Preparation method of biaxially oriented polyphenylene sulfide composite film

A polyphenylene sulfide and composite film technology, which is applied in the field of preparation of polyphenylene sulfide composite films, can solve the problems of low toughness and elongation at break, and achieve the effects of improving heat resistance, controlling agglomeration, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

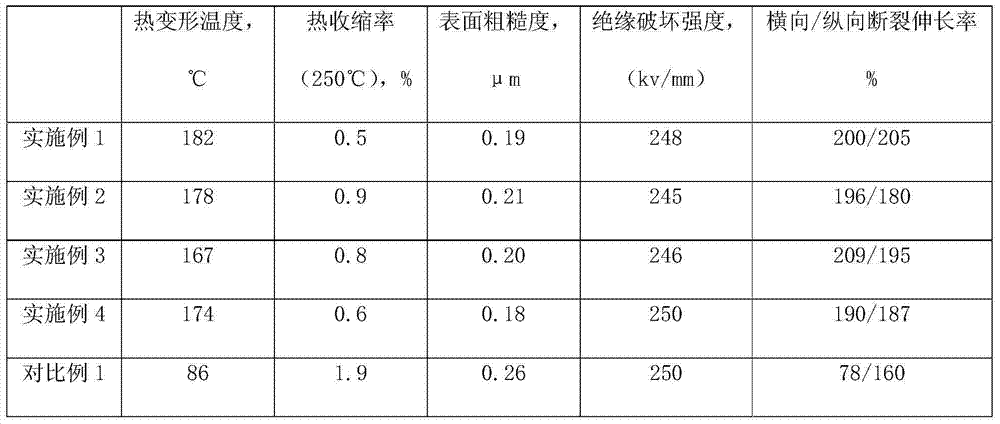

Examples

Embodiment 1

[0022] A preparation method of biaxially oriented polyphenylene sulfide composite film, the preparation method has the following steps:

[0023] (1) Masterbatch preparation

[0024] According to the mass ratio, prepare film-grade polyphenylene sulfide resin, polypropylene and silicon dioxide, wherein the ratio of film-grade polyphenylene sulfide resin to polypropylene is 85:15, film-grade polyphenylene sulfide resin and polypropylene The ratio of the sum of the total amount and silicon dioxide is 100:0.4; the above materials are added to the twin-screw extruder according to the order of film-grade polyphenylene sulfide resin, polypropylene, and silicon dioxide. The phenylene sulfide resin and polypropylene are fully stirred to obtain a mixed resin, and then silicon dioxide is added to the mixed resin, and the masterbatch is made after twin-screw extrusion, and the temperature of the extruder is 310°C;

[0025] (2) cast cast sheet

[0026] Mix the masterbatch obtained in step...

Embodiment 2

[0032] A preparation method of biaxially oriented polyphenylene sulfide composite film, the preparation method has the following steps:

[0033] (1) Masterbatch preparation

[0034] According to the mass ratio, prepare film-grade polyphenylene sulfide resin, polypropylene and silicon dioxide, wherein the ratio of film-grade polyphenylene sulfide resin to polypropylene is 85:15, film-grade polyphenylene sulfide resin and polypropylene The ratio of the sum of the total amount and silicon dioxide is 100:0.4; the above materials are added to the twin-screw extruder according to the order of film-grade polyphenylene sulfide resin, polypropylene, and silicon dioxide. The phenylene sulfide resin and polypropylene are fully stirred to obtain a mixed resin, and then silicon dioxide is added to the mixed resin, and the masterbatch is made after twin-screw extrusion, and the temperature of the extruder is 320°C;

[0035] (2) cast cast sheet

[0036] Mix the masterbatch obtained in step...

Embodiment 3

[0042] A preparation method of biaxially oriented polyphenylene sulfide composite film, the preparation method has the following steps:

[0043] (1) Masterbatch preparation

[0044] According to the mass ratio, prepare film-grade polyphenylene sulfide resin, polypropylene and silicon dioxide, wherein the ratio of film-grade polyphenylene sulfide resin to polypropylene is 85:15, film-grade polyphenylene sulfide resin and polypropylene The ratio of the sum of the total amount and silicon dioxide is 100:0.4; the above materials are added to the twin-screw extruder according to the order of film-grade polyphenylene sulfide resin, polypropylene, and silicon dioxide. The phenylene sulfide resin and polypropylene are fully stirred to obtain a mixed resin, then silicon dioxide is added to the mixed resin, and a masterbatch is made after twin-screw extrusion, and the temperature of the extruder is 315°C;

[0045] (2) cast cast sheet

[0046] Mix the masterbatch obtained in step (1) w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com