Al-Mg-Si-Cu alloy and preparation method and application thereof

A technology of alloys and alloy materials, applied in the field of Al-Mg-Si-Cu alloys and their preparation, can solve the problems of limited wide application of Al-Cu alloys, scratches on the surface of workpieces, corrosion of grain boundaries, etc., and achieve excellent anodic oxidation performance , good machinability, good cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

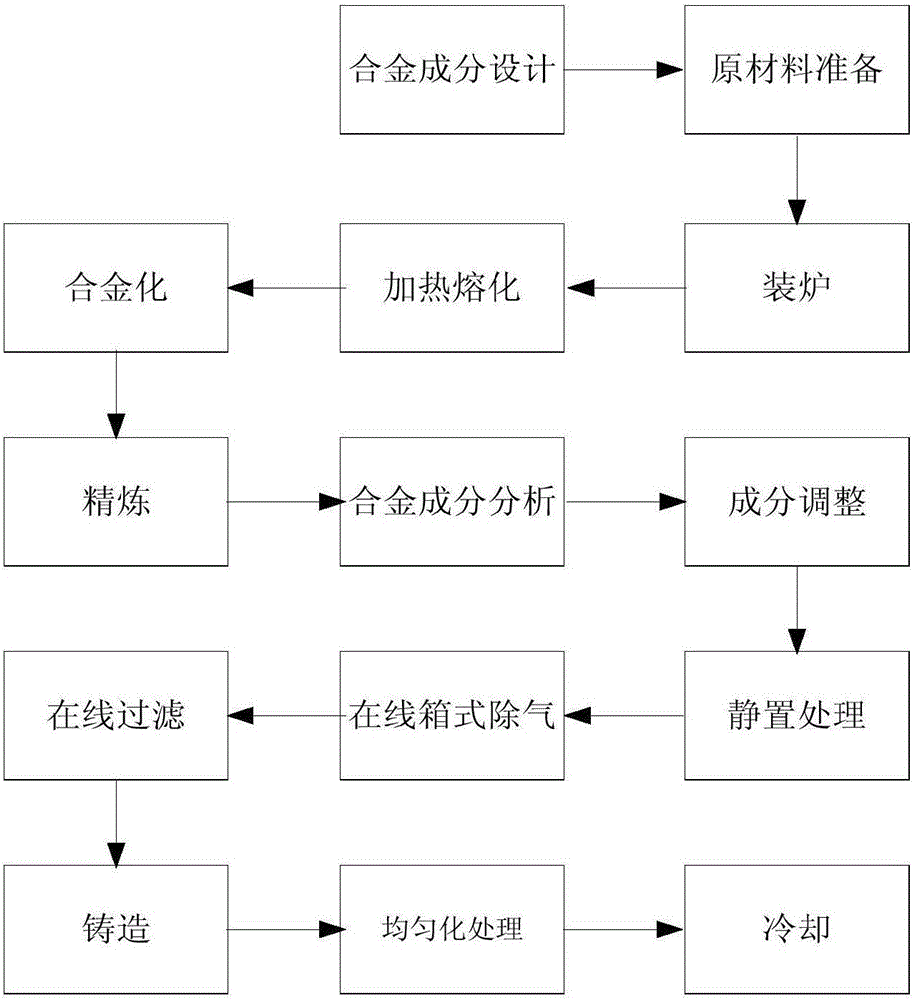

Method used

Image

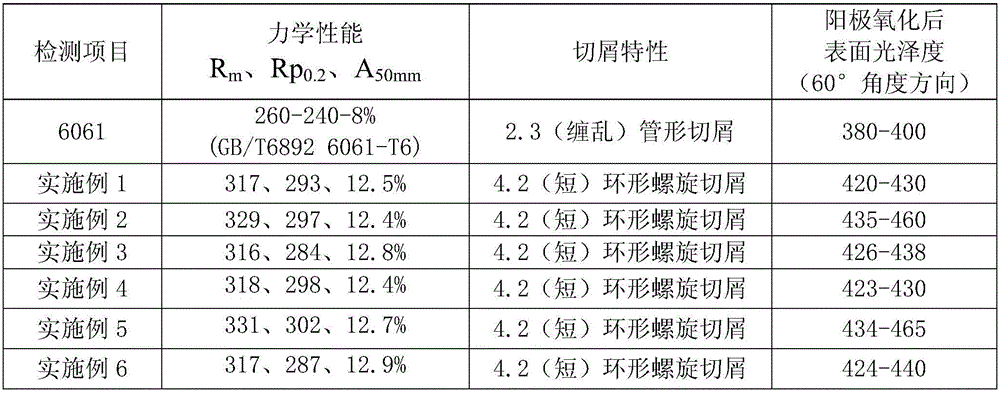

Examples

Embodiment 1

[0060] The raw materials are as follows:

[0061] Aluminum ingot: use the aluminum ingot with the brand name Al99.7, the mass percentage of Al in the aluminum ingot is more than 99.70%, and the mass percentage of Fe is 0.12%, which meets the standard GB / T 1196-2008 "Aluminum Ingots for Remelting";

[0062] Magnesium ingots: Magnesium ingots with the brand Mg9990 are used, and the mass percentage of Mg in the magnesium ingots is more than 99.9%, which meets the standard GB / T 3499-2003 "Primary Magnesium Ingots";

[0063] Zinc ingots: Zn9995 zinc ingots are used, and the mass percentage of Zn in the zinc ingots is more than 99.95%, which meets the standard GB / T470-1997 "Zinc Ingots";

[0064] Alloy additives (aluminum-silicon, aluminum-manganese, aluminum-chromium, aluminum-copper, aluminum-iron): AlSi12, AlMn10, AlCr3, AlCu40 and AlFe20 master alloys are used respectively, and the quality meets the YS / T282-2000 standard;

[0065] Refining agent: the brand is PROMAG RI granular...

Embodiment 2

[0090] 1. Manufacturing method of aluminum round ingot:

[0091] According to the chemical composition of Al-Mg-Si-Cu alloy in terms of mass percentage: Si is 0.79%, Mg is 1.18%, Fe is 0.45%, Mn is 0.11%, Cr is 0.12%, Zn is 0.15%, Cu is 0.21% %, Ti≤0.10%, and the balance is Al for material preparation, and the same process as in Example 1 is used to produce an Al-Mg-Si-Cu alloy round ingot.

[0092] 2. Manufacturing methods of aluminum extrusion profiles, pipes and rods:

[0093] Take a round pipe with an outer diameter of 33mm and a wall thickness of 5mm as an example:

[0094] (1) Cut the alloy round ingot (aluminum rod) obtained above into 500mm long, and use a five-zone slow-speed aluminum rod heating furnace. ) temperature is 540°C, the temperature of the third zone (intermediate heat preservation zone) is 560°C, the temperature of the fourth zone (intermediate heat preservation zone) is 540°C, the temperature of the fifth zone (exit zone) is 480°C, and it is heated for...

Embodiment 3

[0100] 1. Manufacturing method of aluminum round ingot:

[0101] According to the chemical composition of Al-Mg-Si-Cu alloy in terms of mass percentage: Si is 0.622%, Mg is 1.03%, Fe is 0.35%, Mn is 0.13%, Cr is 0.15%, Zn is 0.13%, Cu is 0.20 %, Ti≤0.10%, and the balance is Al for material preparation, and the same process as in Example 1 is used to produce an Al-Mg-Si-Cu alloy round ingot.

[0102] 2. Manufacturing methods of aluminum extrusion profiles, pipes and rods:

[0103] Take a round pipe with an outer diameter of 33mm and a wall thickness of 5mm as an example:

[0104](1) Cut the alloy round ingot (aluminum rod) obtained above into a length of 650 mm, use a five-zone slow-speed aluminum rod heating furnace, the temperature of the first zone (entry preheating zone) is 500 ° C, and the second zone (intermediate heat preservation zone) ) temperature is 540°C, the temperature in the third zone (intermediate heat preservation zone) is 560°C, the temperature in the fourt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com