Patents

Literature

133results about How to "Excellent appearance characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

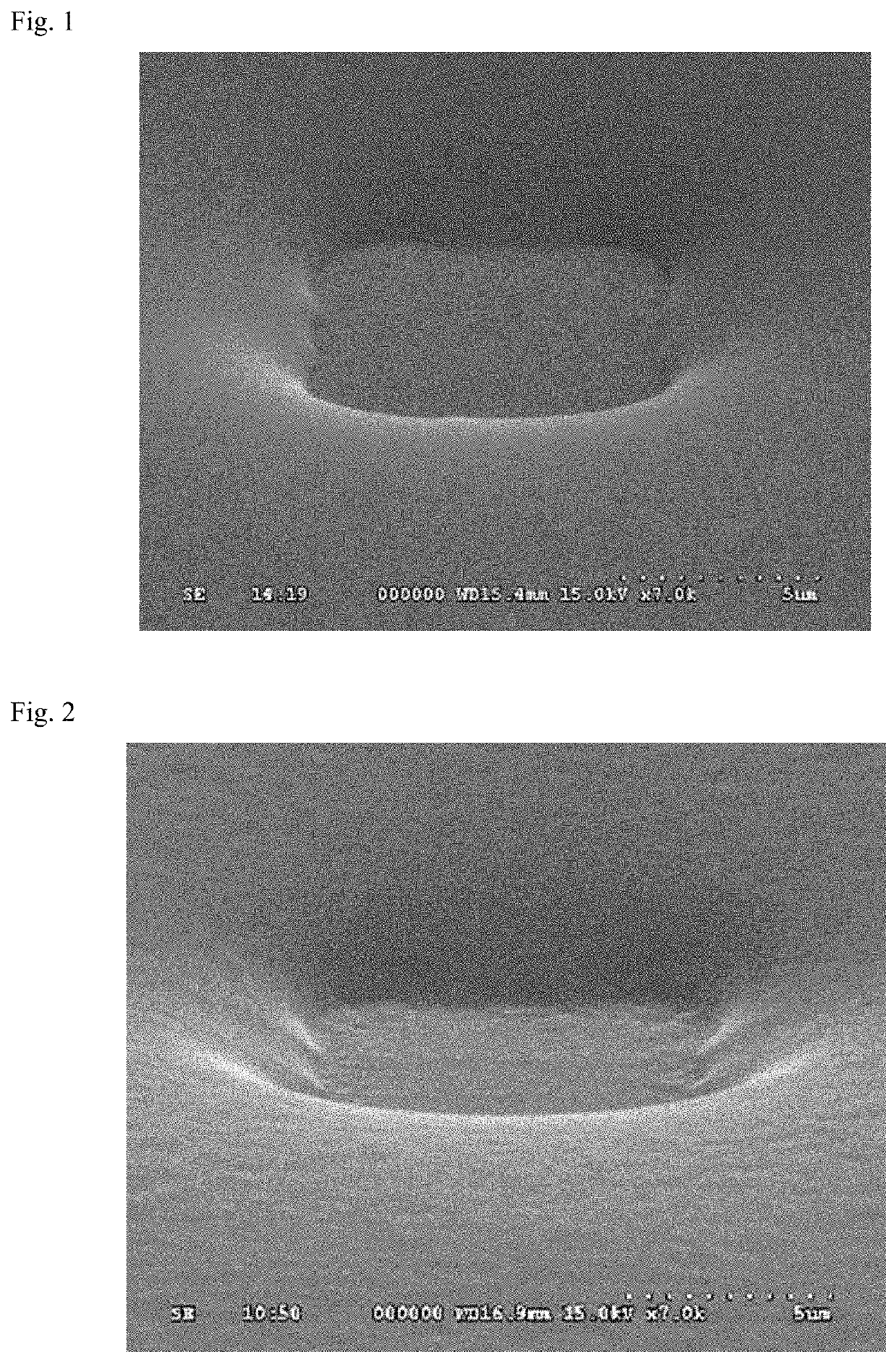

Black surface treatment process of electrolytic copper foil

ActiveCN101906630AImprove antioxidant capacityAccelerated corrosionSuperimposed coating processZinc alloysCopper foil

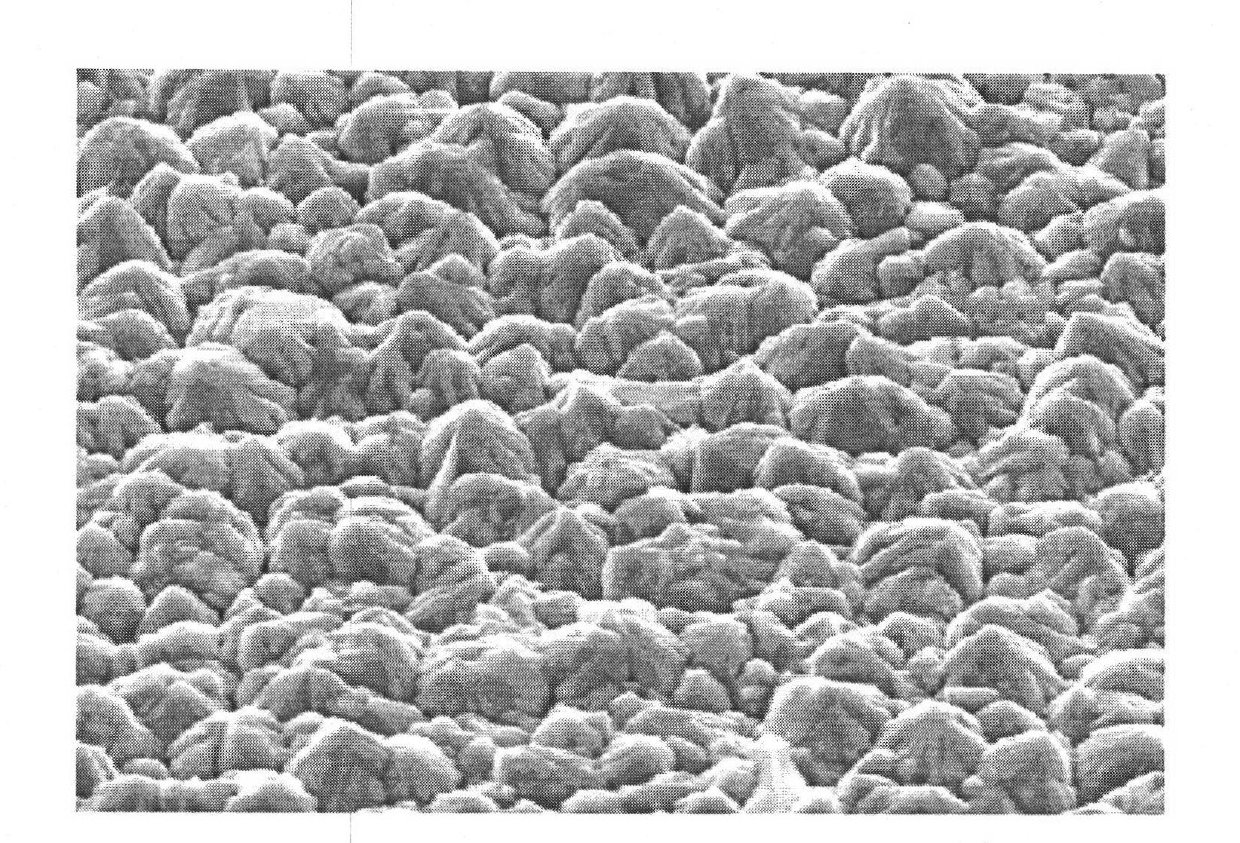

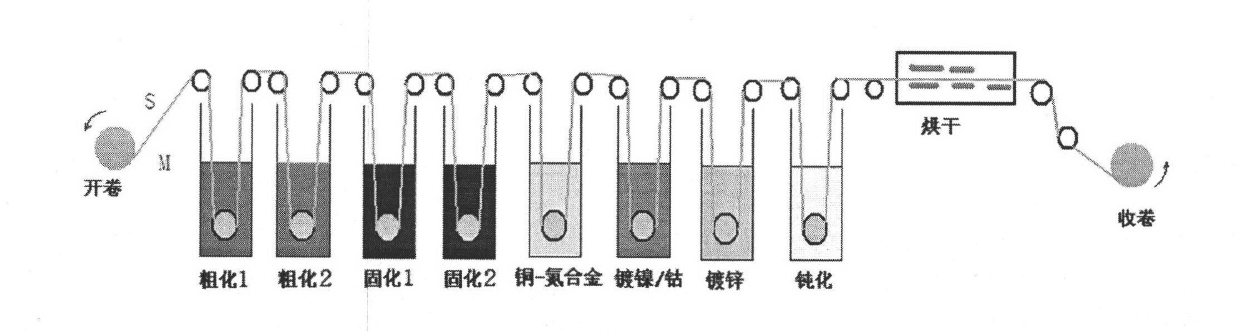

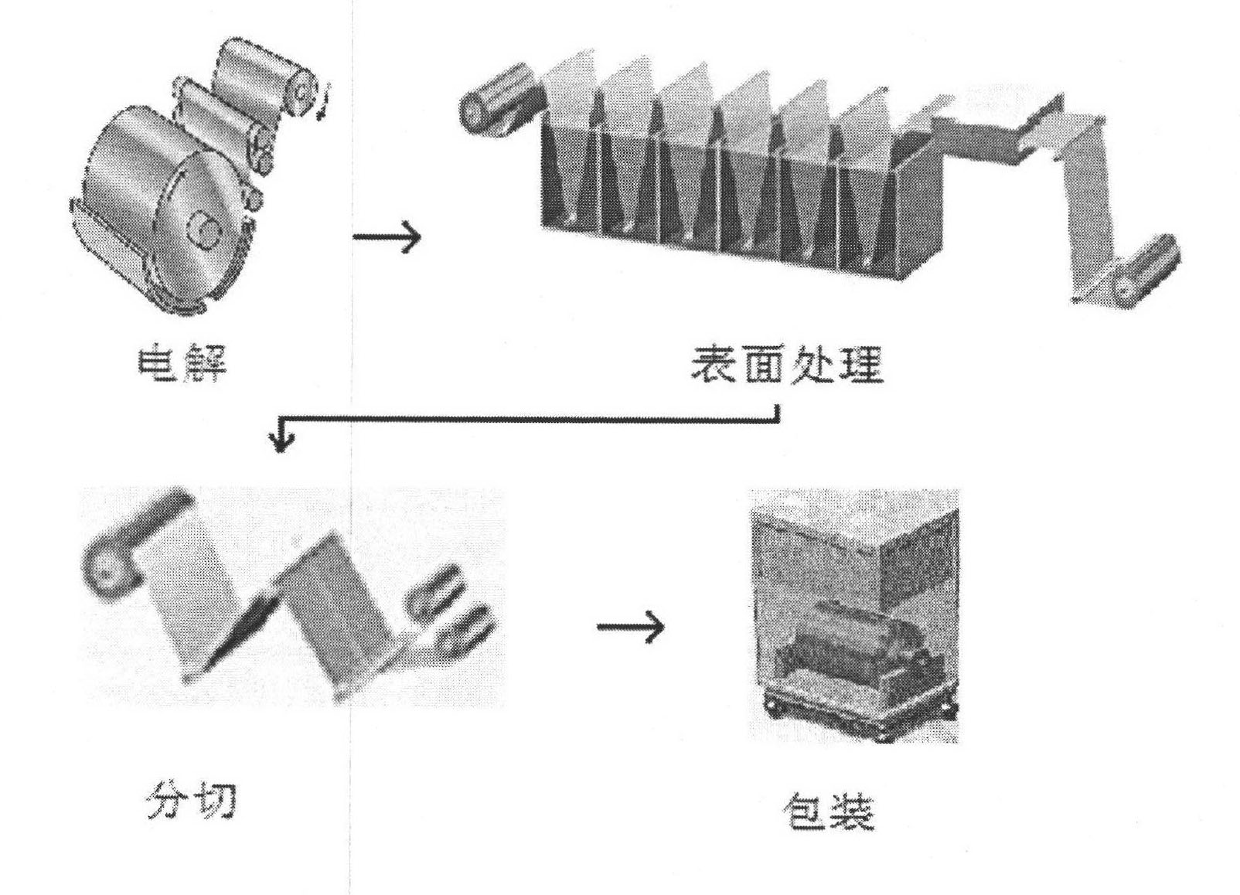

The invention relates to a black surface treatment process of an electrolytic copper foil, belonging to the technical field of production processes of high and precision electrolytic copper foils. The black surface treatment process of an electrolytic copper foil is characterized in that a VLP (Very Low Profile) electrolytic copper foil of 8-12 mu m is used as an electrode, and then copper or copper alloy is roughened, solidified, weakly roughened and electrically deposited at a running speed of 25.0+ / -0.1m / min; a layer of nano-scale nickel or cobalt alloy and a layer of nano-scale zinc alloy are sequentially and electrically deposited; and then alkaline chromate passivation is carried out and a layer of coupling agent is coated. In the invention, the black copper foil for an FPC (Flexible Printing Circuit) is obtained by carrying out a series of special surface treatments on the ultrathin and VLP electrolytic copper foil of 8-12 mu m, wherein the surface roughness Ra of the obtained copper foil is smaller than or equal to 0.30 mu m, Rz is smaller than or equal to 2.5 mu m; the thickness of the copper foil subjected to the surface treatments is increased by 1.40-1.80 mu m; the copper foil does not contain elements having serious damages to the human body, such as lead, mercury, cadmium, stibium, and the like and has excellent oxidation resistance as well as corrosion and etching resistance; the peel strength of the copper foil on a PI (Polyimide) film reaches higher than 1.0N / mm, and the folding strength on the PI film reach more than 100 thousand numbers of times; the copper foil has good appearance characteristics after the copper foil is microetched, and after the copper foil is made into an FCCL (Flexible Copper Clad Laminate), the copper foil has similar appearance characteristics to a rolled copper foil; and the properties of the copper foil product are equivalent to that of an electrolytic copper foil with the same specification for the FCCL.

Owner:SHANDONG JINBAO ELECTRONICS

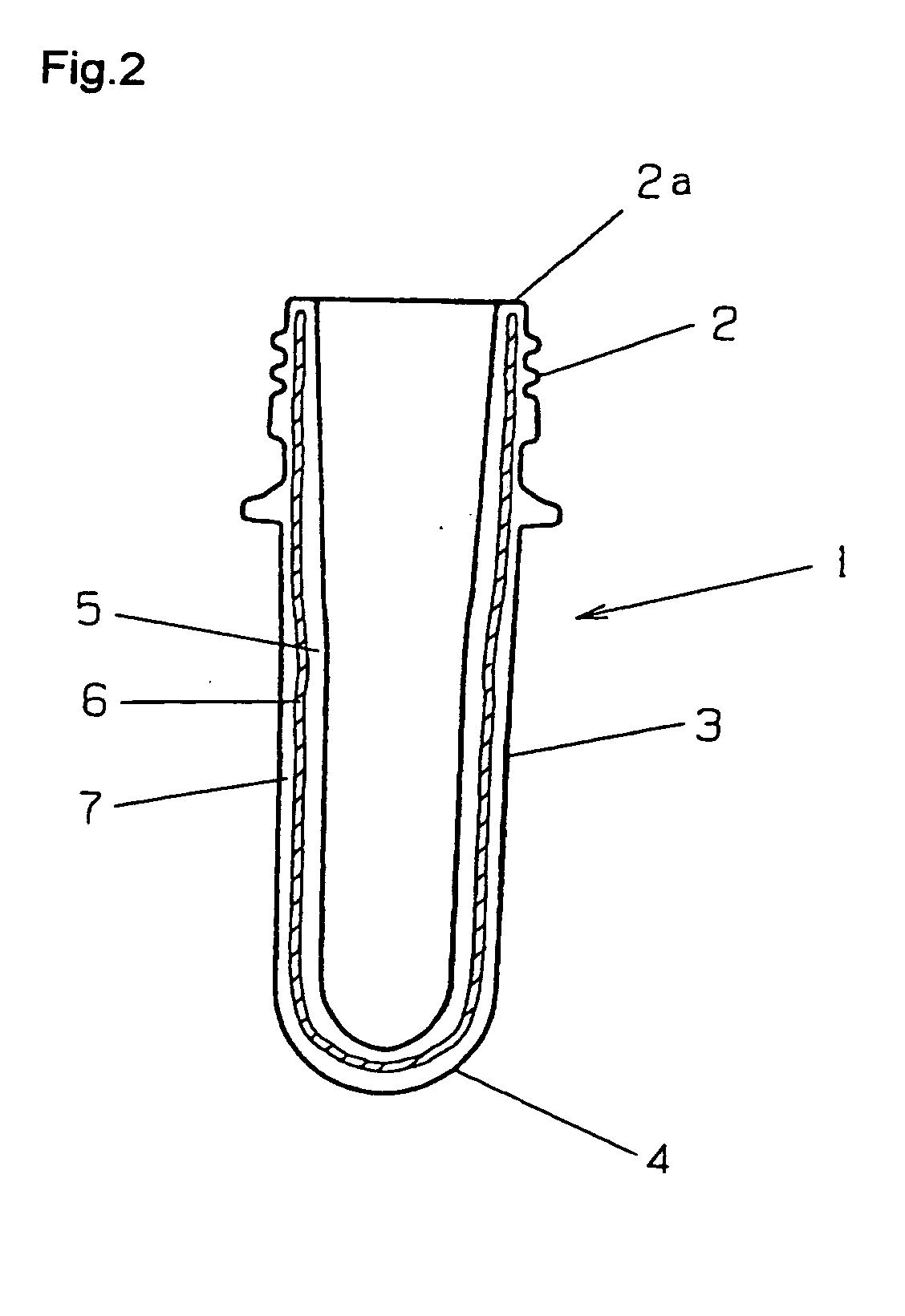

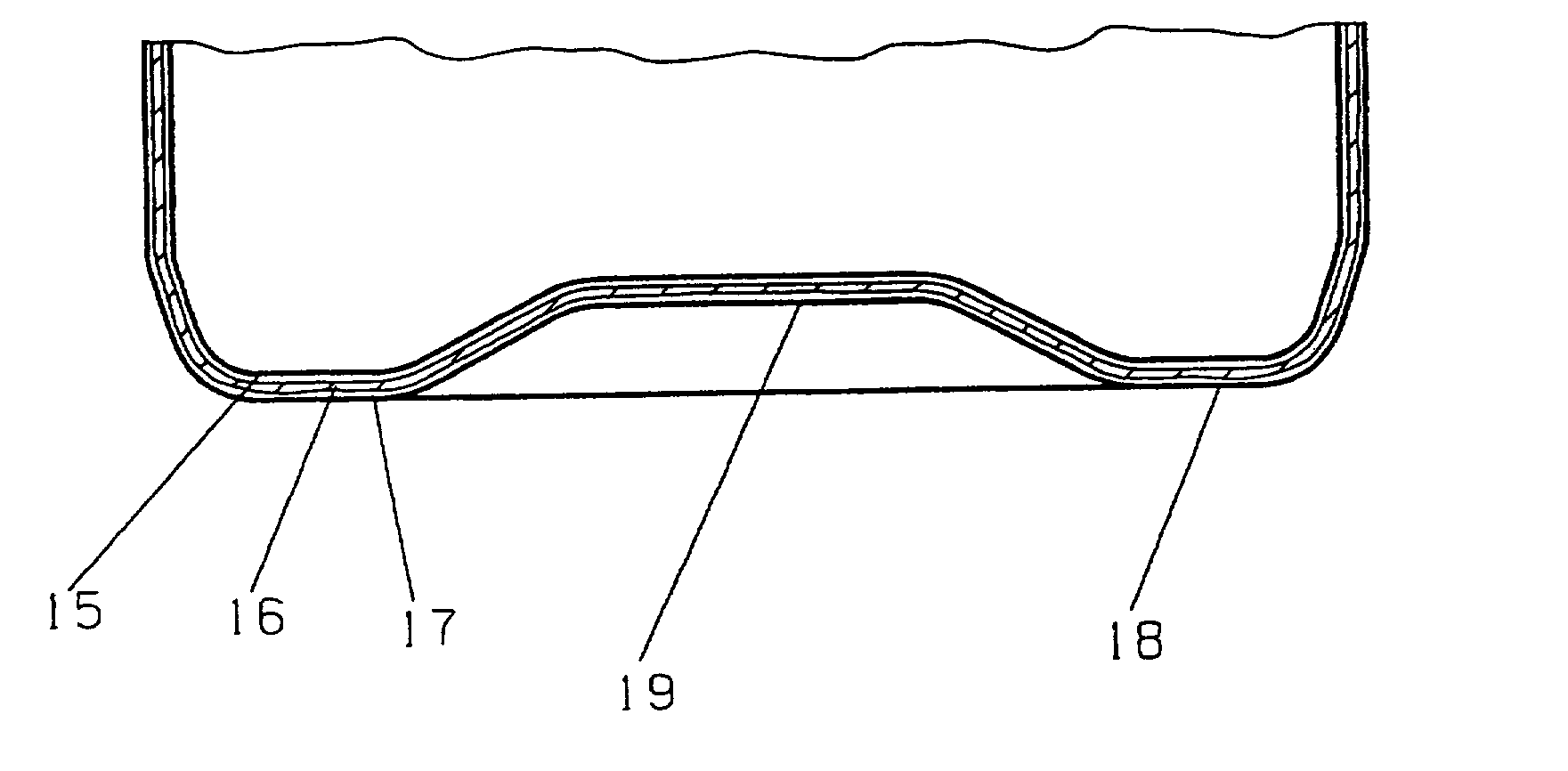

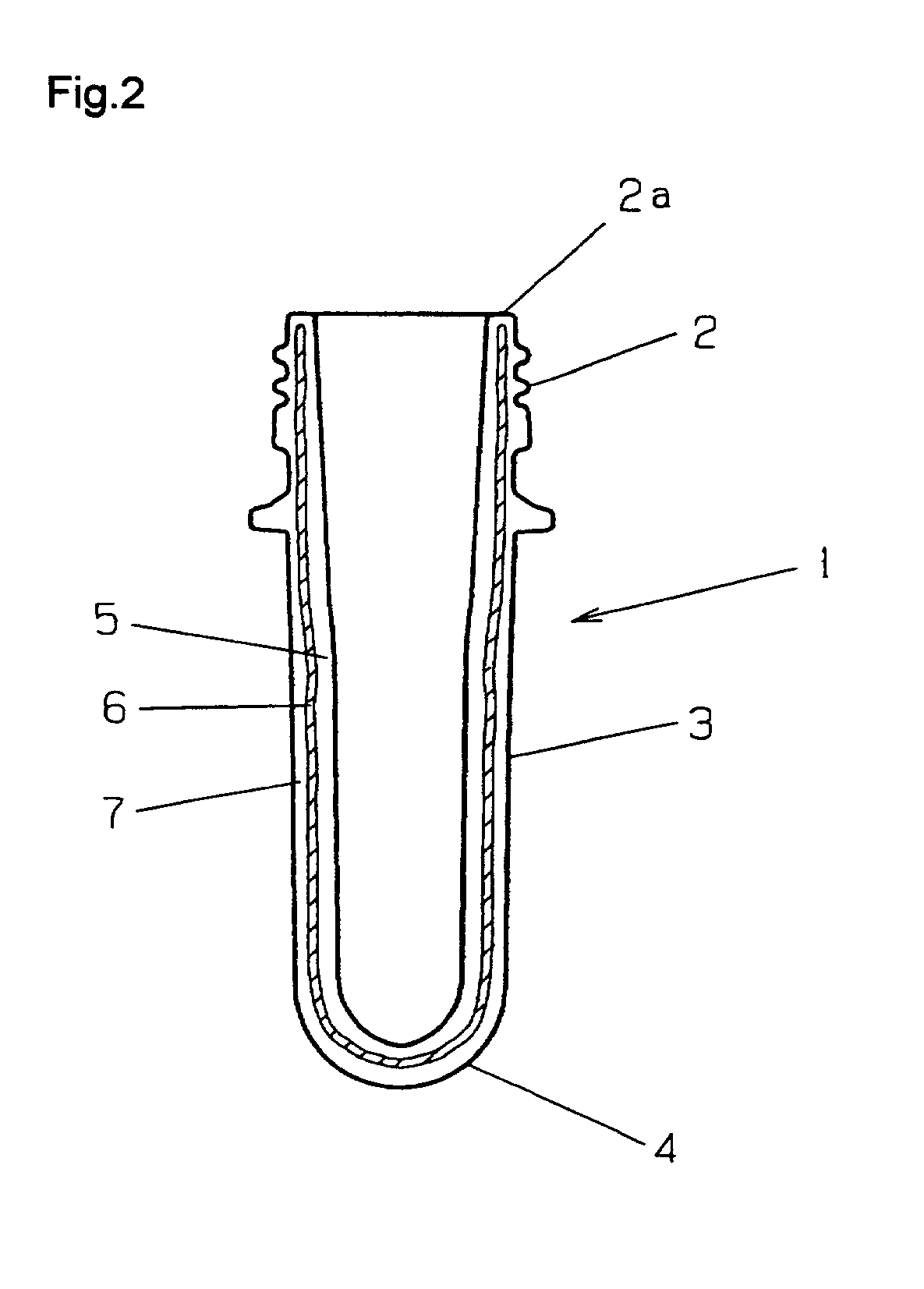

Multi-layered preform and multi-layered bottle manufactured by using the same

InactiveUS20040091652A1EfficientlyImprove impact resistanceBottlesSynthetic resin layered productsBlow moldingCompression molding

A multi-layered perform for substantially preventing the generation of strains and obtaining improved stress cracking resistance with excellent appearance characteristics includes a mouth portion, a body portion and a bottom portion and has at least the body portion and the bottom portion formed of an inner layer, an intermediate layer, and an outer layer by a compression molding. A multi-layered bottle is manufactured by performing a biaxial stretch blow molding of such multi-layered perform. The multi-layered bottle includes a mouth portion a shoulder portion, a body portion and a bottom portion. At least the shoulder portion, the body portion and the bottom portion include an inner layer, an intermediate layer and an outer layer.

Owner:TOYO SEIKAN KAISHA LTD

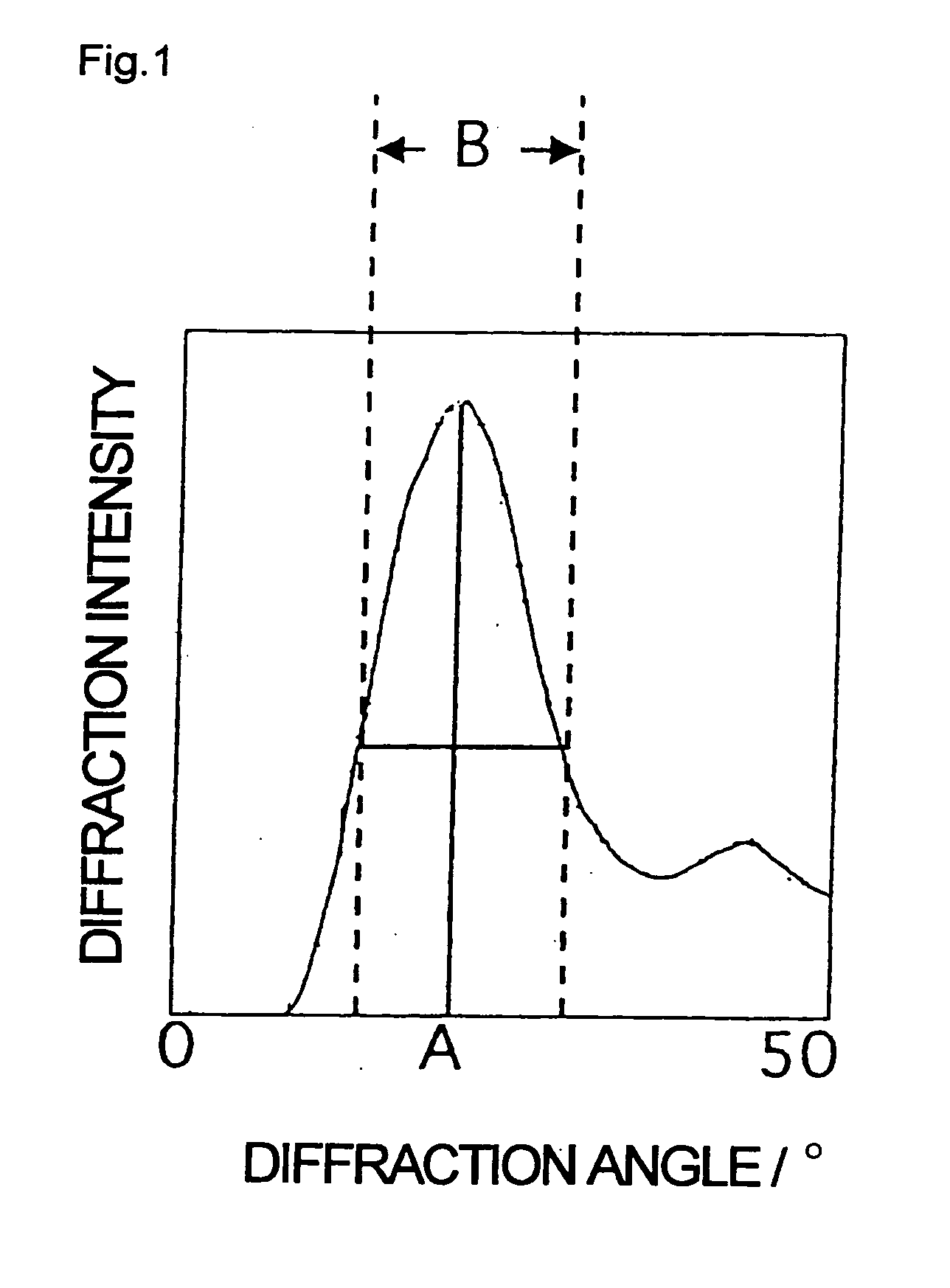

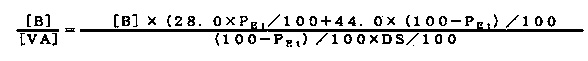

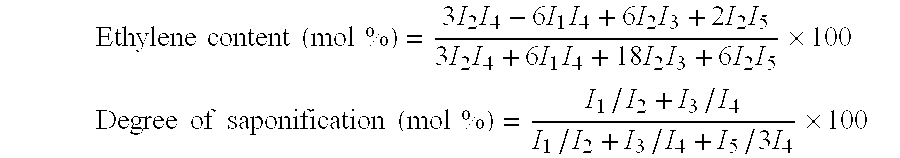

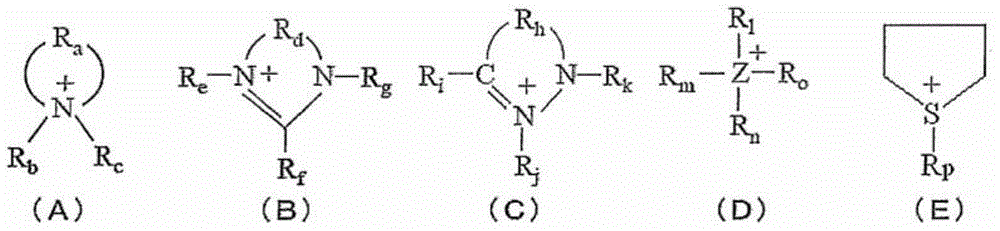

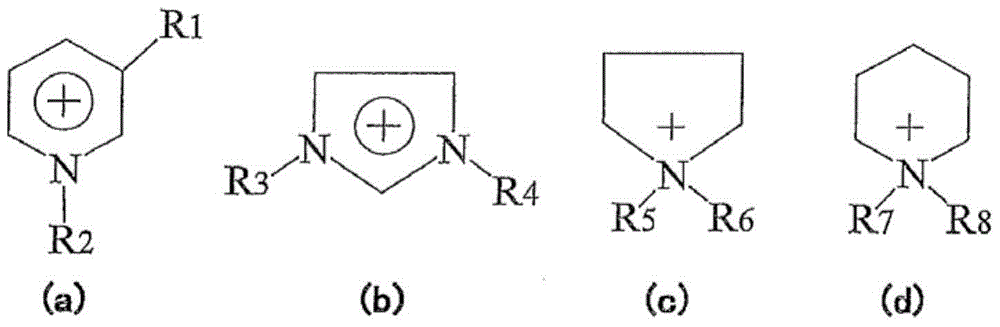

Ethylene-vinyl alcohol copolymer resin composition and method for producing same

The purpose of the present invention is to provide an ethylene-vinyl alcohol copolymer resin composition which has excellent appearance characteristics (particularly being reduced in coloration and hue spots) and is suppressed in occurrence of yellowing and the like during melt molding. The present invention is an ethylene-vinyl alcohol copolymer resin composition, which contains (A) an ethylene-vinyl alcohol copolymer and (B) a compound having an enediol structure, and wherein the molar ratio of the compound (B) relative to the vinyl alcohol unit of the ethylene-vinyl alcohol copolymer (A) is from 2.70*10-9 to 2.70*10-5 (inclusive).

Owner:KURARAY CO LTD

Multi-layered preform and multi-layered bottle manufactured by using the same

InactiveUS20020098310A1Not damage qualityImprove stress resistanceBottlesSynthetic resin layered productsCompression moldingBlow molding

A multi-layered preform for substantially preventing the generation of strains and obtaining improved stress cracking resistance with excellent appearance characteristics includes a mouth portion, a body portion and a bottom portion and has at least the body portion and the bottom portion formed of an inner layer, an intermediate layer, and an outer layer by a compression molding. A multi-layered bottle is manufactured by performing a biaxial stretch blow molding of such multi-layered perform. The multi-layered bottle includes a mouth portion, a shoulder portion, a body portion and a bottom portion. At least the shoulder portion, the body portion and the bottom portion include an inner layer, an intermediate layer and an outer layer.

Owner:TOYO SEIKAN KAISHA LTD

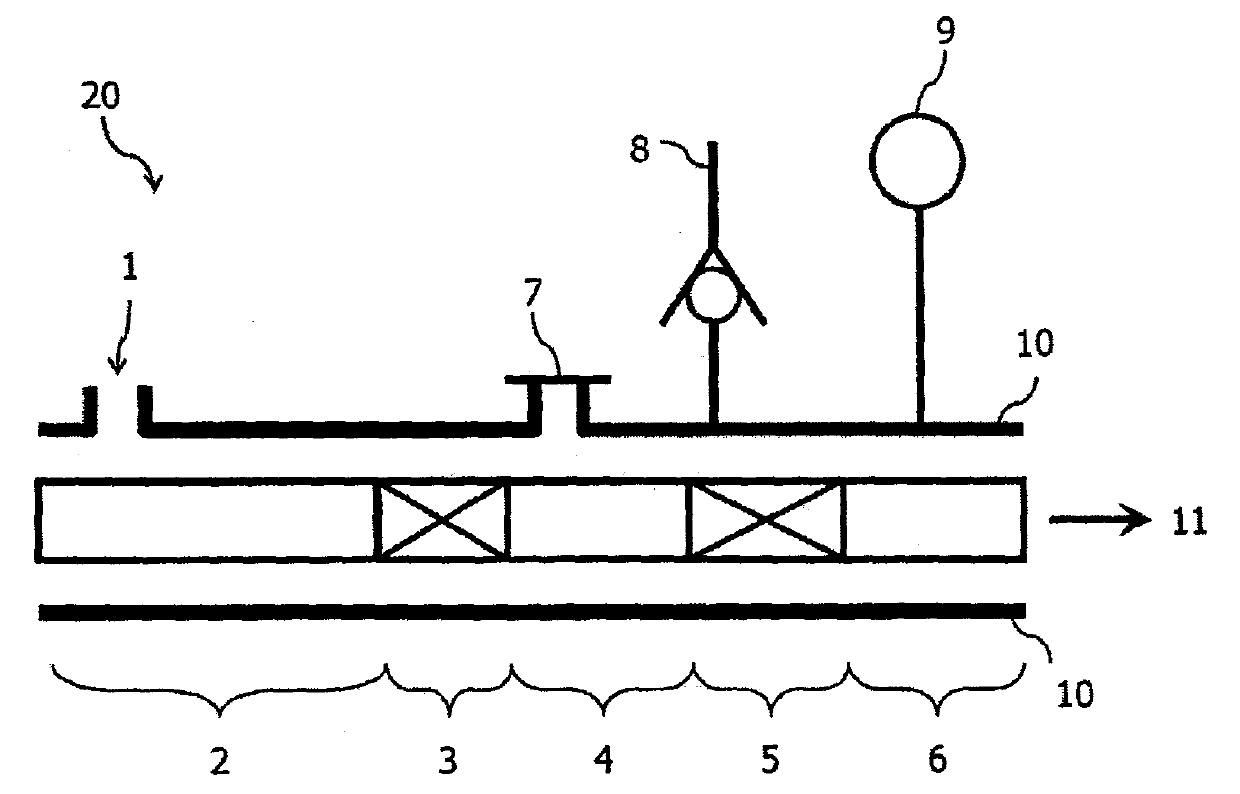

Ethylene-vinyl alcohol resin composition, multilayer structure, multilayer sheet, container, and packaging material

ActiveUS20150159005A1Excellent appearance characteristicsHigh mechanical strengthSynthetic resin layered productsFood preservationAldehydeEthylene vinyl alcohol copolymer

The present invention provides a resin composition containing: an ethylene-vinyl alcohol copolymer (A) having an ethylene content of 20 mol % or more and 60 mol % or less; a polyamide resin (B); a carboxylic acid metal salt (C); and an unsaturated aldehyde (D), the mass ratio (A / B) of the ethylene-vinyl alcohol copolymer (A) to the polyamide resin (B) being 60 / 40 or more and 95 / 5 or less, the content of the carboxylic acid metal salt (C) with respect to a resin content in terms of a metal element equivalent being 1 ppm or more and 500 ppm or less, and the content of the unsaturated aldehyde (D) with respect to the resin content being 0.05 ppm or more and 50 ppm or less.

Owner:KURARAY CO LTD

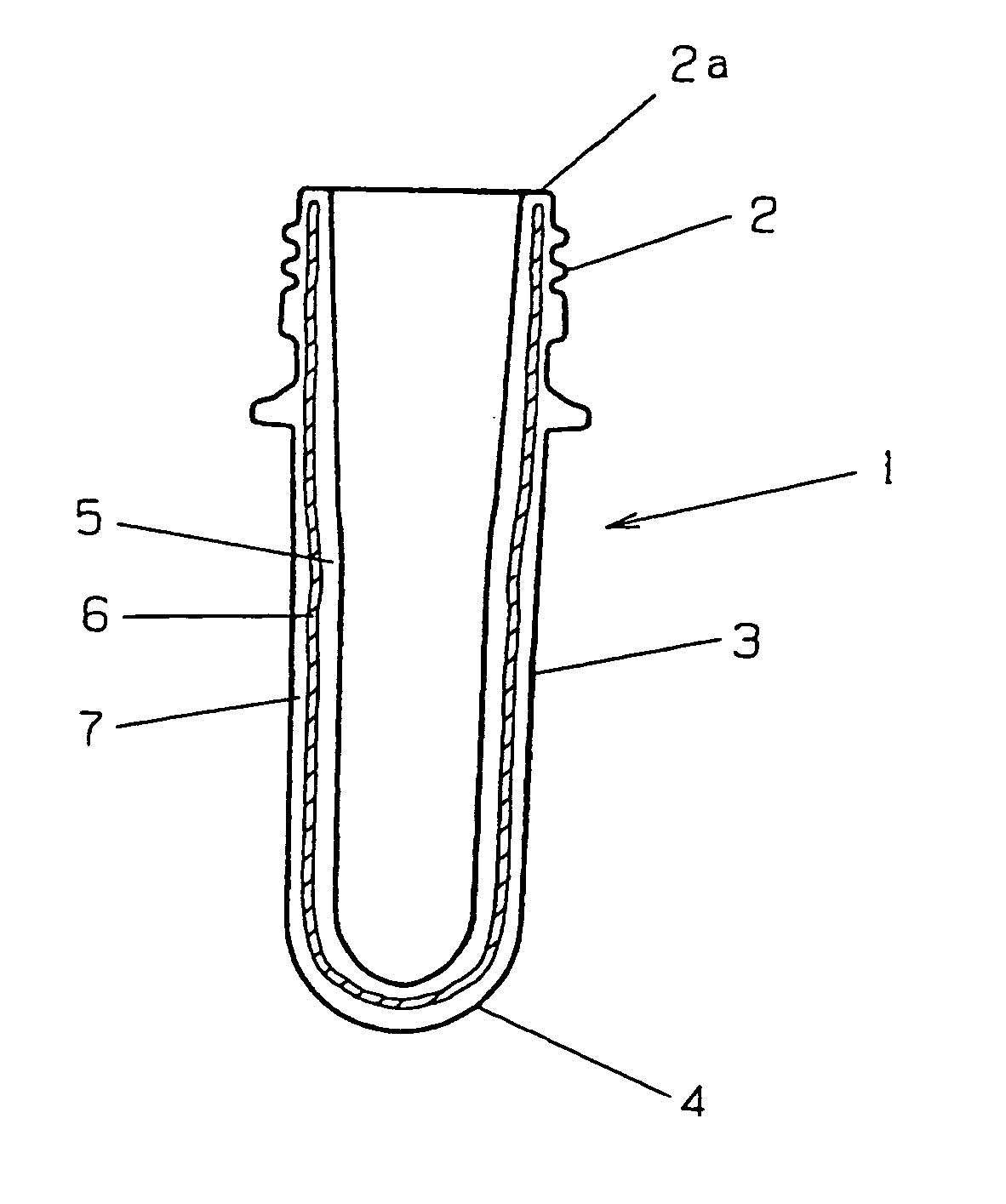

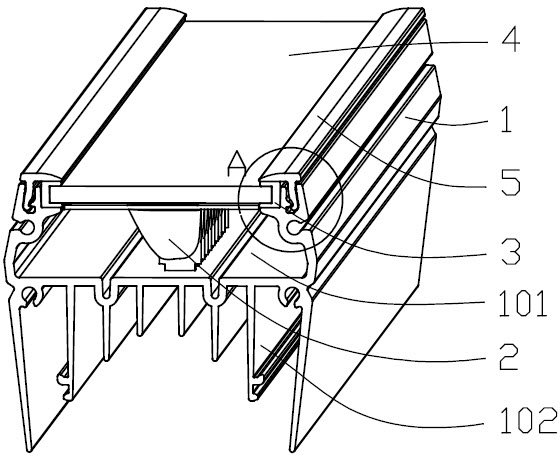

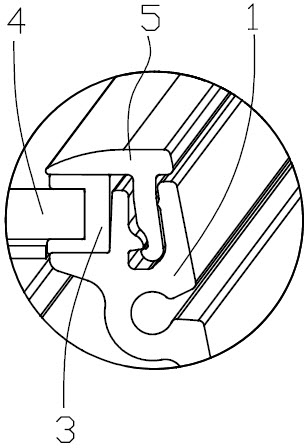

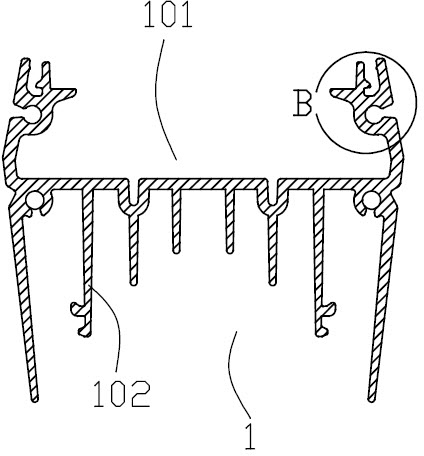

Sealing structure for strip-shaped lamp

InactiveCN102182994AExcellent appearance characteristicsImprove assembly efficiencyLighting heating/cooling arrangementsElectric lightingTransfer modeEngineering

The invention discloses a sealing structure for a strip-shaped lamp. The sealing structure comprises a strip-shaped section lamp body, a transparent lamp housing and a C-shaped sealing strip, wherein the lamp body is provided with a U-shaped lamp groove; an opening part of the lamp groove is provided with a longitudinal run-through seal groove; the sealing strip is clamped on a side edge of the transparent lamp housing in a C shape and is locked through a transfer type clamping mechanism consisting of a clamping groove and a clamping strip; the clamping groove is formed on the opening part of the lamp groove and runs through longitudinally; the part, which is close to the bottom, of an inner side wall of the clamping groove is provided with a locking bump; the part, which is close to the upper opening part, of an outer side wall of the clamping groove is provided with a transfer bump; the section of the clamping strip is T-shaped and is provided with a pressing plate part, a straight part and a locking hook; the pressing plate part is tightly pressed on the sealing strip; the straight part is formed downwardly vertical to the pressing plate part; and the locking hook is arranged on the same side as the pressing plate part and is matched with the locking bump. Through the structure, the clamping strip is clamped into the clamping groove in a transfer mode, and self-locking of the clamping strip is realized by means of elastic reacting force of the sealing strip; water-proof sealing of the strip-shaped lamp is realized; the lamp has a simple structure, is easy to assemble and has high efficiency; and the appearance of the lamp is not affected.

Owner:ZHEJIANG JL LIGHTING

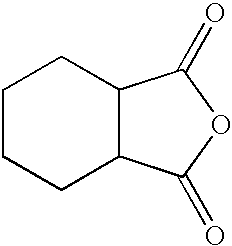

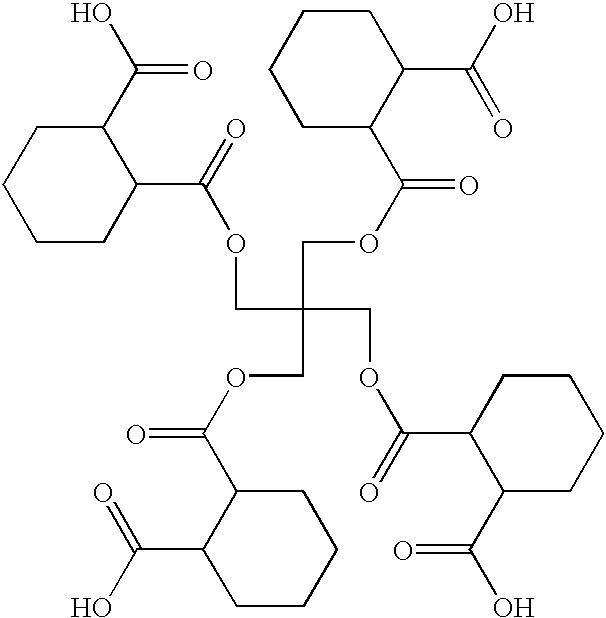

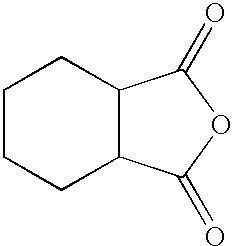

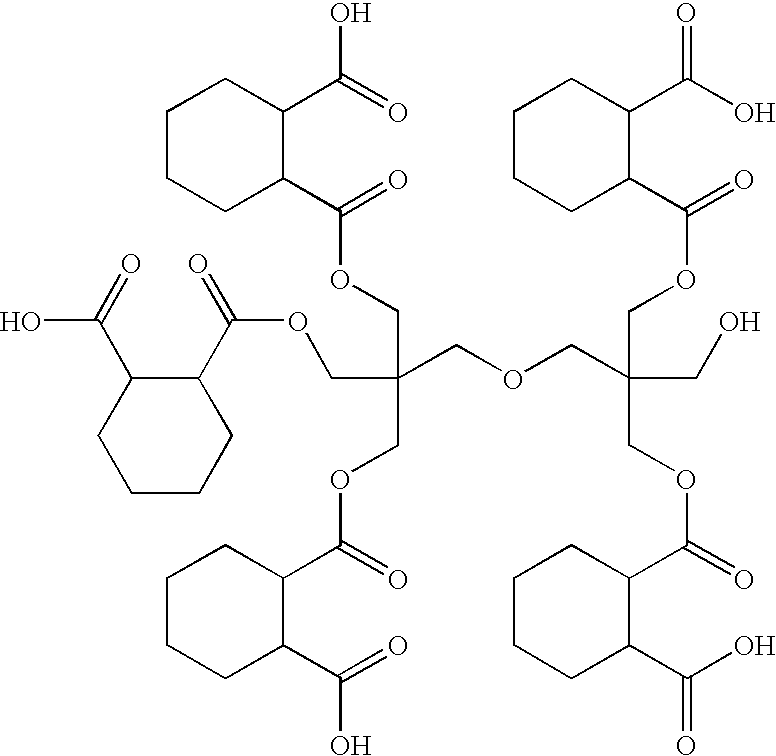

Polymeric pigment dispersant utilized as a grind resin for pigments in solventborne pigment dispersions and method of preparing the same

InactiveUS7005473B2Good color travelEnough timeTransportation and packagingOrganic dyesPolyesterCarbamate

The present invention is directed to a polyester polycarbamate polymeric pigment dispersant to be used as a grind resin to incorporate pigment into pigment dispersions for coating compositions. The pigment dispersant is the reaction product of a first compound having a plurality of hydroxyl groups, a carboxylic acid anhydride, a second compound having at least one epoxy group, and a carbamate compound. The present invention is also directed to a method of preparing the pigment dispersant.

Owner:BASF CORP

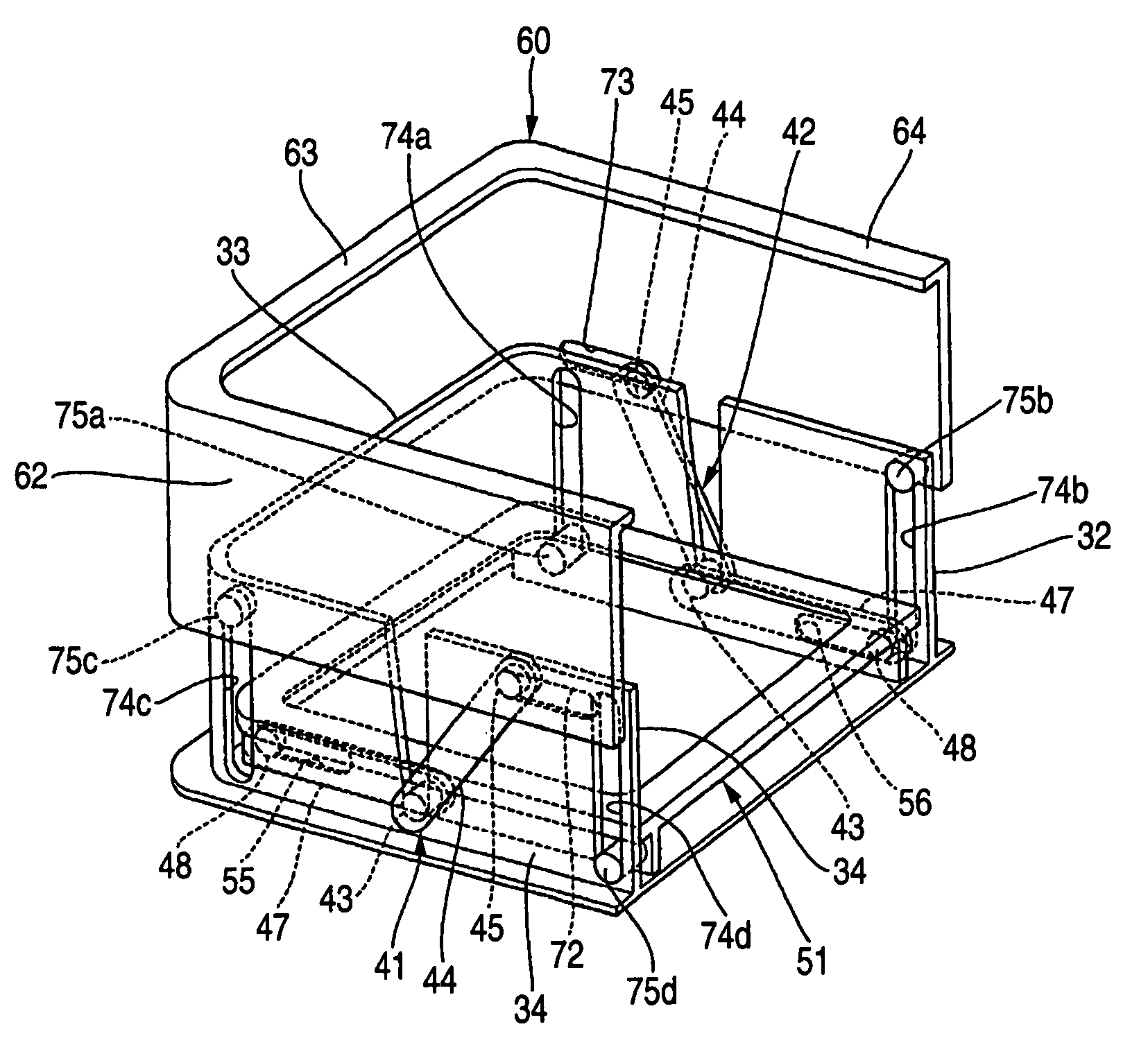

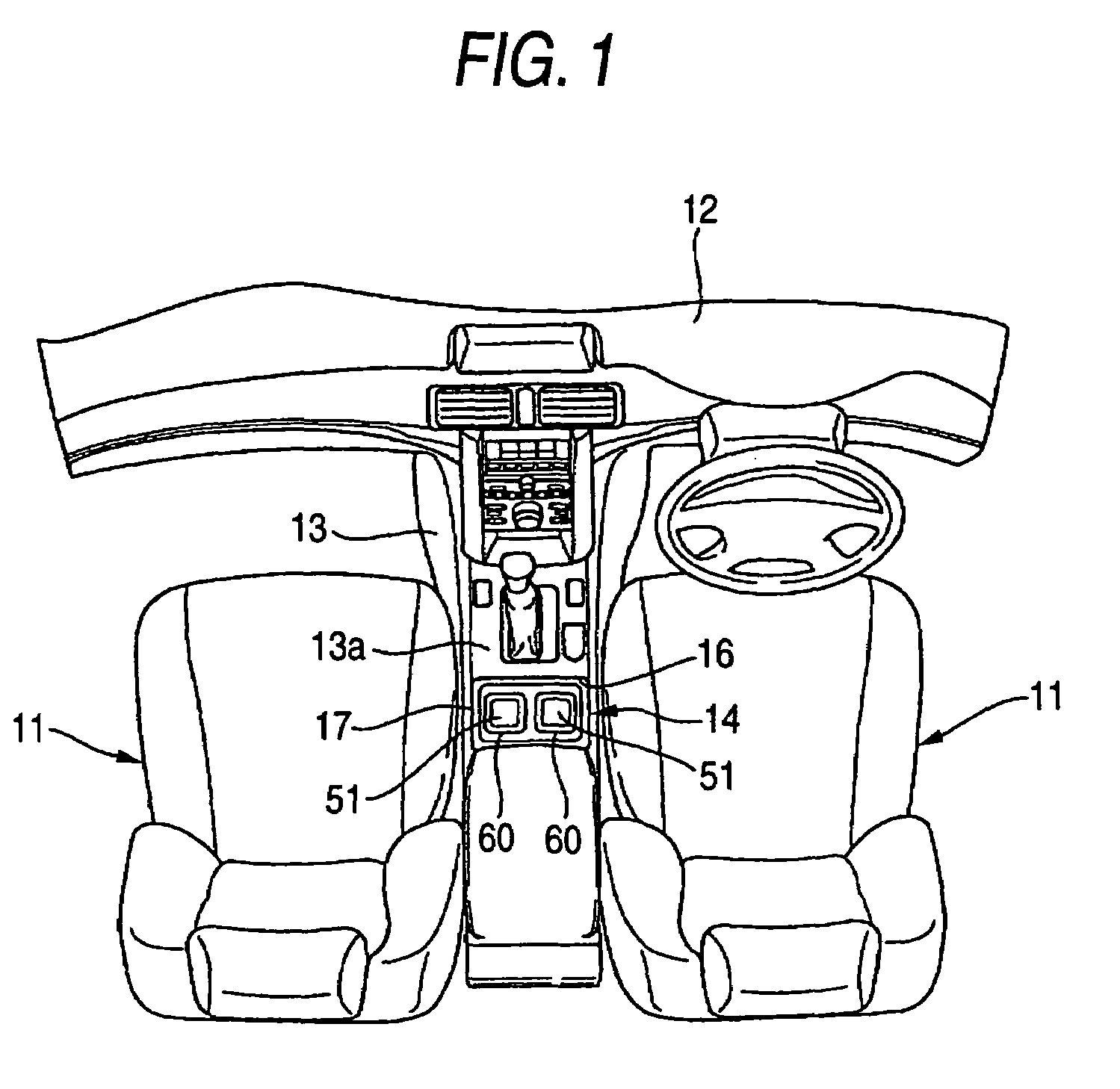

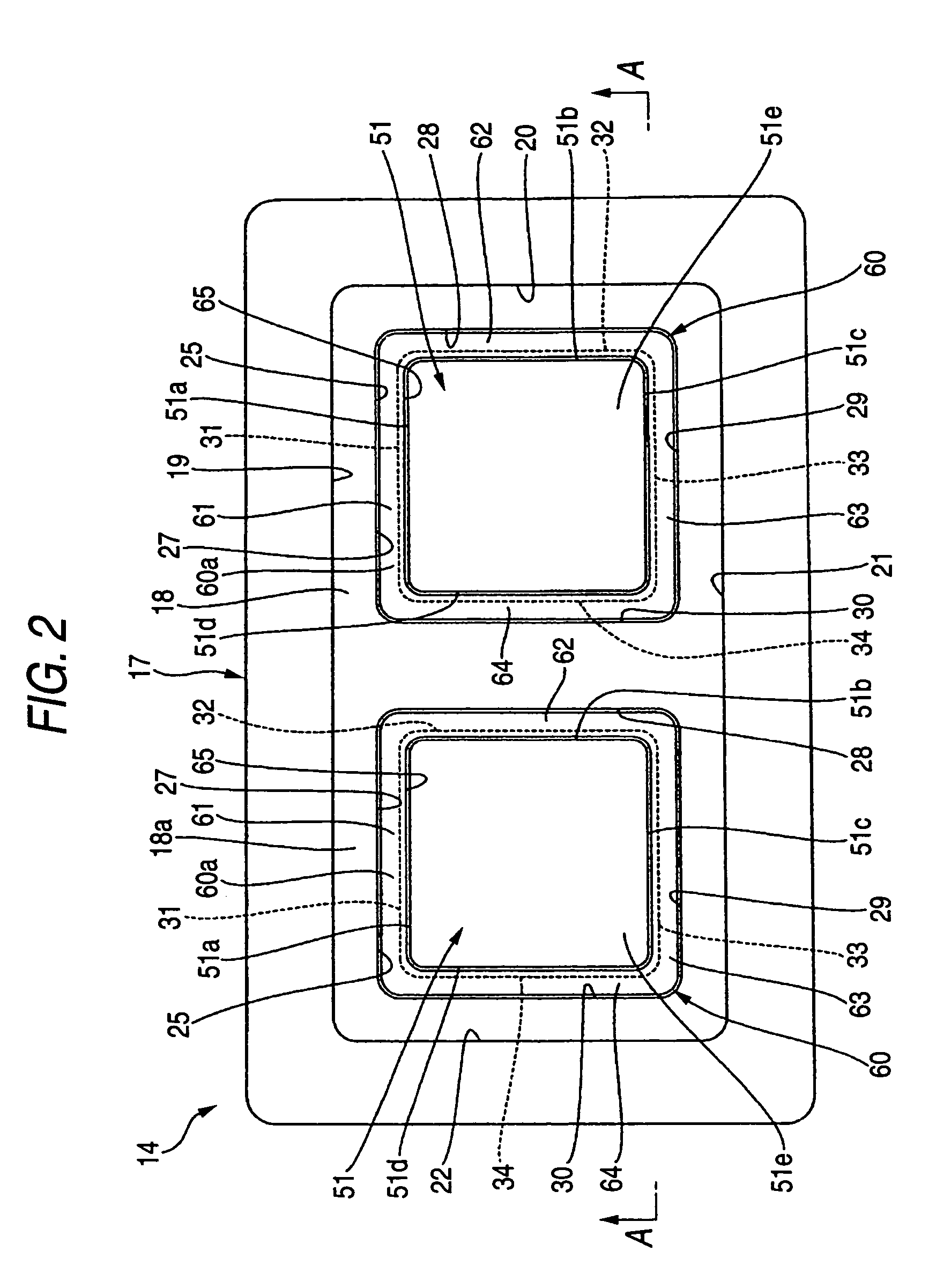

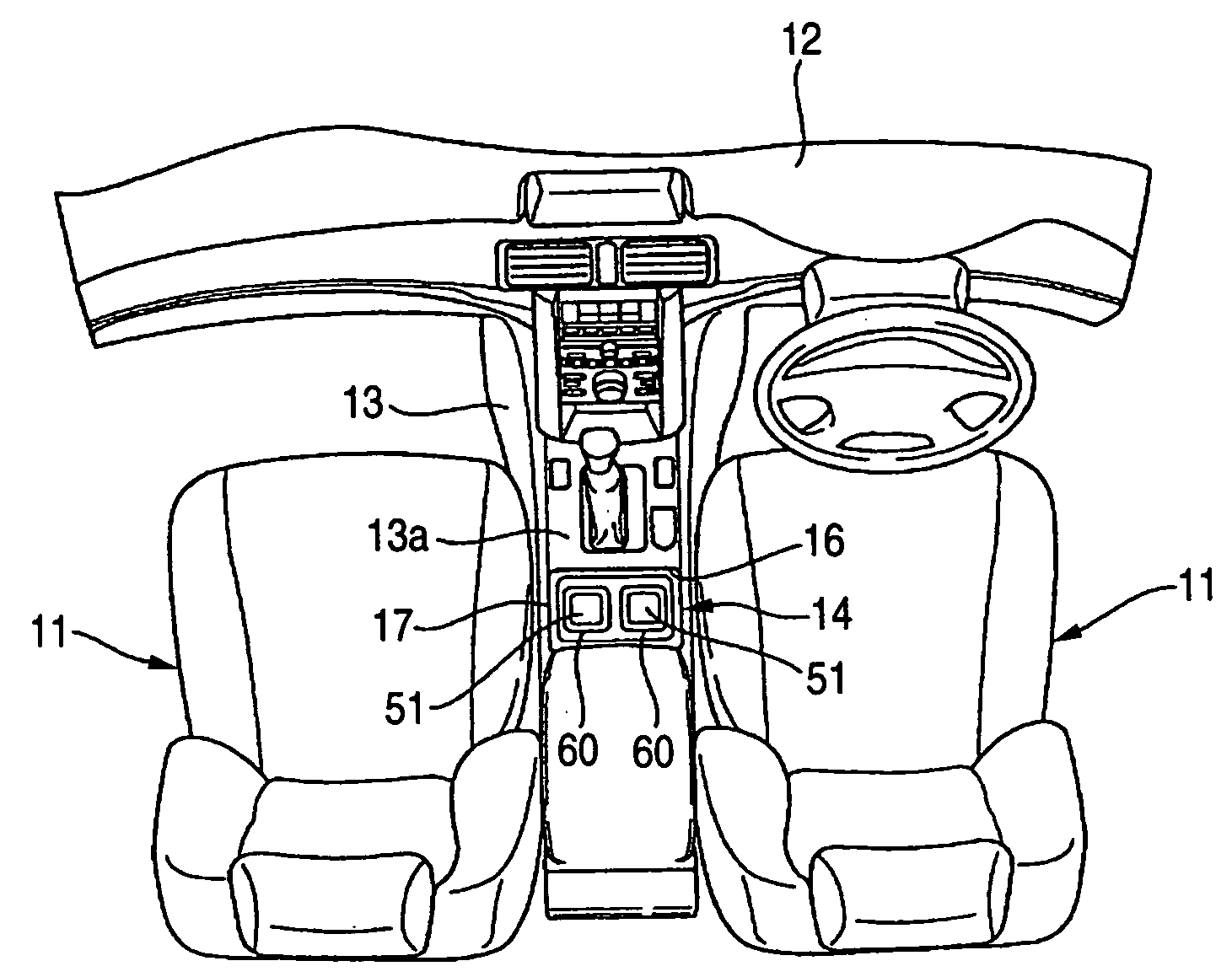

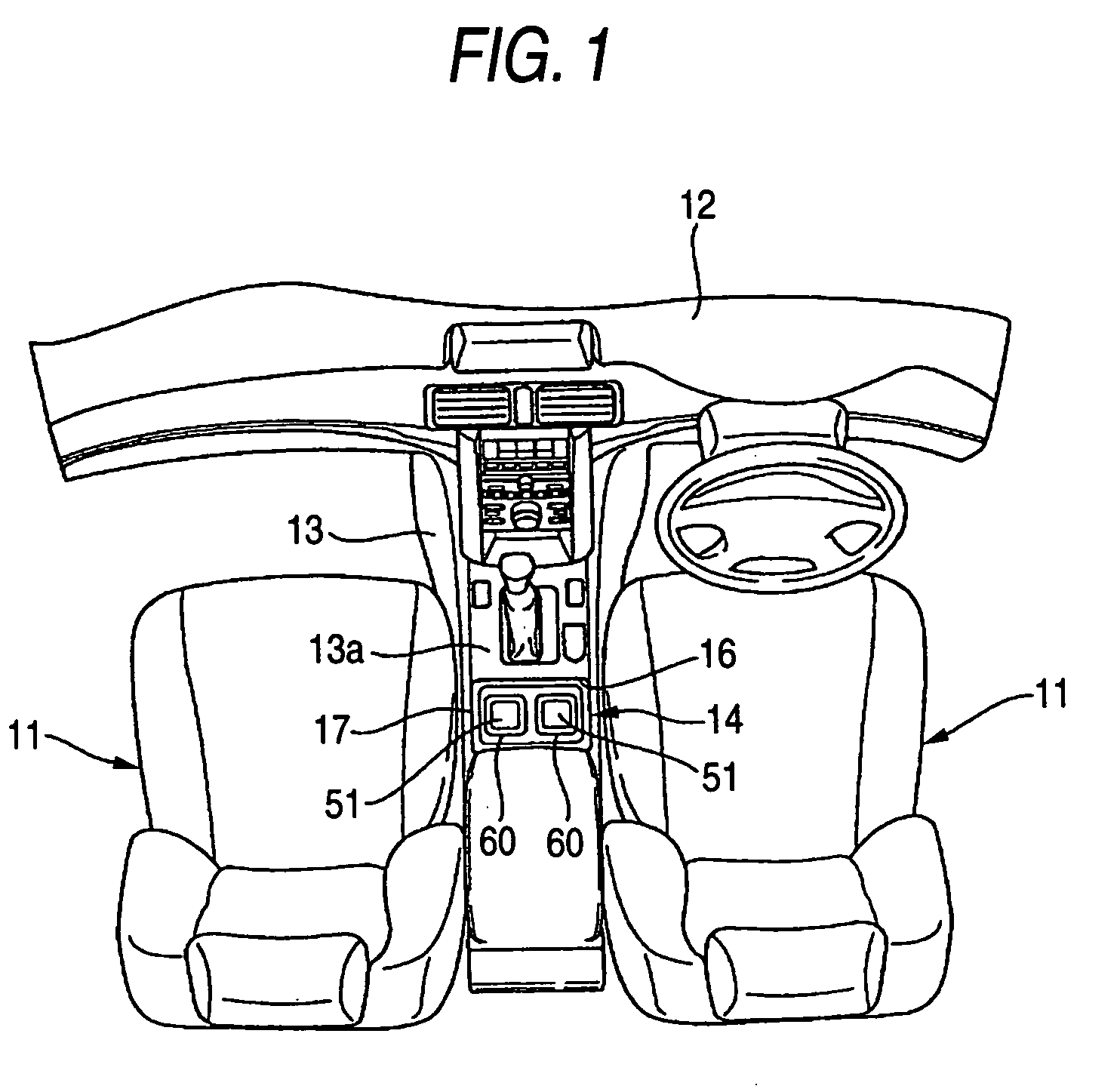

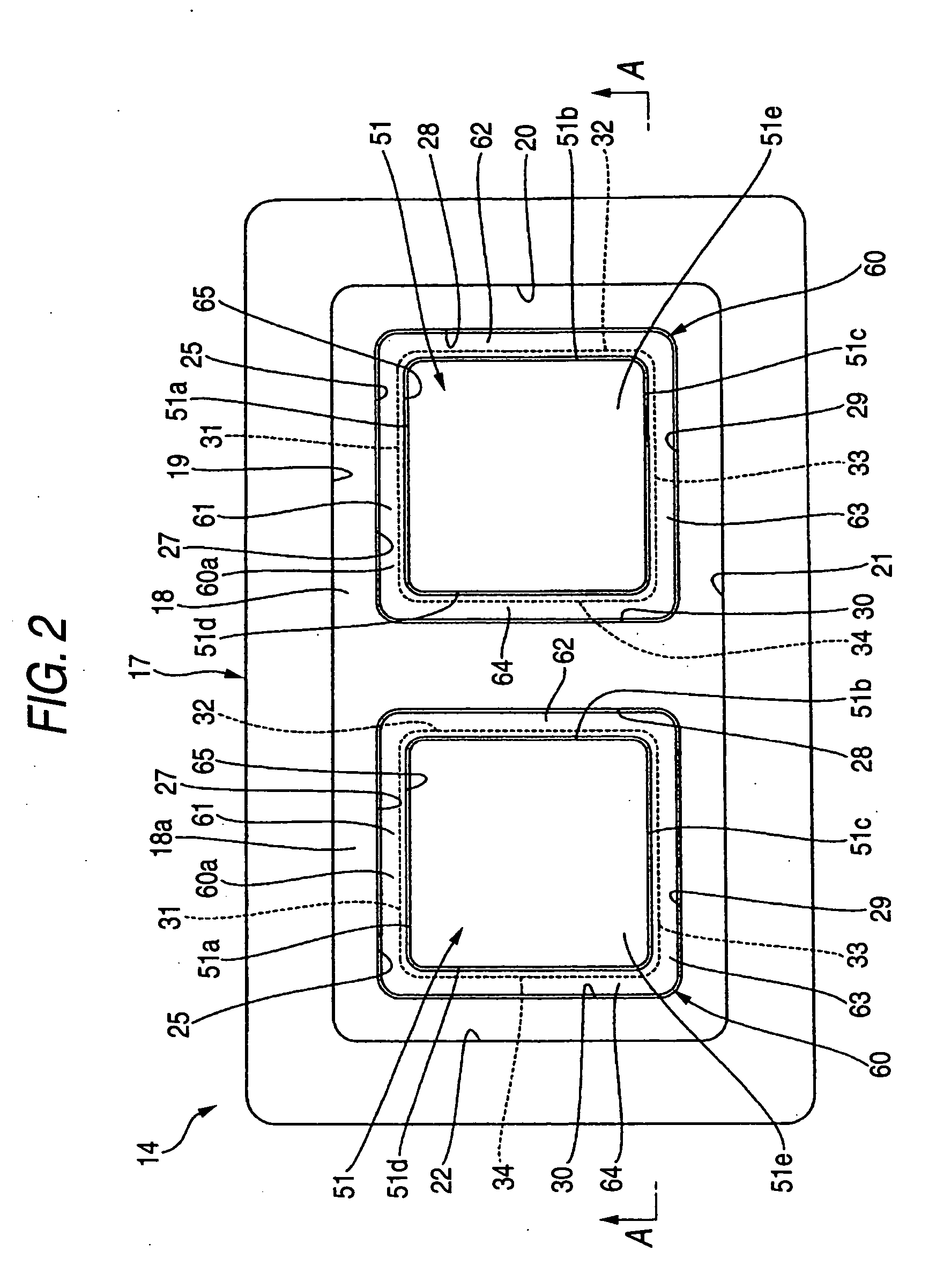

Automotive container holding apparatus

ActiveUS7455341B2Reduce the overall heightStably a tall containerTravelling carriersVehicle arrangementsEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

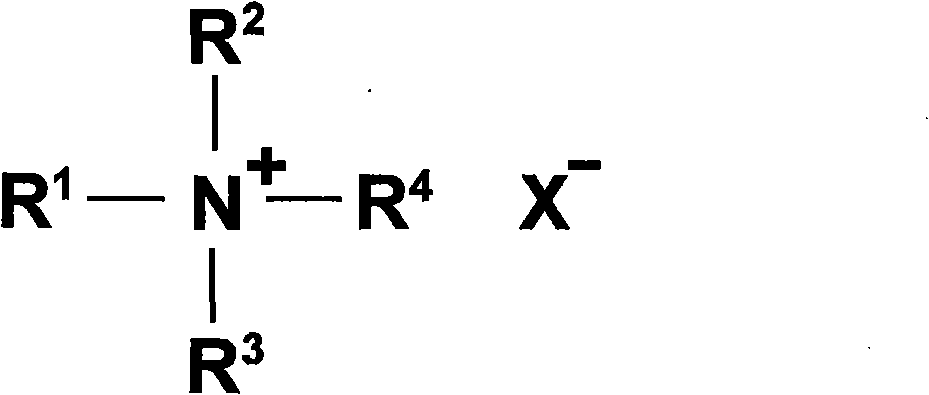

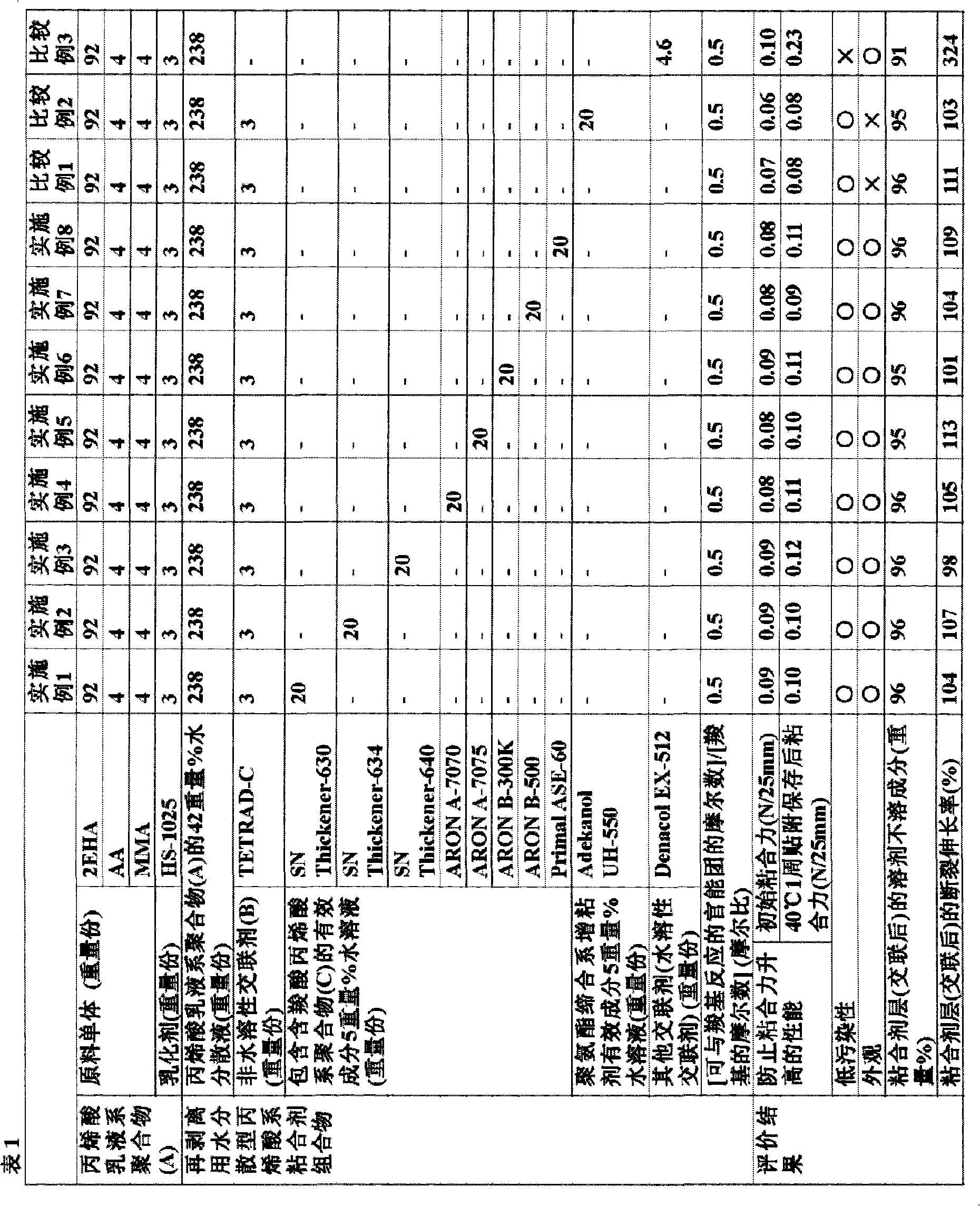

Removable water-dispersible acrylic pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet

InactiveUS20120219795A1Reduce stainsResistant to increase in adhesive strengthLayered productsEster polymer adhesivesWater dispersiblePolymer science

A removable water-dispersible acrylic pressure-sensitive adhesive composition according to the present invention includes an acrylic emulsion polymer (A), a water-insoluble crosslinking agent (B), and a carboxylic-acid-containing acrylic polymer (C). The polymer (A) includes a (meth) acrylic alkyl ester and a carboxyl-containing unsaturated monomer as essential constitutive monomers and has a content of the (meth) acrylic alkyl ester of 70 to 99.5 percent by weight and a content of the carboxyl-containing unsaturated monomer of 0.5 to 10 percent by weight, each based on the total amount of constitutive monomers. The polymer (C) includes (meth) acrylic acid as an essential constitutive monomer and has a total content of acrylic acid and methacrylic acid of 11 percent by weight or more based on the total amount of constitutive monomers.

Owner:NITTO DENKO CORP

Ethylene-vinyl alcohol copolymer resin composition and method for producing same

ActiveUS20140213701A1Excellent appearance characteristicsLess coloring and unevenness of hueAdhesivesPolymer scienceEthylene

Provided by the present invention is an ethylene-vinyl alcohol copolymer resin composition having superior appearance characteristics (particularly decreased coloring and unevenness of the hue), and is accompanied by suppressed occurrence of yellowing, etc., in melt molding. An ethylene-vinyl alcohol copolymer resin composition containing an ethylene-vinyl alcohol copolymer (A) and a compound having an enediol structure (B), in which a molar ratio of the compound (B) to vinyl alcohol units of the ethylene-vinyl alcohol copolymer (A) is 2.70×10−9 or greater and 2.70×10−5 or less.

Owner:KURARAY CO LTD

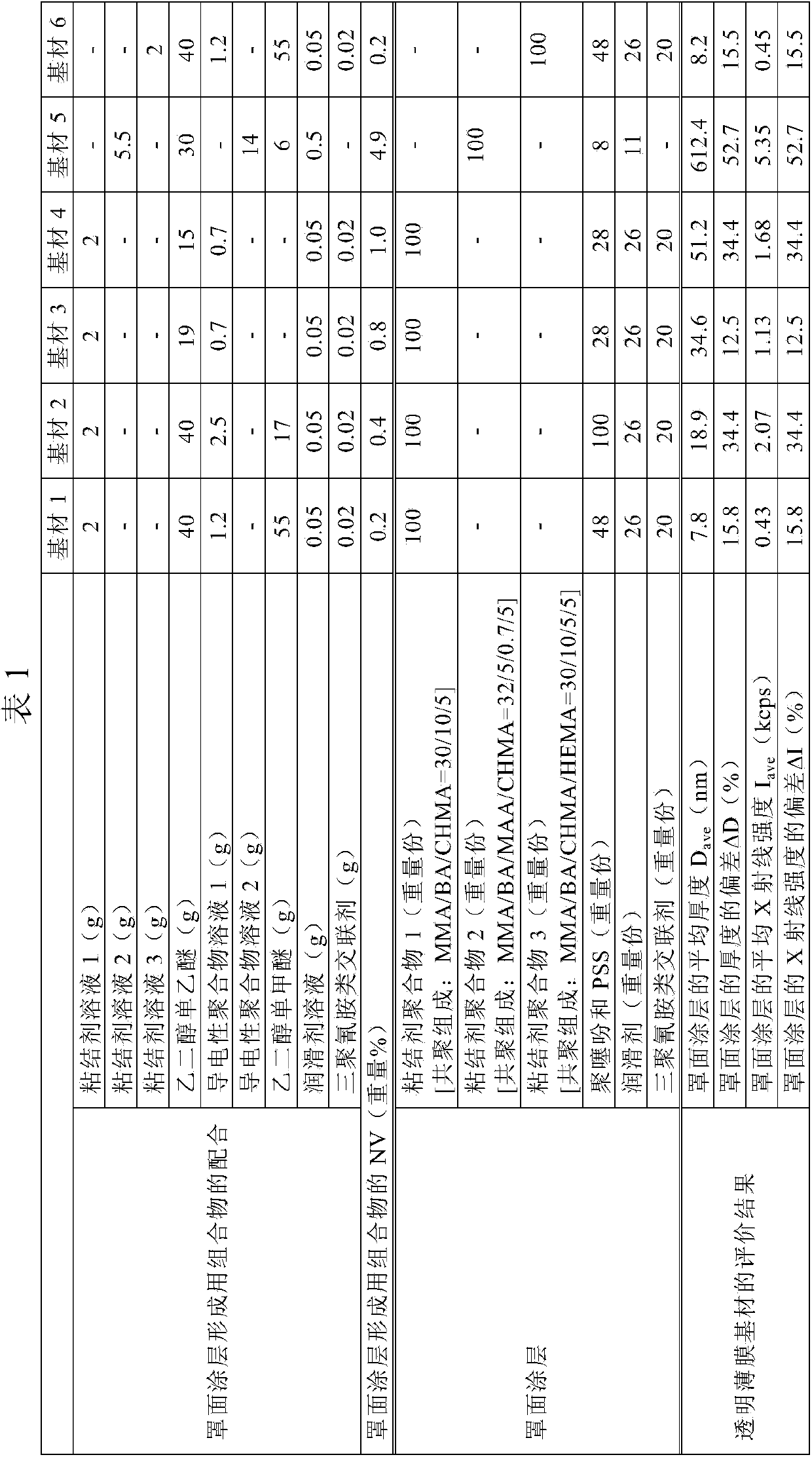

Adhesive composition and adhesive sheet

ActiveCN104099045AExcellent appearance characteristicsUseful for surface protection purposesNon-macromolecular adhesive additivesFilm/foil adhesivesWater dispersibleMeth-

The invention relates to an adhesive composition and an adhesive sheet. Provided is a water-dispersible acrylic pressure-sensitive adhesive composition which can form a pressure-sensitive adhesive layer excellent in antistatic property, repeeling property (light peeling property), and appearance property. The repeelable water-dispersible acrylic pressure-sensitive adhesive composition of the present invention contains an acrylic emulsion-based polymer composed of 70 to 99.5% by weight of a (meth)acrylic acid alkyl ester and 0.5 to 10% by weight of a carboxyl group-containing unsaturated monomer as monomer components, a crosslinking agent, an ionic compound, and a nonionic surfactant with an HLB value of 6 or more.

Owner:NITTO DENKO CORP

Removable water-dispersible acrylic pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet

ActiveCN102732191ANot easy to bleachExcellent peelabilityNon-macromolecular adhesive additivesMacromolecular adhesive additivesWater dispersiblePolymer science

Owner:NITTO DENKO CORP

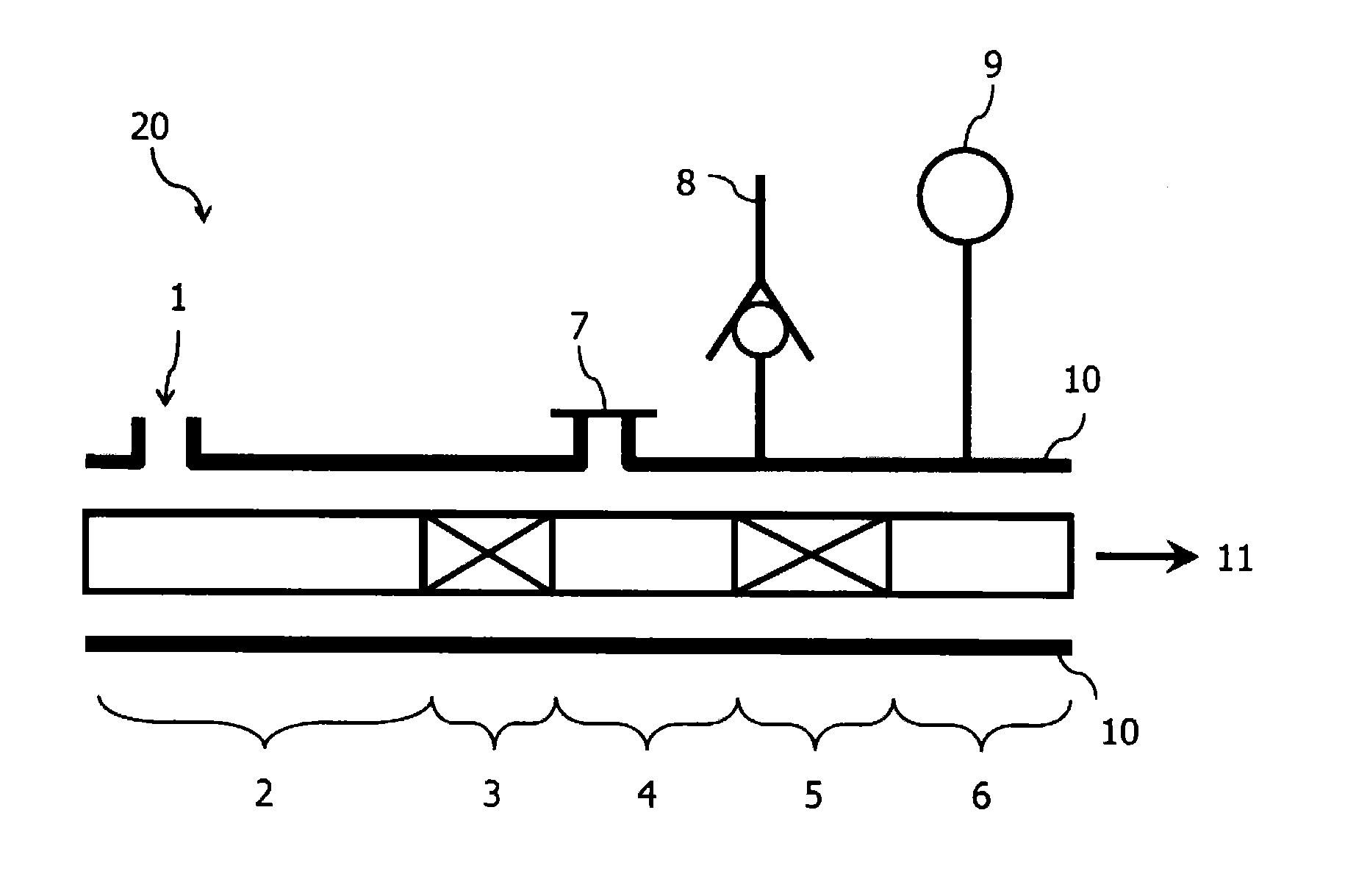

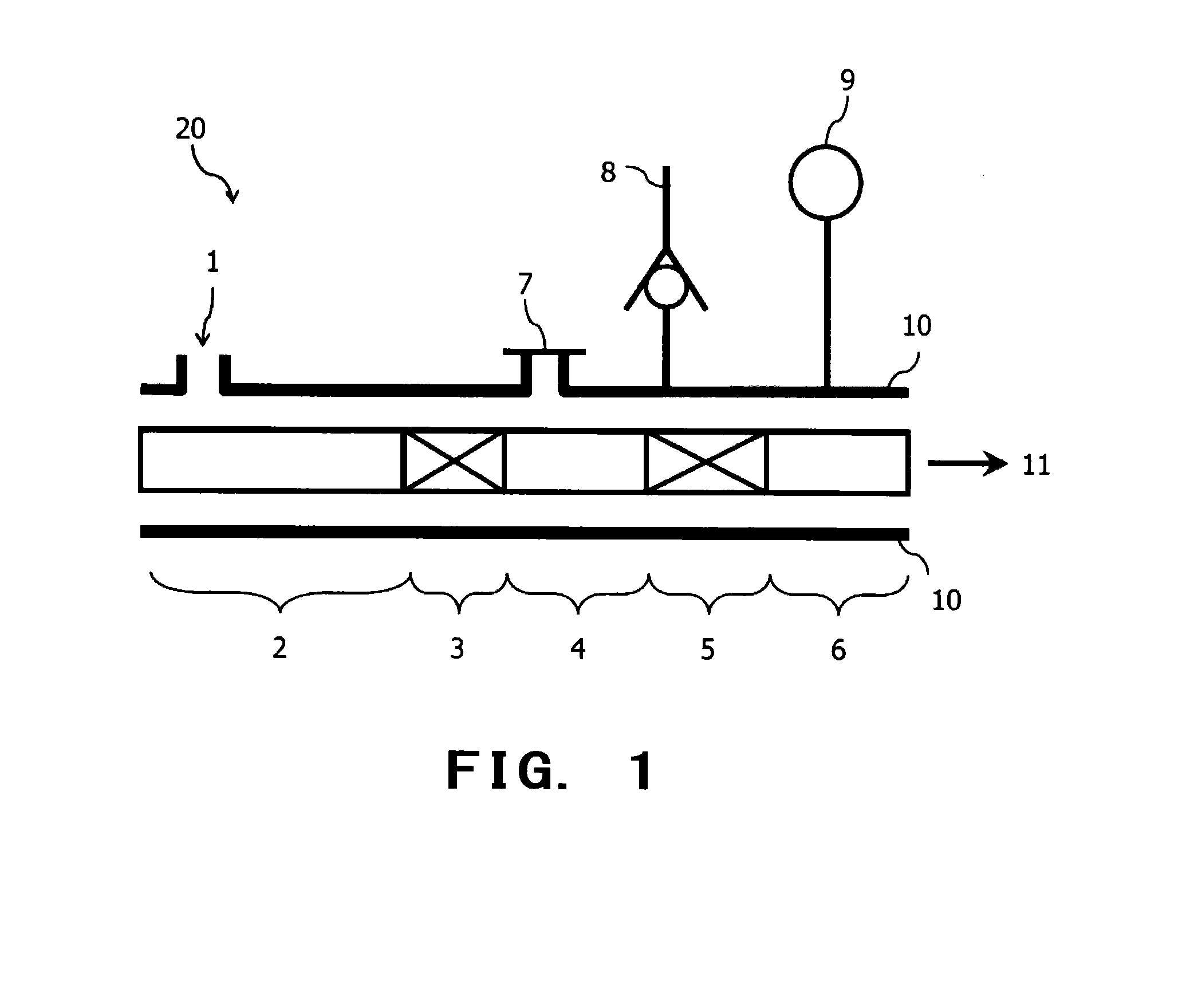

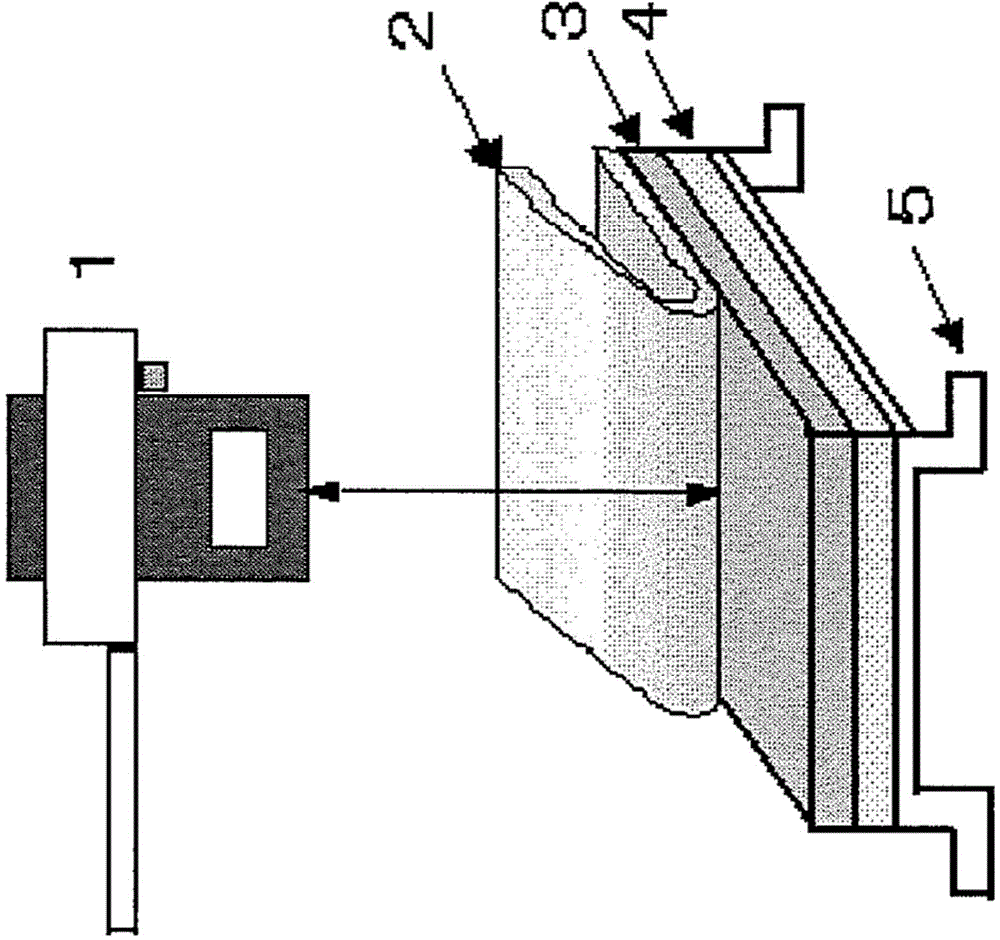

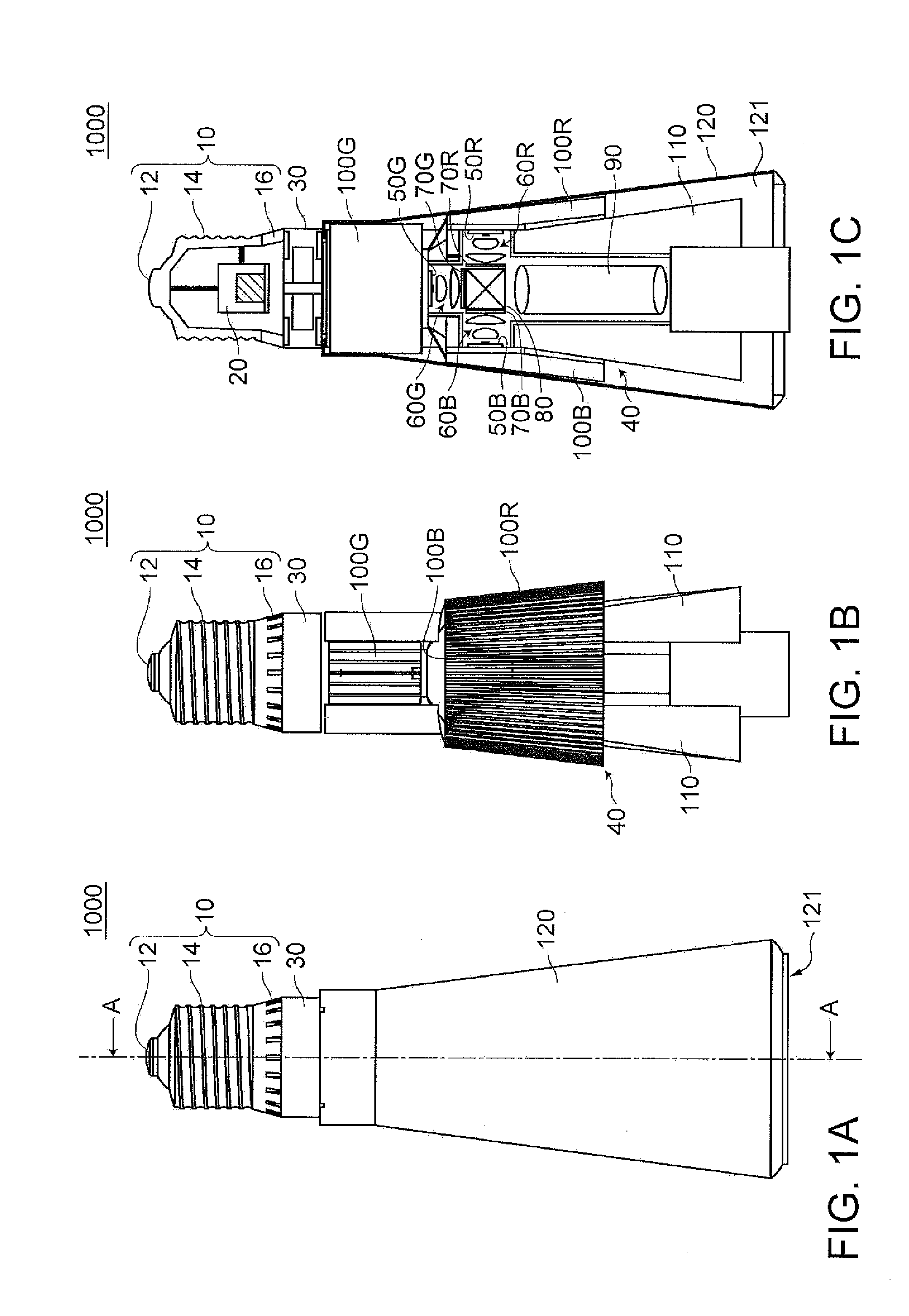

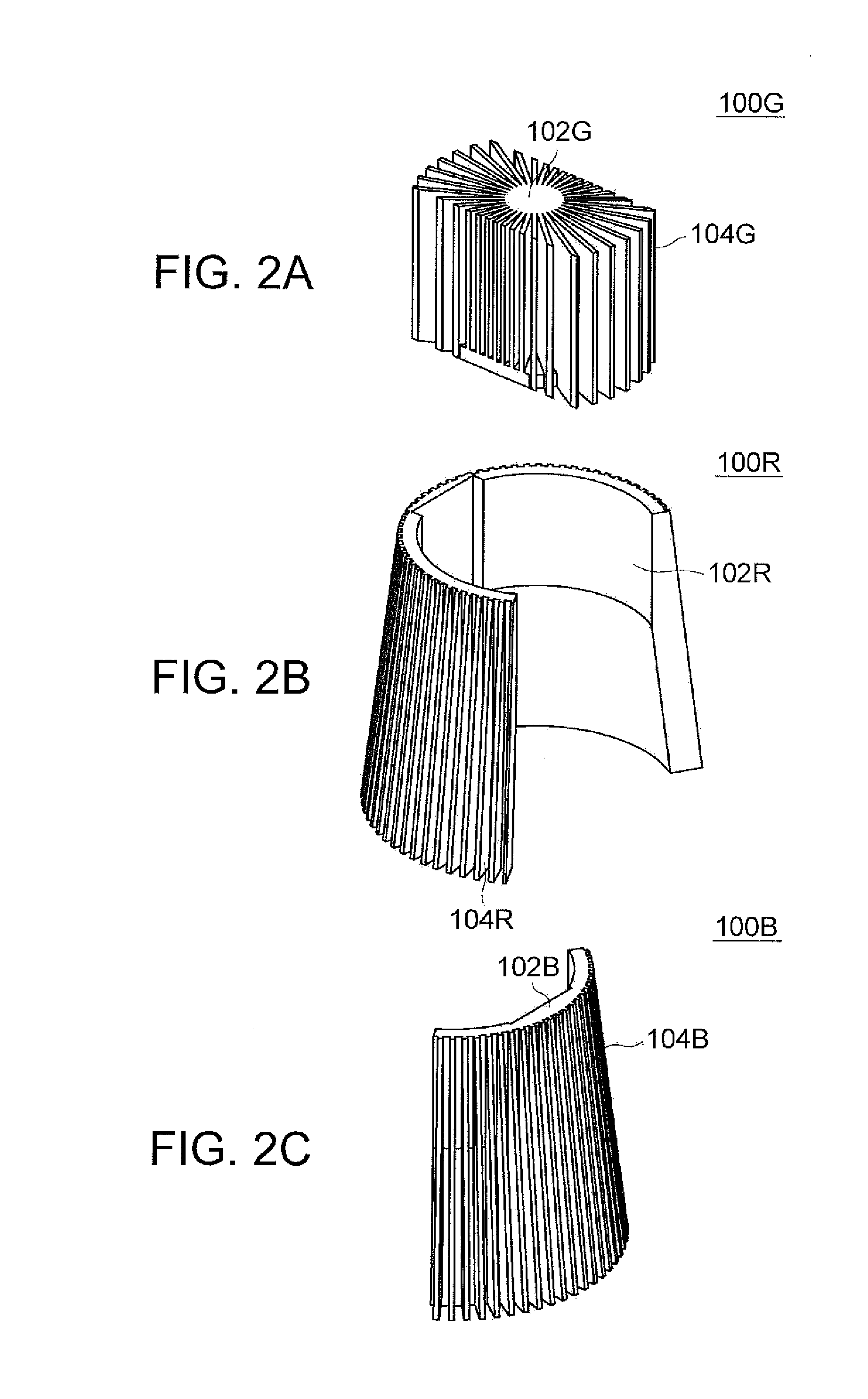

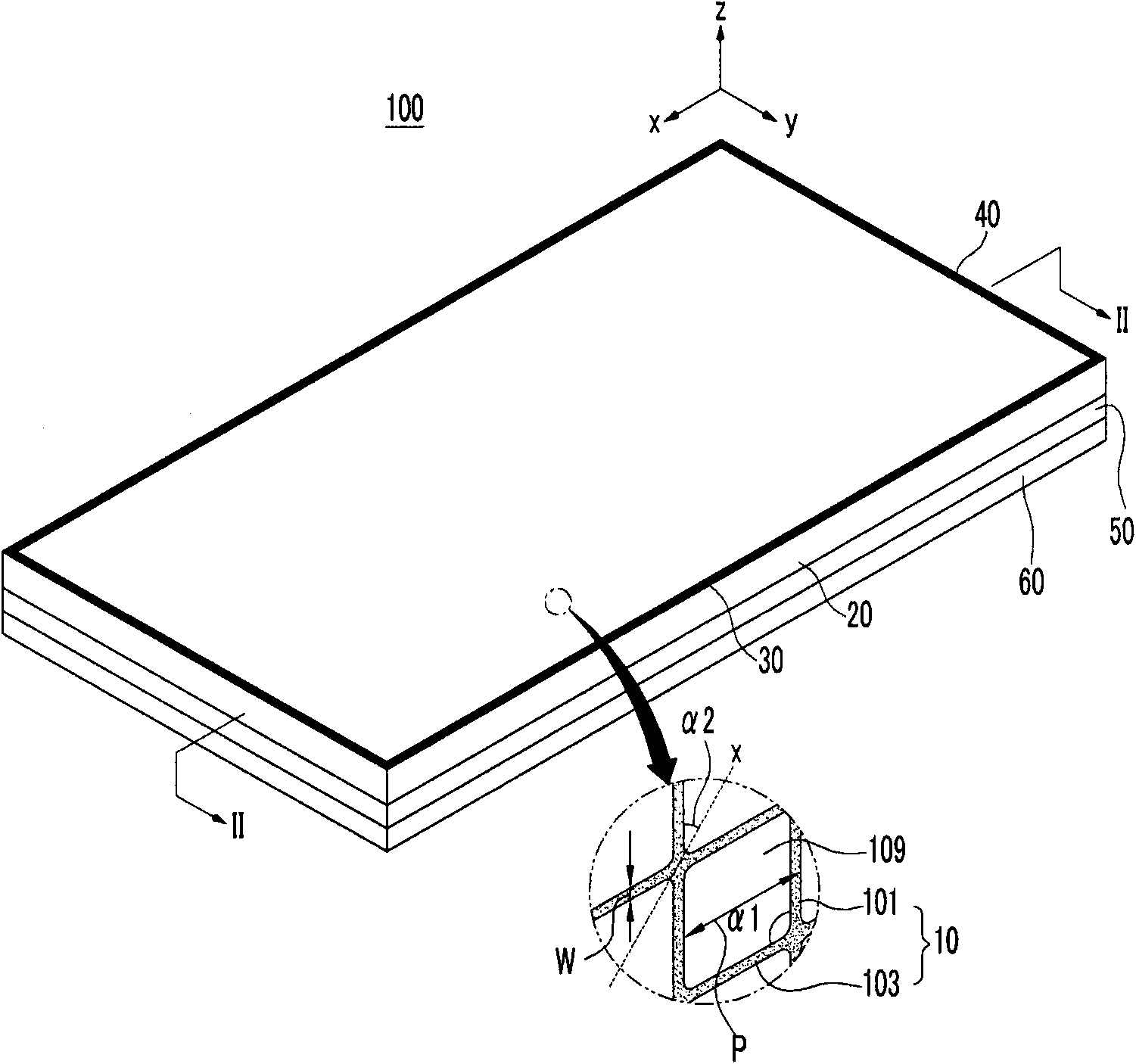

Projector

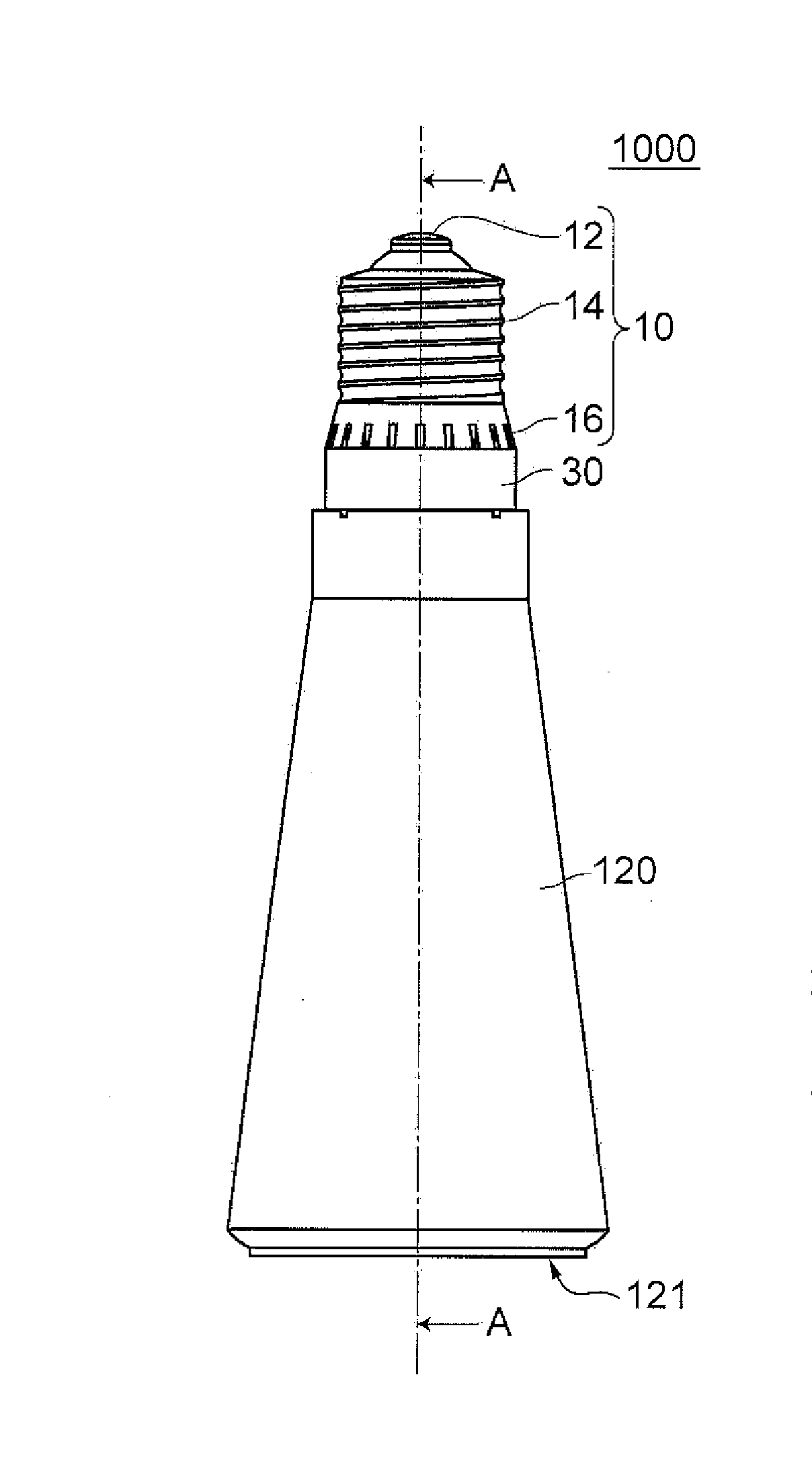

ActiveUS20140139812A1Improve cooling efficiencyExcellent appearance characteristicsProjectorsColor photographyEngineeringElectric power

A projector includes an optical engine unit including a light source unit configured to emit light, a light modulating unit configured to modulate, according to image information, the light emitted from the light source unit, and a projecting unit configured to project the light modulated by the light modulating unit, a connecting unit connectable to a bulb socket, a power supply unit configured to supply electric power received from the connecting unit to the optical engine unit, and a cooling unit arranged between the connecting unit and the optical engine unit and configured to circulate the air to cool the power supply unit and the optical engine unit.

Owner:SEIKO EPSON CORP

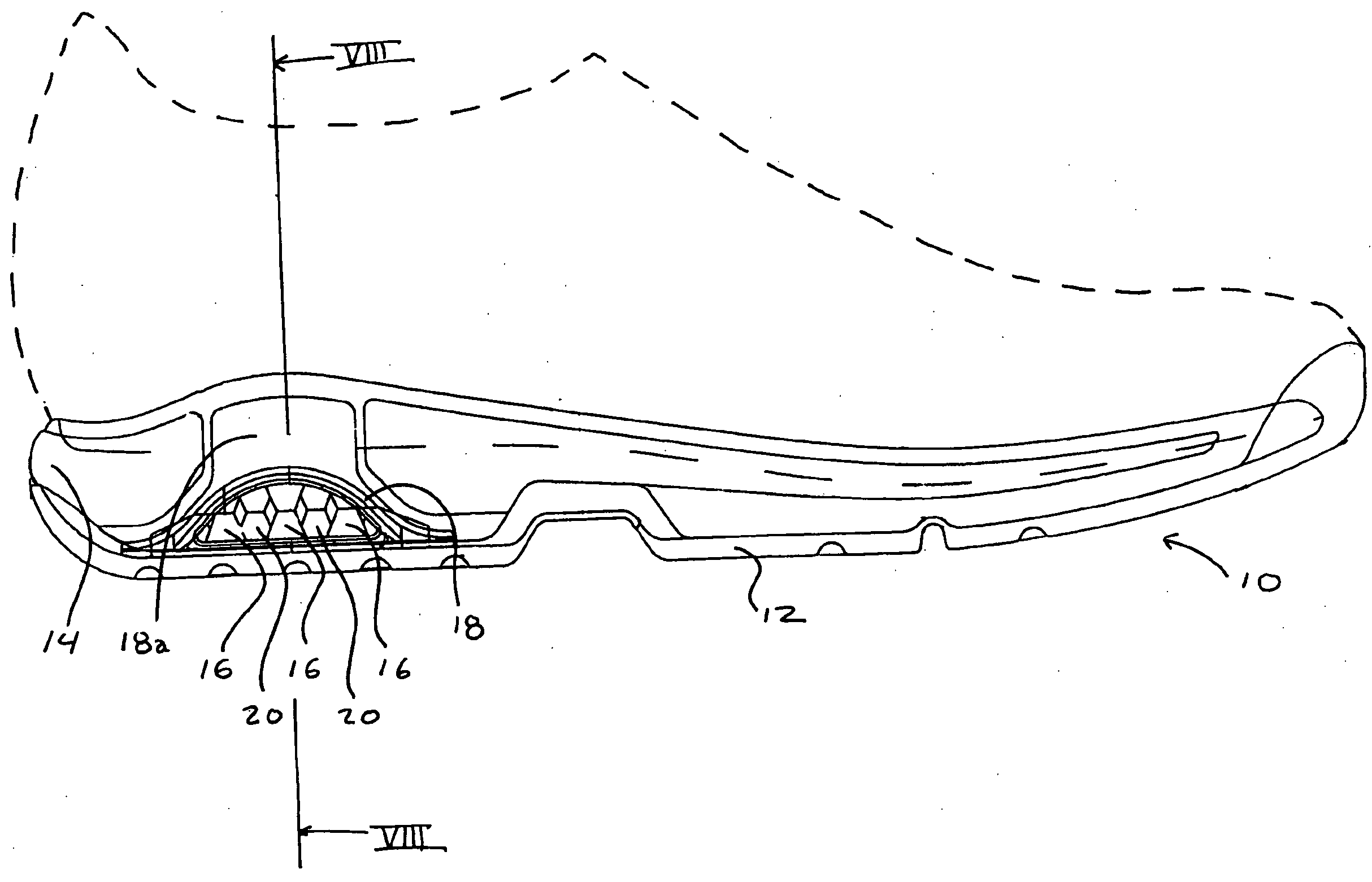

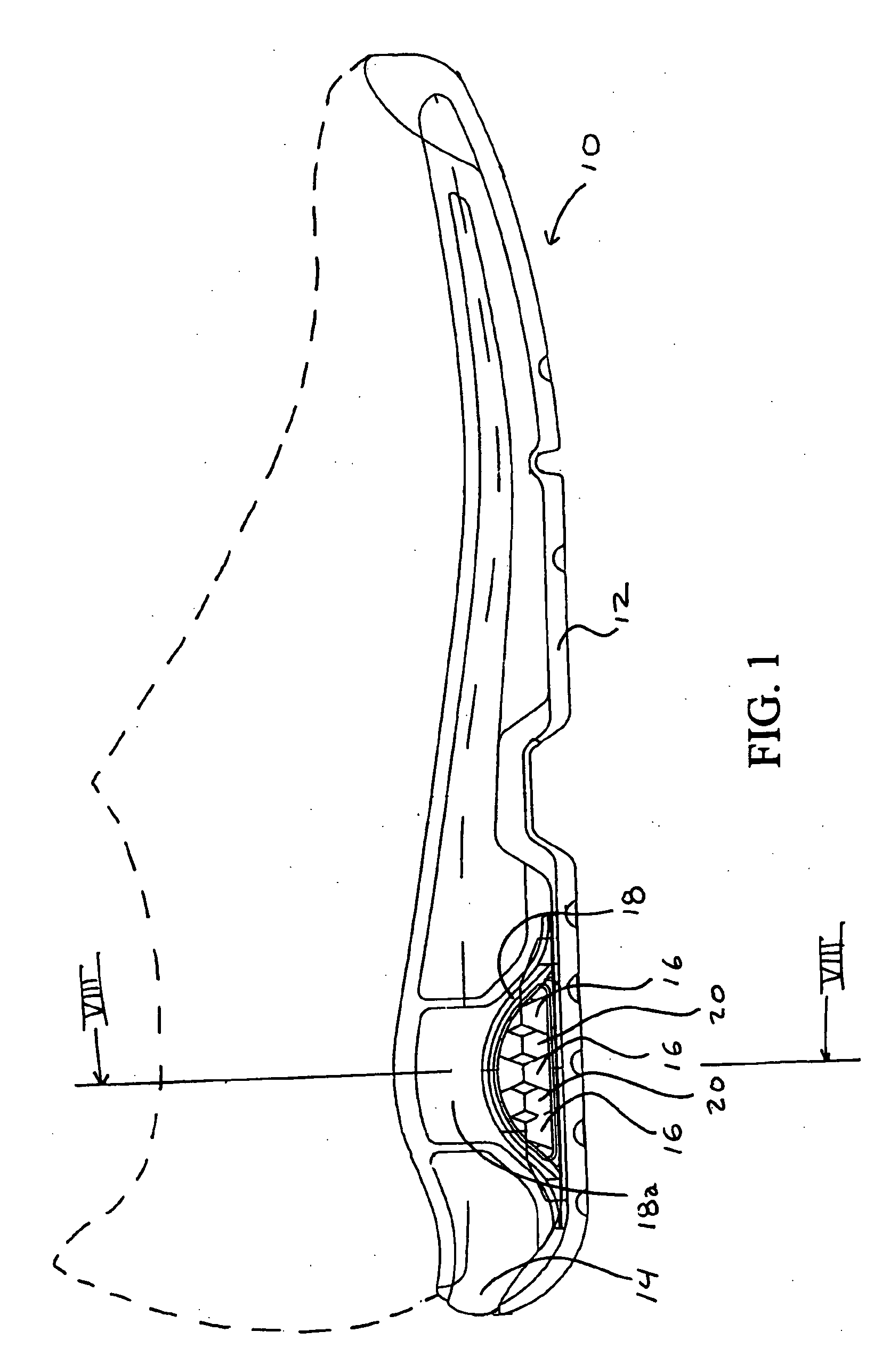

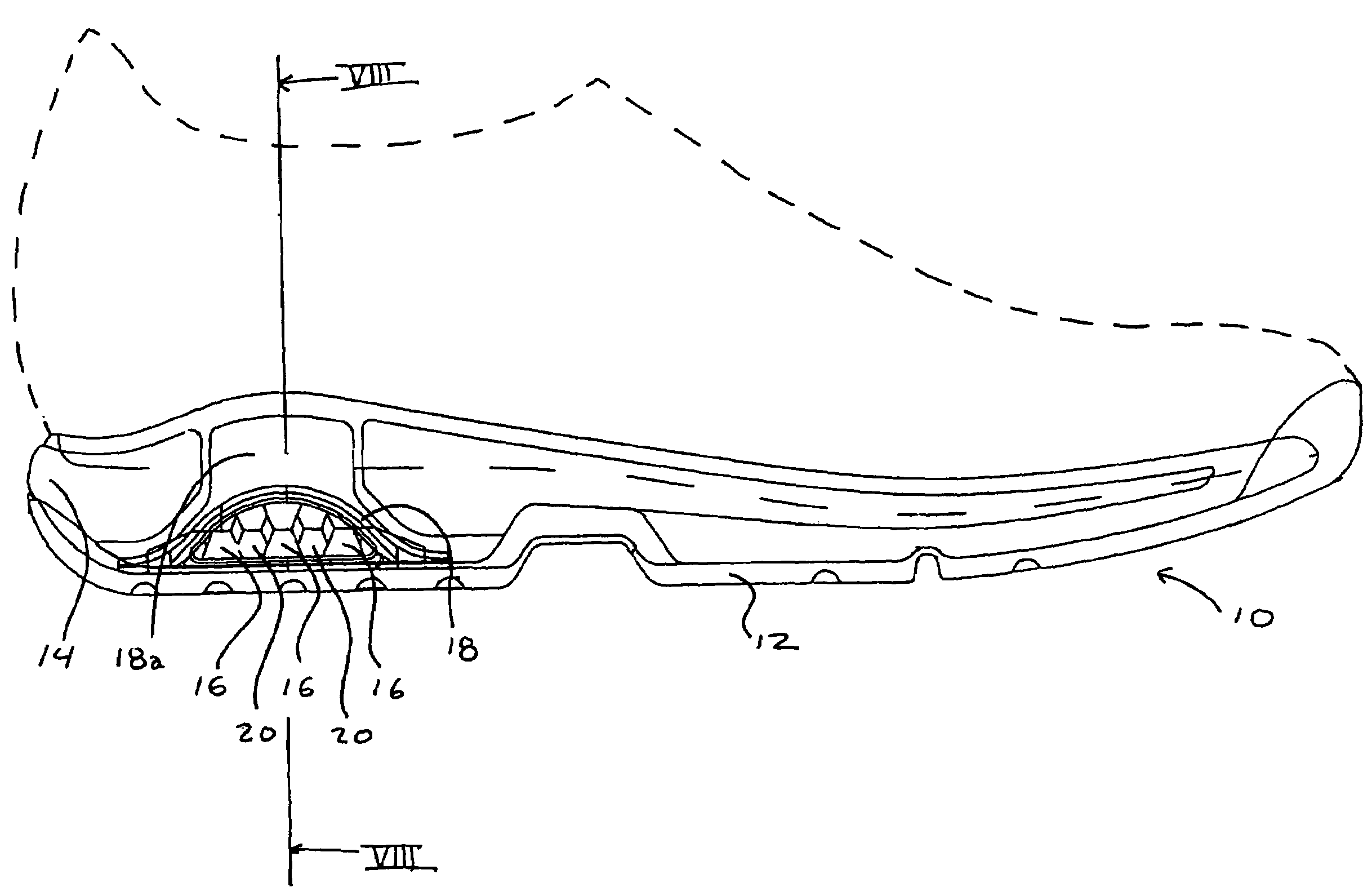

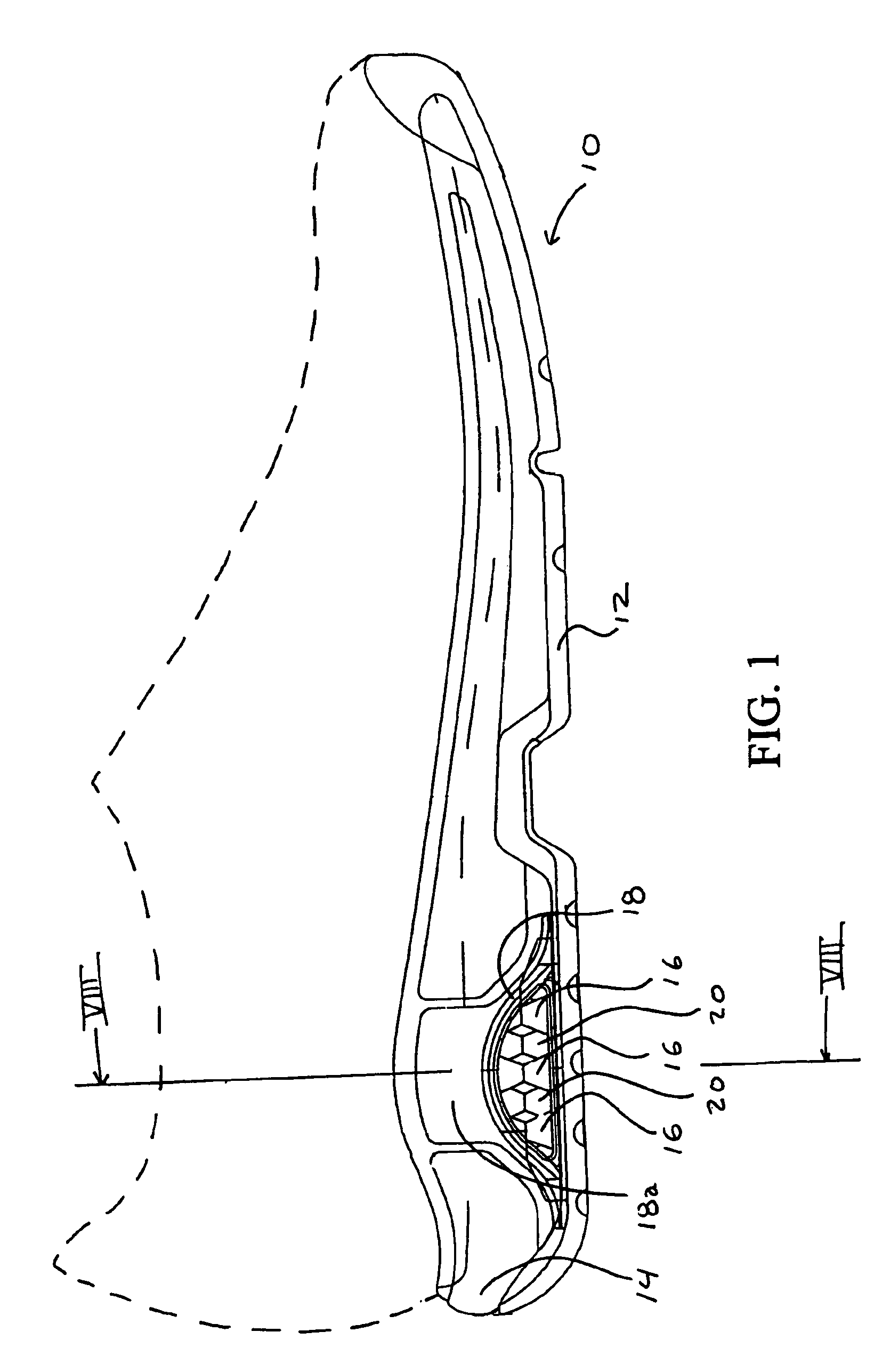

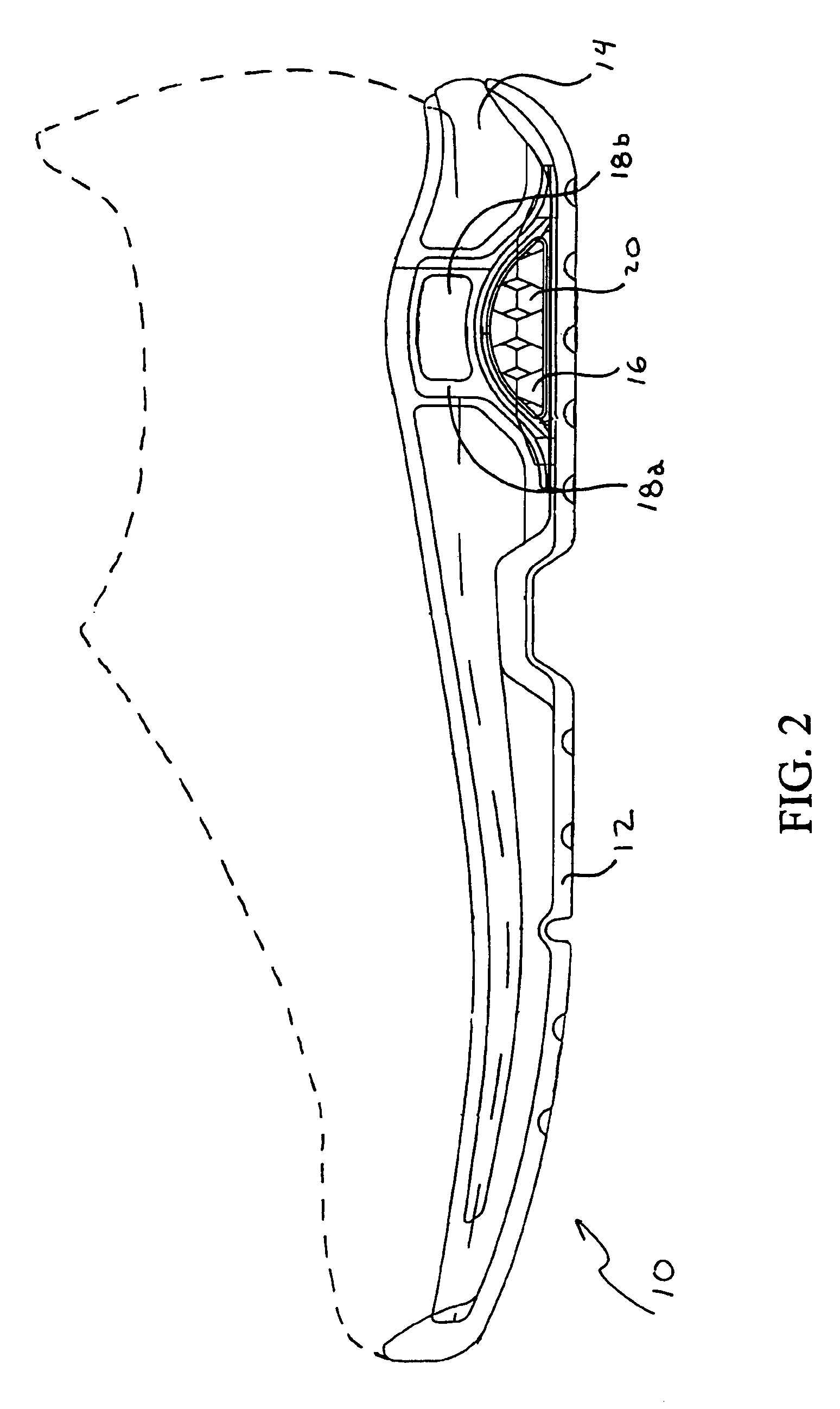

Cushioning assembly in an athletic shoe

An athletic shoe includes a sole assembly and a cushioning arrangement disposed within the sole assembly. The cushioning arrangement includes a cushioning element, and a stiffening spring at least partially surrounding the cushioning element. The spring has a stiffness greater than the cushioning element. The athletic shoe can include a sole assembly having cushioning arrangements provided across a width of the sole assembly. In a preferred arrangement, similar cushioning assemblies are disposed on medial and lateral sides of the shoe, with three additional cushioning assemblies provided between the lateral and medial assemblies. Each of the lateral and medial assemblies can include a stiffening spring that at least partially surrounds at least one cushioning element.

Owner:K-SWISS

Resin composition containing ethylene-vinyl alcohol copolymer

ActiveUS20150105508A1Superior appearance characteristicSuperior long-run workabilitySynthetic resin layered productsAldehydeEthylene vinyl alcohol copolymer

The present invention provides a resin composition containing (A) an ethylene-vinyl alcohol copolymer and (B) an unsaturated aldehyde (B), in which the content of the unsaturated aldehyde (B) with respect to the resin composition containing the ethylene-vinyl alcohol copolymer is 0.01 ppm or more and 100 ppm or less. The unsaturated aldehyde (B) is preferably crotonaldehyde, 2,4-hexadienal, 2,4,6-octatrienal or a combination thereof. In addition, it is preferred that the resin composition further contains a boron compound, and the content of the boron compound is 100 ppm or more and 5,000 ppm or less. Also, it is preferred that the resin composition further contains a conjugated polyene compound, and the content of the conjugated polyene compound is 0.01 ppm or more and 1,000 ppm or less.

Owner:KURARAY CO LTD

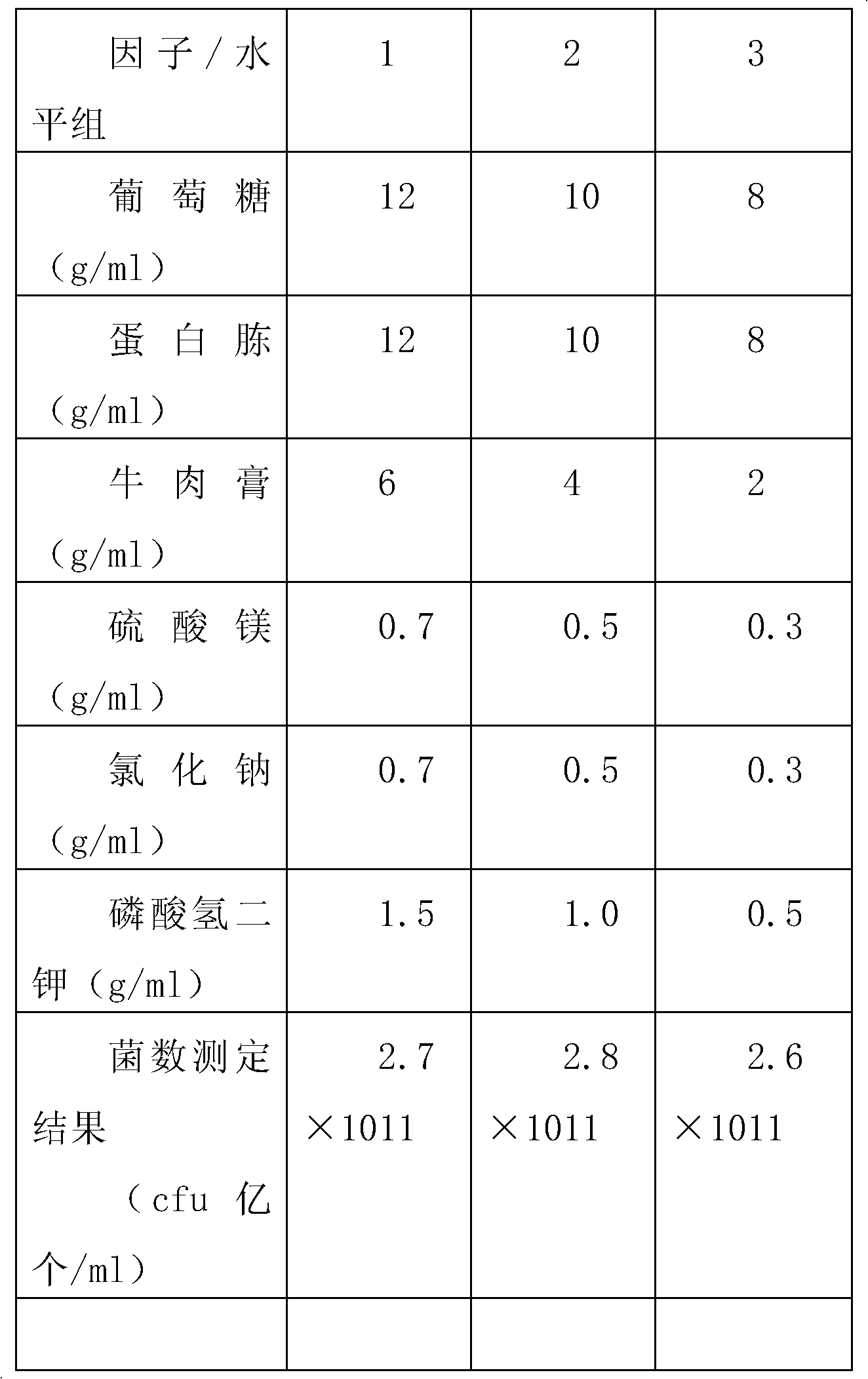

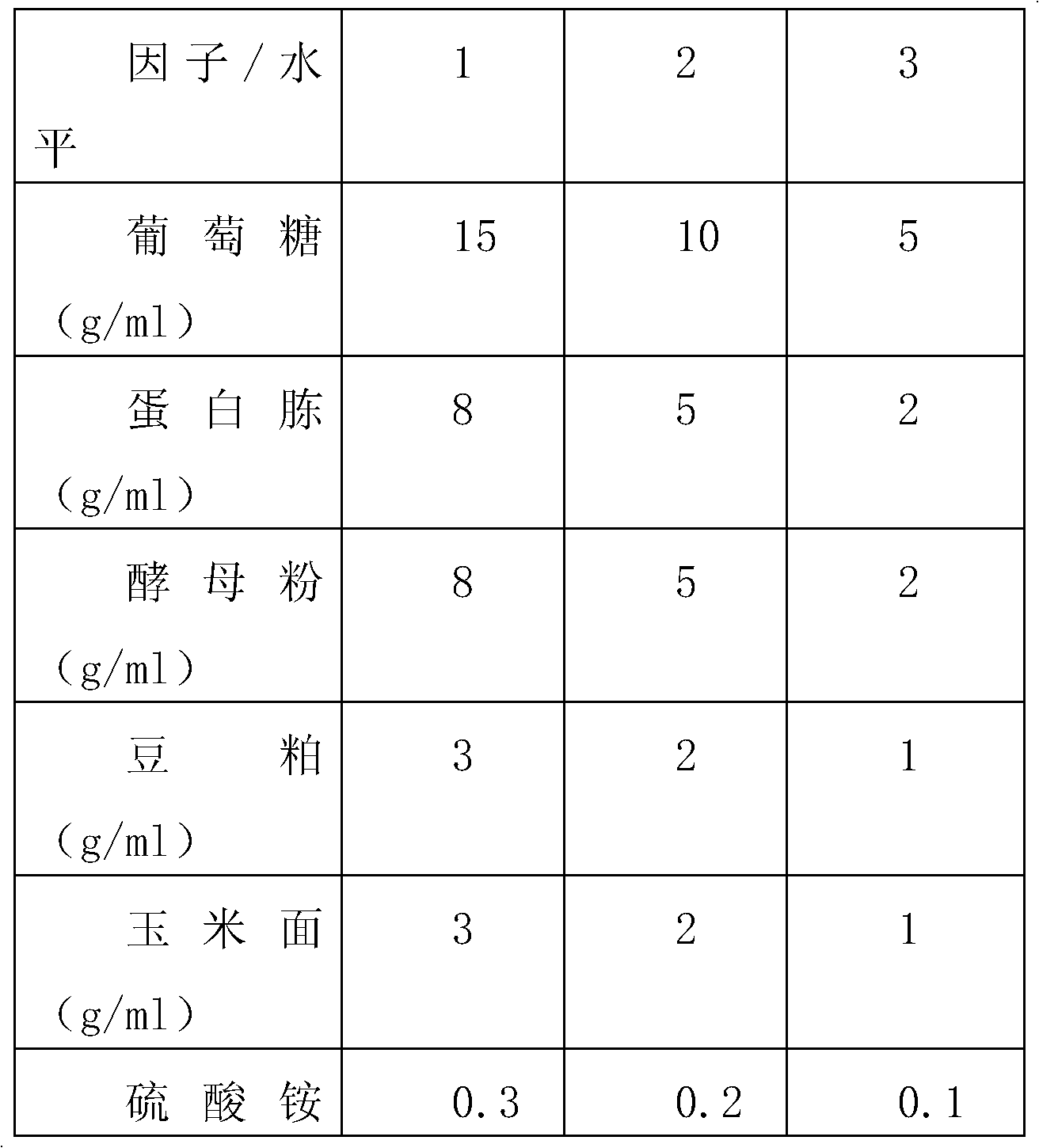

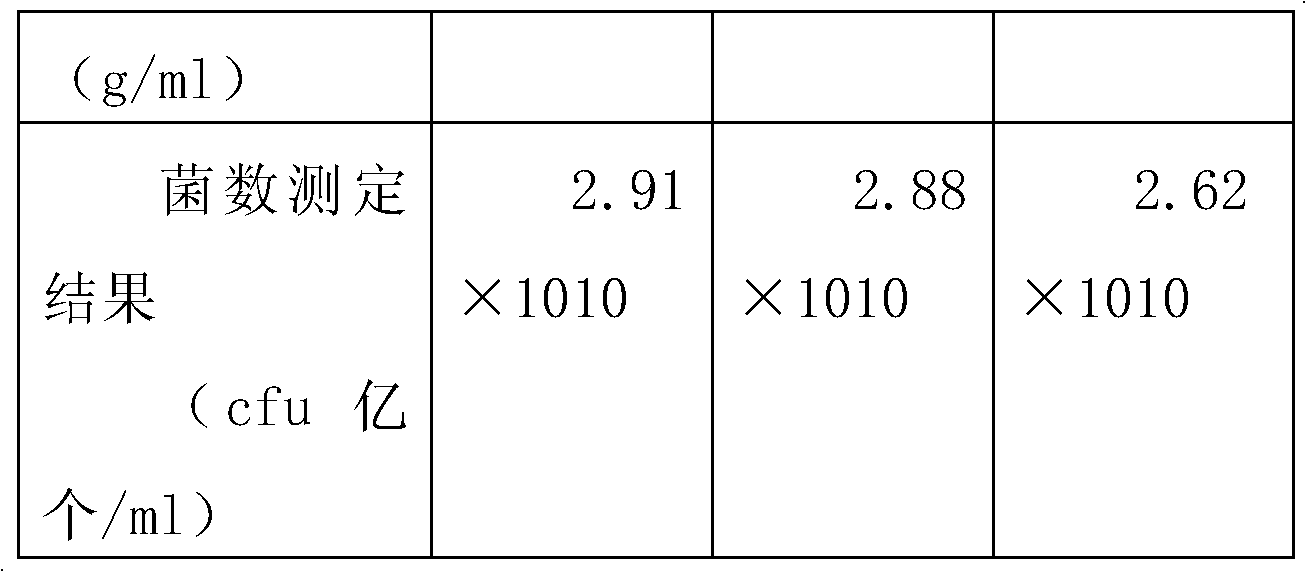

Production method of bacillus subtilis biological agent used for sodium humate-containing feed in medium

ActiveCN103184174AChoose appropriateNew technologyBacteriaAnimal feeding stuffBacterial strainFermentation

The invention relates to a microbe biological agent, and concretely relates to a production method of a bacillus subtilis biological agent used for a sodium humate-containing feed in a medium. The bacillus subtilis bacterial strain is subjected to first-stage solid seed culture and second-stage liquid seed fermentation culture to obtain a bacterial classification liquid. The bacterial classification liquid is inoculated in the medium which takes glucose, sodium humate, soybean meal, corn and wheat bran as raw materials for three-stage solid aerobic fermentation, the culture condition is adjusted to form spore, the spore can be treated, dried, and crushed to produce the bacillus subtilis biological agent. The biological agent contains more than or equal to 200 hundreds million / g of acillus subtilis, the pH value is 5.6-6.6, the moisture is less than or equal to 10%, and the granularity is greater than or equal to 100 meshes, the color presents special shallow grey or grey black, and the shelf life is 18 months. The biological agent can be taken as an additive application in aquatic product, and livestock and poultry culture, can increase the production performance and improve the culture environment.

Owner:SHENYANG BOSHAN YINGSHENG BIOLOGICAL TECH CO LTD

Cushioning assembly in an athletic shoe

Owner:K-SWISS

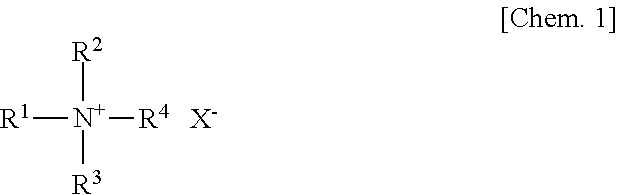

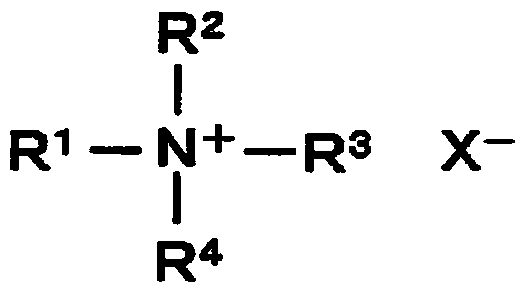

Re-peelable aqueous dispersion-type acrylic adhesive composition and adhesive sheet

InactiveCN103930508AImprove anti-static effectImprove adhesionNon-macromolecular adhesive additivesFilm/foil adhesivesEmulsionHigh humidity

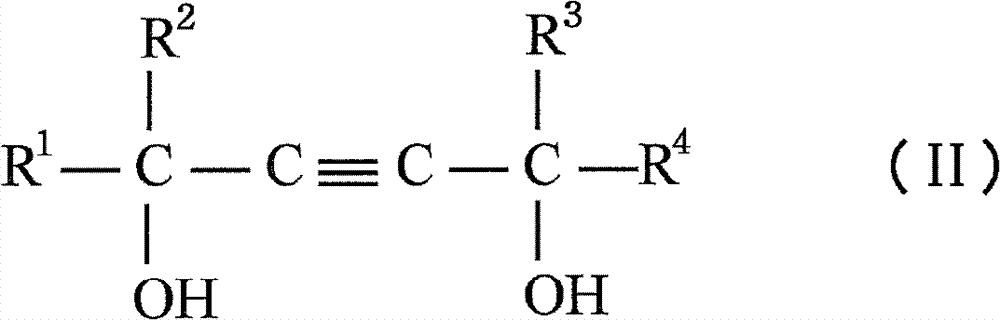

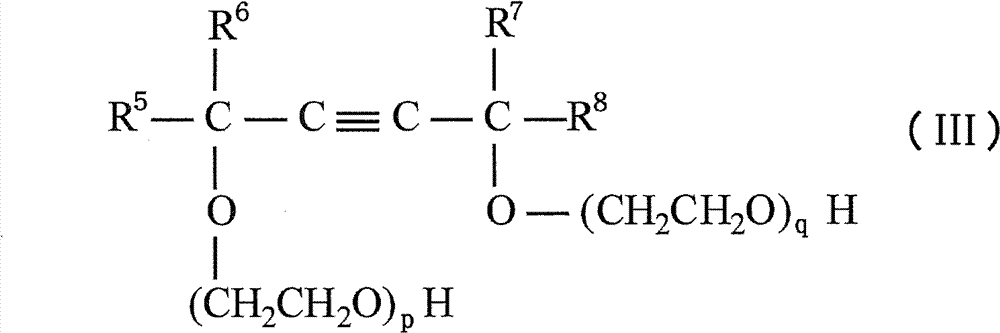

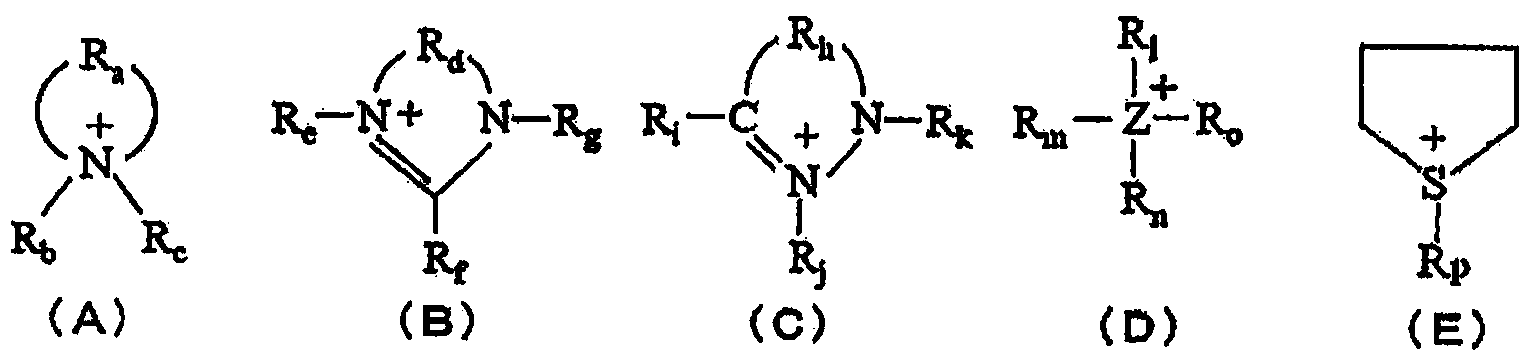

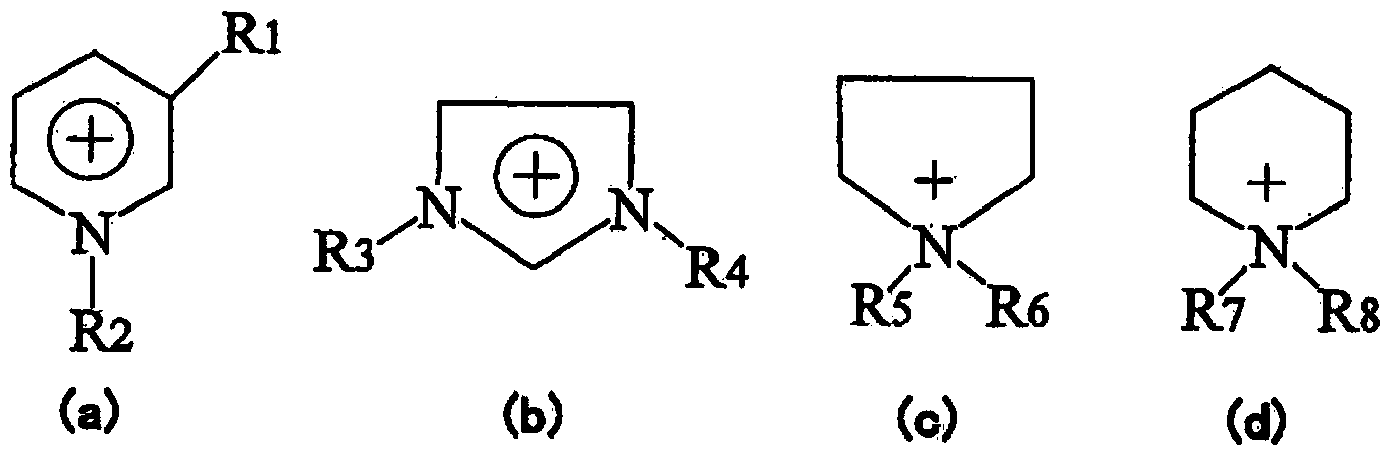

Provided is a re-peelable aqueous dispersion-type acrylic adhesive composition with which it is possible to form an adhesive layer that has excellent antistatic performance, adhesion properties, re-peelability, peeling stability, resistance to a rise in adhesive force, resistance to the formation of marks on an object to be adhered, particularly resistance to the formation of white marks (white mark resistance) on an object to be adhered under high-humidity conditions, and excellent appearance properties. This re-peelable aqueous dispersion-type acrylic adhesive composition is characterized by containing an acrylic emulsion polymer formed from 70 to 99.5 wt% of a (meth)acrylic acid alkyl ester and 0.5 to 10 wt% of a carboxyl group-containing unsaturated monomer as the monomer units; an ionic compound; and a polyether-type defoaming agent represented by the following formula (I). (I) HO-(PO)n1-(EO)m1-H [In formula (I), PO is an oxypropylene group, EO is an oxyethylene group, m1 is an integer between 0 and 40, n1 is an integer of at least 1, and the form of addition of EO or PO is random or block.]

Owner:NITTO DENKO CORP

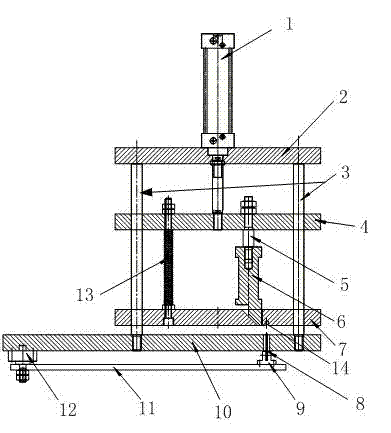

Hot sealing and cold cutting device for plastic film bag making machine

InactiveCN102529160ASimple methodExcellent appearance characteristicsPaper-makingBox making operationsEngineeringPlastic film

The invention provides a hot sealing and cold cutting device for a plastic film bag making machine, which comprises an upper fixing plate, a lower fixing plate and a cylinder. The cylinder is fixed to the upper end of the upper fixing plate, two ends of the upper fixing plate are fixed onto the lower fixing plate by mounting guide rods, an upper movable plate and a lower movable plate which are capable of sliding and are spaced from each other are disposed on the guide rods, the upper movable plate is fixed to a piston rod of the cylinder, the distance between the same sides of the upper movable plate and the lower movable plate is fixed by a spring hanger rod, a hot sealing cutter device is arranged in a gap between the other same sides of the upper movable plate and the lower movable plate, a hot sealing cutter of the lower end of the hot sealing cutter device matches with a hot sealing cutting edge disposed on the lower movable plate, a blade groove is arranged at the lower end of the lower movable plate, a cutter saddle oscillating bar is mounted on a rotary driver and extends to a blade through hole, the lower end of a cutter saddle is fixed onto the cutter saddle oscillating bar, the upper end of the cutter saddle is attached to the lower end of the lower fixing plate, a blade is mounted on the cutter saddle, and the top end of the blade is protruded out of the blade through hole. Cutting and sealing can be completed on the same device, and work efficiency can be effectively improved.

Owner:冯春

Automotive container holding apparatus

ActiveUS20060113311A1Reduce the overall heightStably a tall containerVehicle arrangementsTravelling carriersEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

Adhesive sheet

ActiveCN103476890AImprove scratch resistanceImprove anti-static effectNon-macromolecular adhesive additivesAcid polymer adhesivesMeth-Acrylic resin

Provided is a removable adhesive sheet that is highly scratch-resistant, is resistant to whitening (moisture-absorption whitening) when stored in humid conditions, and has excellent appearance characteristics and antistatic performance. Said pressure-sensitive adhesive sheet has an acrylic adhesive layer on at least one surface of a transparent film substrate and is characterized in that: said transparent film substrate has a base layer comprising a resin material and a top-coat layer provided on a first surface of said base layer; said top-coat layer comprises a polythiophene, an acrylic resin, and a melamine cross-linker, with the average thickness (Dave) of said top-coat layer being 2 to 50 nm and the amount of variation ([delta]D) in said thickness being no more than 40%; and the aforementioned acrylic adhesive layer is formed from a water-dispersed acrylic removable adhesive composition containing an acrylic emulsion polymer that is polymerized using a reactive emulsifier containing a radical-polymerizable functional group and comprises feedstock monomers including an alkyl (meth)acrylate ester (A) and a carboxyl-group-containing unsaturated monomer (B), with said alkyl (meth)acrylate ester (A) constituting 70% to 99.5% and said carboxyl-group-containing unsaturated monomer (B) constituting 0.5% to 10% of the total weight of the feedstock monomers.

Owner:NITTO DENKO CORP

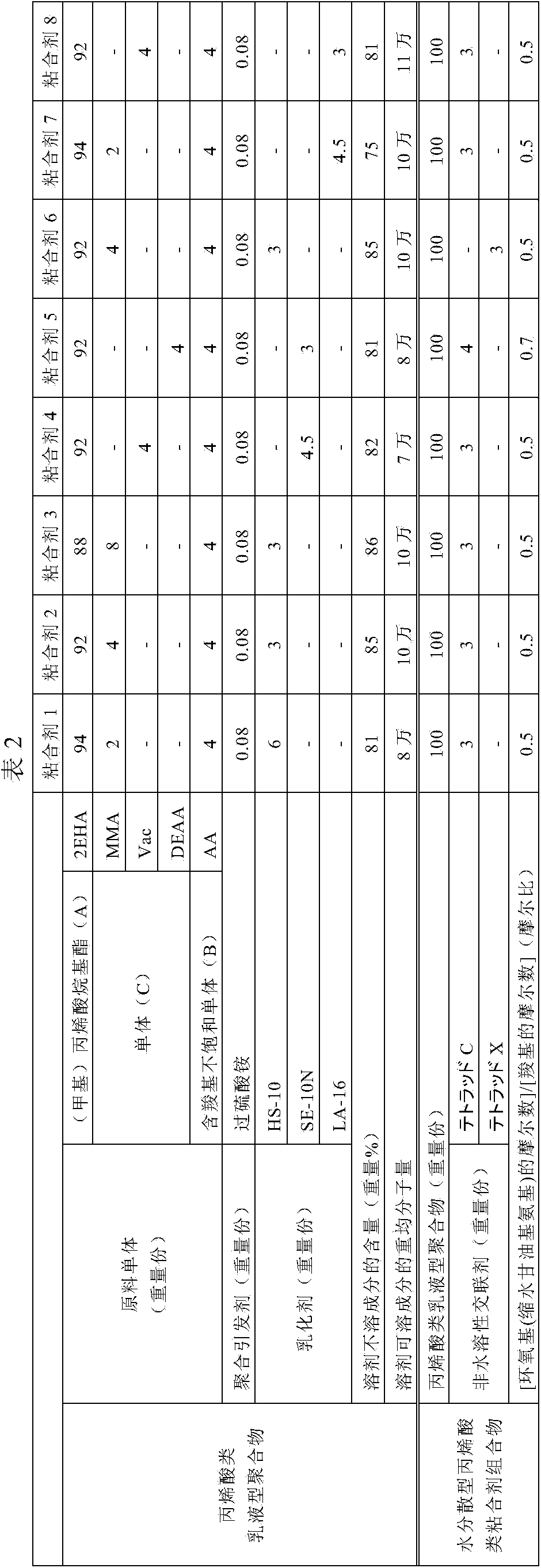

Electromagnetic wave preventing filter, manufacturing method thereof and display comprising the filter

InactiveCN101600332AReduce reflectionReduce the problem of poor moisture resistanceMagnetic/electric field screeningScreening apparatusElectromagnetic electron waveDisplay device

The present invention relates to an electromagnetic wave preventing filter and a display with the same. The electromagnetic wave preventing filter comprises the following components: a transparent strengthened glass substrate which has a tin surface with more tin abundance and has an air surface with less tin abundance compared with the tin surface; and an electromagnetic wave shielding part which is formed on the tin surface of the transparent strengthened substrate with a screen mesh shape. The filter is used for shielding the electromagnetic wave in a plasma display panel. Furthermore the external light reflection can be reduced and the blackness can be increased according to appropriate yellowing phenomenon of the conductive metal in the tin surface and the electromagnetic shielding part. Additionally the wet fastness problem can be reduced furthest even the printing layer in the final product is exposed in the external gas environment.

Owner:DONGJIN SEMICHEM CO LTD

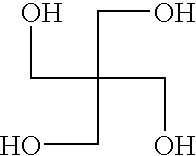

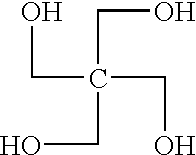

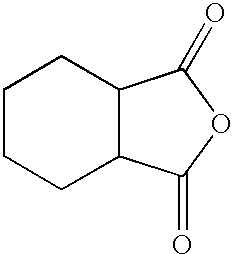

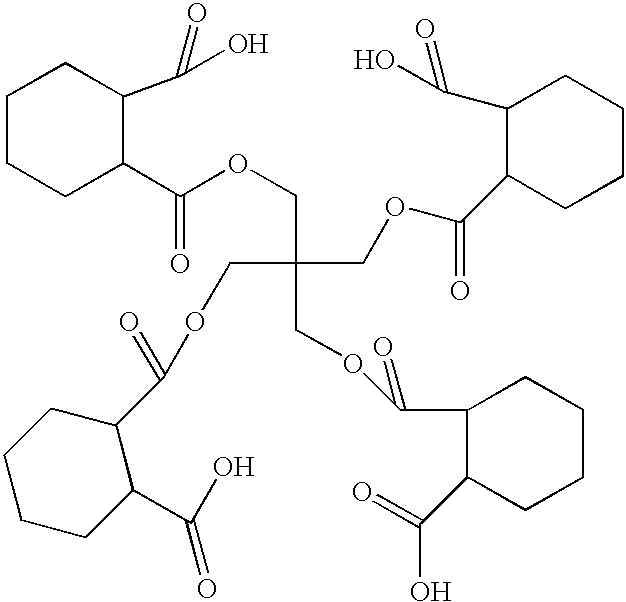

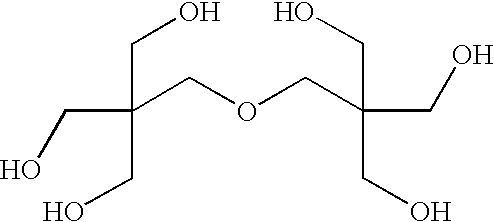

Polymeric pigment dispersant utilized as a grind resin for pigments and method of preparing the same

InactiveUS6657002B2Enough timeIncreased pigment-to-binder ratioTransportation and packagingOrganic dyesPolyesterPentaerythritol

The present invention is directed to a polyester carboxylate polymeric pigment dispersant to be used as a grind resin to incorporate inorganic pigment into a pigment dispersion for a coating composition. The polymeric pigment dispersant is the reaction product of pentaerythritol, hexahydrophthalic anhydride, glycidylneodecanoate, and dimethylethanolamine. The present invention is also directed to a method of preparing the polymeric pigment dispersant. In this method, the pentaerythritol and the hexahydrophthalic anhydride are polymerized to form an intermediate compound. Next, an epoxy group of the glycidylneodecanoate reacts with the intermediate compound, and then the dimethylethanolamine neutralizes the intermediate compound to form the completed polymeric pigment dispersant. The polymeric pigment dispersant is utilized for efficient wetting and grinding of the pigment.

Owner:BASF CORP

Non-pollution, natural and multi-functino elastic health-care underclothes

A health-care and multifunctional elastic underwear is prepared from the negative-ion far infrared viscose fibers made of Chinese medical stone, natural cotton fibers and elastic fibers through blending or interweaving. Its advantages are sure medical, physiotherapeutic and health-care functions, better comfortability, hydroscopicity, air permeability and elasticity, and not deforming.

Owner:TIANJIN JIANLONG TECH

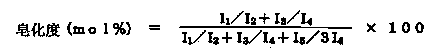

Method for producing ethylene-vinyl alcohol copolymer resin, ethylene-vinyl alcohol copolymer resin, and multilayer structure

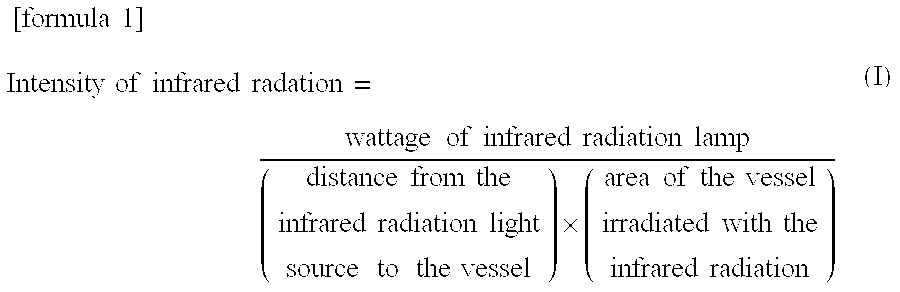

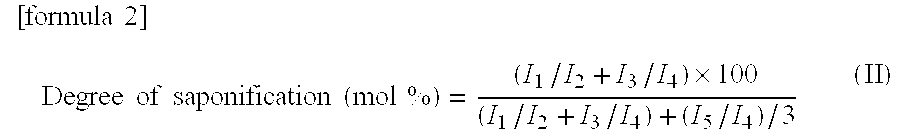

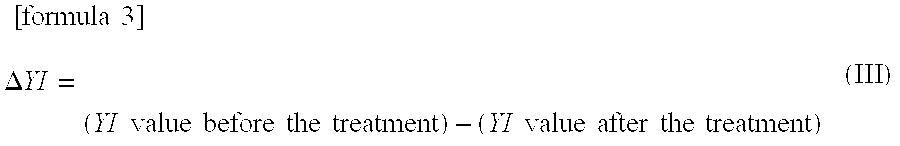

ActiveUS20120248640A1Improve performanceAvoid it happening againNon-woven fabricsElectric/magnetic/electromagnetic heatingVinyl esterEthylene

Provided is by the present invention is a method for producing an EVOH resin having sufficient long-run workability in melt molding and enabling prevention of coloring such as yellowing, an EVOH resin obtained by this method for production, and a laminate obtained from this resin.The present invention is a method for producing an ethylene-vinyl alcohol copolymer resin, the method including a step of saponifying an ethylene-vinyl ester copolymer to obtain an ethylene-vinyl alcohol copolymer, in which the method is characterized by further including a step of irradiating the ethylene-vinyl ester copolymer or the ethylene-vinyl alcohol copolymer with an infrared ray.

Owner:KURARAY CO LTD

Polymeric pigment dispersant utilized as a grind resin for pigments and method of preparing the same

InactiveUS6849686B2Improve stabilityEffectively wettedOrganic chemistryOther chemical processesPolymer scienceHexahydrophthalic anhydride

The present invention is directed to a polymeric pigment dispersant to be used as a grind resin to incorporate pigment into a pigment dispersion for a coating composition. The polymeric pigment dispersant is the reaction product of dipentaerylthritol, hexahydrophthalic anhydride, glycidylneodecanoate, dimethylethanolamine, and polyphosphoric acid. The present invention is also directed to a method of preparing the polymeric pigment dispersant. In this method, the dipentaerythritol and the hexahydrophthalic anhydride are polymerized to form an intermediate compound. Next, an epoxy group of the glycidylneodecanoate reacts with the intermediate compound, and then the dimethylethanolamine salts the intermediate compound. Finally, the polyphosphoric acid is added to form the completed polymeric pigment dispersant. The polymeric pigment dispersant has improved stability in the pigment dispersion and is utilized for efficient wetting and grinding of the pigment in the pigment dispersion.

Owner:BASF CORP

Removable water-dispersible acrylic pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet

ActiveCN102676094AExcellent peelabilityGood adhesionAcid polymer adhesivesEster polymer adhesivesPolymer scienceWater dispersible

A removable water-dispersible acrylic pressure-sensitive adhesive composition according to the present invention includes an acrylic emulsion polymer (A), a water-insoluble crosslinking agent (B), and a carboxylic-acid-containing acrylic polymer (C). The polymer (A) includes a (meth)acrylic alkyl ester and a carboxyl-containing unsaturated monomer as essential constitutive monomers and has a content of the (meth)acrylic alkyl ester of 70 to 99.5 percent by weight and a content of the carboxyl-containing unsaturated monomer of 0.5 to 10 percent by weight, each based on the total amount of constitutive monomers. The polymer (C) includes (meth)acrylic acid as an essential constitutive monomer and has a total content of acrylic acid and methacrylic acid of 11 percent by weight or more based on the total amount of constitutive monomers.

Owner:NITTO DENKO CORP

Flame retardant polycarbonate resin composition

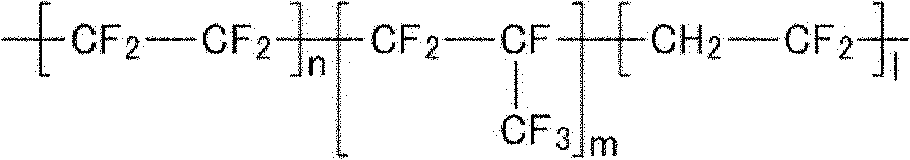

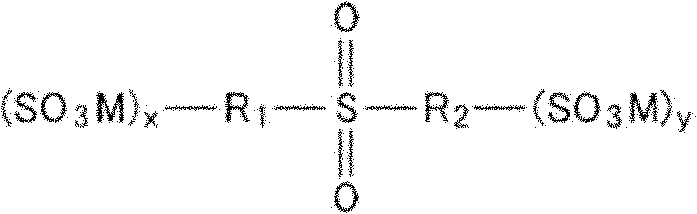

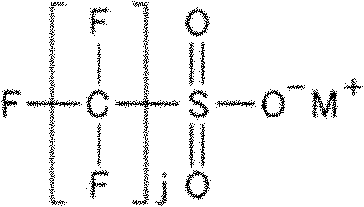

InactiveCN102027064AImprove flame retardant performanceImprove heat resistanceHeat resistancePolycarbonate

The flame retardant polycarbonate resin composition of the present invention includes (A) a polycarbonate resin, (B) a rubber-modified vinyl-based graft copolymer, (C) a metal salt of sulfonic acid, and (D) an anti-drip agent including a fluorinated terpolymer. The polycarbonate resin composition of the present invention has excellent flame retardancy, heat resistance, and mechanical strength, well-balanced mechanical properties such as impact resistance, heat resistance, and fine workability, and an excellent appearance characteristic. Therefore, it is useful for fabrication of molded products such as electric household appliances, office appliances, electrical and electronic devices, and internal parts thereof.

Owner:CHEIL IND INC

Multi-curative-effect external ointment and preparation method thereof

InactiveCN108451781ASoft textureExcellent moist feelingCosmetic preparationsAntipyreticSolubilityMicrocrystalline wax

The invention discloses a multi-curative-effect external ointment and a preparation method thereof. The external ointment is prepared from, by weight, vaseline, white oil, beewax, microcrystalline wax, menthol, american vine fruit oil, borneol, wintergreen oil, eucalyptus oil, symsitive, camphor, symrelief, mint essence, powder essence and the like. Every three components are mixed, heated, melted, evenly stirred, cooled and then poured into a mixing tank, and then the mixtures continue to be stirred till all the materials are fully mixed. The ointment is fine in compounding, soft in texture and obvious in wet feeling, the solubility of all kinds of grease is enhanced, and the antibacterial and anti-corrosion effects are achieved; the use comfort is improved while the product stability isimproved, the ointment has the effects of caring skin, resisting allergy, being cool, stopping itching, relieving swelling and pain, refreshing and restoring consciousness, moistening and moisturizingthe skin, activating subcutaneous microcirculation, forming a protective film on the skin surface, preventing the loss of water and functional substances, fixing the medicinal components and enhancing the overall curative effect. The method is simple in preparation process, low in production cost and low in investment risk.

Owner:SOUTH CHINA AGRI UNIV

Positive-type photosensitive resin composition and cured film prepared therefrom

InactiveUS20200407510A1Improve solubilityEnhancing pattern developabilityCoatingsPhotosensitive materials for photomechanical apparatusRough surfacePolymer science

The present invention relates to a positive-type photosensitive resin composition and a cured film prepared therefrom. The positive-type photosensitive resin composition introduces a multifunctional monomer into a positive-type photosensitive resin composition comprising a mixed binder in which a siloxane copolymer is added to an acrylic copolymer, whereby the penetration of a developer into the binder can be facilitated at the time of development of a pre-baked film to increase the solubility in the developer, thereby further enhancing the pattern developability and sensitivity. Further, a cured film prepared from the composition has excellent appearance characteristics without a rough surface of the film and a scum or the like at the bottom of the film during development.

Owner:ROHM & HAAS ELECTRONICS MATERIALS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com