Strippable semiconductive shielding rubber for rubber insulation and preparation method thereof

A semi-conductive and rubber technology, applied in the direction of power cables with shielding/conducting layers, etc., can solve the problems of unsatisfactory, uneven dispersion of carbon black, thermal aging and electrical aging of products, and achieve the effect of avoiding performance deviation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

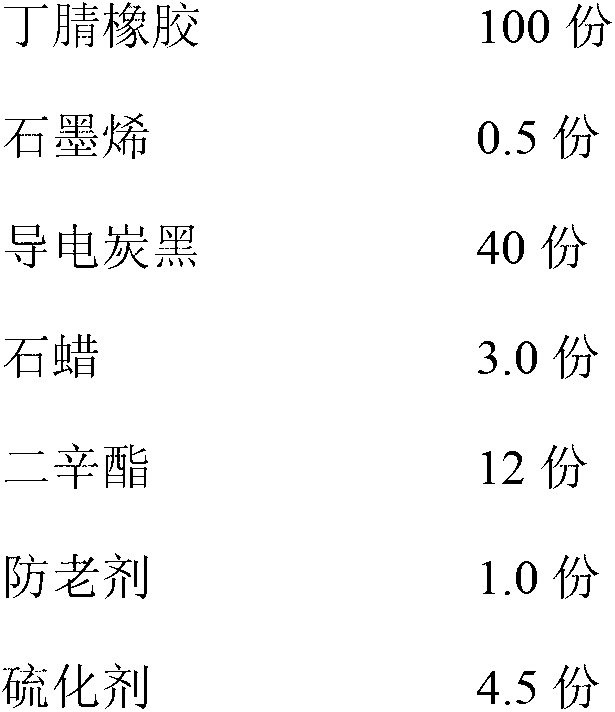

Embodiment 1

[0024]

[0025] The nitrile rubber is a polar rubber system with an acrylonitrile content of 33%; the anti-aging agent is quinoline anti-aging agent RD; the vulcanizing agent is dicumyl peroxide.

[0026] Implementation process:

[0027] Masticating: After weighing the relevant materials according to the proportion, masticate the nitrile rubber. The masticating temperature is controlled at 80°C. After the mastication is completed, place it for 12 hours before carrying out the subsequent mixing operation.

[0028] Mixing: During the mixing operation, first add graphene to the nitrile rubber, after mixing evenly, add 1 / 2 conductive carbon black, add the remaining carbon black, paraffin and dioctyl ester after about 3 minutes, and then mix After 2 minutes, add other processing aids, and finally add vulcanizing agent and mix for 1 minute before unloading. The temperature during the whole mixing process should not exceed 120°C.

[0029] Film output: After unloading, the semi-c...

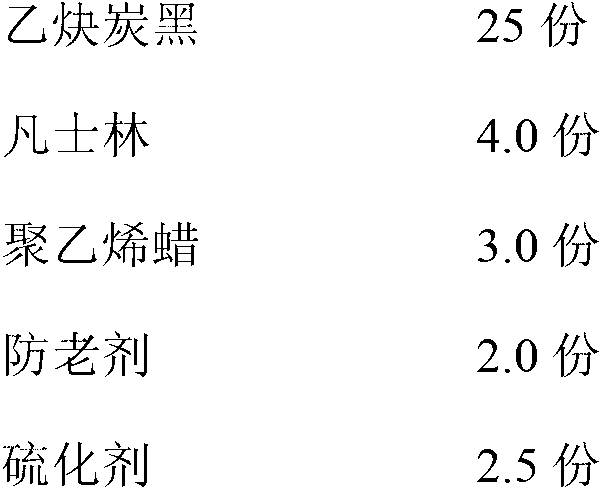

Embodiment 2

[0031]

[0032]

[0033] The acrylonitrile content of the nitrile rubber is 26%; the anti-aging agent is diphenylamine anti-aging agent HS911; the vulcanizing agent is bis-tert-butylperoxycumene.

[0034] Implementation process:

[0035] The difference between the implementation steps of this example and the implementation mode and Example 1 is that the graphene is first added to the nitrile rubber during the mixing process, and 1 / 2 of the acetylene carbon black is added after the mixing is uniform, and the remaining acetylene carbon black is added after about 3 minutes. Acetylene carbon black, Vaseline and polyethylene wax, and then knead for 2 minutes before adding other processing aids, and finally add vulcanizing agent and knead for 1 minute before unloading. The temperature of the whole mixing process does not exceed 120 °C.

Embodiment 3

[0037]

[0038] The acrylonitrile content of the nitrile rubber is 28%; the anti-aging agent is quinoline anti-aging agent RD; the vulcanizing agent is dicumyl peroxide.

[0039] Implementation process:

[0040] The difference between the implementation steps of this example and the implementation mode and Example 1 is that the graphene is first added to the nitrile rubber during the mixing process, and 1 / 2 of the conductive carbon black is added after the mixing is uniform, and the remaining carbon black is added after about 3 minutes. Conductive carbon black and dioctyl ester, then add other processing aids after mixing for 2 minutes, and finally add vulcanizing agent and mix for 1 minute before unloading. The temperature of the whole mixing process does not exceed 120 °C.

[0041] Take a certain amount of mixed rubber in the example, vulcanize it on a flat vulcanizing machine at 160°C for 30 minutes, press it into a test piece with a thickness of 2mm, and press it into a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com