A kind of strippable semi-conductive shielding rubber for rubber insulation and preparation method thereof

A semi-conductive and rubber technology, applied in the direction of power cables with shielding layer/conductive layer, etc., can solve the problems of product thermal aging, electrical aging, unsatisfactory, unstable electrical parameters, etc., to prevent electrical aging problems and avoid performance Deviation, heat aging prevention effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

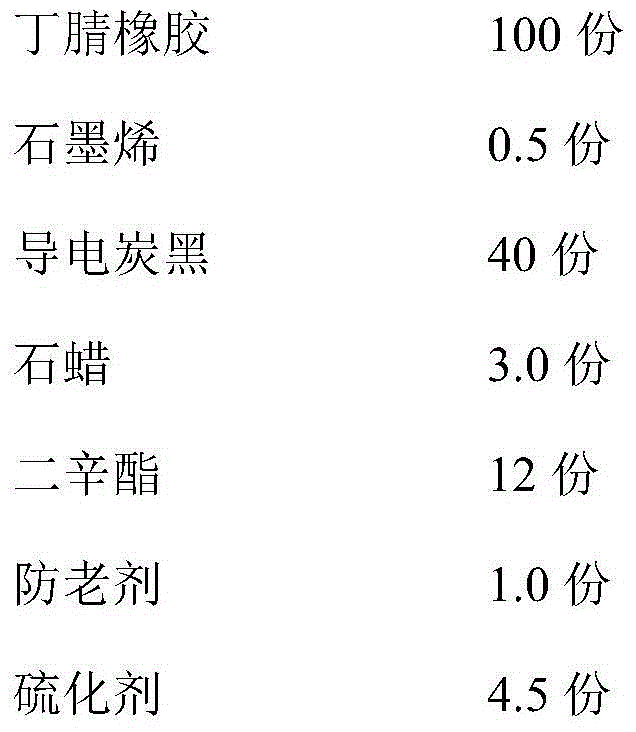

Embodiment 1

[0019]

[0020] The nitrile rubber is a polar rubber type system; the vulcanizing agent is a peroxide vulcanization system.

[0021] Implementation process:

[0022] Masticating: After weighing the relevant materials according to the proportion, masticate the nitrile rubber. The masticating temperature is controlled at 80°C. After the mastication is completed, place it for 12 hours before carrying out the subsequent mixing operation.

[0023] Mixing: During the mixing operation, first add graphene to the nitrile rubber, after mixing evenly, add 1 / 2 conductive carbon black, add the remaining carbon black, paraffin and dioctyl ester after about 3 minutes, and then mix After 2 minutes, add other processing aids, and finally add vulcanizing agent and mix for 1 minute before unloading. The temperature during the whole mixing process should not exceed 120°C.

[0024] Film output: After unloading, the semi-conductive shielding rubber is produced on the film output machine. The w...

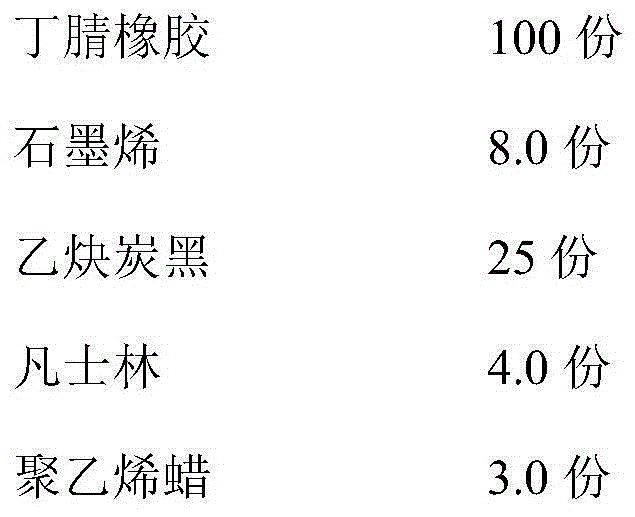

Embodiment 2

[0026]

[0027]

[0028] The nitrile rubber is a polar rubber type system; the vulcanizing agent is a peroxide vulcanization system.

[0029] Implementation process:

[0030] The difference between the implementation steps of this example and the implementation mode and Example 1 is that the graphene is first added to the nitrile rubber during the mixing process, and 1 / 2 of the acetylene carbon black is added after the mixing is uniform, and the remaining acetylene carbon black is added after about 3 minutes. Acetylene carbon black, Vaseline and polyethylene wax, and then knead for 2 minutes before adding other processing aids, and finally add vulcanizing agent and knead for 1 minute before unloading. The temperature of the whole mixing process does not exceed 120 °C.

Embodiment 3

[0032]

[0033] The nitrile rubber is a polar rubber type system; the vulcanizing agent is a peroxide vulcanization system.

[0034] Implementation process:

[0035] The difference between the implementation steps of this example and the implementation mode and Example 1 is that the graphene is first added to the nitrile rubber during the mixing process, and 1 / 2 of the conductive carbon black is added after the mixing is uniform, and the remaining carbon black is added after about 3 minutes. Conductive carbon black and dioctyl ester, then add other processing aids after mixing for 2 minutes, and finally add vulcanizing agent and mix for 1 minute before unloading. The temperature of the whole mixing process does not exceed 120 °C.

[0036] Take a certain amount of mixed rubber in the example, vulcanize it on a flat vulcanizing machine at 160°C for 30 minutes, press it into a test piece with a thickness of 2mm, and press it into a test piece with a thickness of 2mm. The typic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electron mobility | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com