Polyester resin for thermoformed optical film and biaxially oriented polyester film obtained from the same

A polyester resin and optical film technology, applied in optics, optical components, instruments, etc., can solve the problems of difficulty in forming high-definition patterns, low heat resistance, poor formability, etc., and achieve excellent transparency and thermoformability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

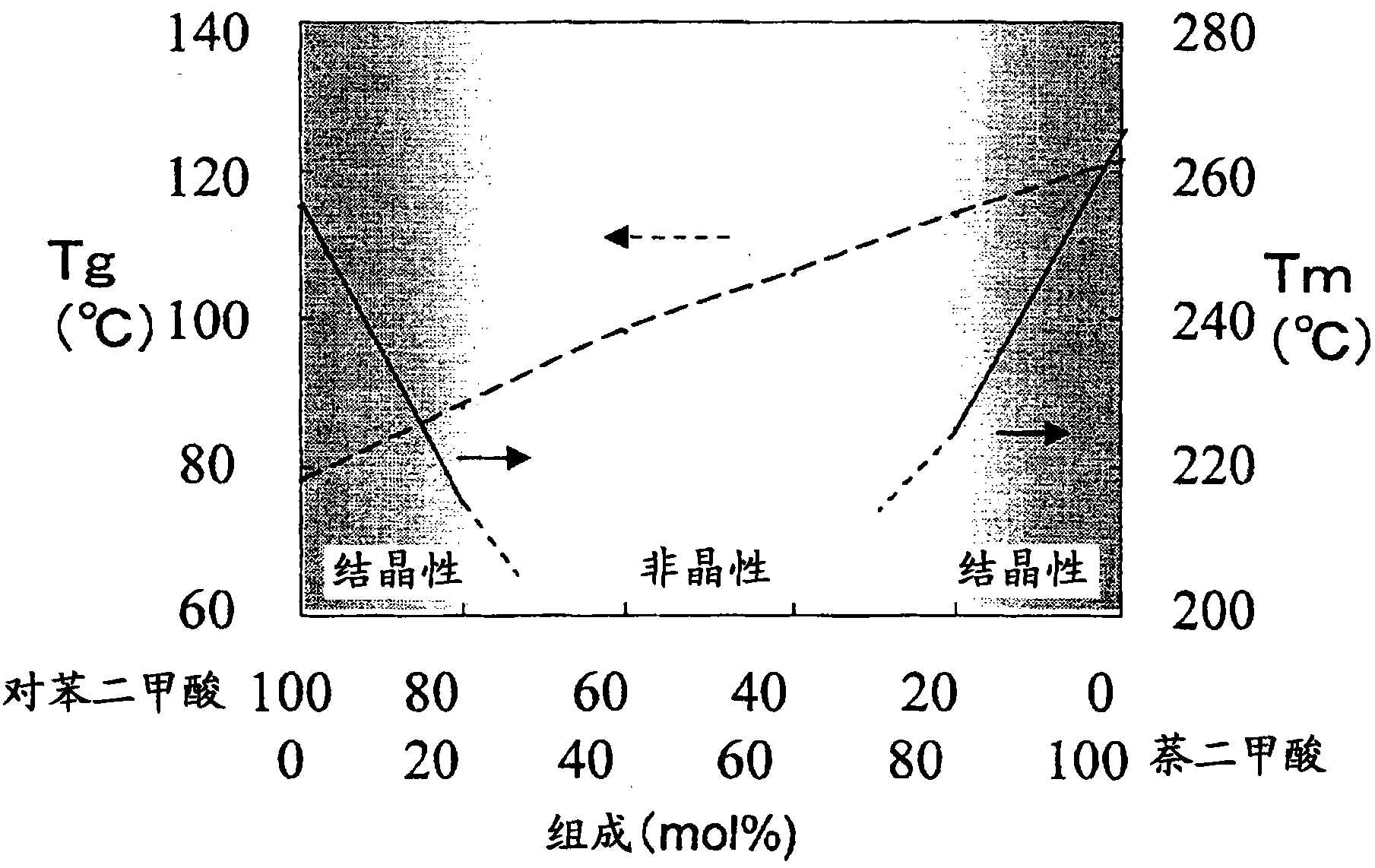

[0154] According to the ratio of 86.2 parts by weight dimethyl terephthalate, 14.8 parts by weight 2,6-dimethyl naphthalene dicarboxylate, 62.6 parts by weight of ethylene glycol (2 times the mole of the dicarboxylic acid composition) The monomer is added to the transesterification reaction device, the content is melted at 150°C, and then 0.06 parts by weight of magnesium acetate tetrahydrate, 0.02 parts by weight of antimony trioxide, and 0.003 parts by weight of lithium acetate dihydrate are added as catalysts, Stir.

[0155] The temperature was raised to 190°C over 60 minutes, the temperature was raised to 200°C over 60 minutes, and methanol was distilled off while raising the temperature to 240°C over 90 minutes. After a predetermined amount of methanol was distilled off, an ethylene glycol solution containing 0.04 parts by weight of triethyl phosphonoacetate was added as a deactivator for the catalyst, and stirred for 5 minutes to terminate the transesterification reactio...

Embodiment 2

[0163] Except having changed the copolymerization composition ratio, it carried out similarly to Example 1, and obtained the polyester resin. IV, solution turbidity, and thermal properties of the obtained polyester resin are shown in Table 1.

[0164] A three-layer laminated film was obtained in the same manner as in Example 1 except that this polyester resin was used as a sublayer, and then a thermoformed molded article was obtained. Table 1 shows the results of the 85°C brightness retention of the obtained molded articles.

Embodiment 3

[0166] Except having changed the copolymerization composition ratio, it carried out similarly to Example 1, and obtained the polyester resin. IV, solution turbidity, and thermal properties of the obtained polyester resin are shown in Table 1.

[0167] A three-layer laminated film was obtained in the same manner as in Example 1 except that this polyester resin was used as a sublayer, and then a thermoformed molded article was obtained. Table 1 shows the results of the 85°C brightness retention of the obtained molded articles.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com