Superplastic high-strength heatproof magnesium alloy and preparation method thereof

A technology of magnesium alloy and superplasticity, which is applied in the preparation of magnesium-based alloys, high-strength heat-resistant magnesium alloys and their preparation fields, can solve problems affecting the thermal processing and forming properties of alloys, and achieve large-scale promotion and application, improve mechanical properties, The effect of good heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

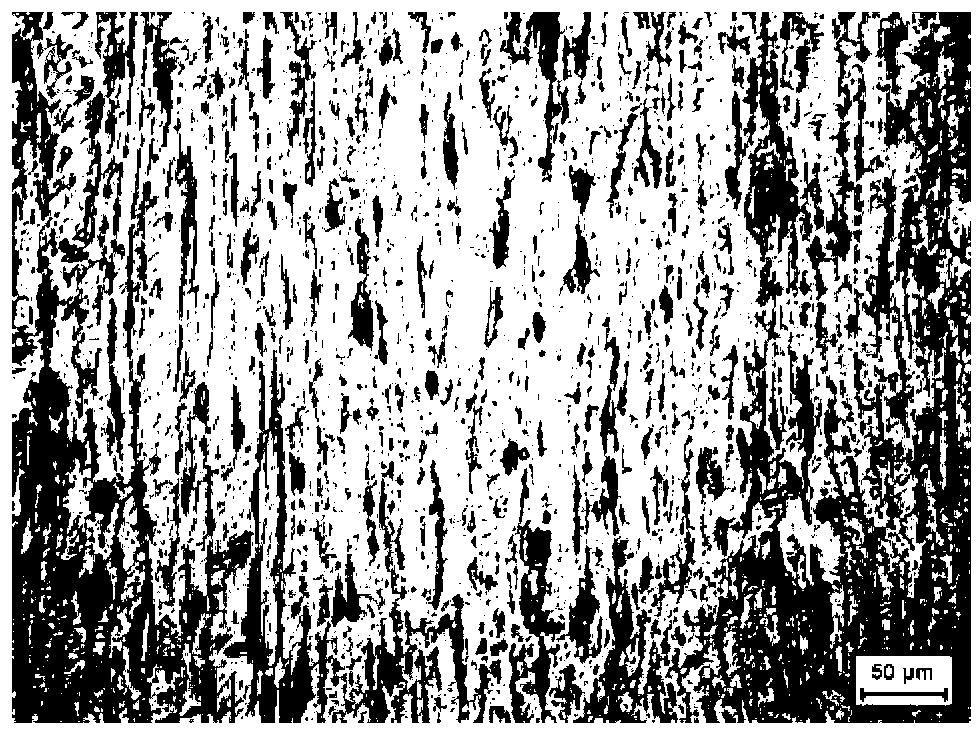

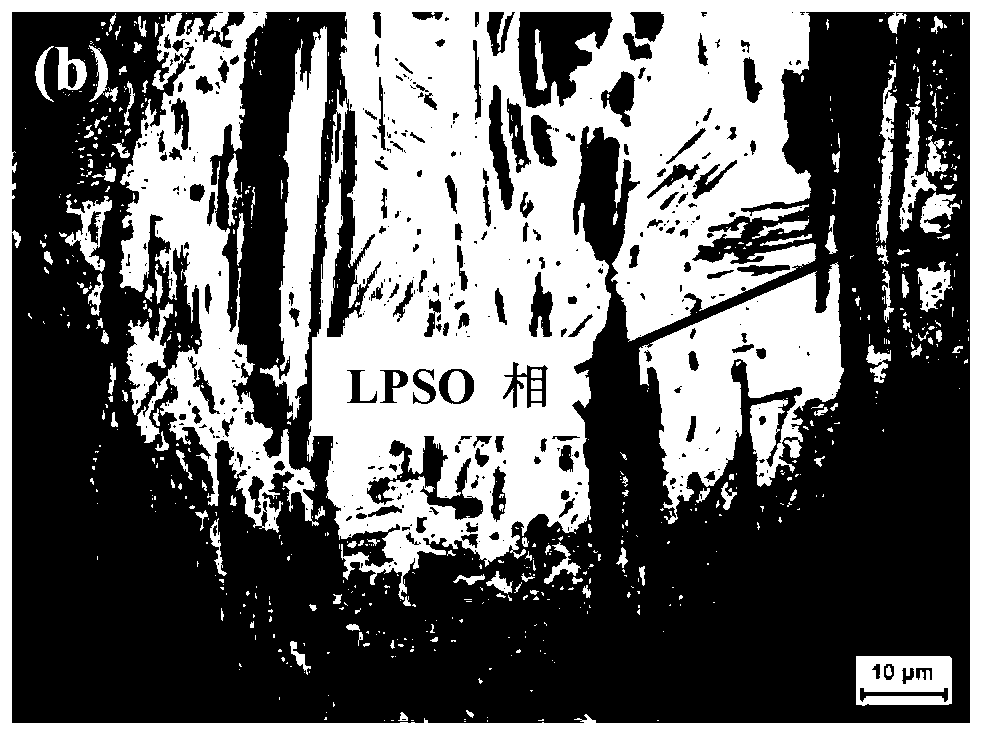

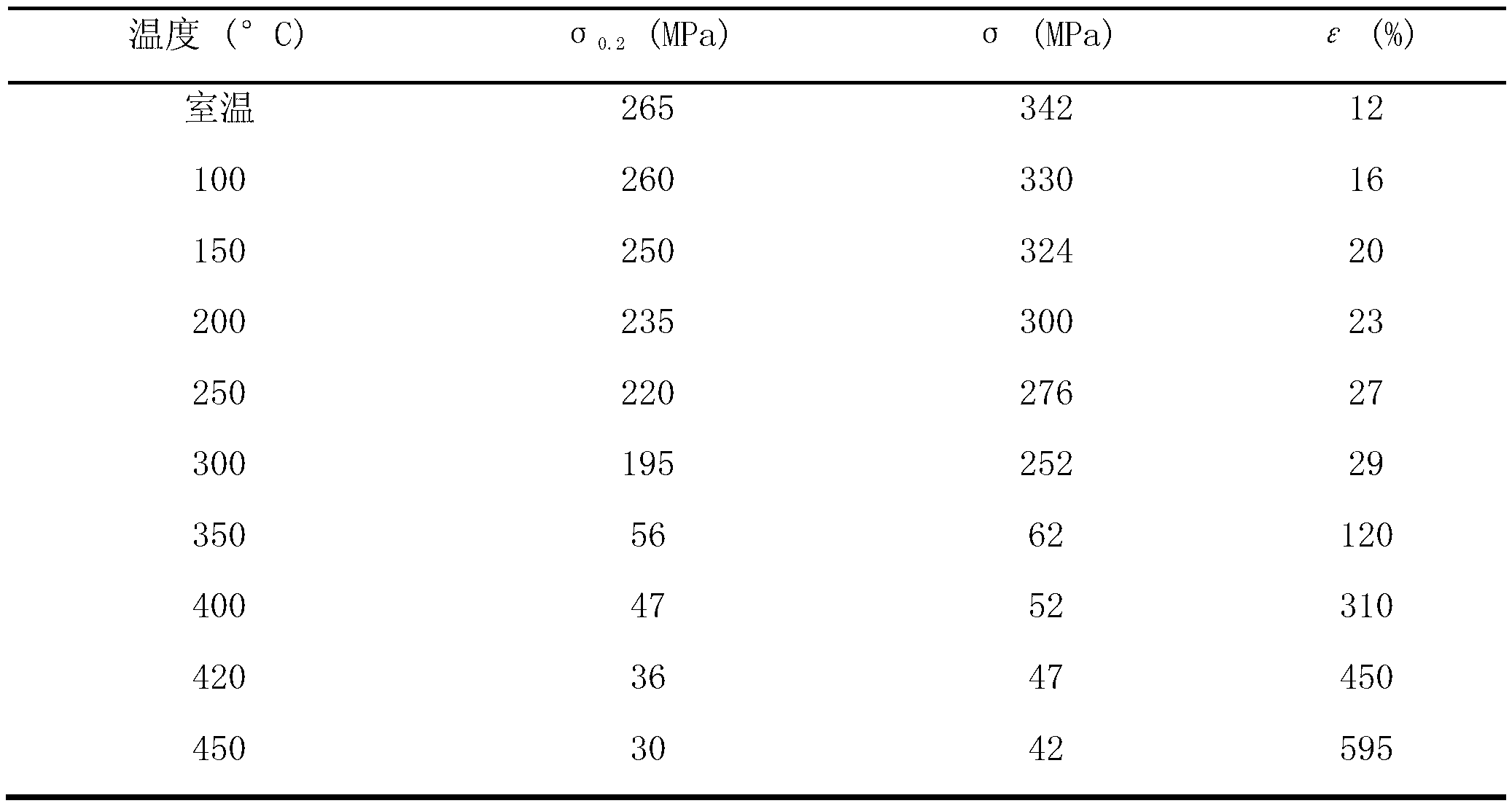

[0023] The chemical composition (mass percentage) of the alloy is: 6.0%Y, 2.0%Nd, 1.8%Zn, the total amount of impurity elements Fe, Cu, Ni, Si is less than 0.03%, and the balance is Mg.

[0024] The melting, casting and processing technology for preparing the alloy is as follows: first, weigh the materials according to the proportion, preheat Mg, Zn, Mg-Y master alloy, and Mg-Nd master alloy to 200°C, and then put Mg into the crucible preheated to 100°C in, and pass into SF 6 :CO 2 Protective gas with a volume ratio of 1:100, add Zn after the Mg is completely melted, add Mg-Y master alloy and Mg-Nd master alloy when the melt temperature reaches 740°C, and pass in argon after the added master alloy is melted Refining and stirring for 10 minutes, after removing slag, let it stand at 740°C for 25 minutes, and after the temperature drops to 700°C, cast it into a round bar with a water-cooled mold. The obtained cast rod was homogenized at 450°C for 10 hours, then air-cooled, and ...

Embodiment 2

[0030] The chemical composition (mass percentage) of the alloy is: 5.8%Y, 2.5%Nd, 2.6%Zn, the total amount of impurity elements Fe, Cu, Ni, Si is less than 0.03%, and the balance is Mg.

[0031] The melting, casting and processing technology for preparing the alloy is as follows: first, weigh the materials according to the proportion, preheat the Mg, Zn, Mg-Y master alloy, and Mg-Nd master alloy to 250°C, and then put Mg into the crucible preheated to 120°C in, and pass into SF 6 :CO 2Protective gas with a volume ratio of 1:100, add Zn after the Mg is completely melted, add Mg-Y master alloy and Mg-Nd master alloy when the melt temperature reaches 750°C, and pass in argon after the added master alloy is melted Refining and stirring for 15 minutes, after removing the slag, let it stand at 740°C for 45 minutes, and after the temperature drops to 710°C, cast it into a round bar with a water-cooled mold. The obtained cast rod was homogenized at 480°C for 10 hours, then air-coole...

Embodiment 3

[0038] The chemical composition (mass percentage) of the alloy is: 7.2%Y, 0.8%Nd, 3%Zn, the total amount of impurity elements Fe, Cu, Ni, Si is less than 0.03%, and the balance is Mg.

[0039] The melting, casting and processing technology for preparing the alloy is as follows: first, weigh the materials according to the proportion, preheat Mg, Zn, Mg-Y master alloy, and Mg-Nd master alloy to 240°C, and then put Mg into the crucible preheated to 120°C in, and pass into SF 6 :CO 2 Protective gas with a volume ratio of 1:100, add Zn after the Mg is completely melted, add Mg-Y master alloy and Mg-Nd master alloy when the melt temperature reaches 760°C, and pass in argon after the added master alloy is melted Refining and stirring for 15 minutes, after removing slag, let it stand at 750°C for 30 minutes, and after the temperature drops to 720°C, cast it into a round bar with a water-cooled mold. The obtained cast rods were homogenized at 480°C for 15 hours, then air-cooled, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com