Titanium aluminum alloy applied to golf club head

A golf club head, titanium-aluminum alloy technology, applied in golf balls, golf clubs, rackets, etc., to achieve the effects of improving normal and high temperature strength, good hot working formability, and reducing specific gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further explain the technical means and effects adopted by the present invention to achieve the intended purpose of the invention, the specific implementation methods, Structure, characteristic and effect thereof are as follows in detail.

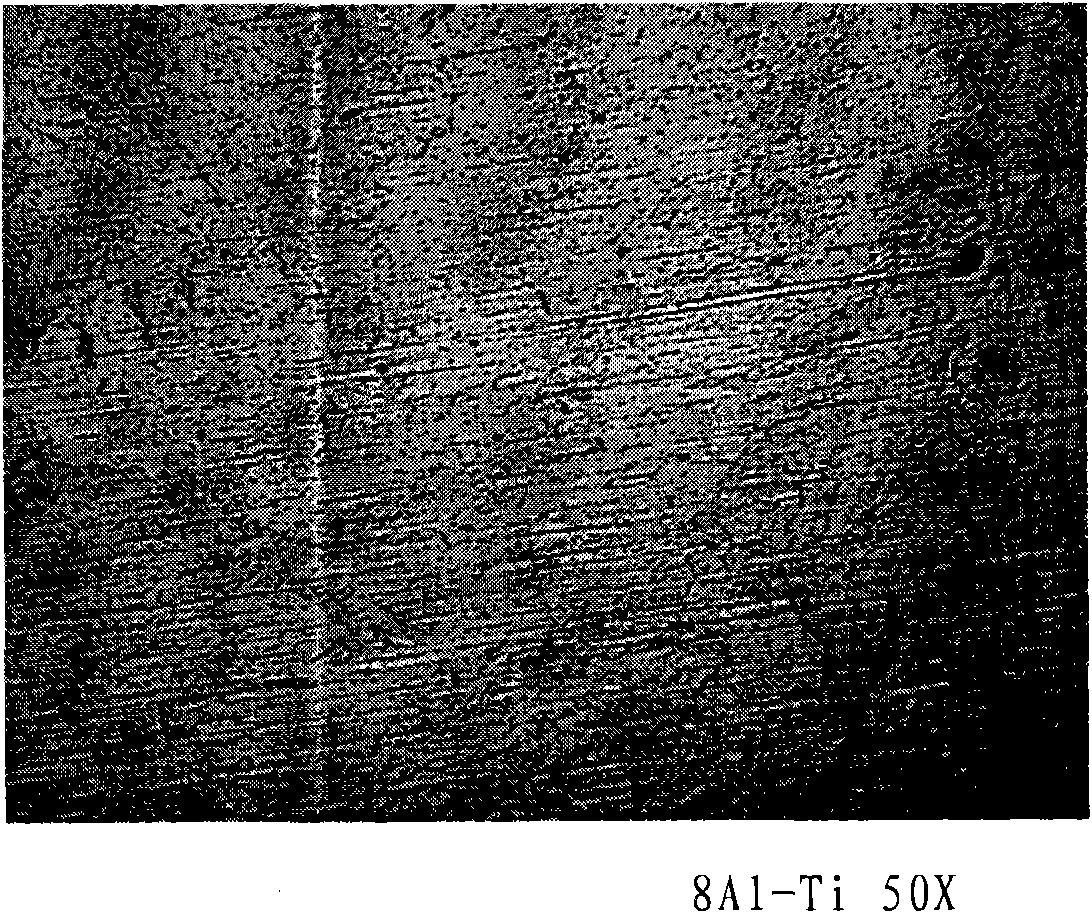

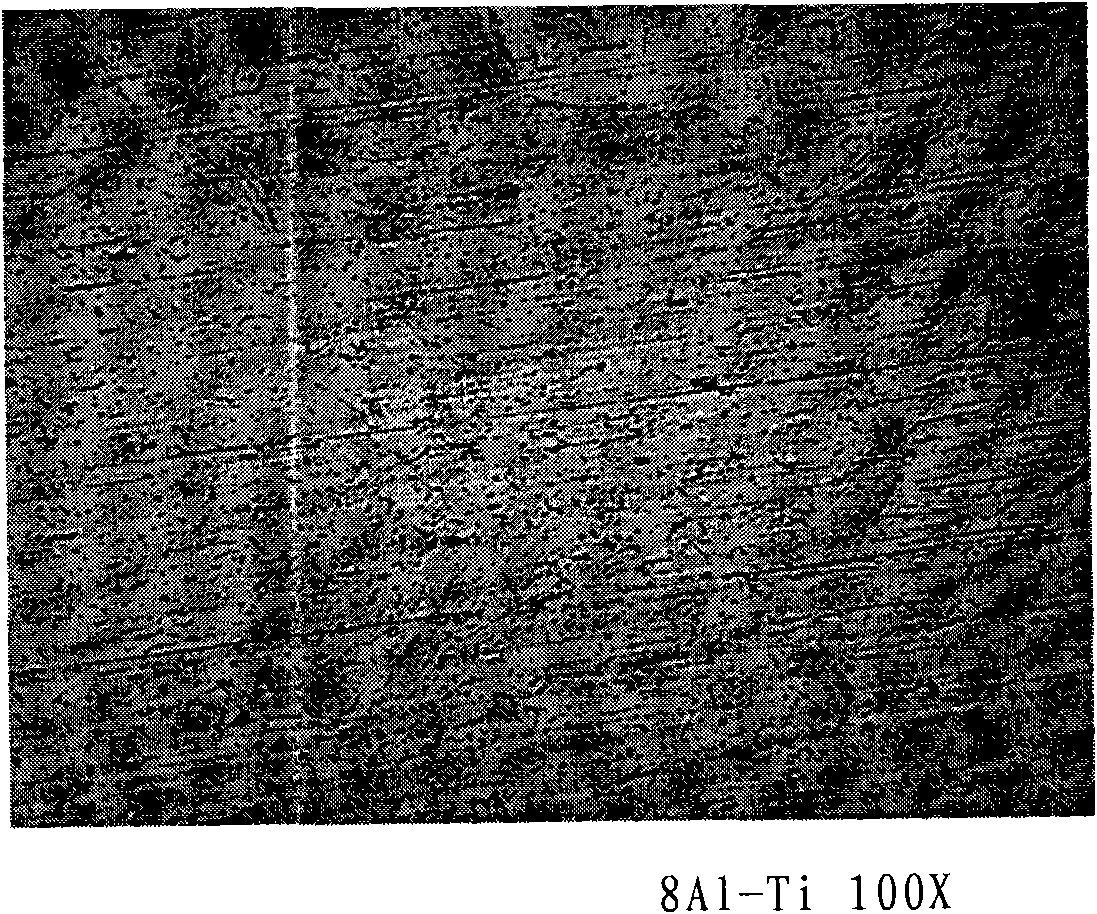

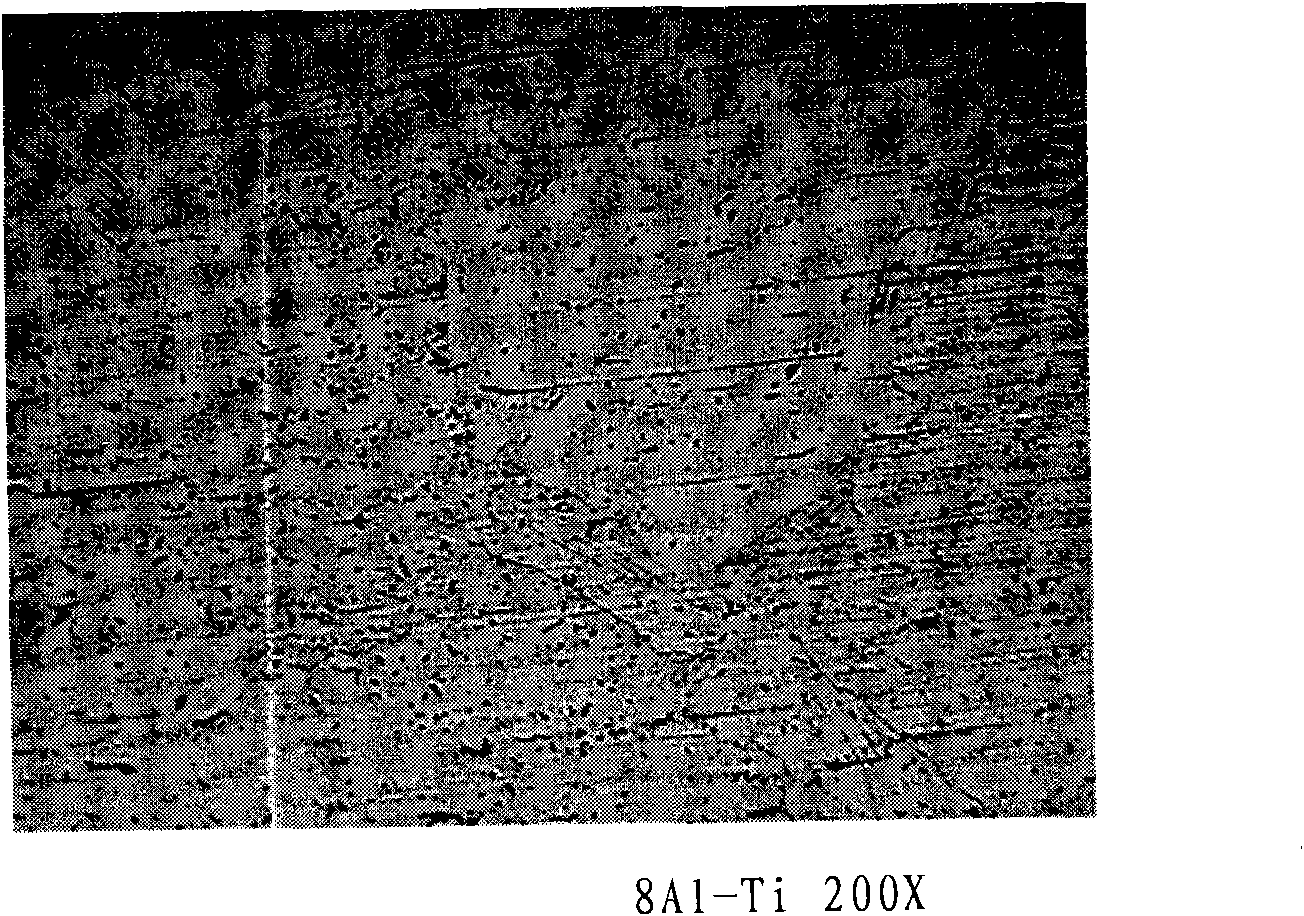

[0026] Please refer to figure 1 , figure 2 and image 3 As shown, the titanium-aluminum alloy of the first embodiment of the present invention contains, by weight percentage: 88% to 92% titanium and 7.5% to 10% aluminum, the elongation of the composition is 8% to 16%, and the density range is 4.40g / cm 3 the following.

[0027] The present invention can also adjust its characteristics by adding trace modifying elements, such as being selected from the group consisting of elements such as niobium, vanadium, molybdenum, chromium, iron, silicon, oxygen and nitrogen, for example, by adding A small amount of niobium can increase the strength of the alloy without reducing its elongation properties; the fluidity and auxilia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com