Easily-cut silicon brass alloy and preparation method thereof

A silicon brass, free-cutting technology, applied in the field of free-cutting silicon-brass alloy and its manufacturing, can solve the problems of high antimony content, antimony leaching exceeding the requirements of hygienic and safety performance, affecting use, etc., achieving easy composition and cost-effectiveness Superior and beneficial effect on recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

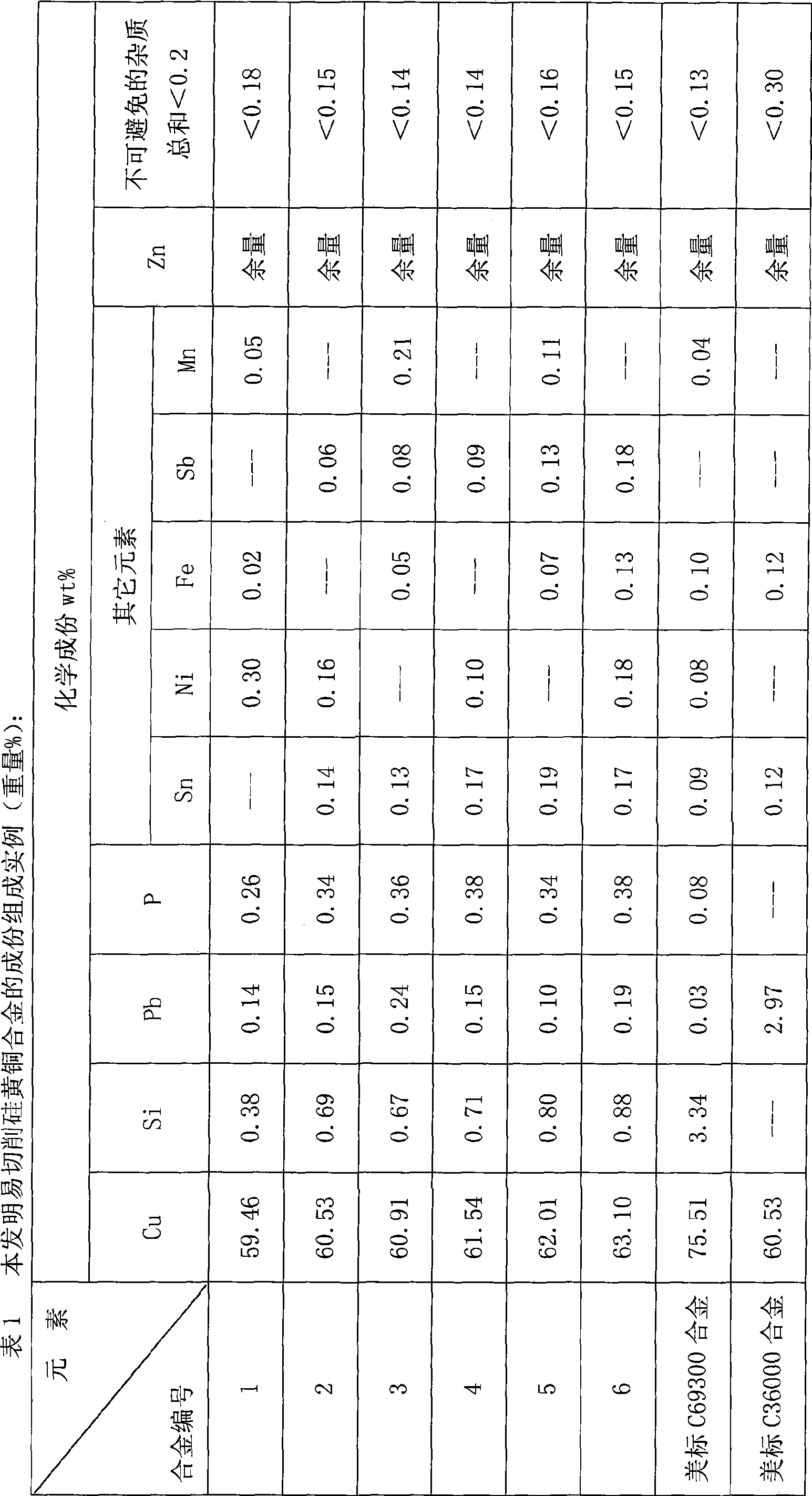

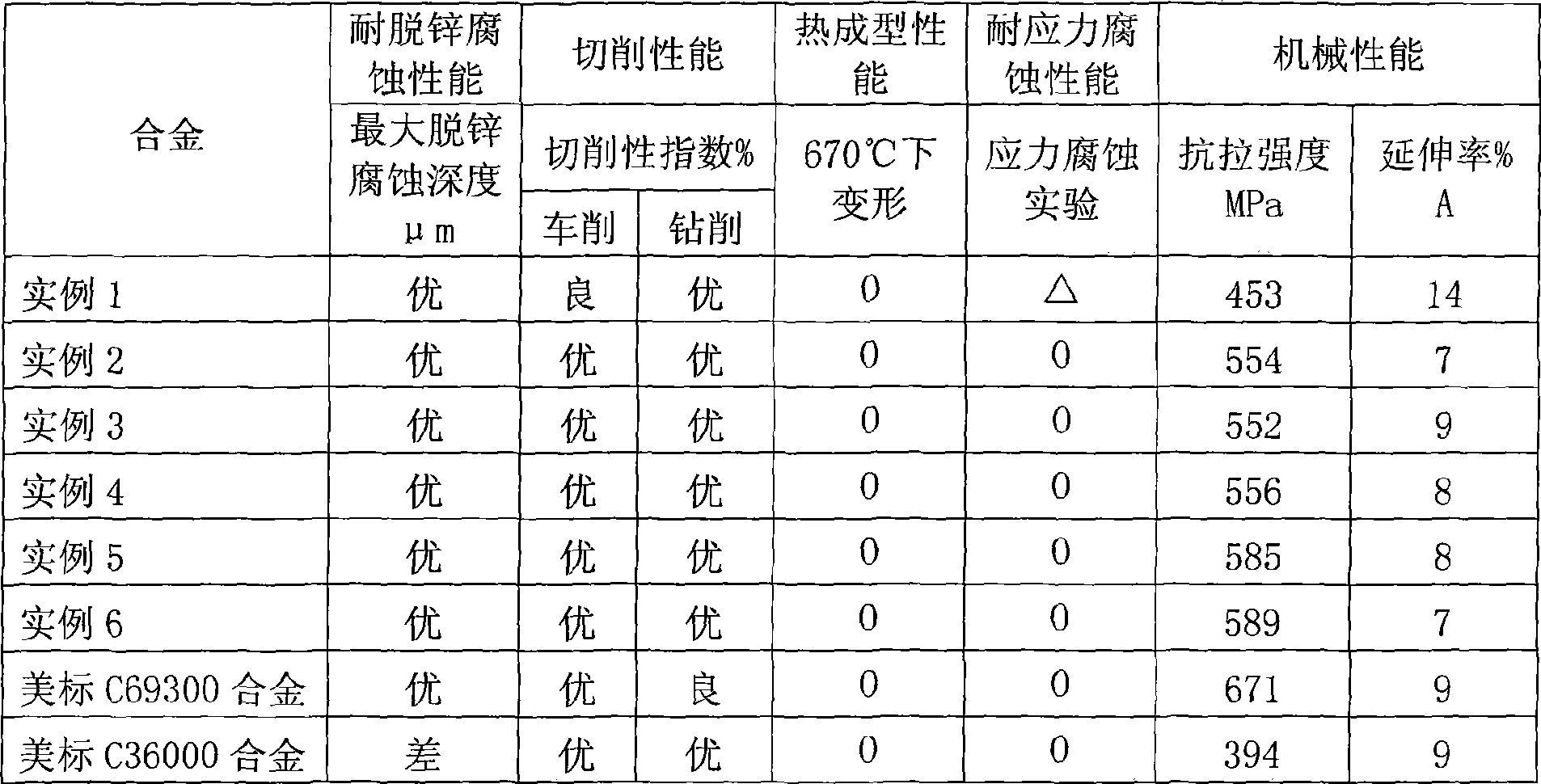

[0039] The production technological process of silicon brass alloy in the embodiment of the present invention is as follows:

[0040] Raw material preparation and batching - alloying refining - continuous ingot casting - ingot billet heating - hot extrusion - stretching - heat treatment - pickling - stretching - stress relief annealing - straightening Polishing - inspection of finished product packaging and storage.

[0041] Specifically, it can be expressed as follows: adopt the method of alloying treatment and covering protection, slag removal and metamorphic refining to melt and cast silicon brass alloy, and continuously cast silicon brass ingot at 1010-1050 °C, and heat it at 660-700 °C. Processing, after 4-25% cold working, intermediate heat treatment at a temperature of 560-660 ° C, and the final product is subjected to stress relief annealing at a temperature lower than 380 ° C.

[0042] In the embodiment, the silicon brass alloy of the present invention is formed into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com