Removable water-dispersible acrylic pressure-sensitive adhesive composition and pressure-sensitive adhesive sheet

An acrylic, dispersion-type technology, applied in the direction of acid copolymer adhesives, adhesive types, ester copolymer adhesives, etc., can solve the adverse effects of optical properties of optical components, difficulty in inspection of adherends, contamination and other problems, to achieve the effects of excellent re-peelability, inhibition of adhesion increase over time, and low contamination.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

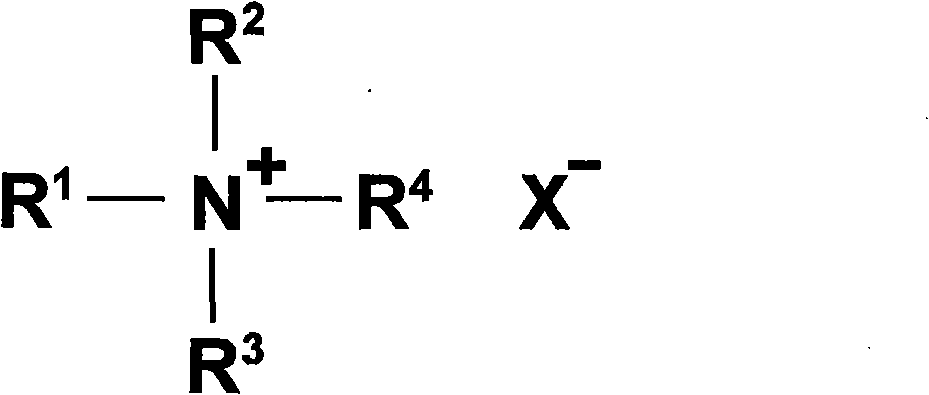

Method used

Image

Examples

Embodiment 1

[0135] (Preparation of Acrylic Emulsion Polymer (A))

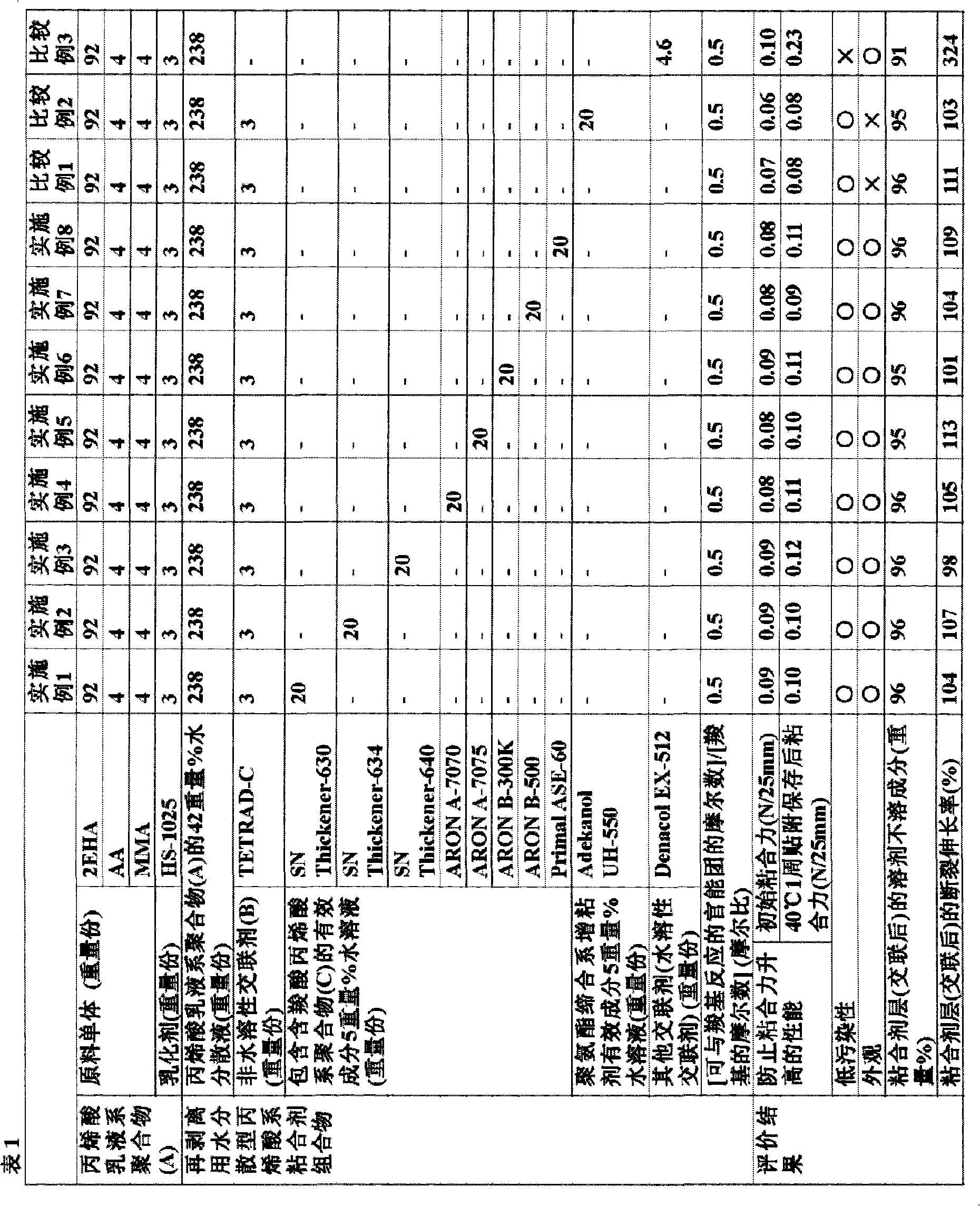

[0136] 90 parts by weight of water, raw material monomers and emulsifiers in the compounding amounts shown in Table 1 were mixed in a container, and then stirred and mixed by a homomixer to prepare a monomer emulsion.

[0137] Next, in a reaction vessel provided with a cooling pipe, a nitrogen introduction pipe, a thermometer and a stirrer, 50 parts by weight of water, 0.01 part by weight of a polymerization initiator (ammonium persulfate) and 10% by weight of the monomer emulsion prepared above were added. The amount of the above-mentioned monomer emulsion was stirred and emulsion polymerized at 75°C for 1 hour. Thereafter, 0.05 parts by weight of a polymerization initiator (ammonium persulfate) was further added, and then, while stirring, all the remaining monomer emulsions (an amount corresponding to 90% by weight) were added over 3 hours, and thereafter, at 75° C. React for 3 hours. Next, it was cooled to 30°C, and a...

Embodiment 2~8

[0144] As shown in Table 1, the kind of the tackifier containing the carboxylic acid-containing acrylic polymer (C) was changed, and it carried out similarly to Example 1, and obtained the peelable water dispersion type acrylic adhesive composition and the adhesive sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy equivalent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com