Manufacturing method of temporary spacer in artificial joint replacement operation

A technology of artificial joints and manufacturing methods, which is applied to joint implants, joint implants, etc., can solve problems such as operation failure, patient mental and economic pressure, and temporary spacers without uniform manufacturing standards and manufacturing methods, so as to avoid waste Useful bone loss, avoiding soft tissue contracture of the joint capsule, and shortening the operation time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

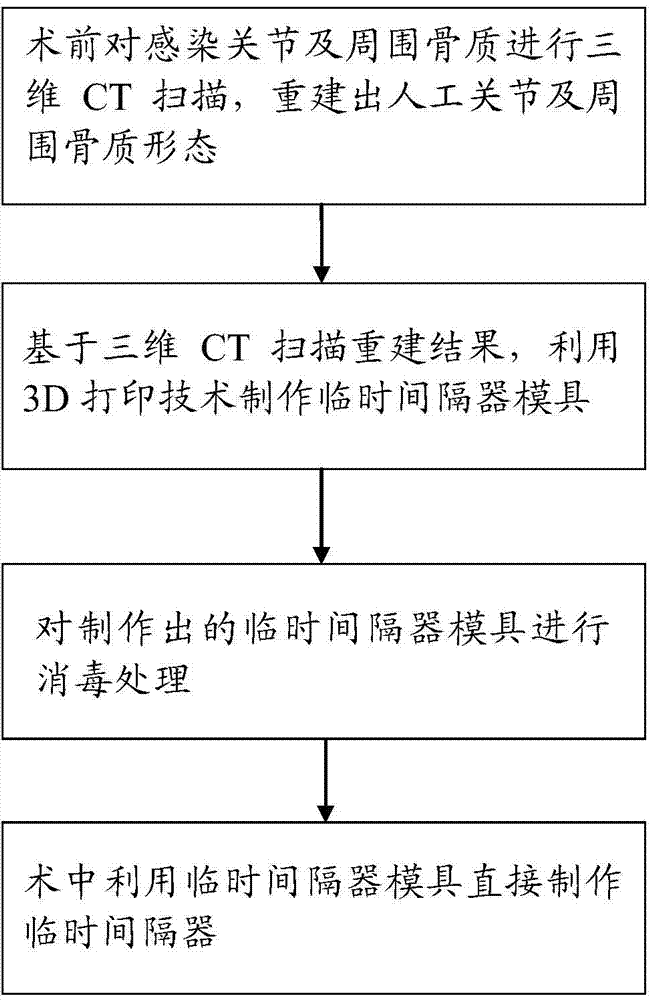

[0019] In order to fully understand the purpose, features and effects of the present invention, a method for making a temporary spacer in artificial joint replacement surgery according to the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0020] Such as figure 1 As shown, the manufacturing method of the temporary spacer in the artificial joint replacement operation of the present invention is used when infection occurs after operation, and includes the following steps: first, before the infection operation, perform three-dimensional CT scanning on the infected joint and surrounding bone , to reconstruct the artificial joint and surrounding bone morphology. Secondly, based on the results of 3D CT scan reconstruction, 3D printing technology was used to make a temporary spacer mold. Then, the manufactured temporary spacer mold is sterilized. Finally, during the infection operation, the temporary spacer mold is used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com