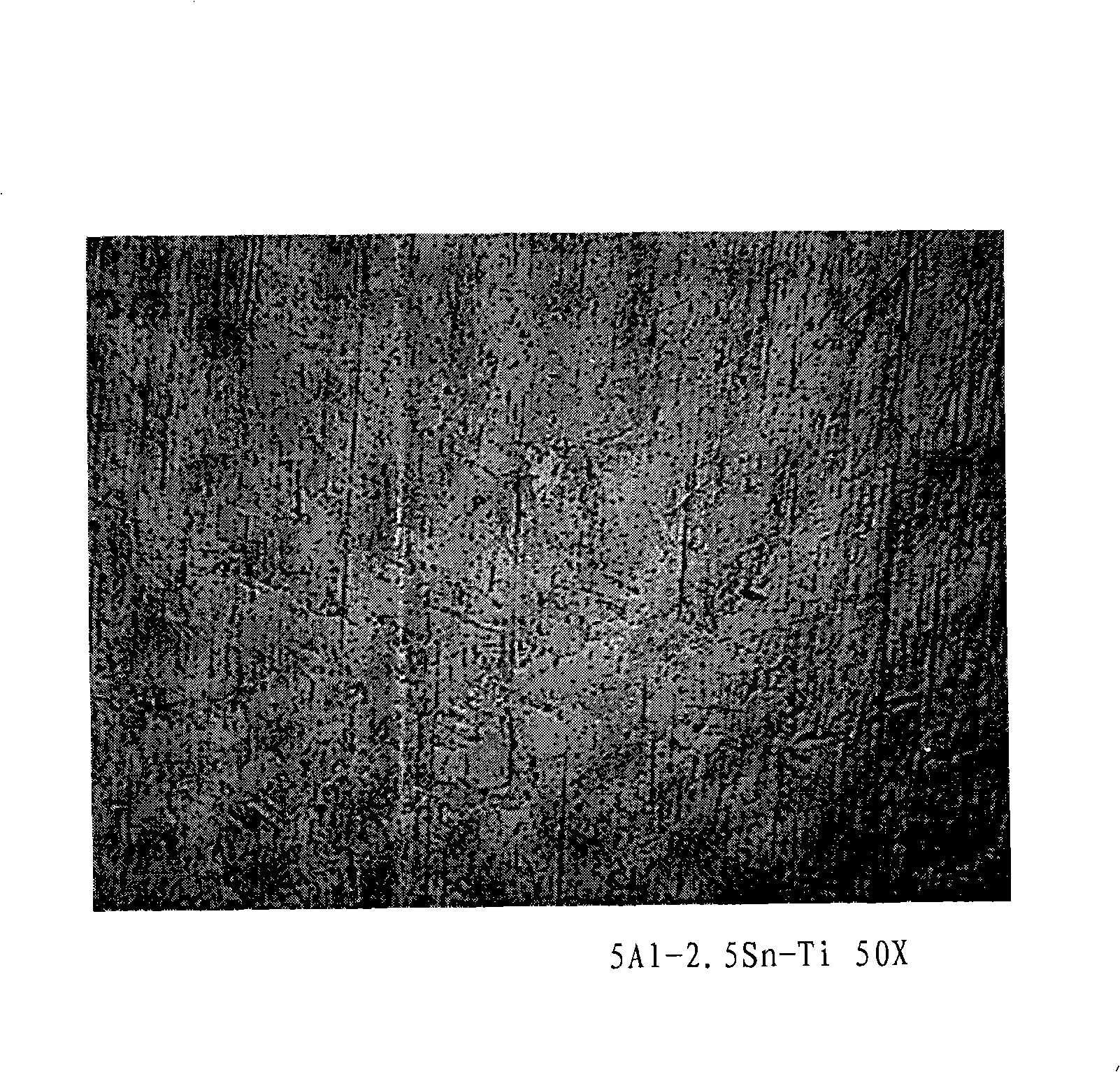

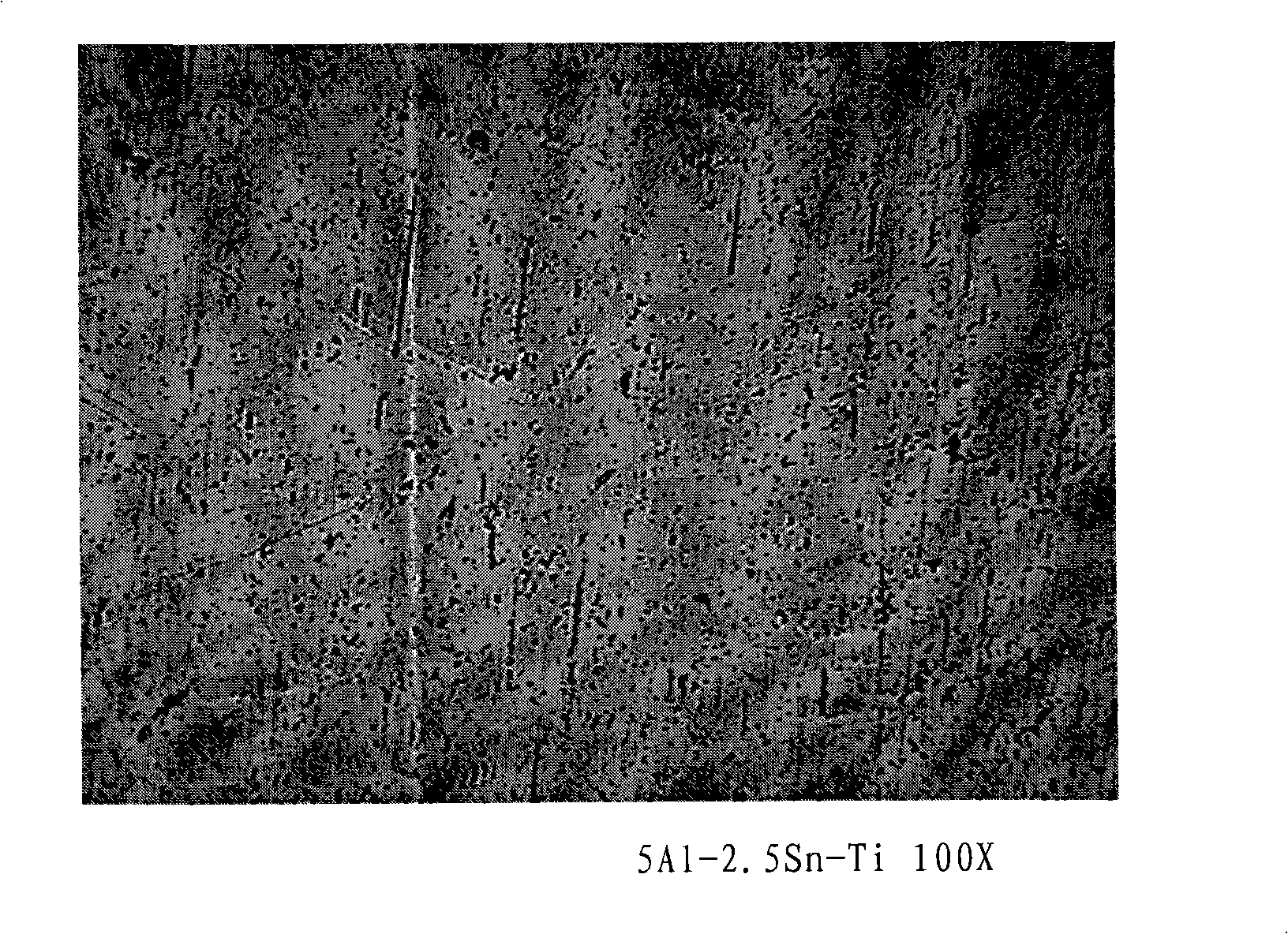

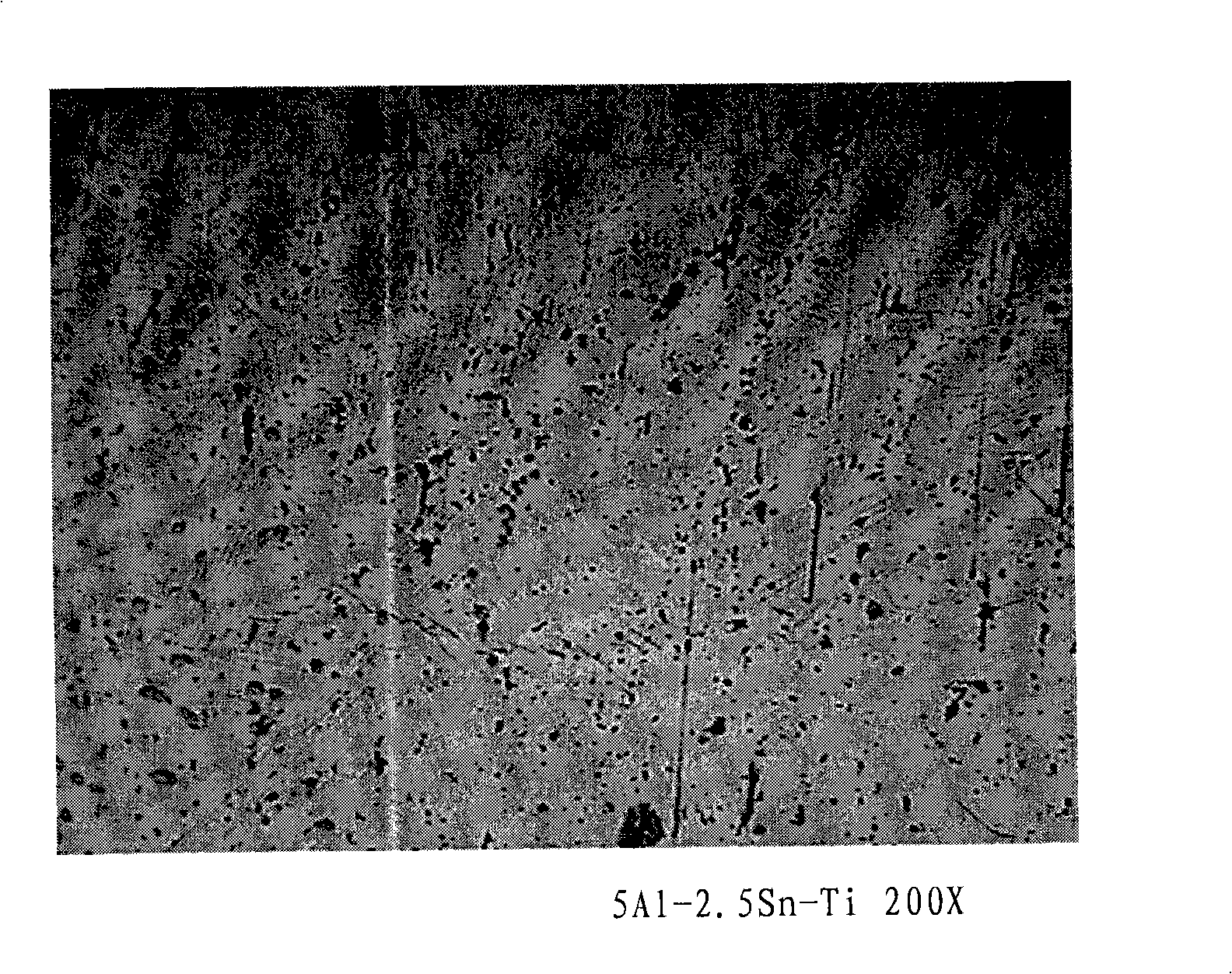

Titanium-aluminum-tin alloy applied to golf club head

InactiveCN101514412ARaise room temperatureHigh temperature strengthGolf clubsRacket sportsNiobiumAlloy

The invention relates to a titanium-aluminum-tin alloy applied to a golf club head, which comprises the following materials in percentage by weight: 89 to 95 percent of titanium, 3.5 to 6.5 percent of aluminum and 1.5 to 3.5 percent of tin. The titanium-aluminum-tin alloy can be selectively added with trace elements such as niobium, vanadium, molybdenum, zirconium, chromium, iron, silicon, oxygen, nitrogen, and the like to form a high elongation material with the elongation of between 11 and 15 percent and the tensile strength of between 700 and 950 Mpa. The high elongation material can be applied to a body and a batter side of the golf club head; and by the design of an internal structure of the body and the design of a structure of balance weight and fins, products of the golf club head have good beating performance, shock controlling and golf controlling performances, adjustable angles and individuation.

Owner:ADVANCED INT MULTITECH CO LTD

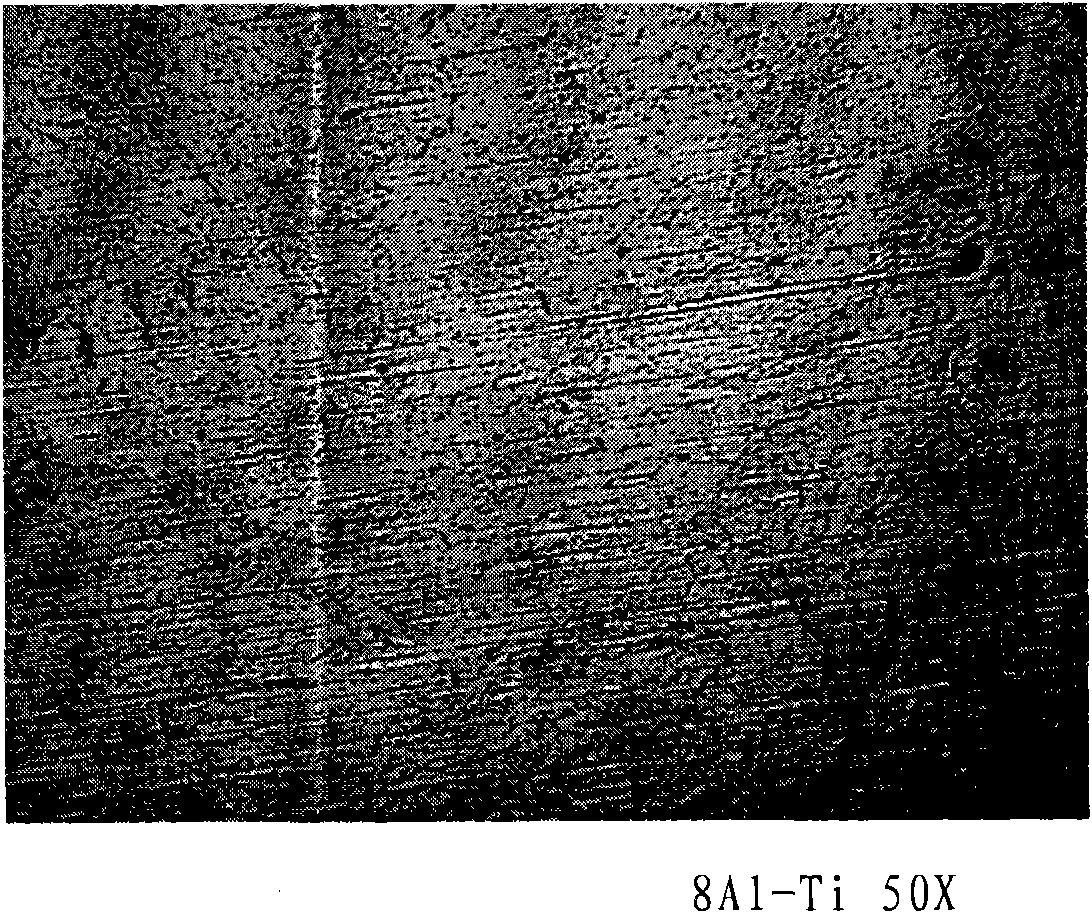

Titanium aluminum alloy applied to golf club head

InactiveCN101514411AImprove room temperature and high temperature strengthLight weightGolf clubsRacket sportsAngle modulationNiobium

The invention discloses a titanium aluminum alloy applied to a golf club head, which comprises 88 to 92 percent of titanium and 7.5 to 10 percent of aluminum in percentage by weight, the elongation rate of the titanium aluminum alloy is 8 to 16 percent, the titanium aluminum alloy can be selectively added with niobium, vanadium, molybdenum, chromium, iron, silicon, oxygen, nitrogen and other microelements to form a high elongation rate material with the tensile strength of between 650 and 950 Mpa, and the high elongation rate material is applied to a body of the golf club head and combines the golf club head formed by a batting panel of a 6AL-4V-TI titanium alloy or a beta alloy with better rigidity to realize golf head products with better batting, vibration control and ball control of which the club part can be subjected to angle modulation for customization.

Owner:ADVANCED INT MULTITECH CO LTD

Polypropylene-based resin composition and foam sheet

ActiveUS20150004394A1Improve acceleration performanceGood lookingSynthetic resin layered productsVehicle componentsPolymer scienceHeat resistance

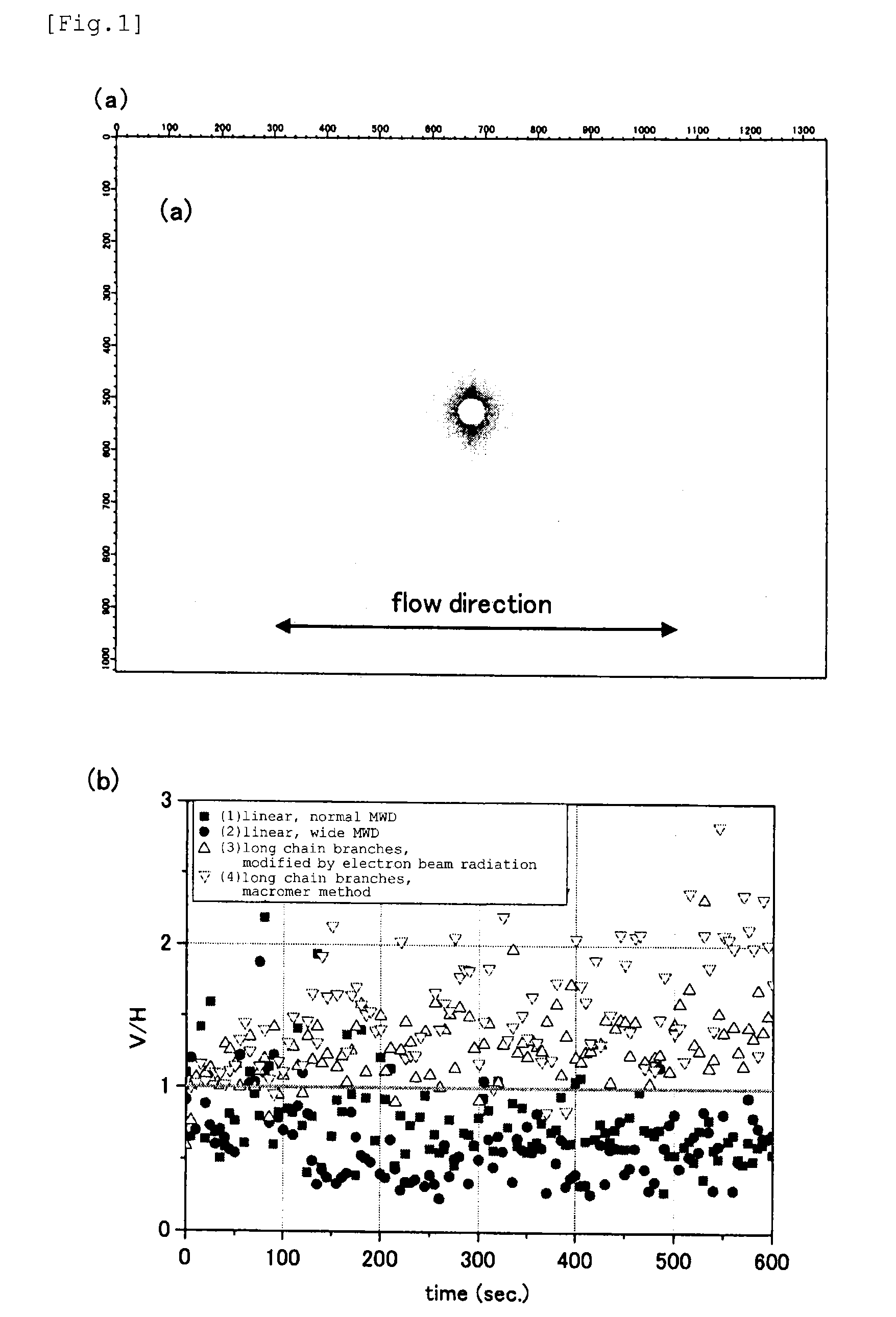

Provided is a polypropylene-based resin composition which gives uniform and fine cells and from which a foamed sheet and thermoform excellent in appearance, thermoformability, impact resistance, lightness, stiffness, heat resistance, heat insulating properties, oil resistance and the like can be produced. A polypropylene-based resin composition comprising (X) 5 to 99% by weight of a polypropylene resin having a structure with long chain branches, and (Y) 1 to 95% by weight of a propylene-based block copolymer produced by sequential polymerization, which block copolymer comprises (Y-1) a propylene (co)polymer and (Y-2) a propylene-ethylene copolymer, said resin (X) having properties (X-i) to (X-iv) and said block copolymer (Y) having properties (Y-i) to (Y-v), and the like.

Owner:JAPAN POLYPROPYLENE CORP

Breathable Packaging Film Having Enhanced Thermoformability

InactiveUS20090081439A1Excellent thermoformabilitySimple structureSynthetic resin layered productsDomestic containersPolyesterPolyolefin

The present invention describes thermoformable coextruded film suitable for use in packaging applications having at least a first polymeric layer serving as an outermost exterior-film layer and comprising a cycloaliphatic polyester, an aromatic polyester or blends thereof; a second polymeric layer serving as a thermoforming-assist layer and comprising a polyolefin; and a third polymeric layer serving as an innermost exterior-film layer and comprising a heat-sealing polyolefin material. The films of the present invention are oxygen-permeable in that they exhibit an oxygen transmission rate of between 2-1000 cm3 / 100 in2 / 24 h. atm.

Owner:CURWOOD INC

Aluminum alloy profile for aviation and production technology thereof

InactiveCN107675044AImprove mechanical propertiesOmit the steps of manual validationAviationRare-earth element

The invention belongs to the field of aluminum alloy profile production, and relates to an aluminum alloy profile for aviation and a production technology thereof. The aluminum alloy profile includes,by mass, no more than 0.25% of Si, no more than 0.4% of Fe, no more than 0.25% of Mn, 5-20% of Zn, no more than 15% of Mg, no more than 8% of Cu, no more than 1% of Zr, no more than 1% of Ti, 0.01-1.0% of Sr and the balance Al. By adding a proper amount of rare earth element Sc into a composition of 7xxx series aluminum alloy, the prepared aluminum alloy profile can be fine and uniform in grain and have good thermal processing formability, and a recrystallization phenomenon does not exist in the process of hot extrusion and solid solution aging heat treatment, so that grain refining, segregation reduction and more uniform texture of the prepared aluminum alloy profile are achieved.

Owner:CHINA ZHONGWANG

PVDC-polyolefin coextruded thermal-formed high-blocked composite packaging material

ActiveUS8084109B2Improve water vapor barrier performanceStrong anti-greaseDomestic sealsSynthetic resin layered productsPolyolefinEngineering

Owner:JIANGSU CAIHUA PACKING GROUP +2

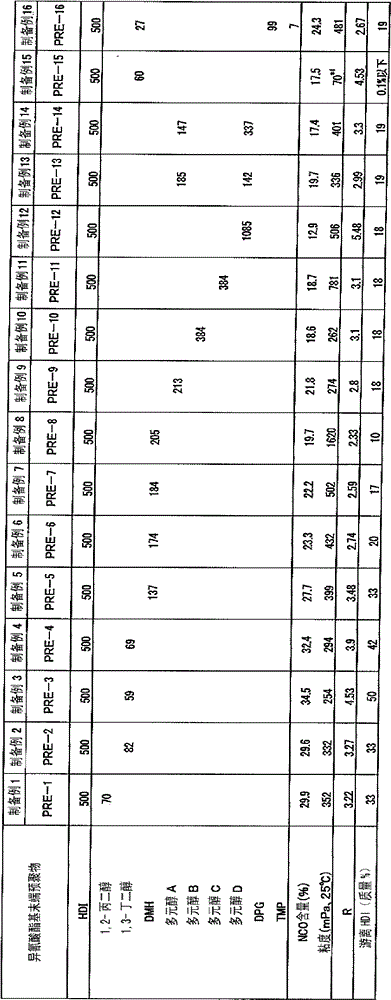

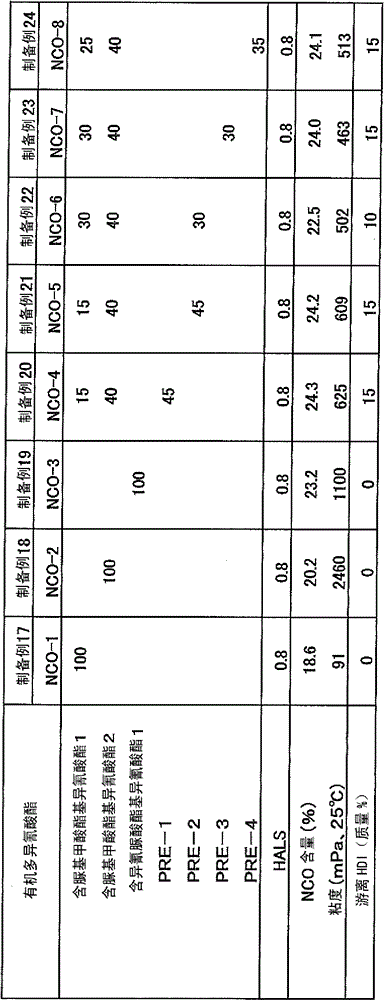

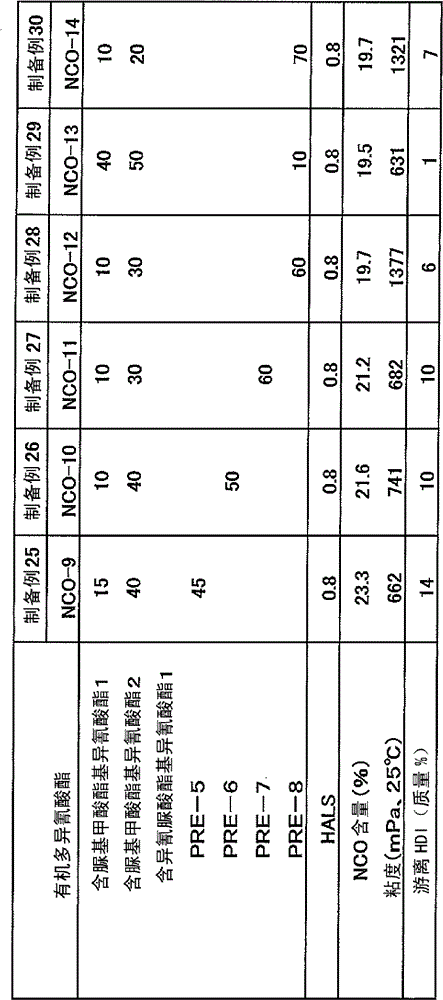

Flexible polyurethane?foam and manufacturing method thereof

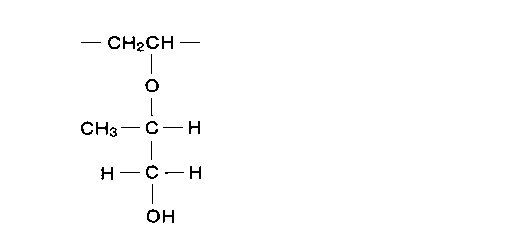

InactiveCN102746485AUniform cell structureExcellent discoloration resistanceAbsorbent padsPackaging toiletriesAllophanePolyol

The invention provides a yellowing-proof flexible polyurethane?foam and a manufacturing method thereof. The manufacturing method of the flexible polyurethane?foam is a manufacturing method allowing reaction of an organic polyisocyanate (A), a polyalcohol (B), a catalyst (C), a foaming agent (D) and a foam stabilizer (E) to form and to be solidified, so as to obtain the flexible polyurethane?foam. The manufacturing method is characterized in that the organic polyisocyanate (A) is mixture of the following substances: an allophanate group-containing organic polyisocyanate composition (A1) which is generated by a monohydric alcohol and an aliphatic and / or alicyclic diisocyanate, an allophanate group-containing organic polyisocyanate composition (A2) which is generated by a hydroxyl group-containing compound having more than two hydroxyl groups and an aliphatic and / or alicyclic diisocyanate, and an organic polyisocyanate compound (A3) which is generated by reaction of an aliphatic and / or alicyclic diisocyanate and a polyalcohol component (a1).

Owner:NIPPON POLYURETHANE IND CO LTD

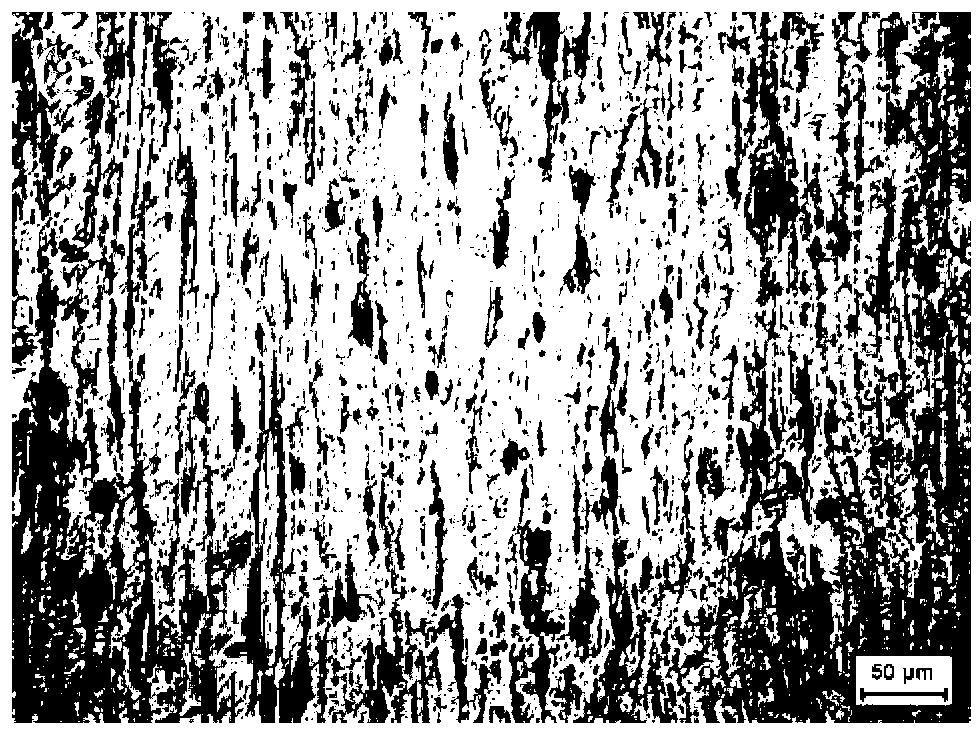

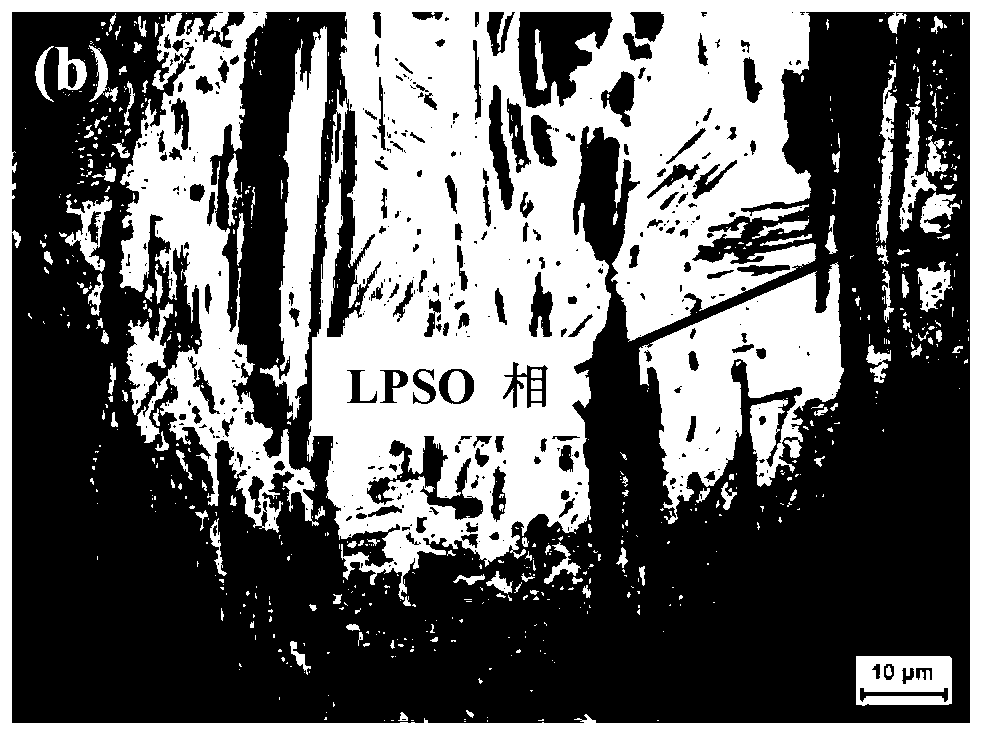

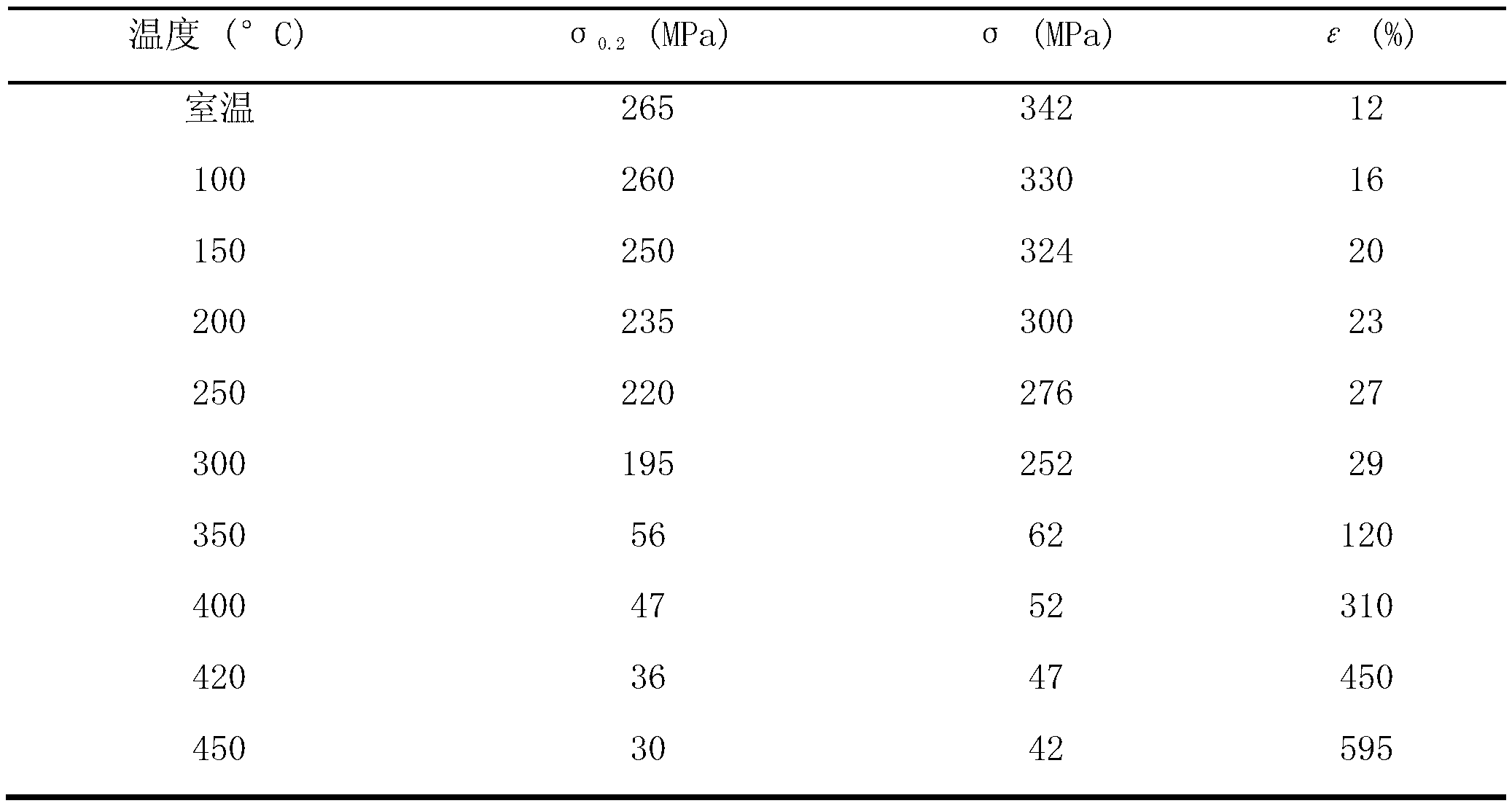

Superplastic high-strength heatproof magnesium alloy and preparation method thereof

InactiveCN103266247AGuaranteed high strength and heat resistanceExcellent thermoformabilitySlagRoom temperature

The invention provides a superplastic high-strength heatproof magnesium alloy and a preparation method thereof. The method which treats pure Mg, pure Zn an Mg-Y intermediate alloy and an Mg-Nd intermediate alloy as raw materials comprises the following steps: melting alloy elements, refining, removing slag, allowing the obtained mixture to stand at a constant temperature, cooling through utilizing a water cooling die to obtain magnesium alloy cast bars, carrying out high temperature homogenization treatment, and carrying out hot extrusion molding on an extruder to obtain the superplastic high-strength heatproof magnesium alloy, wherein the superplastic high-strength heatproof magnesium alloy includes 5.0-8.0mass% of Y, 0.5-2.5mass% of Nd, 1.5-3.5mass% of Zn, below 0.03mass% of inevitable Fe, Cu, Ni and Si impurities, and the balance Mg. The superplastic high-strength heatproof magnesium alloy has a high strength of 230-350MPa and a good plasticity of 10-30% at a temperature in a range of room temperature to 300DEG C, and has a superplastic characteristic and an elongation rate after break of 270-600% at a temperature in a range of 350-450DEG C.

Owner:HARBIN ENG UNIV

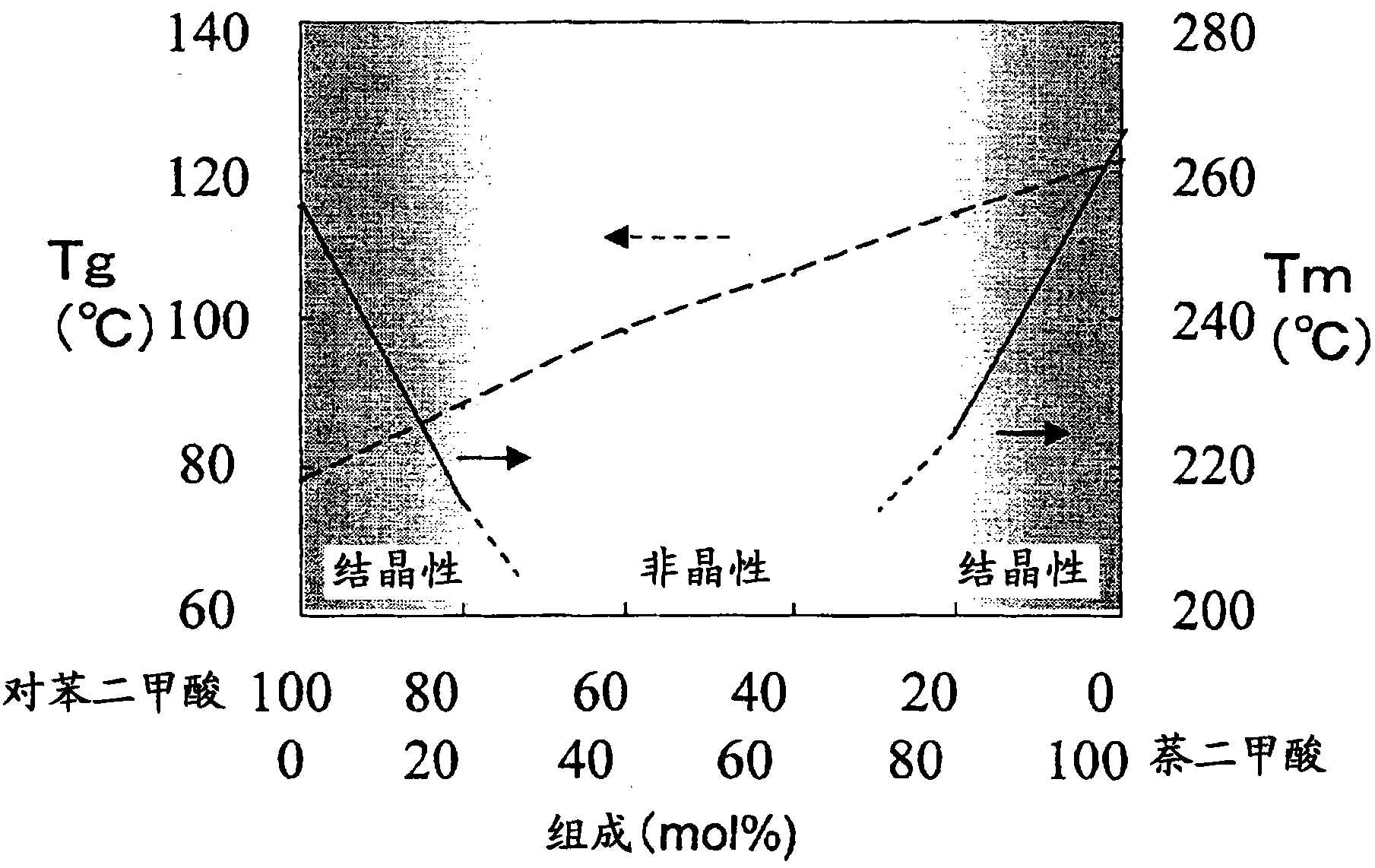

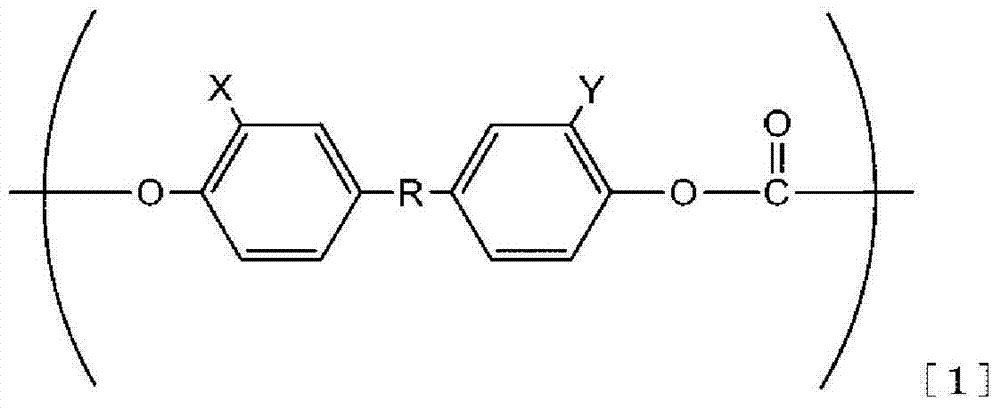

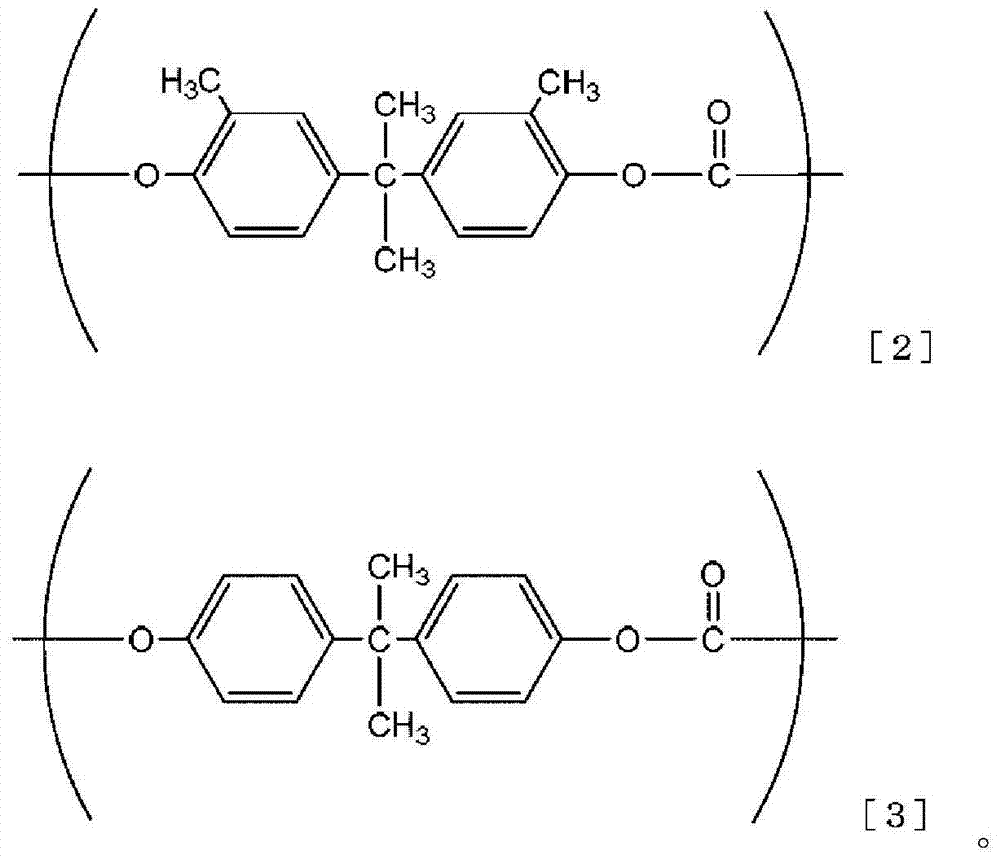

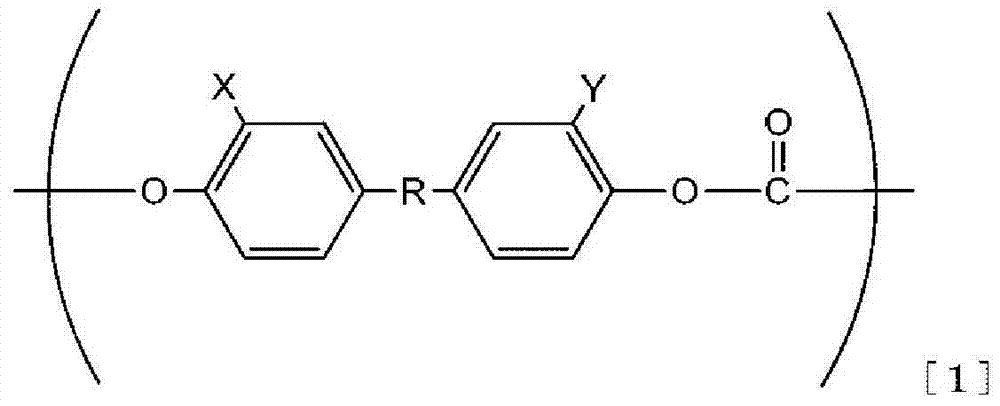

Polyester resin for thermoformed optical film and biaxially oriented polyester film obtained from the same

ActiveCN101959941AExcellent thermoformabilityImprove heat resistancePrismsHeat resistancePolyester resin

A polyester resin composition characterized by having a glass transition temperature (Tg) of 83 DEG C or higher and a melting point (Tm) of 230 DEG C or lower and having controlled crystallizability. This polyester has excellent surface thermoformability. In particular, the surface of the polyester can be formed into various shapes, e.g., a shape having ultrahigh fineness or a high aspect ratio. The polyester is for use as a thermoformed optical film excellent in heat resistance and transparency.

Owner:TORAY IND INC

Quartz/solid surface laminate

InactiveUS20070248836A1Functional performanceFaster laminating timeSynthetic resin layered productsAbrasion apparatusParticulatesPolyester

The present invention relates to a method of fabricating a laminate sheet product by using heat and pressure to form thermoformable particulates, such as acrylics and / or non-thermoformable particulates, such as polyester granules, quartz, or silica, into a sheet product. The invention also includes a particulate laminate sheet product comprising a melamine or phenolic backer sheets and a layer of one or more particulates. In preferred embodiments, melamine overlay sheets are also included in the laminate sheet. The invention also includes a particulate laminate sheet product made by the method of fabricating a laminate sheet product using heat and pressure to form thermoformable particulates, such as acrylics and / or non-thermoformable particulates, such as polyester granules, quartz, or silica, into a sheet product.

Owner:LINDE JOHN

Synthetic resin laminate

ActiveCN104718079AImprove flexibilityExcellent surface hardnessDomestic upholsterySynthetic resin layered productsPolymer alloySynthetic resin

The present invention addresses the problem of providing a synthetic resin laminate having excellent thermoformability (pressure forming, thermal bending molding) or insert moldability, as well as excellent surface hardness and / or impact resistance, the synthetic resin laminate being used as a transparent board material or protective material, and to provide a molded article obtained by molding the synthetic resin laminate. The synthetic resin laminate according to the present invention is obtained by laminating a specific (meth)acrylate copolymer resin and a specific polycarbonate resin on one or both sides of a polycarbonate-based substrate layer, and the polycarbonate-based substrate layer is polymer alloyed, thereby giving the substrate layer a glass transition temperature (Tg) of 110-130°C. A synthetic resin laminate having excellent thermoformability or surface hardness is thereby obtained.

Owner:MITSUBISHI GAS CHEM CO INC +1

Polypropylene resin composition and expanded molding

ActiveUS20150044405A1Excellent characteristicLight weightClosuresLayered productsPolypropyleneStrain rate

A polypropylene-based resin composition is provided that can provide a foam molding that exhibits an excellent closed cell characteristic and excellent extrusion characteristics, that is light weight and has a rigid feel, and that has an excellent recyclability.This polypropylene-based resin composition contains 100 weight % or is less than 100 weight % but at least 70 weight % of component (A) below and contains 0 weight % or is greater than 0 weight % but not more than 30 weight % of component (B) below,component (A):a propylene-based resin composition that comprises at least the following two components: a propylene-α-olefin copolymer (A1) satisfying conditions (A-1) to (A-3) and a propylene homopolymer (A2), (A1) and (A2) being obtained by polymerization by a multistage polymerization method, and this propylene-based resin composition having a content of (A1) of 1 to 20 weight % and a content of (A2) of 99 to 80 weight %, having a melt flow rate in the range from 5 to 20 g / 10 minutes and exhibiting strain hardening in a measurement of extensional viscosity at a temperature of 180° C. and a strain rate of 10 s−1,(A-1) an α-olefin content of 15 to 85 weight %,(A-2) an intrinsic viscosity q of 5 to 20 dL / g,(A-3) a Mw / Mn of 5 to 15;component (B):a propylene-based resin composition comprising at least the following two components: a propylene homopolymer or a propylene-α-olefin copolymer having a content of non-propylene α-olefin of less than 1 weight % (B1), which has an MFR of 10 to 1000 g / 10 minutes, and a propylene-α-olefin copolymer (B2) that has a weight-average molecular weight of 500,000 to 10,000,000 and a content of non-propylene α-olefin of 1 to 15 weight %, (B1) and (B2) being obtained by polymerization by a multistage polymerization method, and this propylene-based resin composition having a content of (B1) of 50 to 90 weight % and a content of (B2) of 50 to 10 weight %, and satisfying prescribed conditions (B-1) to (B-3).

Owner:JAPAN POLYPROPYLENE CORP

Water-repellent, thermoplastic resin sheet, and molded article

ActiveUS20150306852A1Little riskExcellent thermoformabilityOther chemical processesSynthetic resin layered productsCross-linkShell molding

Provided is a water-repellent, thermoplastic resin sheet including a textured layer which is formed from a polyethylene resin composition comprising a water repellent agent and which has a microscopic texture on one surface side, wherein at least the surface region of the textured layer is a cross-linked material which maintains the microscopic texture even after heated drawing. Also provided is a molded article, such as a molded container, formed by thermoforming the thermoplastic resin sheet.

Owner:DENKA CO LTD

Multi-layer film, decorative molding film and molded body

InactiveUS20130129990A1Good transferabilityExcellent surface hardnessDecorative surface effectsDuplicating/marking methodsPolyesterWrinkle skin

A multi-layer film which is excellent in transferability to a metal shape during thermoforming and hardly produces uneven thickness, wrinkles, whitening or cracks on the surface of the obtained molded article.The multi-layer film has a layer (layer A) containing a polycarbonate resin and a polyester-based thermoplastic elastomer and a layer (layer B) containing an acrylic resin, whereinthe layer B is formed on at least one side of the layer A.

Owner:TEIJIN CHEM LTD

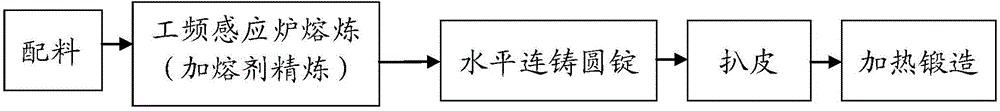

Good-formability environment-friendly brass alloy and manufacturing method thereof

The invention relates to good-formability environment-friendly brass alloy and a manufacturing method thereof. The brass alloy contains 35wt% or more of Zn, 0.1-1.0wt% of Si, 0.01- 0.28wt% of Mn, and the balance Cu and inevitable impurities. The brass alloy has good cold processing formability, hot processing formability, castability, anti-dezincification-corrosion performance, excellent polishing performance and welding performance, and is suitable for parts, of bathroom plumbing, electric products, automobiles and the like, used for forging, casting and direct processing.

Owner:LA VIDA IND +1

Biaxial orientation type polyphenylene sulfide composite membrane

The invention relates to the technical field of preparation of specific membranes, and particularly relates to a biaxial orientation type polyphenylene sulfide composite membrane with good toughness and excellent heat resistance. The composite membrane comprises the following components: membrane-grade polyphenylene resin, an organic elastomer and an inorganic filler, wherein the membrane-grade polyphenylene resin comprises membrane-grade polyphenylene resin for a master batch and membrane-grade polyphenylene resin for casting of a sheet. The biaxial orientation type polyphenylene sulfide composite membrane prepared by adopting the technical scheme provided by the invention has excellent heat resistance, size stability, thermal formability and toughness. The biaxial orientation type polyphenylene sulfide composite membrane disclosed by the invention can be applied to fields of electric insulating materials or forming materials for a motor, a transformer, an insulating cable and the like, a circuit substrate material, a loudspeaker vibrating plate for a mobile phone and the like.

Owner:常州钟恒新材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com