Synthetic resin laminate

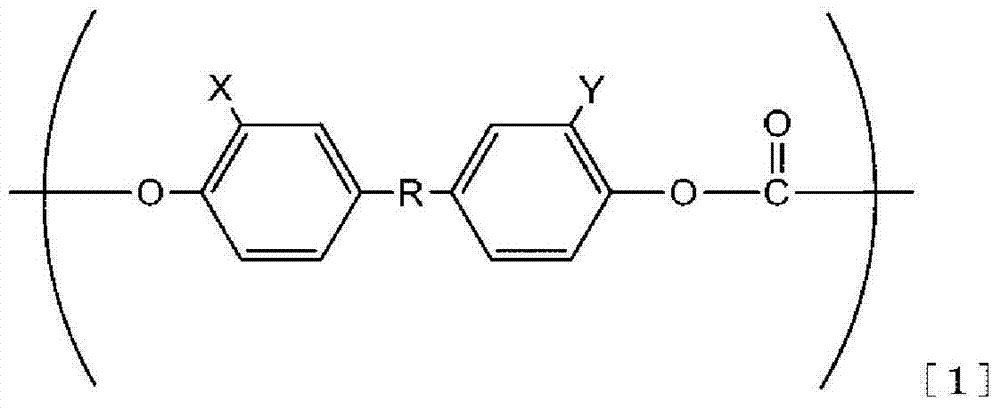

A technology for synthetic resins and laminates, applied in the fields of excellent thermoformability and insert formability, surface hardness and/or impact resistance, which can solve the problems of reduced toughness and flexibility, and achieve high flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0119] Hereinafter, the present invention will be specifically described by way of examples. However, the present invention is not limited by these Examples in any way.

[0120] The measurement of the physical properties of the laminated resins obtained in the production examples and the evaluation of the synthetic resin laminates obtained in the examples and comparative examples were performed as follows.

[0121]

[0122] Based on the calibration curve obtained by dissolving standard polystyrene in chloroform and measuring by gel permeation chromatography (GPC), the acrylic resin and polycarbonate resin were similarly measured by GPC. The device configuration of the GPC is as follows.

[0123] Installation: Waters 2690

[0124] Column: Shodex GPC KF-805L 8Φ×300mm 2 joints

[0125] Developing solvent: chloroform

[0126] Flow rate: 1ml / min

[0127] Temperature: 30°C

[0128] Detector: UV…486nm polycarbonate, aromatic polyester

[0129] RI…special acrylic

[0130] ...

Synthetic example 1

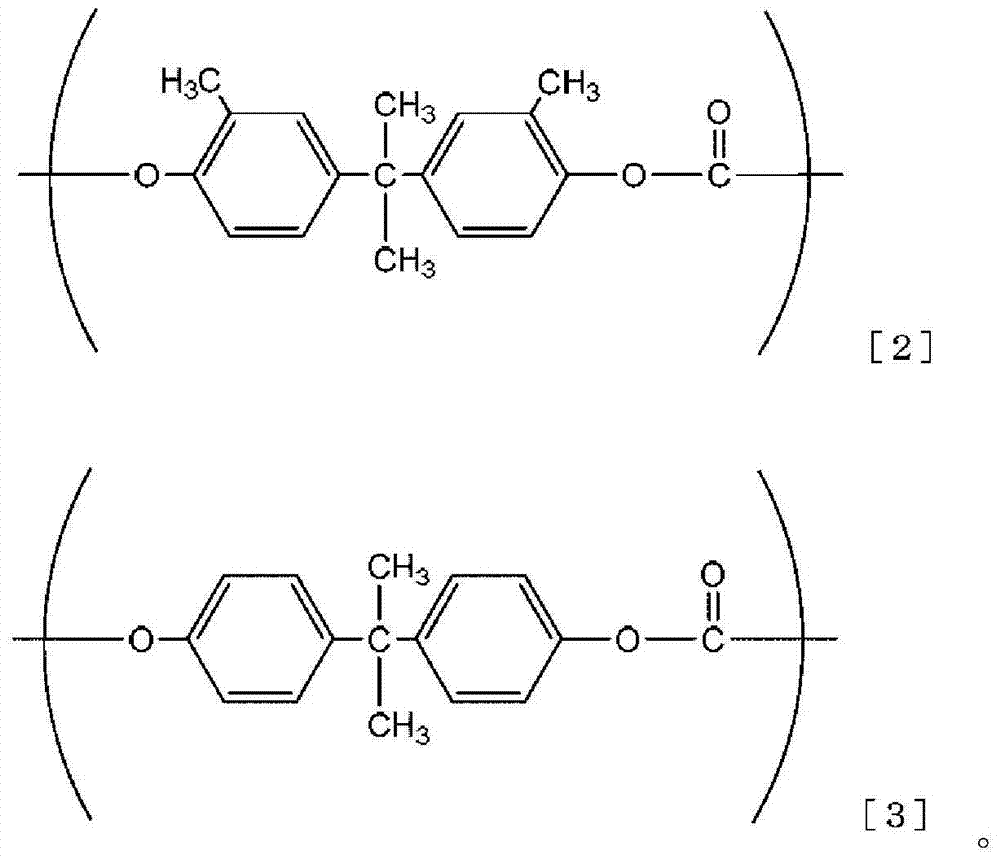

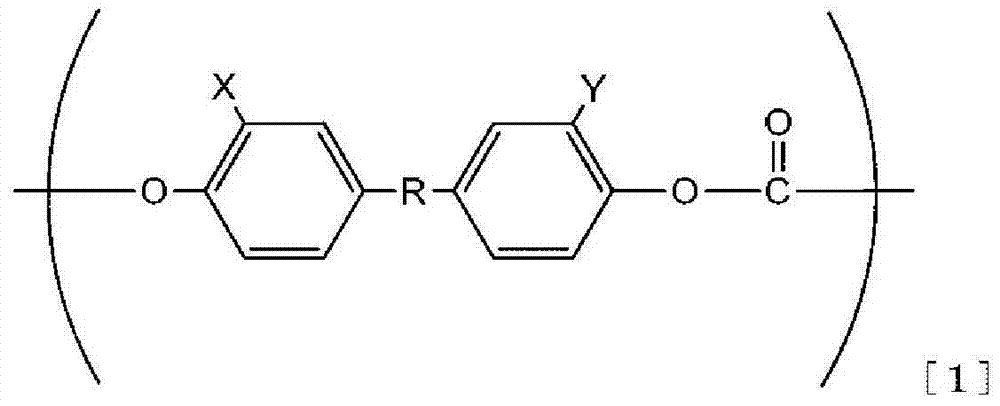

[0142] Synthesis of 2,2-bis(4-hydroxy-3-methylphenyl)propane / 2,2-bis(4-hydroxyphenyl)propane=6 / 4 copolycarbonate

[0143] In 54.5L of 9.0w / w% sodium hydroxide aqueous solution, dissolve 2,2-bis(4-hydroxy-3-methylphenyl)propane (manufactured by Honshu Chemical Industry Co., Ltd.) 6174.7g (24.12mol), 4,086 g (17.98 mol) of 2,2-bis(4-hydroxyphenyl)propane (manufactured by Nippon Steel Chemical Co., Ltd.), 3.8 g of triethylbenzyl ammonium chloride, and 50.0 g of dithionite (Hydrosulfite).

[0144] 24 L of dichloromethane was added thereto and stirred, and 5,390 g of phosgene was blown in over 40 minutes while maintaining the temperature at 15°C.

[0145] After the blowing of phosgene was completed, 210 g of p-tert-butylphenol was added and stirred vigorously to emulsify the reaction solution. After emulsification, 110 ml of triethylamine was added and stirred at a temperature of 20 to 25° C. for about 1 hour to perform polymerization.

[0146]After the polymerization, the reactio...

manufacture example 1

[0147] Production example 1 [manufacture of resin (A11) pellets]

[0148] Metablen H-880 (manufactured by Mitsubishi Rayon Co., Ltd., weight-average molecular weight: 14000, a11 / a12=33 / 66) as a (meth)acrylate copolymer (a1) was added at 40% by mass and polycarbonate resin (a2) 60% by mass of Synthesis Example 1, mixed with a blender for 20 minutes, after that, using a twin-screw extruder with a screw diameter of 35 mm, melted and kneaded at a cylinder temperature of 260° C., extruded It is in the form of strands and is pelletized by a granulator. Pellets were produced stably. The measurement of the glass transition temperature of the high-hardness resin composition showed a single peak at 119° C., and it was confirmed that the resin composition was compatible.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| filtration precision | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com