Cold-rolled hot-molded steel plate and production method thereof

A production method and thermoforming technology, applied in the field of metal material processing, can solve the problems of poor formability of high-strength steel plates, prone to wrinkling, cracking, springback, etc., to achieve good thermoforming performance, improve strength and safety factor, considerable economic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] A cold-rolled hot-formed steel sheet provided in this embodiment, the mass percentage of the chemical composition is as follows:

[0063] C: 0.25%; Si: 0.30%; Mn: 1.40%; P: 0.020%; S: 0.0030%;

[0064] Cr: 0.30%; Alt: 0.060%; B: 0.0040%; Ti: 0.050%; N: 0.006%; Fe: 97.607%.

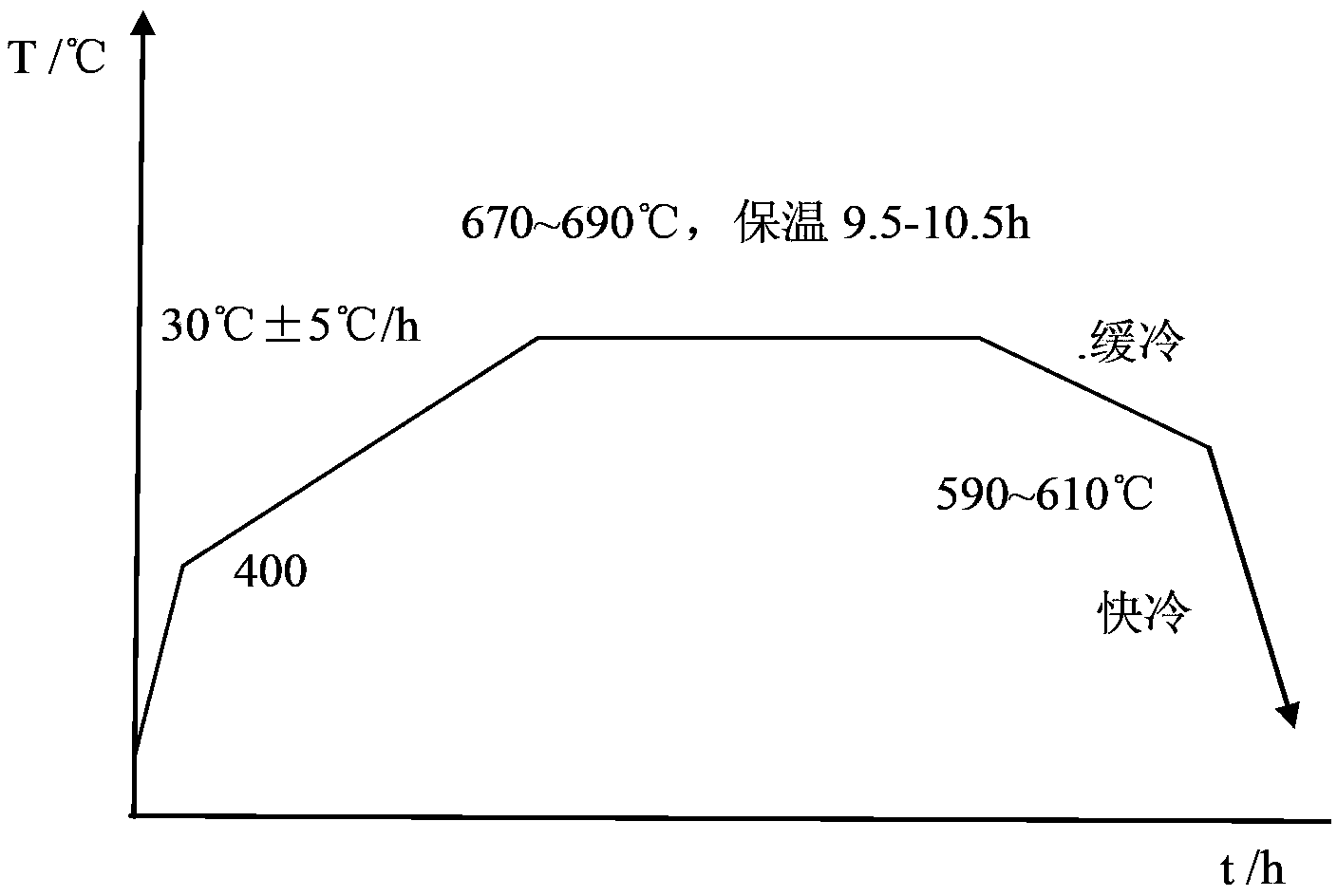

[0065] The molten iron with the above proportioning composition is refined and then continuously cast to obtain a slab, the slab is heated, and the heated slab is hot-rolled to obtain a hot-rolled plate, which is coiled after laminar flow cooling of the hot-rolled plate to obtain a hot-rolled plate. For rolling coils, the finishing temperature of hot rolling is 920°C, and the coiling temperature is 600°C. The hot-rolled coils are cold-rolled to obtain chilled coils, and the cold-rolling reduction rate is controlled at 70%. Then, the bell annealing process is adopted, and the temperature is raised to 400°C by rapid heating first, and then the steel coil is heated slowly at a heating rate of 35°C / h....

Embodiment 2

[0067] A cold-rolled hot-formed steel sheet provided in this embodiment, the mass percentage of the chemical composition is as follows:

[0068] C: 0.23%; Si: 0.25%; Mn: 1.3%; P: 0.014%; S: 0.0025%;

[0069] Cr: 0.17%; Alt: 0.035%; B: 0.0032%; Ti: 0.035%; N: 0.004%; Fe: 97.9563%.

[0070] The molten iron with the above proportioning composition is refined and then continuously cast to obtain a slab, the slab is heated, and the heated slab is hot-rolled to obtain a hot-rolled plate, which is coiled after laminar flow cooling of the hot-rolled plate to obtain a hot-rolled plate. For rolling coils, the finishing temperature of hot rolling is 920°C, and the coiling temperature is 600°C. The hot-rolled coil is cold-rolled to obtain a chilled coil, and the cold-rolling reduction rate is controlled at 60%. Then, the bell annealing process is adopted, and the temperature is raised to 400°C by rapid heating first, and then the steel coil is heated slowly at a heating rate of 30°C / h. ...

Embodiment 3

[0072] A cold-rolled hot-formed steel sheet provided in this embodiment, the mass percentage of the chemical composition is as follows:

[0073] C: 0.22%; Si: 0.24%; Mn: 1.28%; P: 0.015%; S: 0.0024%;

[0074] Cr: 0.216%; Alt: 0.0314%; B: 0.0032%; Ti: 0.028%; N: 0.0028%; Fe: 97.9612%.

[0075] The molten iron with the above proportioning composition is refined and then continuously cast to obtain a slab, the slab is heated, and the heated slab is hot-rolled to obtain a hot-rolled plate, which is coiled after laminar flow cooling of the hot-rolled plate to obtain a hot-rolled plate. For rolling coils, the finishing temperature of hot rolling is 900°C, and the coiling temperature is 590°C. The hot-rolled coils are cold-rolled to obtain chilled coils, and the cold-rolling reduction rate is controlled at 65%. Then, the bell annealing process is adopted, and the temperature is raised to 400°C by rapid heating first, and then the steel coil is heated slowly at a heating rate of 35°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com