Breathable packaging film having enhanced thermoformability

a technology of packaging film and thermoformability, which is applied in the field of food packaging film with thermoformability coextruding, to achieve the effect of improving thermoformability and exceptional optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

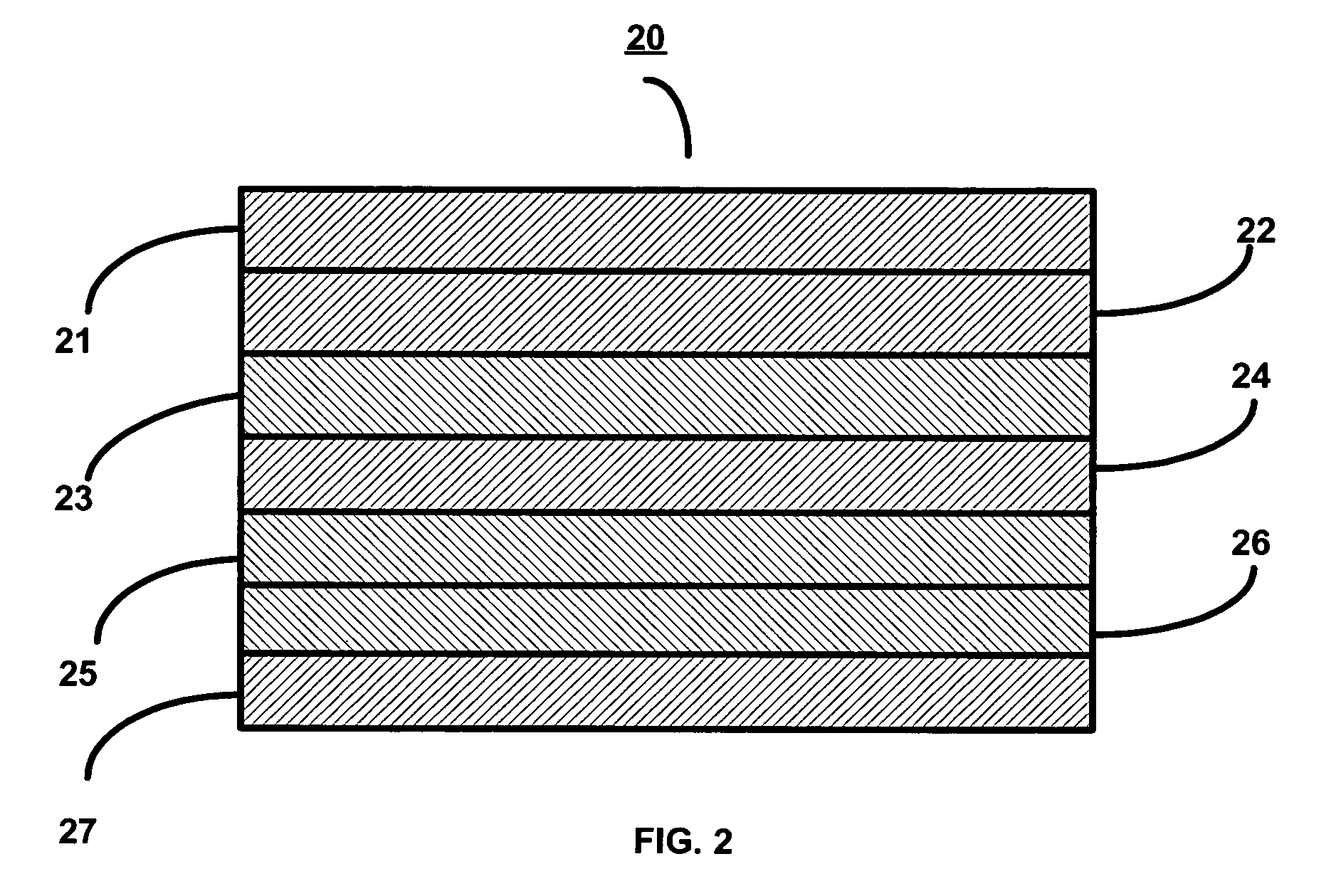

[0052] Example 1 is one embodiment of the present invention of a film having seven layers (see film 20 in FIG. 2). The first polymeric layer (21) comprised a mixture of polyester, anti-block additive and slip additive. The polyester comprised polyethylene terephthalate copolymer having a density of 1.4 g / cm3, a melting point of 240° C., a tensile strength at break (machine direction / transverse direction) of 8.4 / 5.6 kpsi, and is available under the trademark Voridian™ Polymer 9921 from Eastman Chemical Company, Kingsport, Tenn., U.S.A. In Example 1, the second layer (22) was a tie layer comprising ethylene / methyl acrylate copolymer (E / MA) and modified linear low-density polyethylene (m-LLDPE). The ethylene / methyl acrylate copolymer has a density of 0.948 g / cm3, a melting point of 49° C., a melt index of 2.0 g / 10 min., and is available from Eastman Chemical Company, Kingsport, Tenn., U.S.A. The modified linear low-density polyethylene was an anhydride linear low-density polyethylene h...

example 2

[0054] In Example 2, the film is another example of a seven-layer embodiment of the present invention. All the film layers are identical in structure and relative layer thickness as that used in Example 1, except that the overall film thickness was about 8 mil.

[0055] Example 2 had an oxygen transmission rate at 73° C. and 0% R.H. of 20 cm3 / 100 in2 / 24 h. (310 cm3 / m2 / 24 h.) as measured in accordance with ASTM D-3985-02 test method.

[0056] Unless otherwise noted, the physical properties and performance characteristics reported herein were measured by test procedures similar to the following methods. The following ASTM test procedures are each incorporated herein by reference in their entireties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| linear thermal shrinkage | aaaaa | aaaaa |

| linear thermal shrinkage | aaaaa | aaaaa |

| linear thermal shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com