Multilayer structure and method for producing same

A technology for a multilayer structure and a manufacturing method, applied in chemical instruments and methods, layered products, synthetic resin layered products, etc., can solve the problems of reduced durability, insufficient gas barrier properties, and insufficient interlayer adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

[0345] (Manufacture Example 1 [Manufacture of Pellet (A-1)])

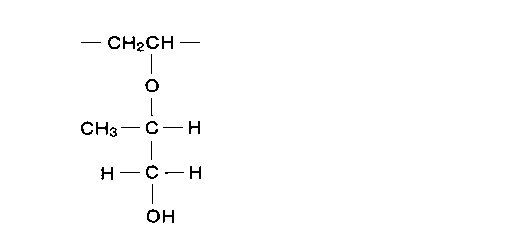

[0346] Add 20,000 parts by mass of vinyl acetate, 2000 parts by mass of methanol, and 10 parts by mass of 2,2'-azobis-(4-methoxy-2,4 -Dimethylvaleronitrile), nitrogen substitution was carried out while stirring, and then ethylene was introduced to adjust the internal temperature to 60°C and the ethylene pressure to 45 Kg / cm 2 , keeping the temperature and pressure, stirring for 4 hours to make it polymerized. Next, 10 parts by mass of sorbic acid (SA) (0.05% by mass relative to the charged vinyl acetate) was dissolved in methanol to make a 1.5% by mass solution and added. The polymerization rate was 45% with respect to the charged vinyl acetate. This copolymerization reaction solution was extruded and supplied, and methanol vapor was introduced from the lower part of the column, whereby unreacted vinyl acetate was removed from the top of the column, and a 40% methanol solution of the copolymer was obtained. ...

manufacture example 2

[0349] (Manufacture example 2 [Manufacture of pellet (A-2)])

[0350] Add 20,000 parts by mass of vinyl acetate, 4000 parts by mass of methanol, 10 parts by mass of acetyl peroxide as a polymerization initiator (500 ppm relative to the amount of vinyl acetate added), 0.4 Parts by mass of citric acid (20 ppm relative to the amount of vinyl acetate added) and 560 parts by mass of 3,4-diacetoxy-1-butene were replaced with nitrogen while stirring, and then ethylene was introduced to adjust to Internal temperature 60°C, ethylene pressure 35 Kg / cm 2 , and then polymerized while slowly adding the entire amount of 180 parts by mass of 3,4-diacetoxy-1-butene, and polymerized for 6 hours until the polymerization rate was 50% relative to the added vinyl acetate. Then, 10 parts by mass of sorbic acid (SA) (500 ppm relative to the amount of vinyl acetate charged) was dissolved in methanol to make a 1.5% by mass solution and added. This copolymerization reaction solution was extruded...

manufacture example 3

[0356] (Manufacture Example 3 [Manufacture of Granules (A-3)])

[0357] Add 20,000 parts by mass of vinyl acetate, 1020 parts by mass of methanol, 3.5 parts by mass of 2,2'-azobis-(4-methoxy-2,4 -Dimethylvaleronitrile), nitrogen substitution was carried out while stirring, and then ethylene was introduced to adjust the internal temperature to 60°C and the ethylene pressure to 59 Kg / cm 2 , keeping the temperature and pressure, stirring for 4 hours to make it polymerized. Next, 10 parts by mass of sorbic acid (SA) (0.05% by mass relative to the charged vinyl acetate) was dissolved in methanol to make a 1.5% by mass solution and added. The polymerization rate was 30% with respect to the charged vinyl acetate. This copolymerization reaction solution was extruded and supplied, and methanol vapor was introduced from the lower part of the column, thereby removing unreacted vinyl acetate from the top of the column, and a 40% by mass methanol solution of the copolymer was obtain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com