Retardation film and image display device provided with the retardation film

A retardation film, independent technology, applied in instruments, polarizing elements, optics, etc., can solve the problems of unstable liquid crystal orientation, high adhesion between liquid crystal and substrate, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-7 and comparative example 1-2

[0242] The composition for liquid crystal layer formation was prepared by the composition described in following Table 1. In Table 1, the compound of chemical formula 16 (manufactured by BASF Corporation), the compound of chemical formula 17 (manufactured by Aekyung Chemical Co., Ltd.) and the chemical formula 18 (manufactured by Aekyung Chemical).

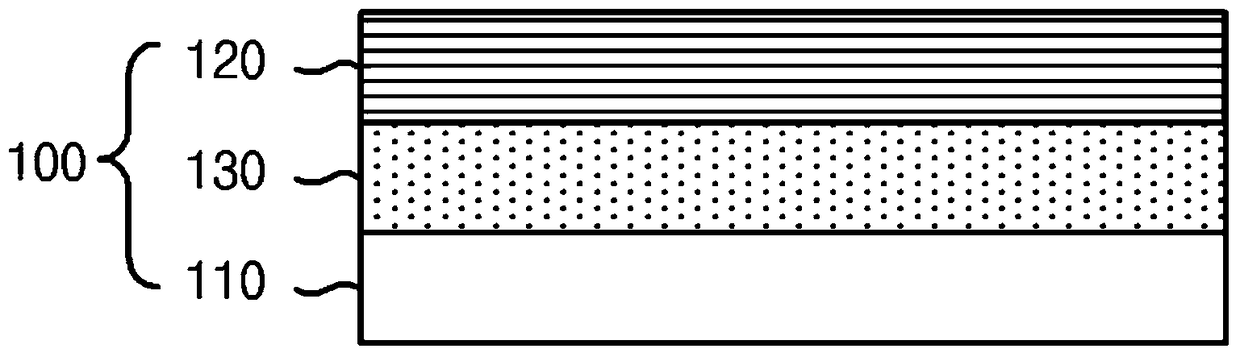

[0243] On the other hand, after the primer layer 130 was formed on the stretched COP film subjected to the plasma surface treatment (excluding Example 5 and Comparative Example 1), the above-mentioned Examples 1 to 7 were coated on the primer layer. And the composition for liquid crystal layer formation of Comparative Examples 1-2 was dried at 60 degreeC for 1 minute. Then, by exposing to light, a curing reaction is induced to produce a retardation film.

[0244] [Table 1]

[0245]

PUM

| Property | Measurement | Unit |

|---|---|---|

| water contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com