Composite waterproof adhesive layer and preparation method thereof

A composite, waterproof and sticky technology, applied to cohesive pavement paved on site, roads, buildings, etc., can solve the problems of affecting the service life of the pavement structure, troublesome normal construction, easy to roll up the grille, etc., and achieve a significant interlayer Stiffening effect, improve crack resistance, improve the effect of interlayer bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] Embodiment 1, selection of rubber asphalt

[0050] The direct shear simulation test is used to select a reasonable level of viscosity, and the inclined shear test is used to select a reasonable level of spraying rate. Now it is described as follows:

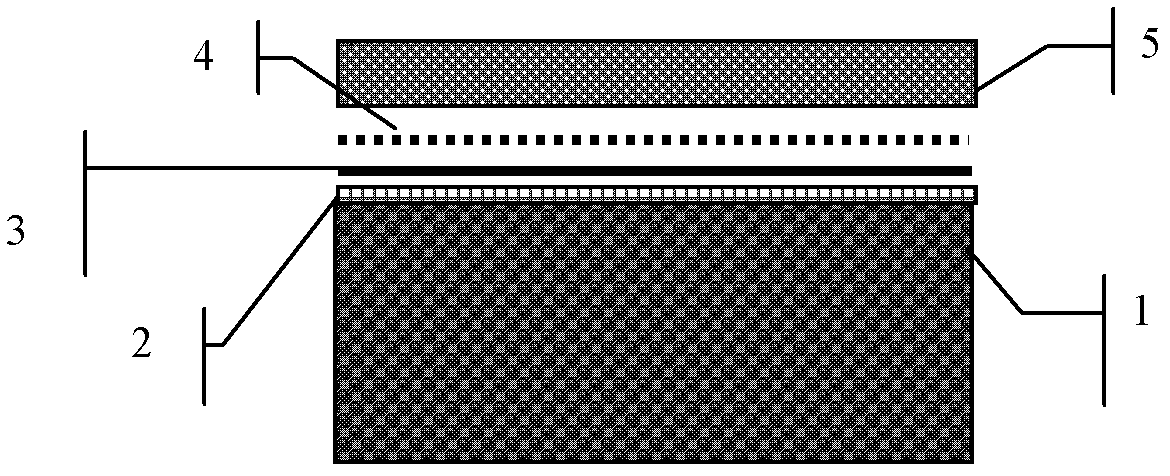

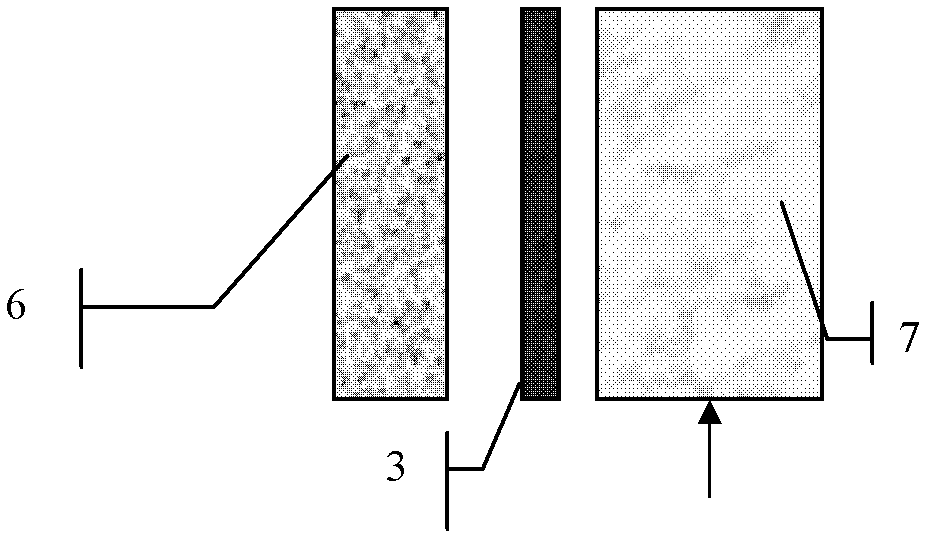

[0051] Direct shear simulation test: Two steel plates A6 and B7 with the same hardness are used to replace the upper and lower bearing layers of the road for direct shear test. The test mode is as follows figure 2 , using rubber asphalt layers 3 with different viscosities as adhesive layer materials.

[0052] The sticky course material is AH-90# asphalt mixed with 5%, 10%, 15%, 20%, 25% of 40-mesh rubber powder to obtain rubber asphalt with different viscosities. See Table 1 for the viscosity test results. The spread amount of rubber asphalt in the test is 2.0kg / m2.

[0053] Table 1: Viscosity test and shear test results of rubberized asphalt

[0054] Rubber asphalt rubber powder content%

5%

10% ...

Embodiment 2

[0067] The amount of gravel spread and the selection of specifications are mainly determined by its intended role and function. The main function of the gravel in the waterproof bonding layer is to provide a construction platform, which is convenient for the construction machinery on the upper bearing layer to work on the waterproof bonding layer; Interlayer resistance to shear deformation.

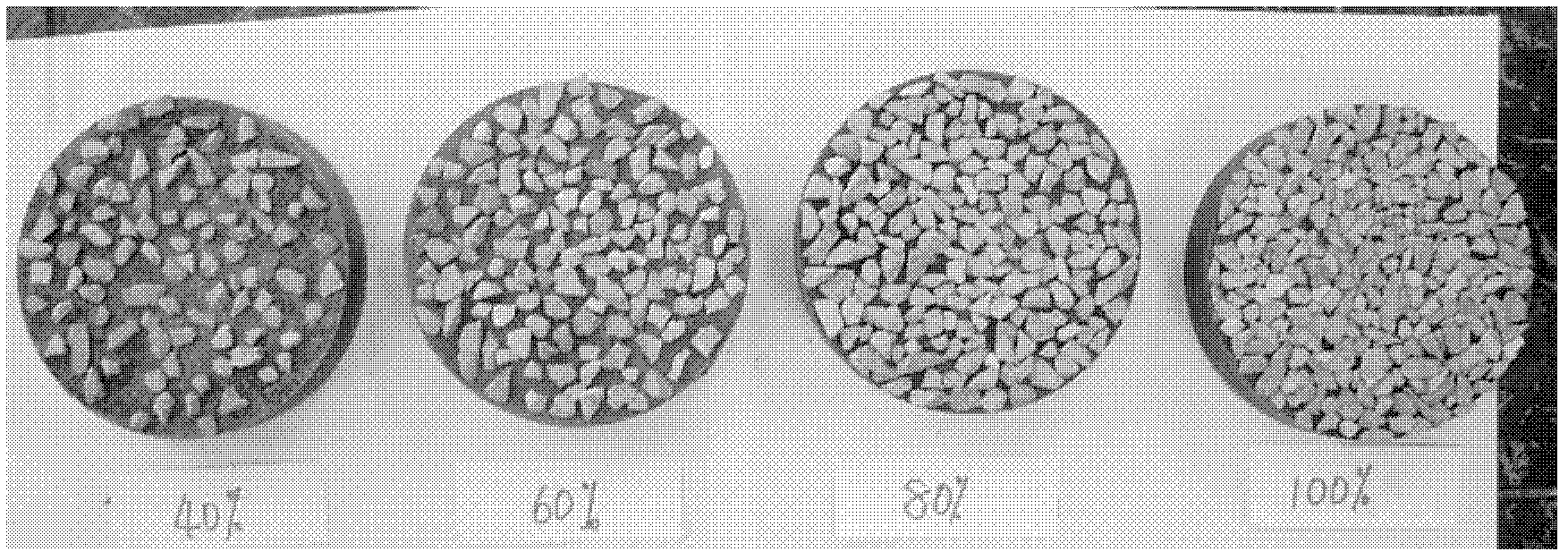

[0068] For the spreading of gravel, it is first necessary to avoid direct contact between the tires of the construction machinery and the spread of asphalt, so as to avoid damage to the spread of asphalt. The depth and width of the tread pattern of heavy-duty transport vehicles used in general engineering are about 1cm. from Figure 3-Figure 6 It can be seen that when spreading finer gravel, the amount of spreading should be larger, otherwise it is easy to stick the wheel and damage the asphalt layer; when spreading coarser gravel, the amount of spreading should be relatively small, abo...

Embodiment 3

[0076] Combined with the design and construction process of a composite waterproof adhesive layer on an expressway, an example is as follows:

[0077] 1. Raw materials and construction equipment

[0078] 1. Technical index of fiberglass geogrid material

[0079] The fiberglass geogrid is two-way warp knitted, with an aperture of 25-30mm, a width of 2m, and a length of 50m. The longitudinal and transverse tensile breaking strength per linear meter is 32.1kN / m, and the longitudinal and transverse breaking elongation is 2.9%. The other technical indicators meet the relevant requirements of "Geosynthetic Geogrid for Traffic Engineering" (JT / T480-2002), and the test method is according to The current "Geosynthetics Test Regulations" (JTG E50-2006) is implemented.

[0080] 2. Technical indicators of rubber asphalt

[0081] The test results of rubber asphalt technical indicators are as follows.

[0082] Table 4 Technical indicators of rubber asphalt

[0083]

[0084]

[00...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com