Electrodischarge machining method for working non-conductive ceramic utilizing conductive magnetic powder

An electrical discharge machining, non-conductive technology, used in electric machining equipment, metal machining equipment, manufacturing tools, etc., can solve the problems of cumbersome production of auxiliary conductive films, not easy to short pulse width, unstable discharge, etc., to expand the scope of processing, Improve the effect of unstable discharge and convenient replacement of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following examples are provided in conjunction with the content of the method of the present invention, and the specific steps are as follows:

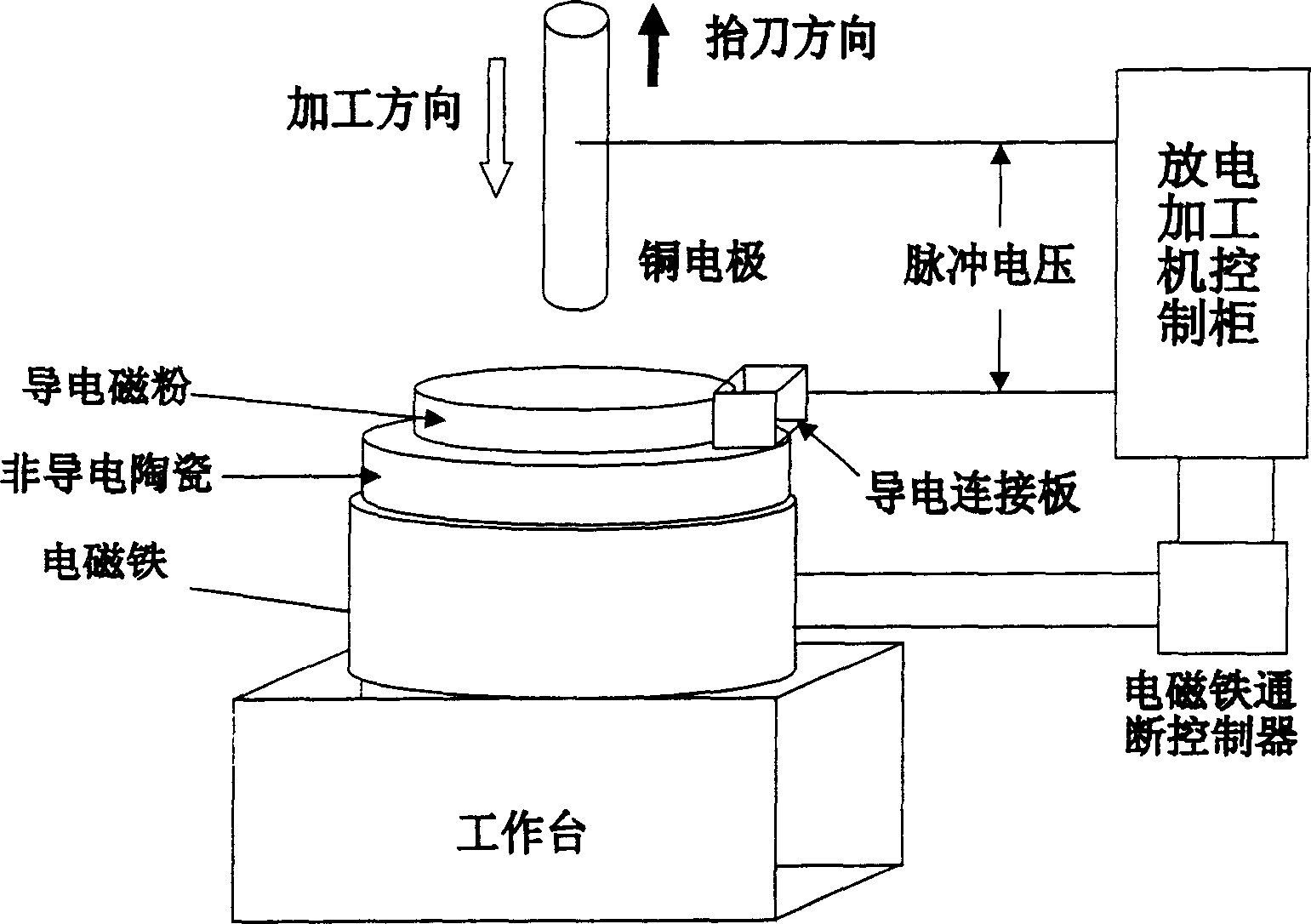

[0018] (1) if figure 1 As shown, the electromagnet device of the present embodiment adopts a circular electromagnet and an electromagnet on-off controller (requirement: when the electrode lifts the knife, the electromagnet is powered off; when the electrode descends, the electromagnet is energized. Electromagnet shape: circular);

[0019] (2) Install copper electrodes for processing on the main shaft of the electric discharge machine (Taiwan large amount of electronic equipment Co., Ltd. produces electric discharge machine troop pnc), with a diameter of 5*50mm and connected to the cathode;

[0020] (3) Place an electromagnet on the workbench of the EDM, the input end of the on-off controller of the electromagnet is connected with the control end of the lifting tool of the control cabinet of the EDM, the output end is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com