Cover film and electronic component package using same

A technology of covering film and antistatic agent, which is applied in the field of electronic component packaging, can solve the problems of increased number of processes, cost, environmental pollution, etc., and achieve the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

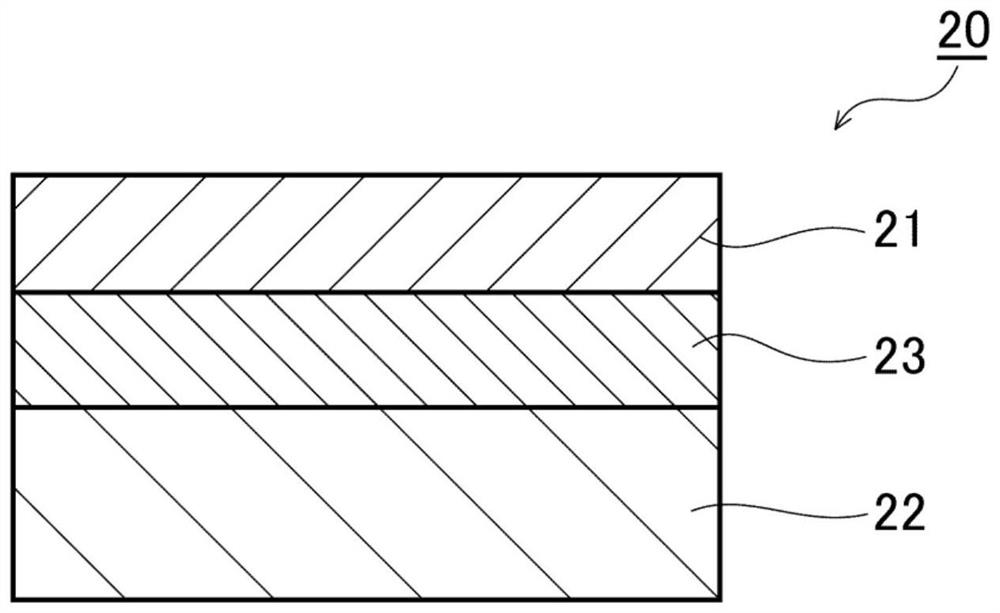

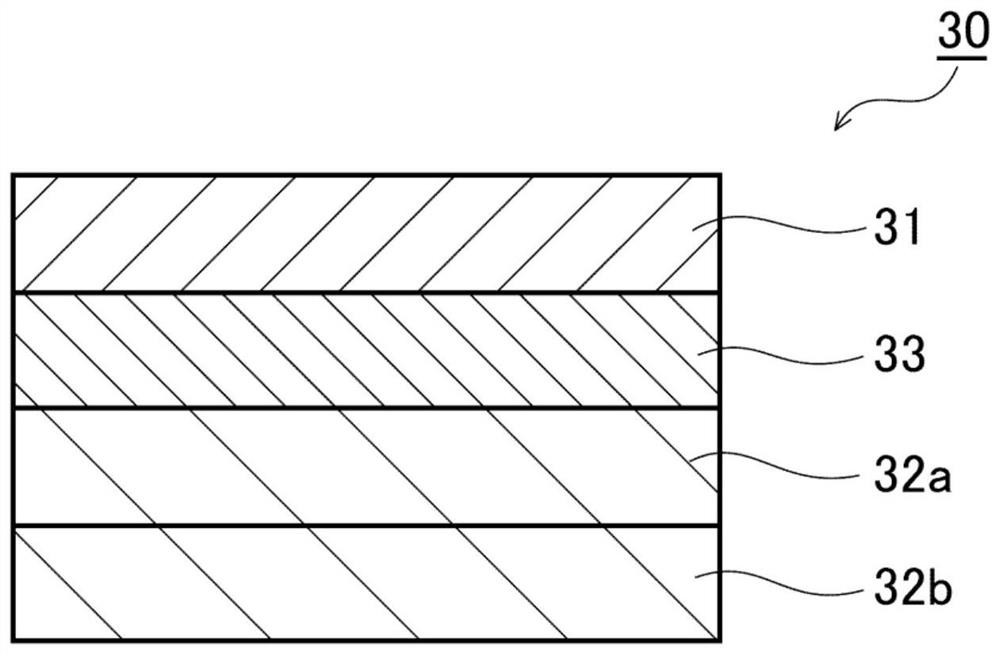

[0119] The cover film having a 3 layer structure of the substrate layer, the intermediate resin layer, and the sealant resin layer is fabricated in order is made in the following manner. As a resin constituting the sealant resin layer, the hydrogenation resin of the three-component copolymer of 100 parts by parts by parts of the drum machine (Asahi Chemicals Co., Ltd., "Tuftec H1041", olefin component 70% by mass), and 25 parts by mass of talc, silica masterbatch (Tokyo Ink system, "PEX-ABT-16", olefin component is 50% by mass), and use uniaxial crowded The film having a thickness of 20 μm was processed. In the sealing agent film and the biaxially tie polyphenylene terephthalate (a thickness of 16 μm), the resin of the intermediate resin layer is extruded in a thickness of 13 μm by a single screw extruder, and by extrusion The laminated method is laminated to obtain a carrier belt covering the electronic component, which is the use of a drum machine to 100 parts by mass of the met...

Embodiment 2~6、8、9

[0120] Example 2 to 6, 8, 9, Comparative Examples 1, 2]

[0121] In addition to the materials and composition shown in Table 1, the cover film is obtained by the same method as in Example 1. Further, in Comparative Examples 1, 2 is an example of a case where there is no epoxidized fatty acid or a derivative thereof in a cover film formed in a three-layer configuration and in the intermediate resin layer in contact with the substrate layer.

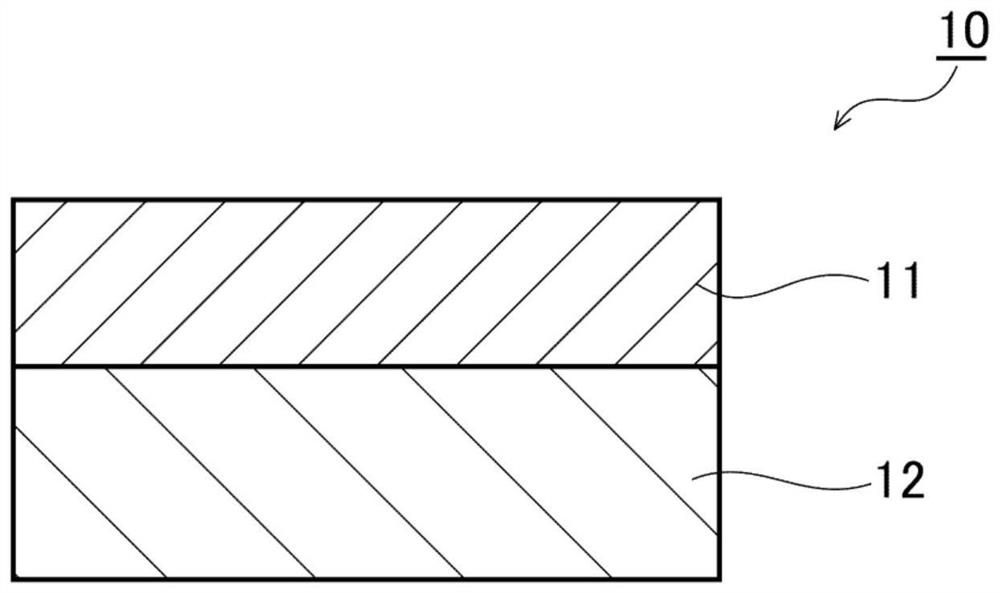

Embodiment 7

[0123] A cover film having a 2 layer structure of the substrate layer and the sealant resin layer in order is produced in order. As a resin constituting the sealant resin layer, the hydrogenation resin of the three-component copolymer of 100 parts by parts by parts of the drum machine (Asahi Chemicals Co., Ltd., "Tuftec H1041", olefin component It is 70% by mass), 25 parts by mass of talc, silica masterbatch (Tung Yang Ink, "PEX-ABT-16", olefin component is 50% by mass), 0.156 parts by mass of epoxidated soybean oil ( Adeka system, "O-130") is mixed, and the single screw extruder is used to extrude the biaxular stretch polybenzothylene terephthalate (thickness of 16 μm) and coated a sealant having a thickness of 20 μm. The film, thereby obtaining a cover film for a carrier belt of an electronic component. At this time, an anchor, an adhesive is not used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com