Electromagnetic wave preventing filter, manufacturing method thereof and display comprising the filter

A technology of anti-electromagnetic wave and manufacturing method, which is applied to the parts of instruments, gas discharge tubes/containers, conductive materials dispersed in non-conductive inorganic materials, etc., can solve problems such as complex processes, improve optical characteristics, and simplify manufacturing Process, the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

[0131] According to the following components and contents, mix acrylate polymer resin, solvent, glass powder, conductive metal, black pigment and dispersant, stir at room temperature, and finally use a three-roller mill to produce the required gravure offset printing black conductive paste composition.

[0132] The black conductive paste composition contains 6% by weight of acrylate polymer resin and monomer, 7% by weight of diethylene glycol monobutyl ether acetate (BCA), 7% by weight of diethylene glycol mixed in a weight ratio of 66.7:33.3. 2.2% by weight of methyl ethyl ether, 0.3% by weight of dispersant, 75% by weight of conductive metal, 5.5% by weight of black powder and 4% by weight of glass powder.

[0133] Among them, the weight-average molecular weight of the acrylate polymer resin is 15000, which is composed of methyl acrylate (MA), butyl methacrylate (BM), hydroxyethyl methacrylate (HEMA) and methyl methacrylate (MMA). They are formed by copolymerization in part...

Embodiment

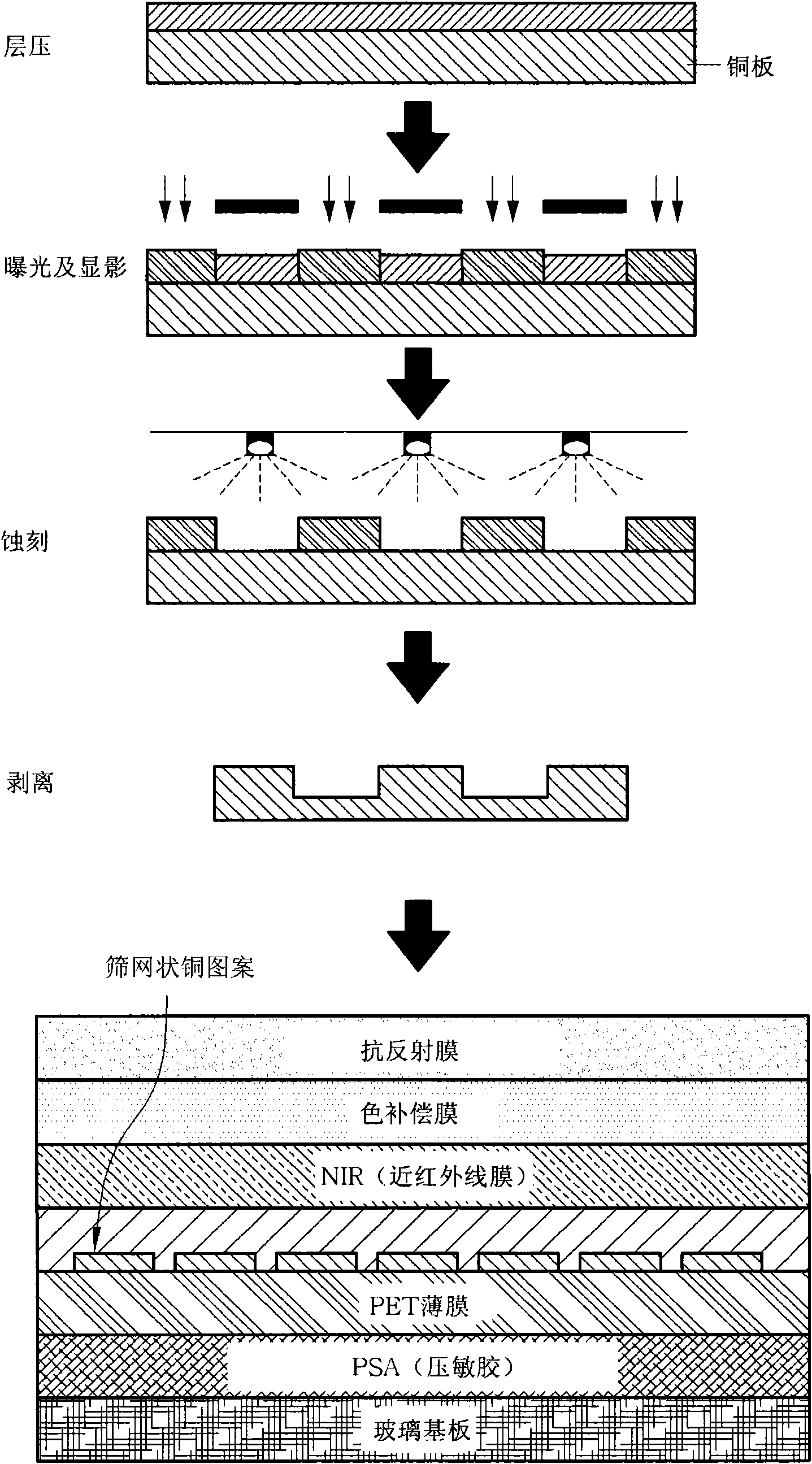

[0137] Preparation of anti-electromagnetic wave filter

[0138] Gravure offset printing was performed according to the pattern specification for the electromagnetic wave shielding filter by using the paste composition prepared in the above-mentioned preparation example.

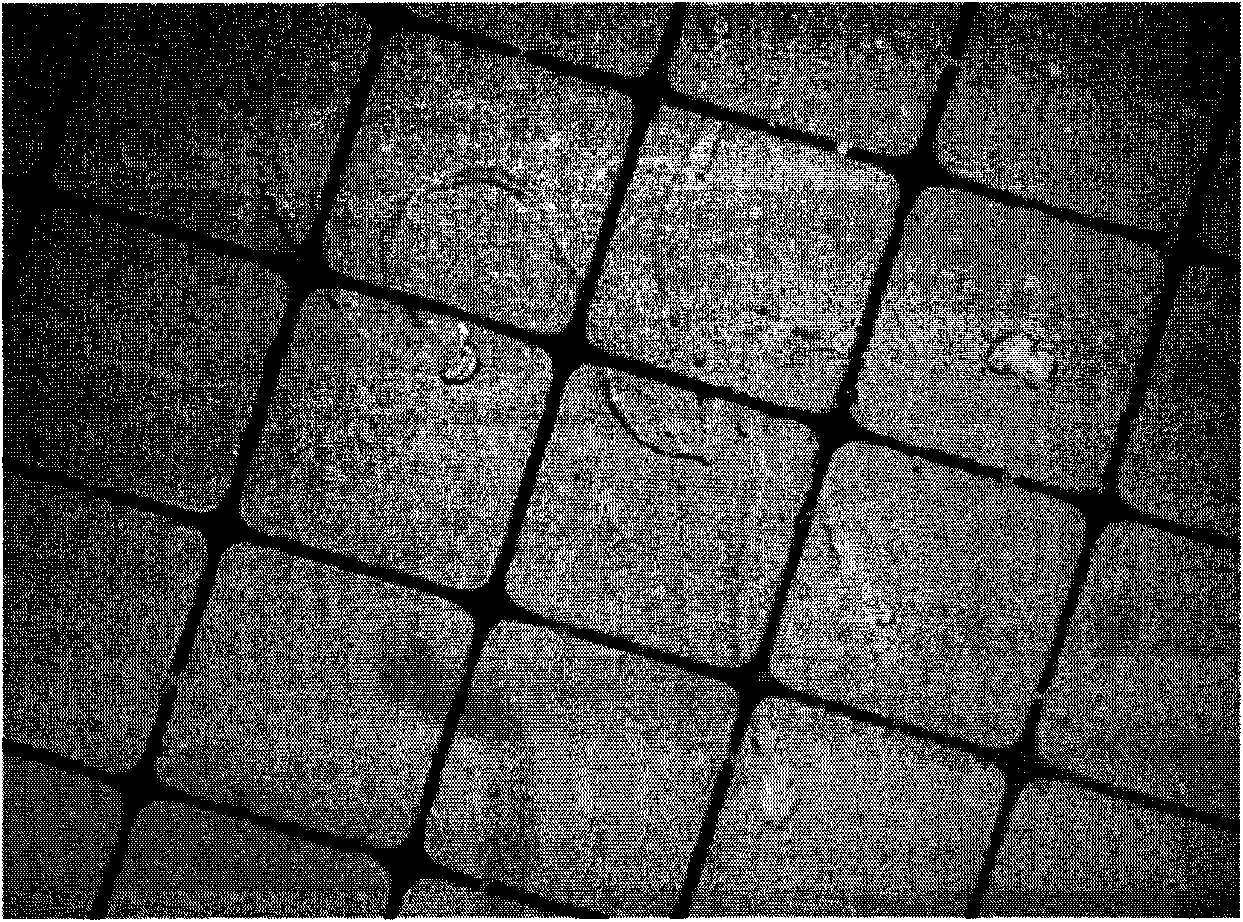

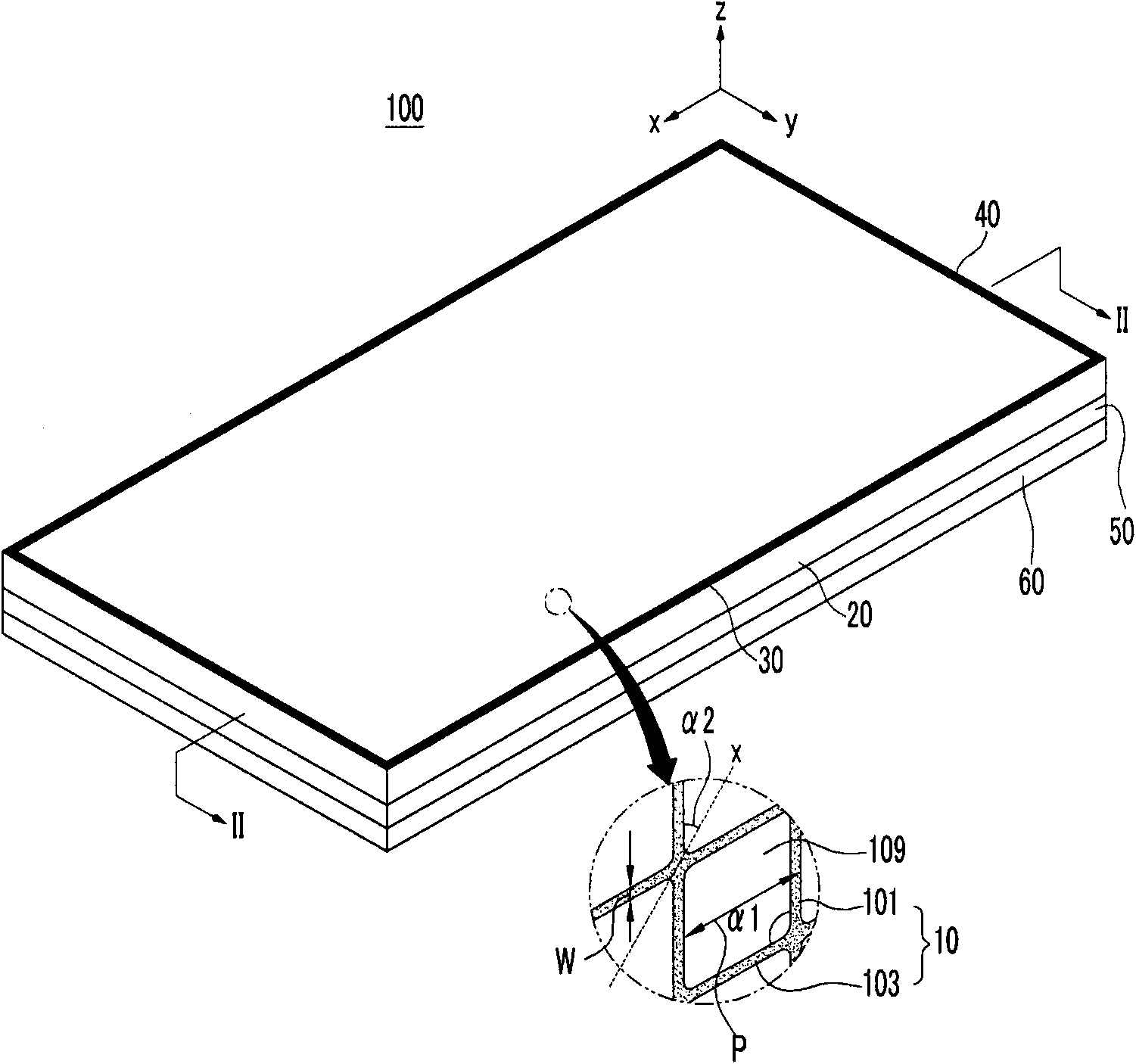

[0139] i.e. by using as Figure 4 The same offset printing apparatus as shown, printed the paste composition onto the tin side of a transparent strengthened glass substrate to form a mesh-like pattern. At this time, the line width of the mesh-like pattern was 25 μm, and the standard average pitch between the patterns was 270 μm.

[0140] Then, in the firing process, at a temperature of 500-540° C., the tin surface of the transparent strengthened glass substrate is kept for 20 minutes in the state where the paste composition is coated, so as to form a mesh pattern for an electromagnetic wave filter.

experiment example

[0145] Characteristic Evaluation of Anti-Electromagnetic Wave Filter

[0146] The following standards were used to compare and evaluate the optical values such as blackness and yellowing of the anti-electromagnetic wave filters provided by the examples and comparative examples, and the results are shown in Table 1. A total of six batches of tests on the optical value difference of each substrate surface were carried out, and the average value was calculated after each batch was printed 30 times. In addition, the durability of the mesh-shaped electromagnetic shielding printed matter provided in Examples and Comparative Examples was evaluated, and the evaluation criteria are as follows.

[0147] Evaluation Criteria for Optical Properties

[0148] Under the condition of a white light source, a D65 light source is applied to the surface opposite to the printed surface of the transparent strengthened glass substrate provided with a screen-shaped anti-electromagnetic wave fil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com