A kind of high-strength re-peelable pressure-sensitive adhesive for window film and preparation method thereof

A re-peelable, pressure-sensitive adhesive technology, applied in the direction of adhesives, adhesive types, film/sheet adhesives, etc., can solve the problems of high production cost, low cost, and high adhesive strength, and achieve good reliability Excellent detachability, re-peelability, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

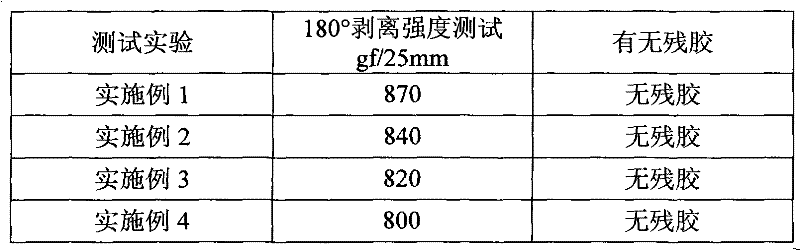

Examples

Embodiment 1

[0035] This embodiment provides a high-strength peelable pressure-sensitive adhesive for window films, and its preparation method is as follows:

[0036] 1), 3 kg of 2-ethylhexyl acrylate, 4 kg of n-butyl acrylate, 2 kg of methyl methacrylate, 0.5 kg of 2-hydroxyethyl acrylate, 0.7 kg of maleic acid, 1 kg of propylene acrylate Ester, 0.5 kg of N-vinylpyrrolidone, 1 kg of vinyl acetate, 7 kg of ethyl acetate, and 0.03 kg of dibenzoyl peroxide were added to the reaction kettle, and heated to 72°C for 30 minutes;

[0037] 2), 6 kg of 2-ethylhexyl acrylate, 8 kg of n-butyl acrylate, 4 kg of methyl methacrylate, 0.8 kg of 2-hydroxyethyl acrylate, 0.6 kg of maleic acid, 0.4 kg of glycidyl acrylate Ester, 0.7 kg of N-vinylpyrrolidone, 0.9 kg of vinyl acetate, 14 kg of ethyl acetate, and 0.05 kg of dibenzoyl peroxide are mixed uniformly, and then added dropwise to the above reaction kettle within 2 hours. After the addition is complete, heat to 65°C and stir for 3 hours;

[0038] 3). Add 0...

Embodiment 2

[0040] 1), 4 kg of 2-ethylhexyl acrylate, 3 kg of isobutyl methacrylate, 2 kg of methyl methacrylate, 0.6 kg of 2-hydroxyethyl methacrylate, 0.7 kg of acrylic acid, 1 kg of methyl Glycidyl acrylate, 0.5 kg of N-vinylpyrrolidone, 1 kg of vinyl acetate, 7 kg of ethyl acetate and 0.03 kg of azobisisobutyronitrile were added to the reaction kettle, heated to 70°C for 20 minutes;

[0041] 2), 8 kg of 2-ethylhexyl acrylate, 6 kg of isobutyl methacrylate, 4 kg of methyl methacrylate, 0.8 kg of 2-hydroxyethyl methacrylate, 0.5 kg of acrylic acid, 0.5 kg of methyl Glycidyl acrylate, 0.4 kilograms of N-vinylpyrrolidone, 0.8 kilograms of vinyl acetate, 14 kilograms of ethyl acetate and 0.05 kilograms of dibenzoyl peroxide are mixed uniformly, and added to the above reaction in a dropwise manner within 2 hours In the kettle, after the dripping is completed, heat to 70°C and stir for 3 hours;

[0042] 3) Add 0.08 kg of hexamethylene diisocyanate and 7 kg of ethyl acetate into the reaction kett...

Embodiment 3

[0044] 1), 4 kg of n-octyl acrylate, 3 kg of n-butyl acrylate, 2 kg of methyl methacrylate, 0.3 kg of 2-hydroxyethyl methacrylate, 0.3 kg of 2-hydroxyethyl acrylate, 0.4 kg of acrylic acid, 0.2 kg of methacrylic acid, 0.5 kg of glycidyl methacrylate, 0.5 kg of glycidyl acrylate, 0.5 kg of N-vinylpyrrolidone, 1 kg of vinyl acetate, 7 kg of ethyl acetate and 0.03 kg of azobisisobutyronitrile Add to the reaction kettle, heat to 75°C for 20 minutes;

[0045] 2), 8 kg n-octyl acrylate, 6 kg n-butyl acrylate, 0.4 kg 2-hydroxyethyl methacrylate, 0.2 kg 2-hydroxyethyl acrylate, 0.6 kg acrylic acid, 0.6 kg methacrylic acid, 0.6 kg Glycidyl methacrylate, 0.7 kilograms of glycidyl acrylate, 0.5 kilograms of N-vinylpyrrolidone, 1 kilogram of vinyl acetate, 14 kilograms of ethyl acetate and 0.05 kilograms of dibenzoyl peroxide are mixed uniformly and added dropwise Add dropwise to the above reaction kettle within 2 hours. After the dropwise addition is completed, heat to 68°C and stir for 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com