Patents

Literature

68results about How to "Appropriate clearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

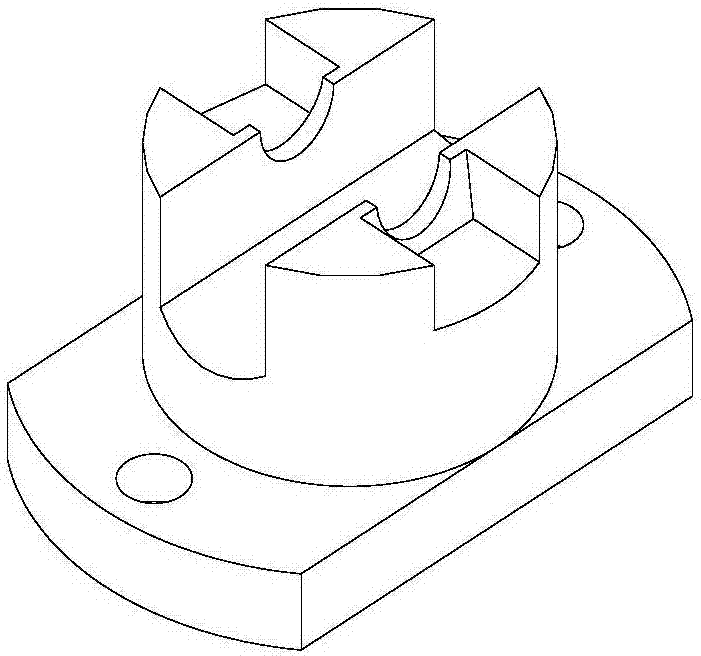

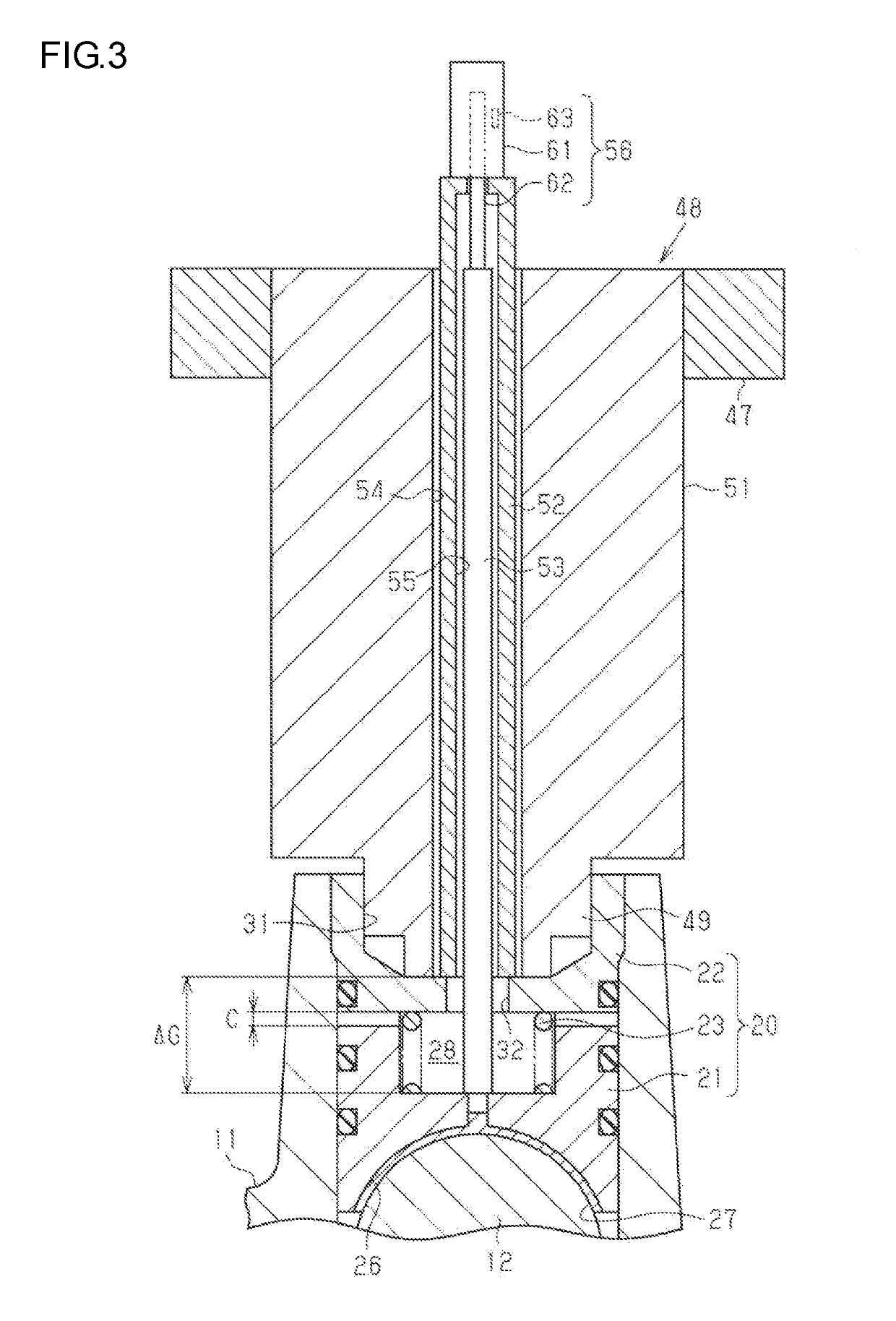

Overhead rotary valve for engines

InactiveUS6308677B1Simple sealing deviceImprove sealingMachines/enginesRotary slide valveCombustion chamberExhaust valve

An overhead rotary valve fitted into a cylinder head with diametrical polygonal openings formed therein for use in combination with an internal combustion engine, driven to bring intake and exhaust ports into and out of alignment with passages leading to and from the combustion chamber. Sleeve bearings are fitted in the cylinder head that provide surface sealing, and annular sealing members prevent the air / fuel mixture or exhaust gases from flowing into regions intermediate ports and individual cylinders. Utilizing this overhead rotary valve and associated seals and bearings increases the efficiency and performance of an internal combustion engine. The overhead rotary valve rotating, at one quarter the speed of the crankshaft, minimizes wear and noise levels, self cleans the ports, allows the engine to operate at higher rpm and imparts proper opening and closing of passages at the proper sequence of valve timing without concern of valve float. The instant invention removes the need for reciprocating intake and exhaust valves, camshafts, rocker arms, lifters, push rods, valve guides and retainers, and other related hardware for actuation, significantly increasing the reliability and effectiveness of the internal combustion engine, while reducing overall manufacturing costs.

Owner:BOHACH WILLIAM LOUIS +1

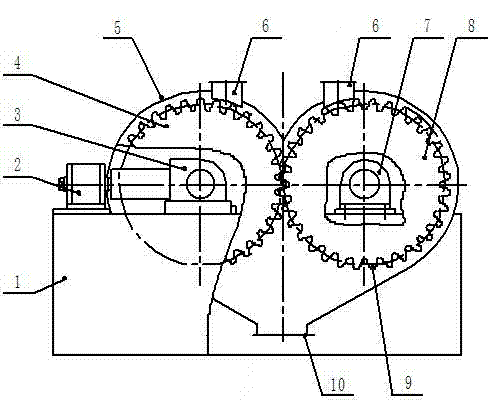

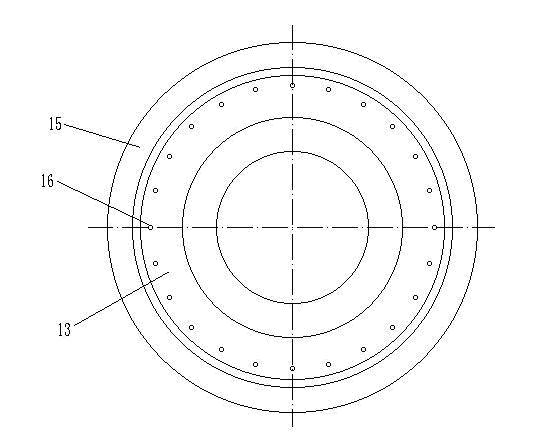

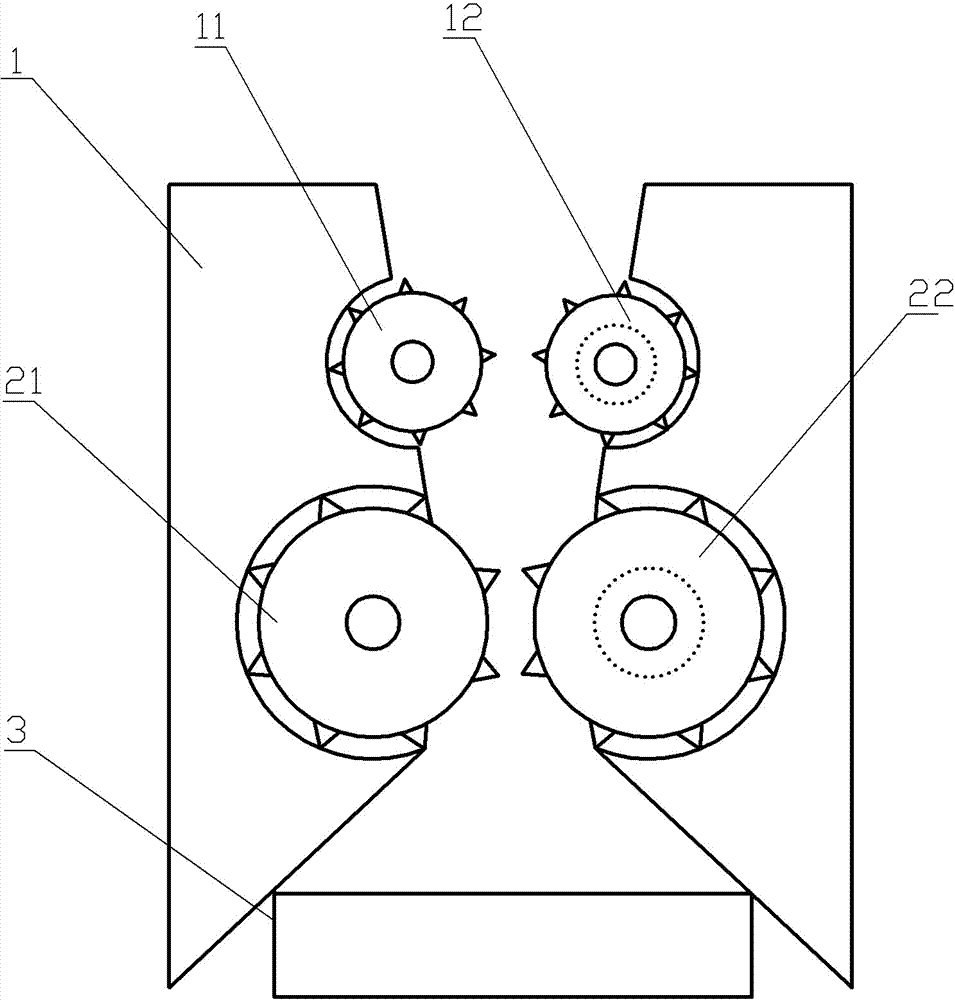

Automatic compression roller gap regulation meshing type extruding and crushing machine

InactiveCN102824936AEasy to wearExtended service lifeGrain treatmentsPulp and paper industryWorkload

The invention discloses an automatic compression roller gap regulation meshing type extruding and crushing machine. The automatic compression roller gap regulation meshing type extruding and crushing machine comprises a fixed compression roller (8) which is driven by a power system and a movable compression roller (4) which is meshed with the extruding teeth (9) of the fixed compression roller (8), wherein the gap between the movable compression roller (4) and the fixed compression roller (8) is regulated through an elastic regulation device which can slide on a guide rail (11) of a rack (1). Under the cooperation action of the power system, the fixed compression roller, the movable compression roller and the elastic device, the gap between the movable compression roller and the fixed compression roller can be automatically and flexibly regulated, and the breaking particle sizes of materials are controlled, thus one machine can medially break, finely break and grind the materials into powder, and the problems that the prior art has a large breaking system, more matching systems, large maintenance workload and the like are solved; and the extruding and crushing machine is simple in structure, and investment cost and production cost are saved.

Owner:四川皇龙智能破碎技术股份有限公司

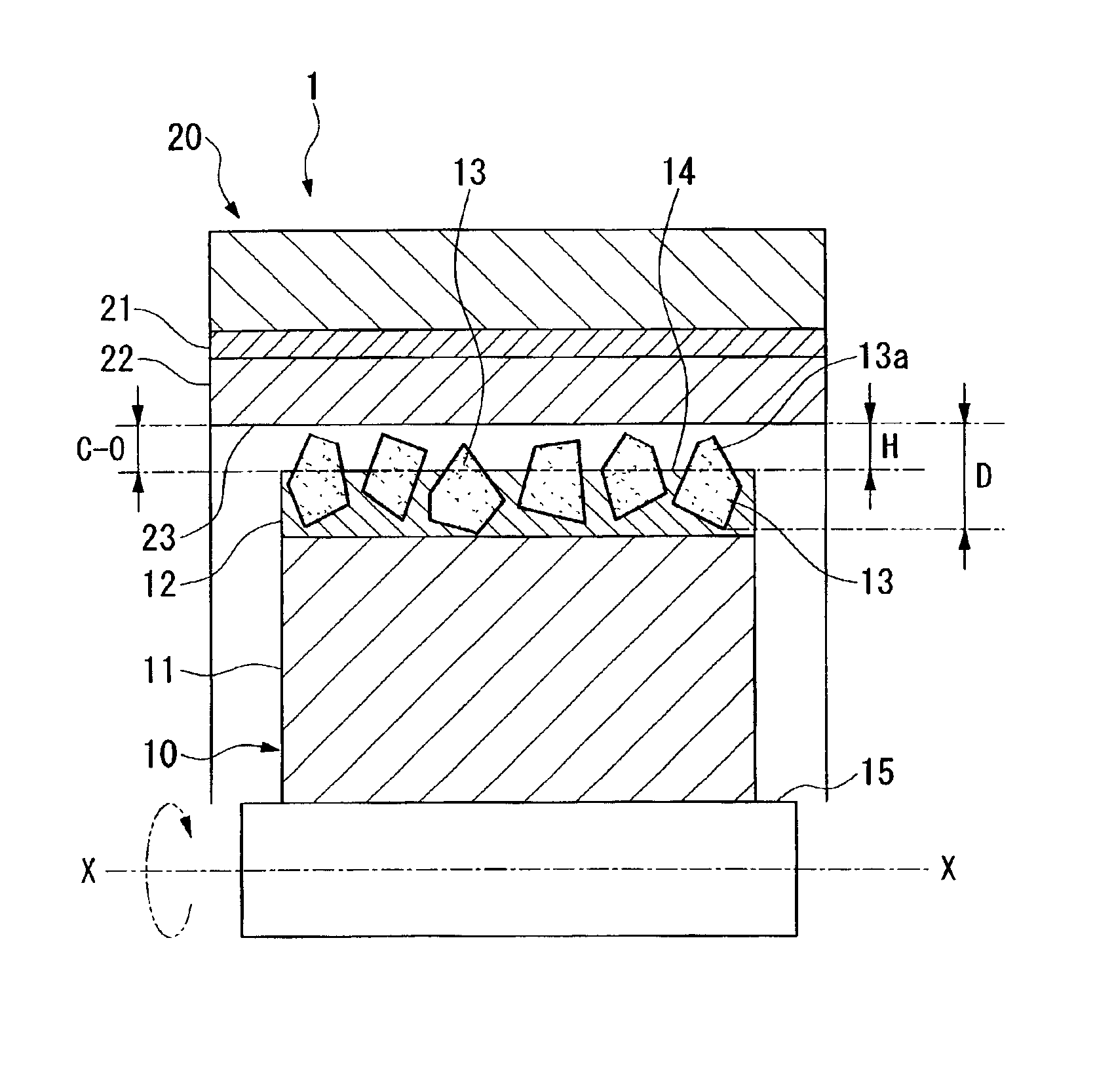

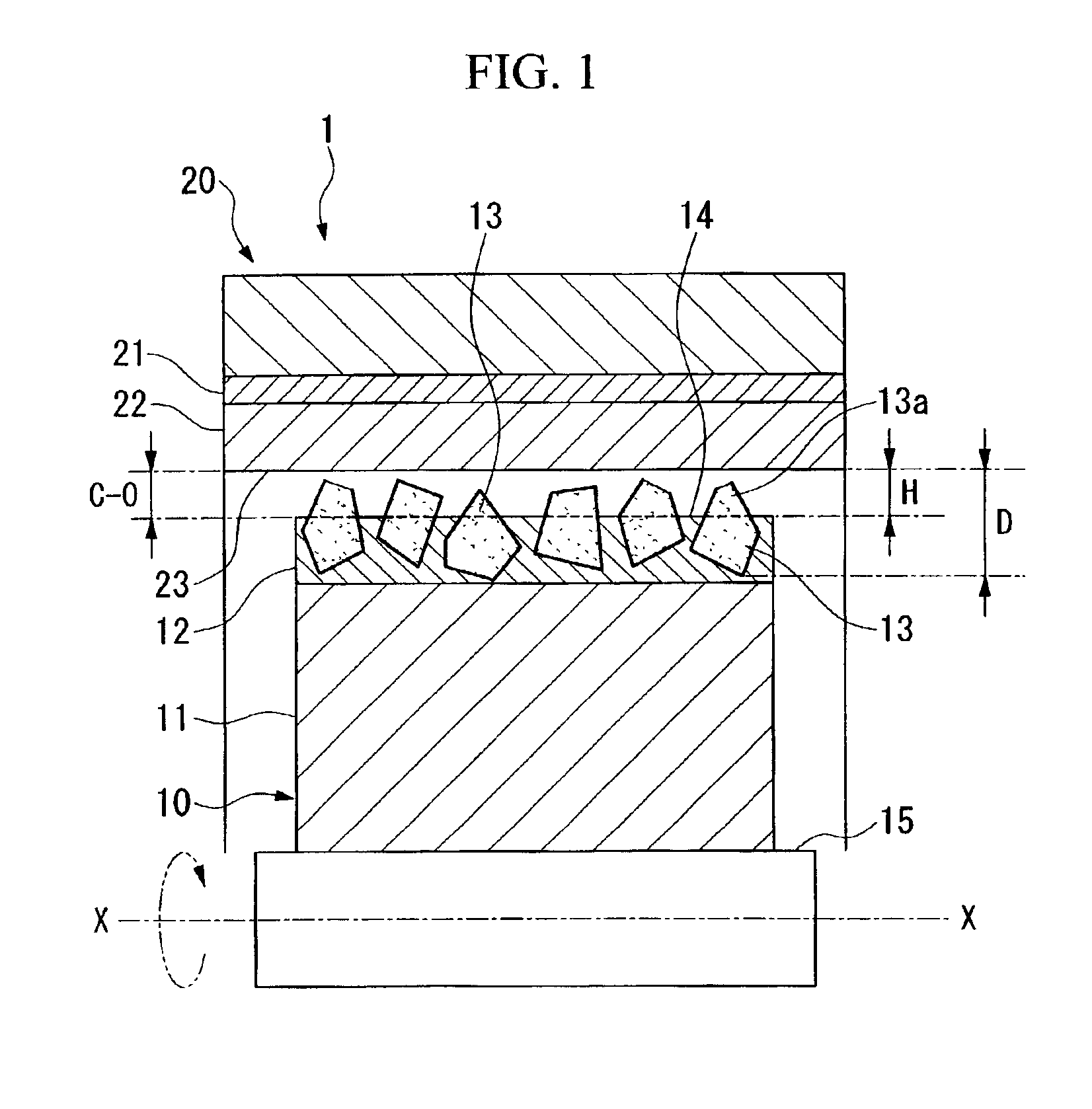

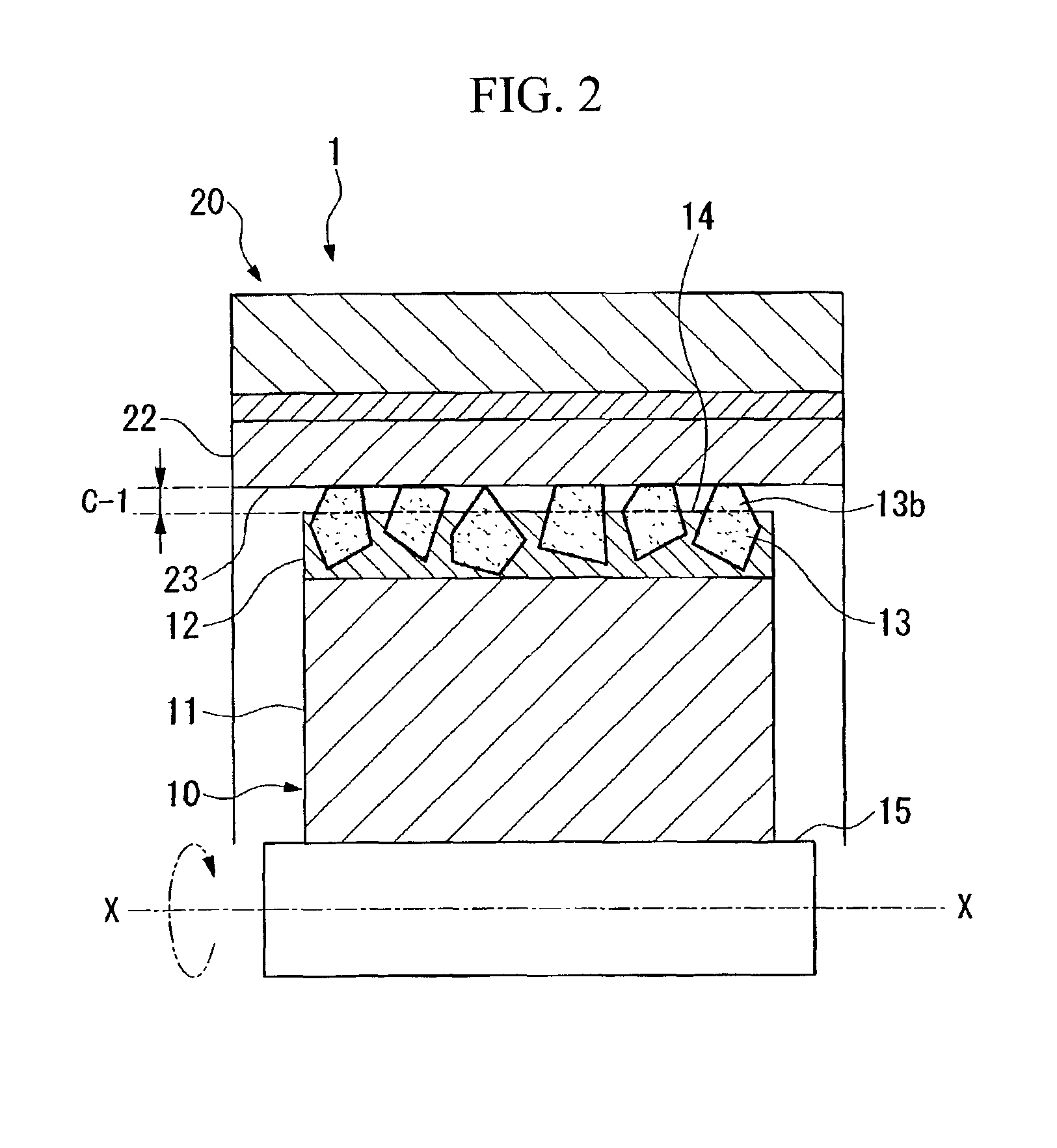

Turbine and manufacturing method therefor

InactiveUS6887036B2Appropriate clearanceLong operationElectrolytic coatingsPump componentsTurbineAbrasive

A tip of rotor blade which rotates is an abradable surface. An inner wall of a shroud as a jacket for the rotor blade is an abrasive surface. A part of an abrasive particle protrudes from the abradable surface. When the tip of the rotor blade which rotates contacts the inner wall of the shroud, the protruding section of the abrasive particle slides with the abrasive surface so as to be ground. By doing this, a turbine which can maintain an appropriate clearance between the rotor blade and the shroud and can be used for a long period under high-temperature conditions with easy restoration and remaking thereof.

Owner:MITSUBISHI HEAVY IND LTD

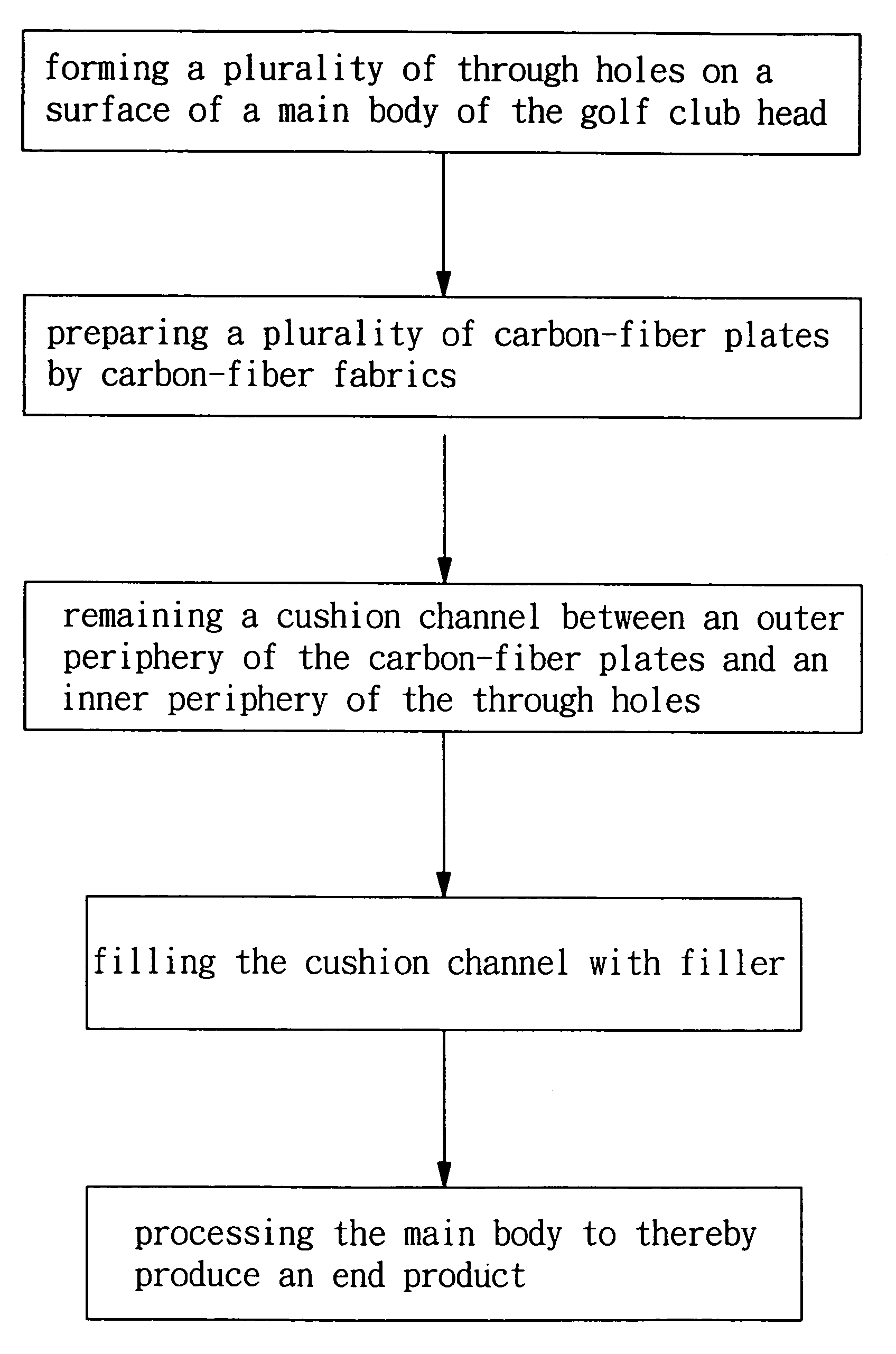

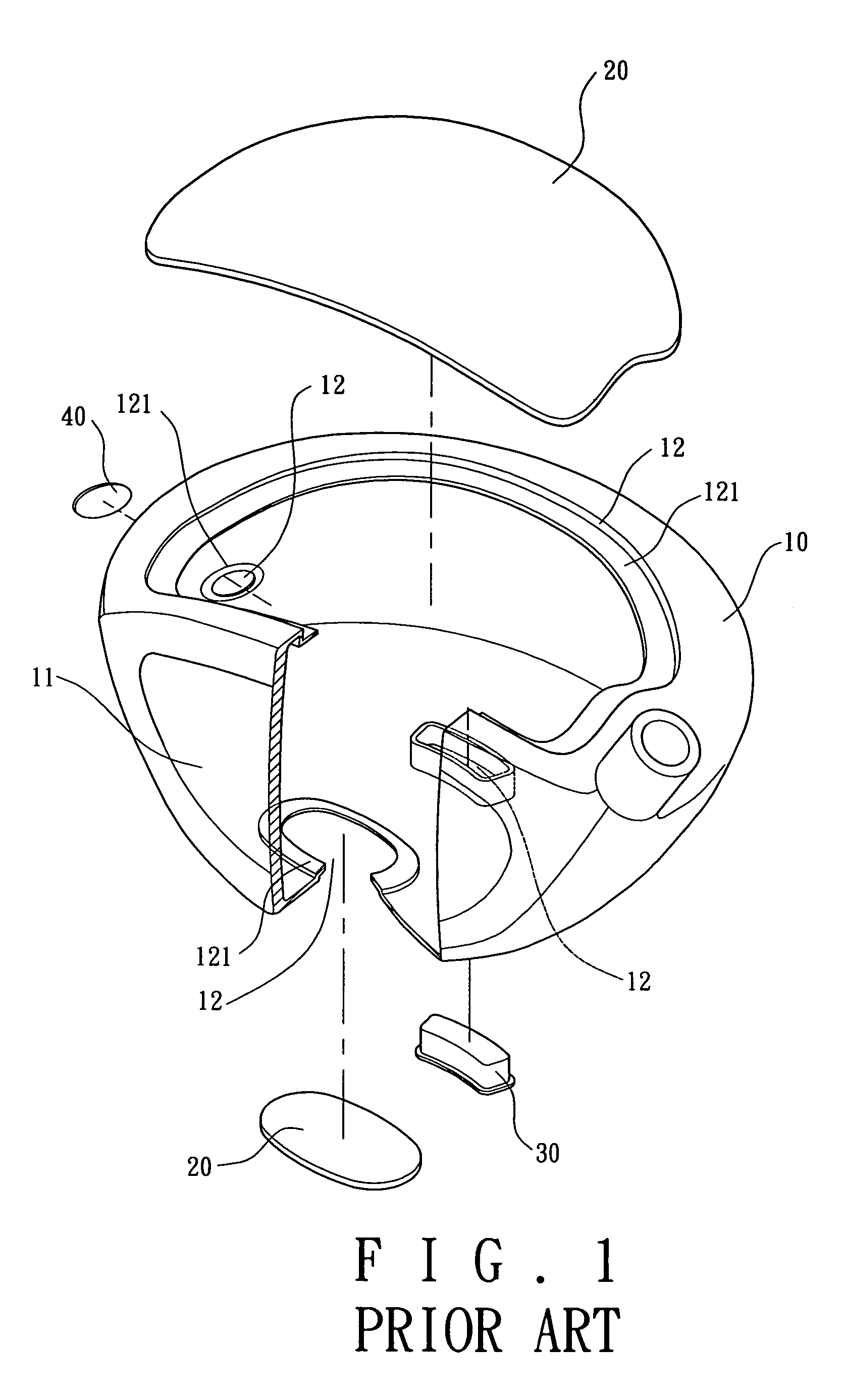

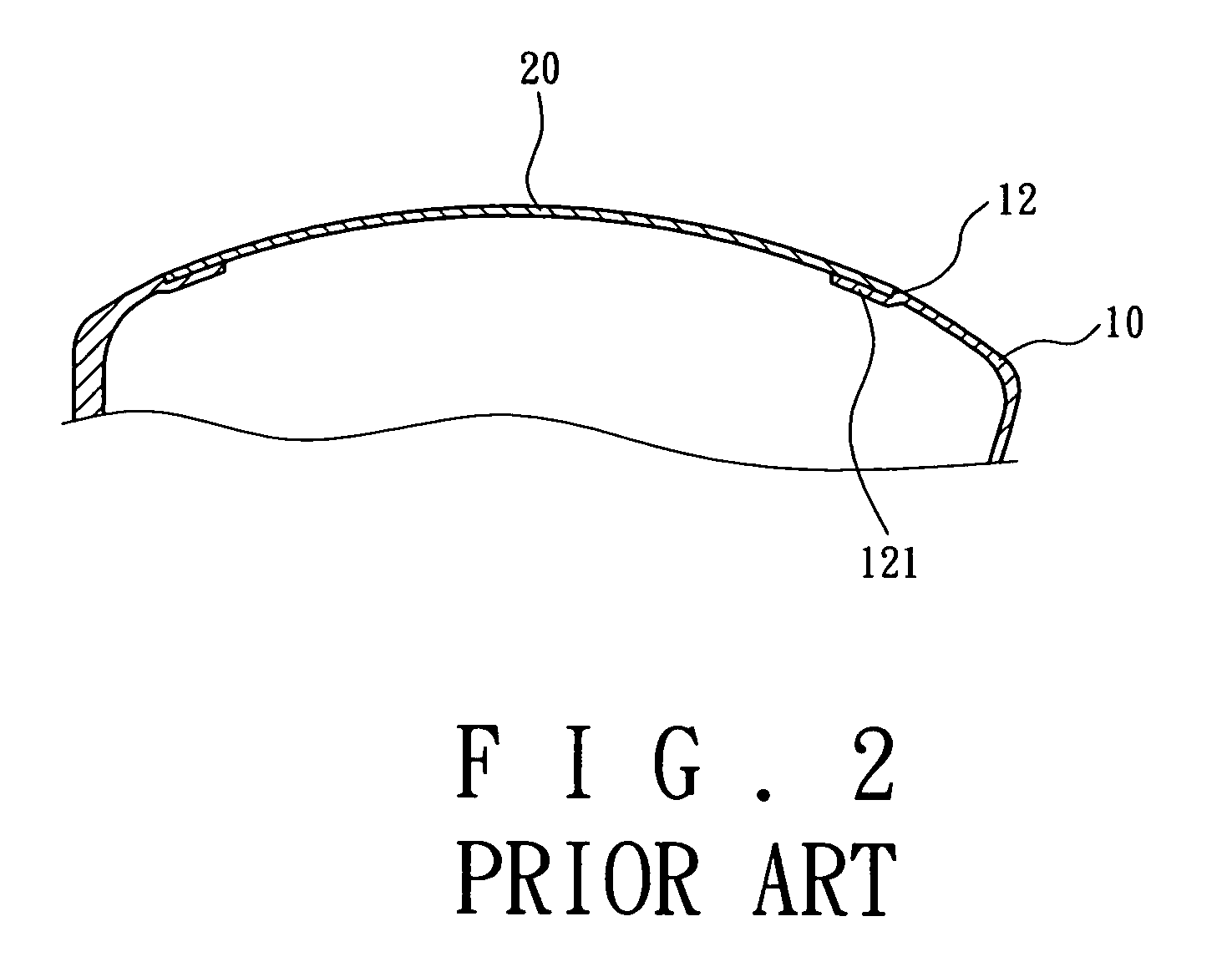

Golf club head and manufacturing method therefor

InactiveUS7022032B2Reduce wrinklesAppropriate clearanceLamination ancillary operationsLaminationFiberCarbon fibers

A golf club head and manufacturing method. The method includes the steps of: selectively forming through holes on a surface of a golf club head; preparing carbon-fiber plates which are made of prepared carbon-fiber fabrics; providing a cushion channel between an outer periphery of the carbon-fiber plate and an inner periphery of the through hole while each of the carbon-fiber plate is combined with the associated through hole of the golf club head; filling the cushion channel with a filler; and finishing the golf club head to produce an end product.

Owner:FUSHENG PRECISION

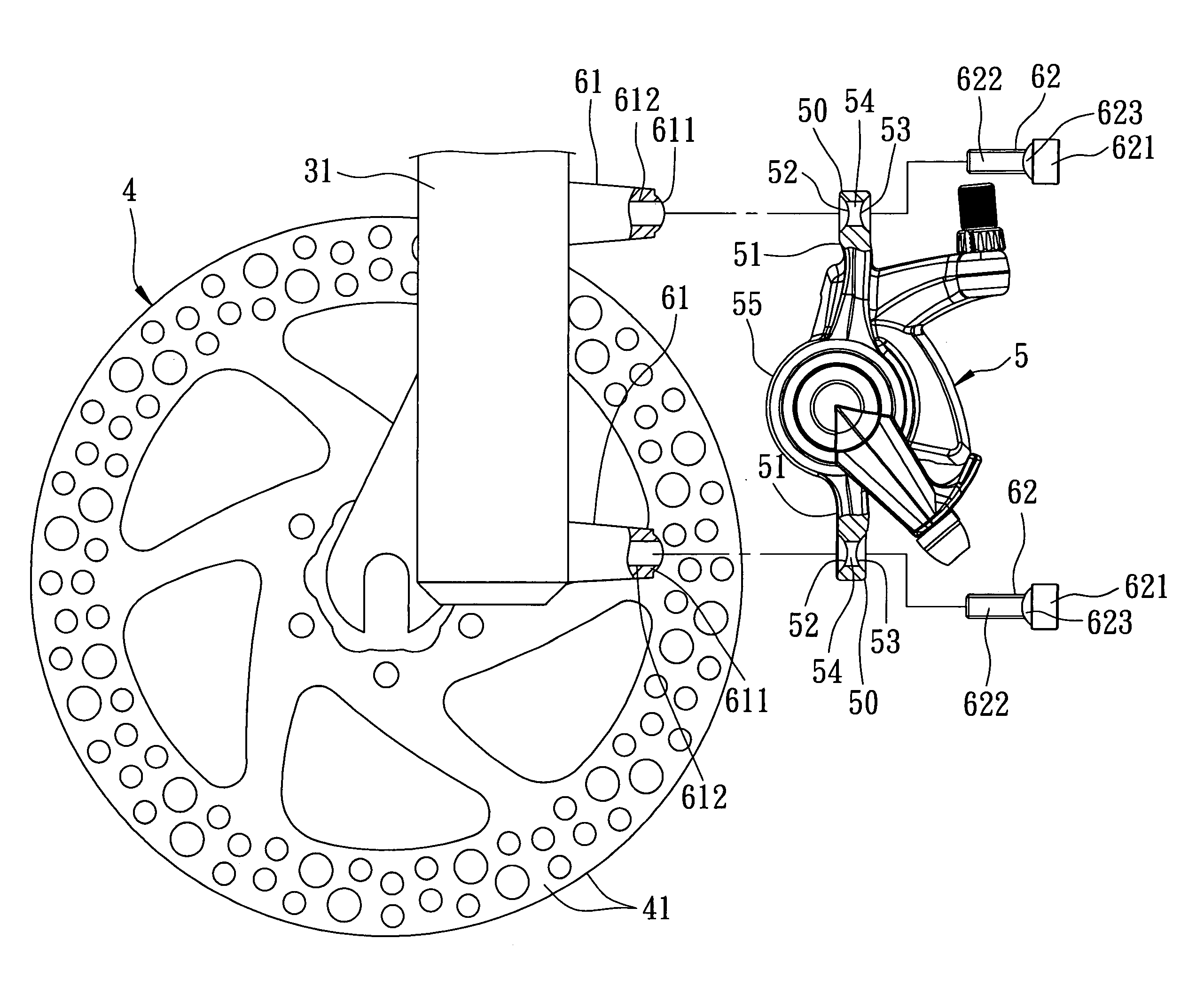

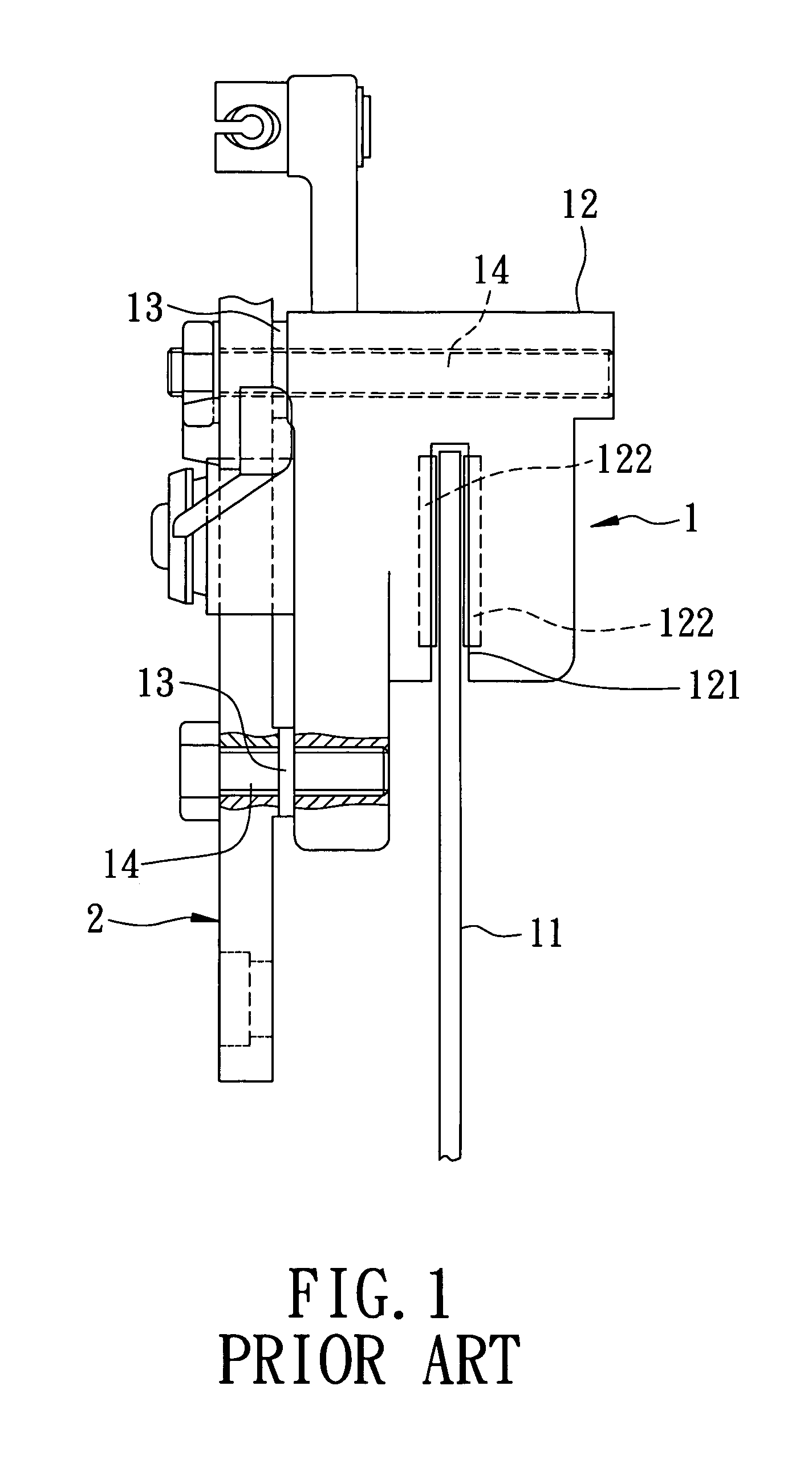

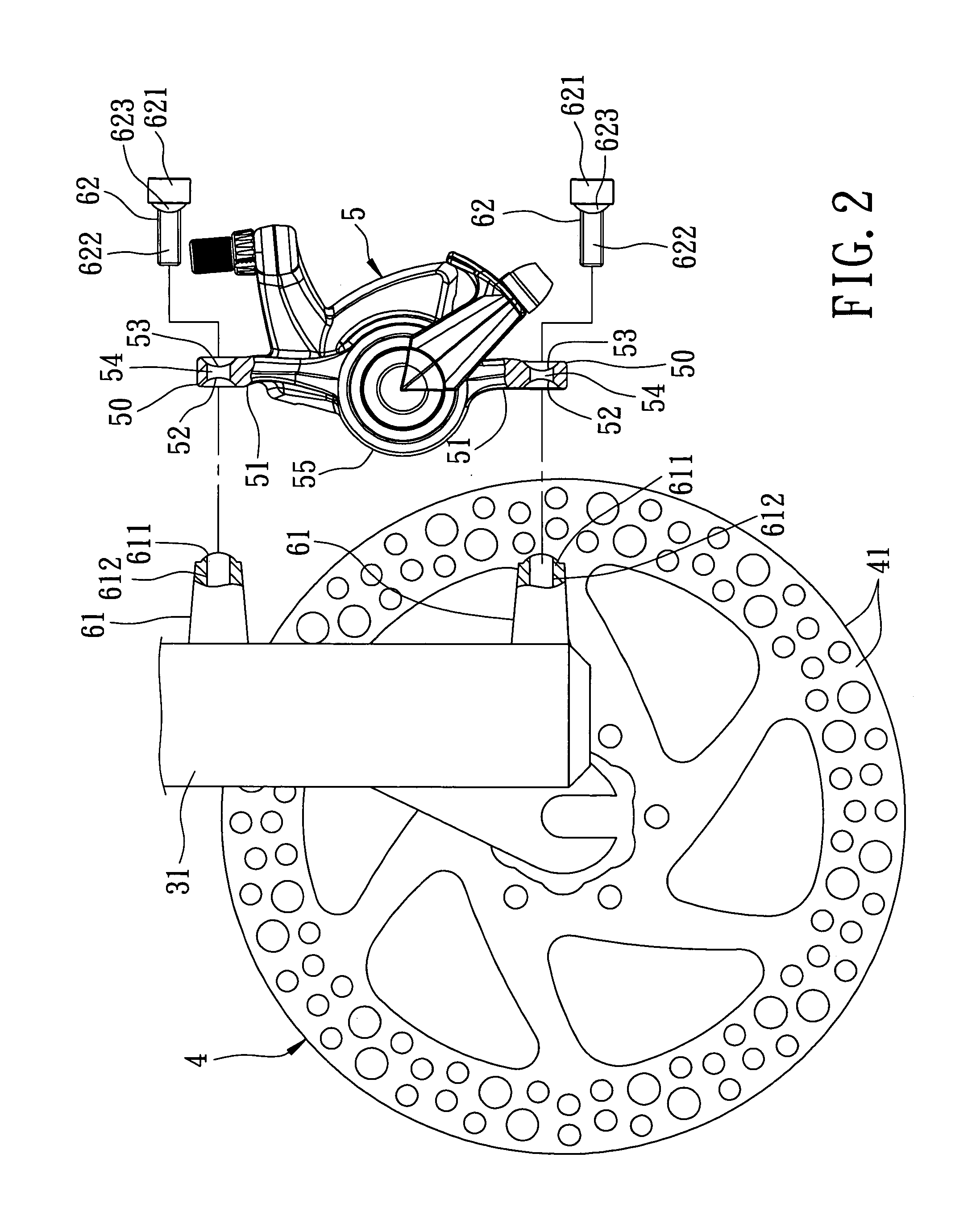

Bicycle disk brake device

InactiveUS7007776B1Easy to adjustAppropriate clearanceAxially engaging brakesCycle brakesCouplingEngineering

A bicycle disk brake device includes an anchored member secured to a bicycle frame and having a coupling wall, a caliper having two brake linings mounted thereon and a compliant wall compliantly mated with the coupling wall, and a brake disk secured to the bicycle frame and spaced apart from the linings. A tightening member is disposed to displace the compliant wall from a slightly loosened position, where the compliant wall is permitted to angularly displace relative to the coupling wall so as to adjust a position of the linings relative to the disk, to a tightened position, where the compliant wall is prevented from moving relative to the coupling wall. Due to the compliant mating of the coupling and compliant walls, the position of the linings can be adjusted conveniently and precisely.

Owner:LIN AH PING

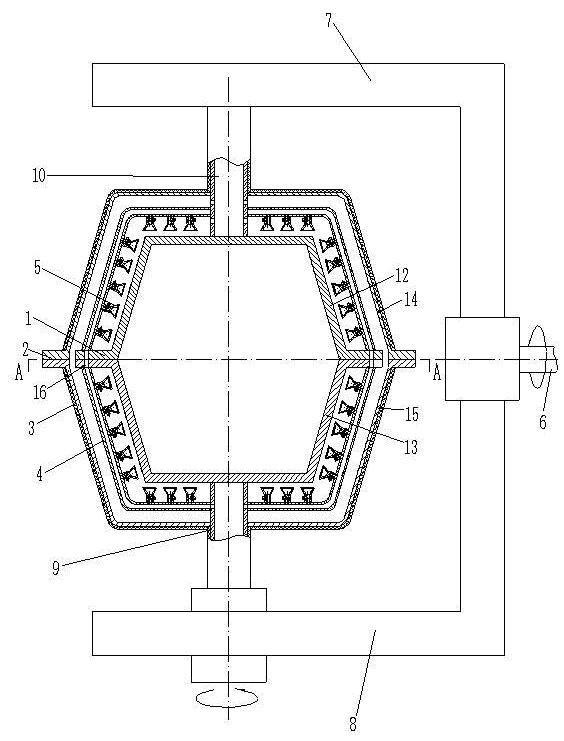

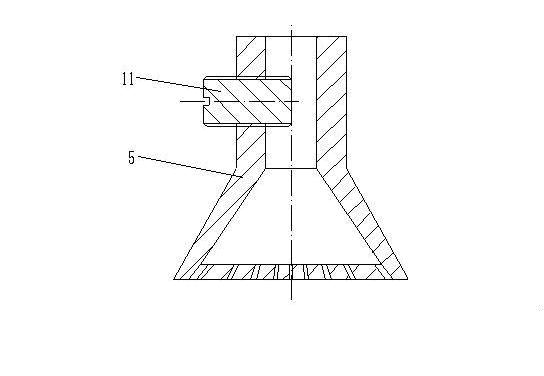

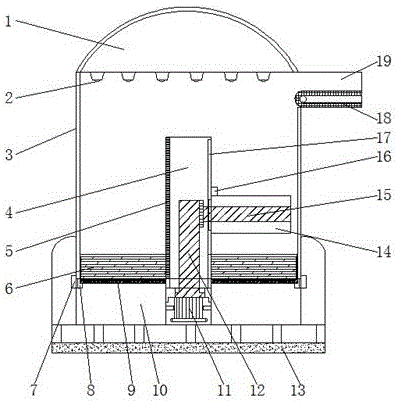

Rotational molding forming device

The invention discloses a rotational molding forming device applying constant-temperature jet-propelled heating, belonging to the technical field of rotational molding. The rotational molding forming device is used for manufacturing large and medium plastic products with complicated shapes by using a rotational molding technology. The rotational molding forming device mainly comprises an air heating system, a forming die, a gas recycling cover, an insulating layer, a hot air distributing pipe, a nozzle, a rotational spindle cylinder, a crank arm, a hot air inlet pipe and a hot air distributing pipe air outlet pipe. Polymers capable of being applied to rotational molding forming can be processed into plastic products by using the device. According to the invention, the deficiency in several kinds of rotational molding more widely applied to the rotational molding forming device is solved to a certain degree. The novel rotational molding forming device has the advantages of high temperature control precision, good temperature uniformity, high heat exchange efficiency and low die cost, and overcomes the defects of large energy loss, long production period, low production efficiency and the like of the rotational molding forming device.

Owner:BEIJING UNIV OF CHEM TECH

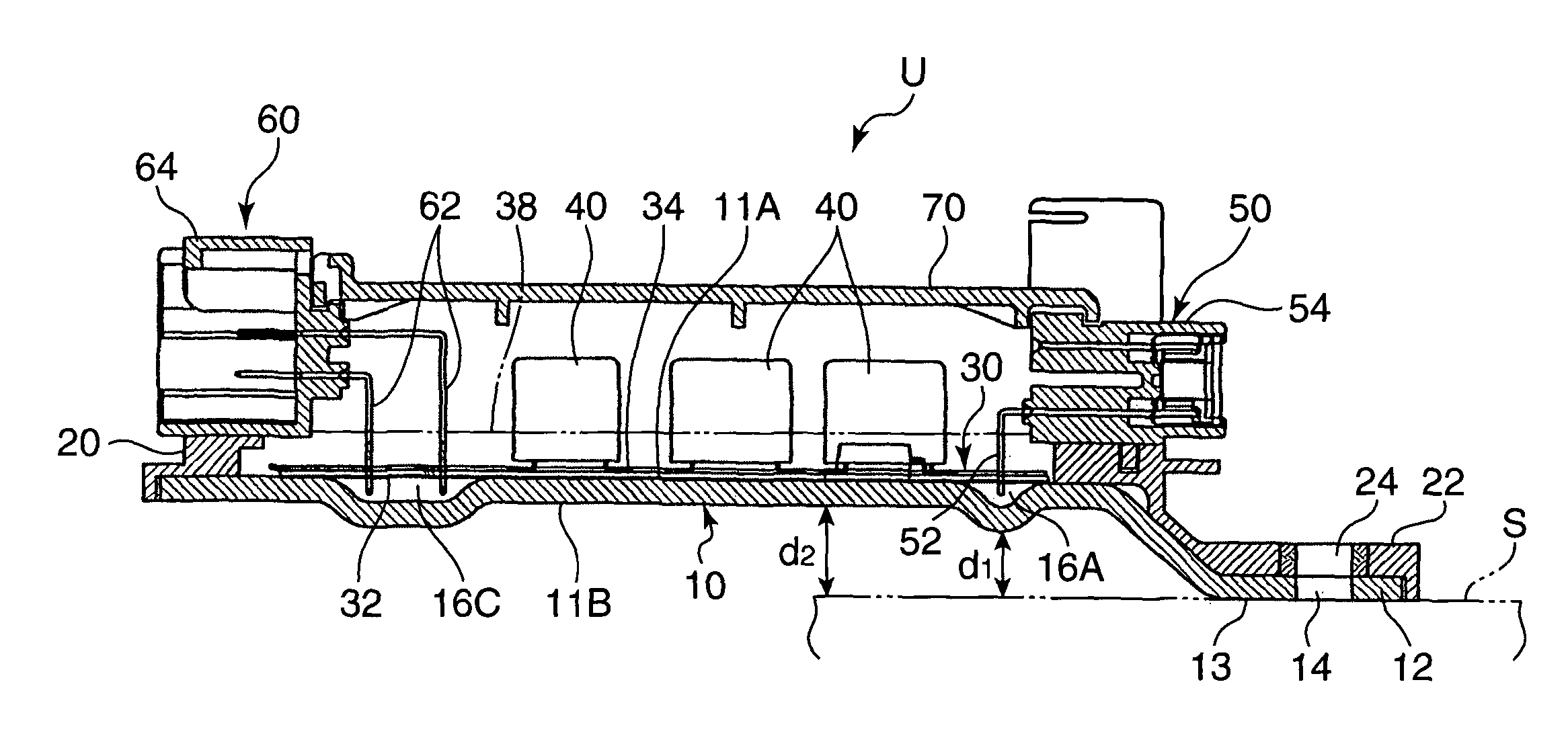

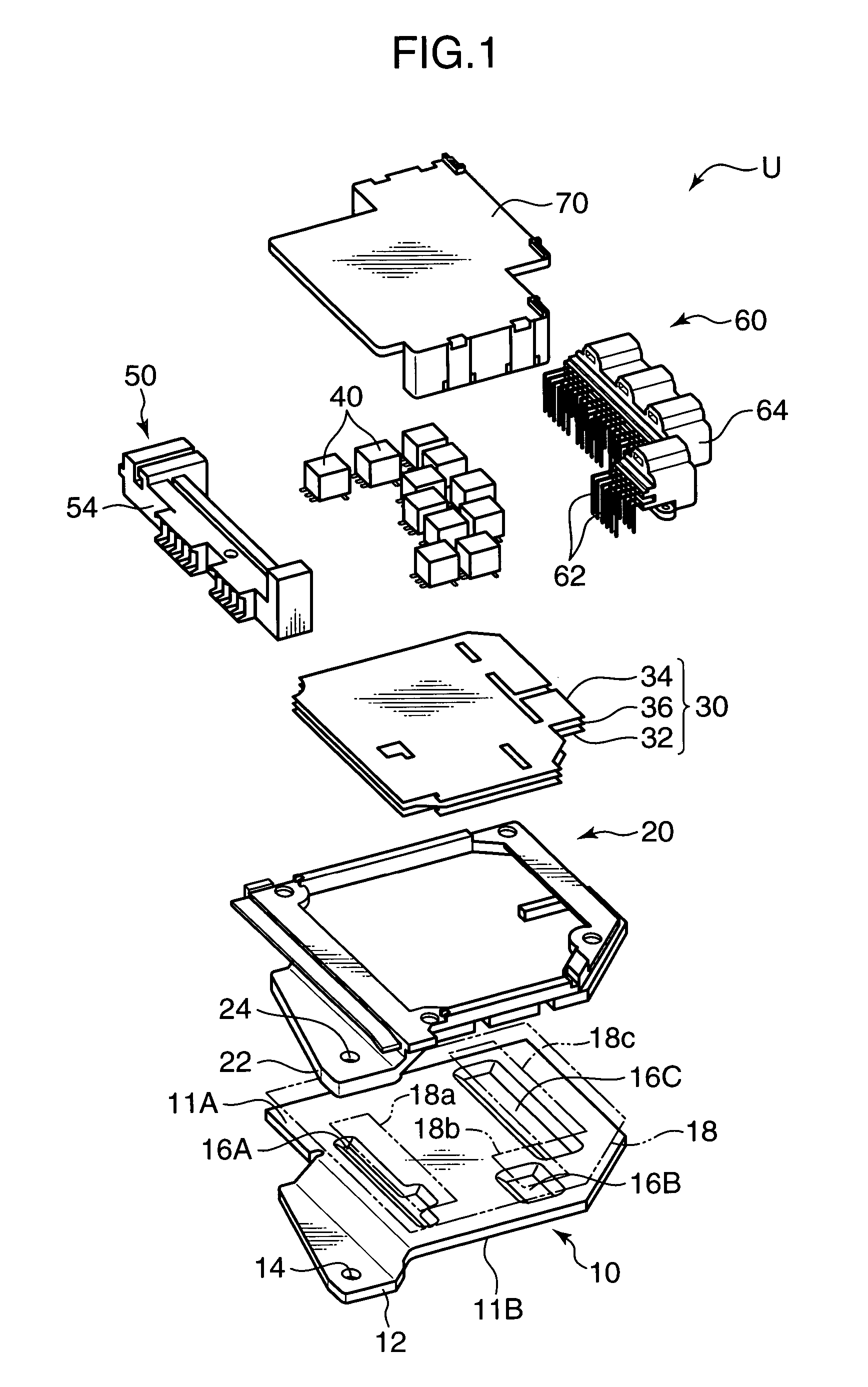

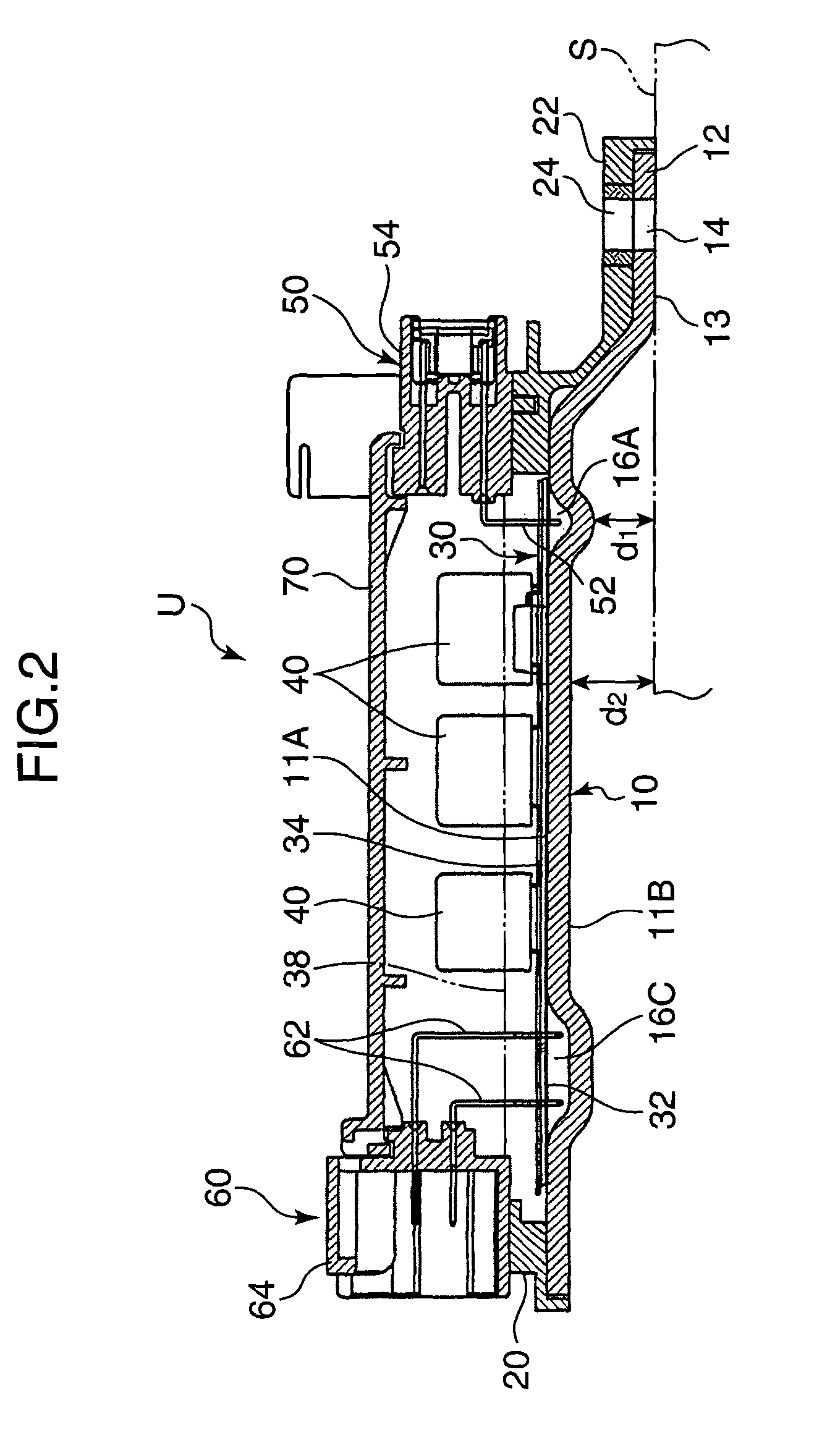

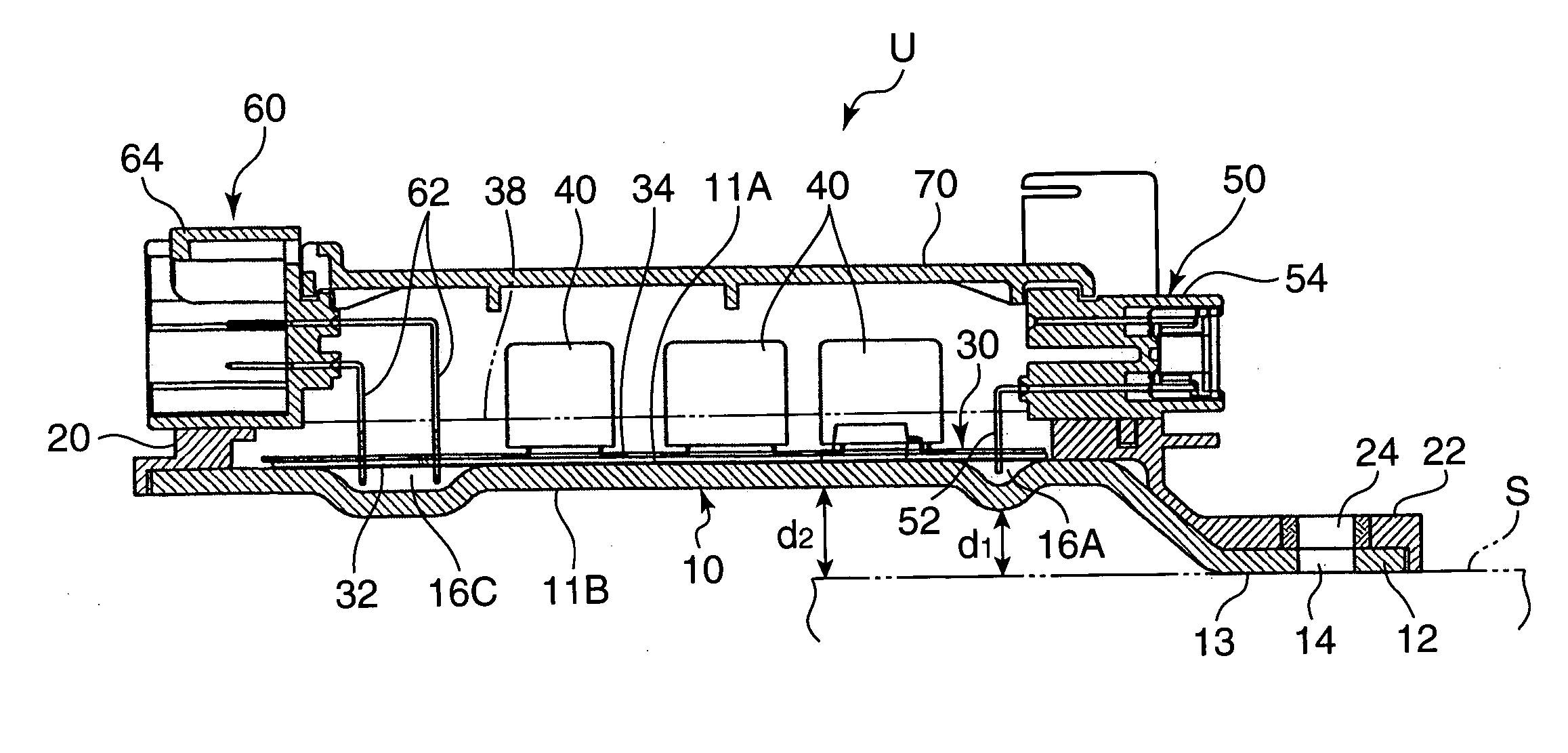

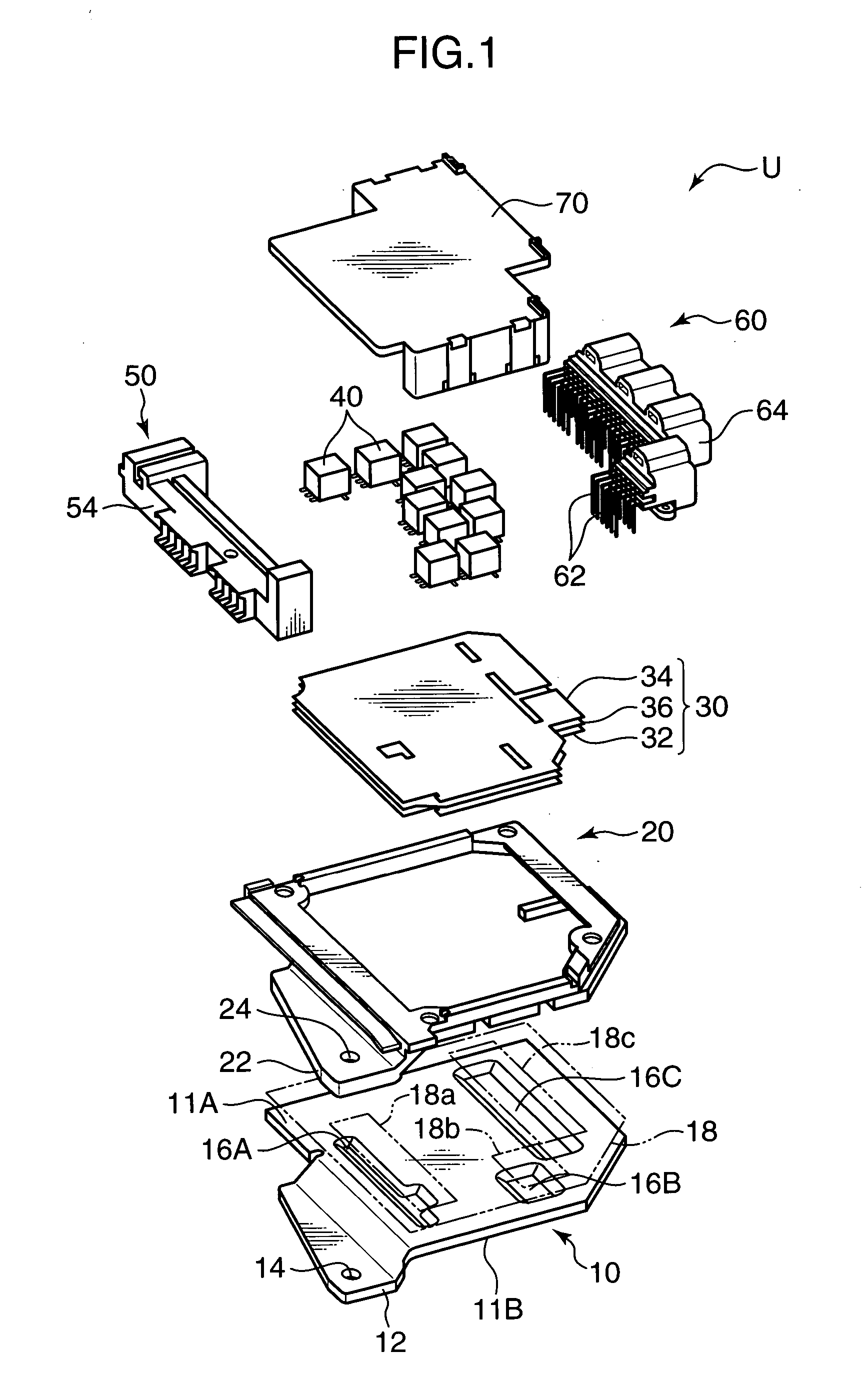

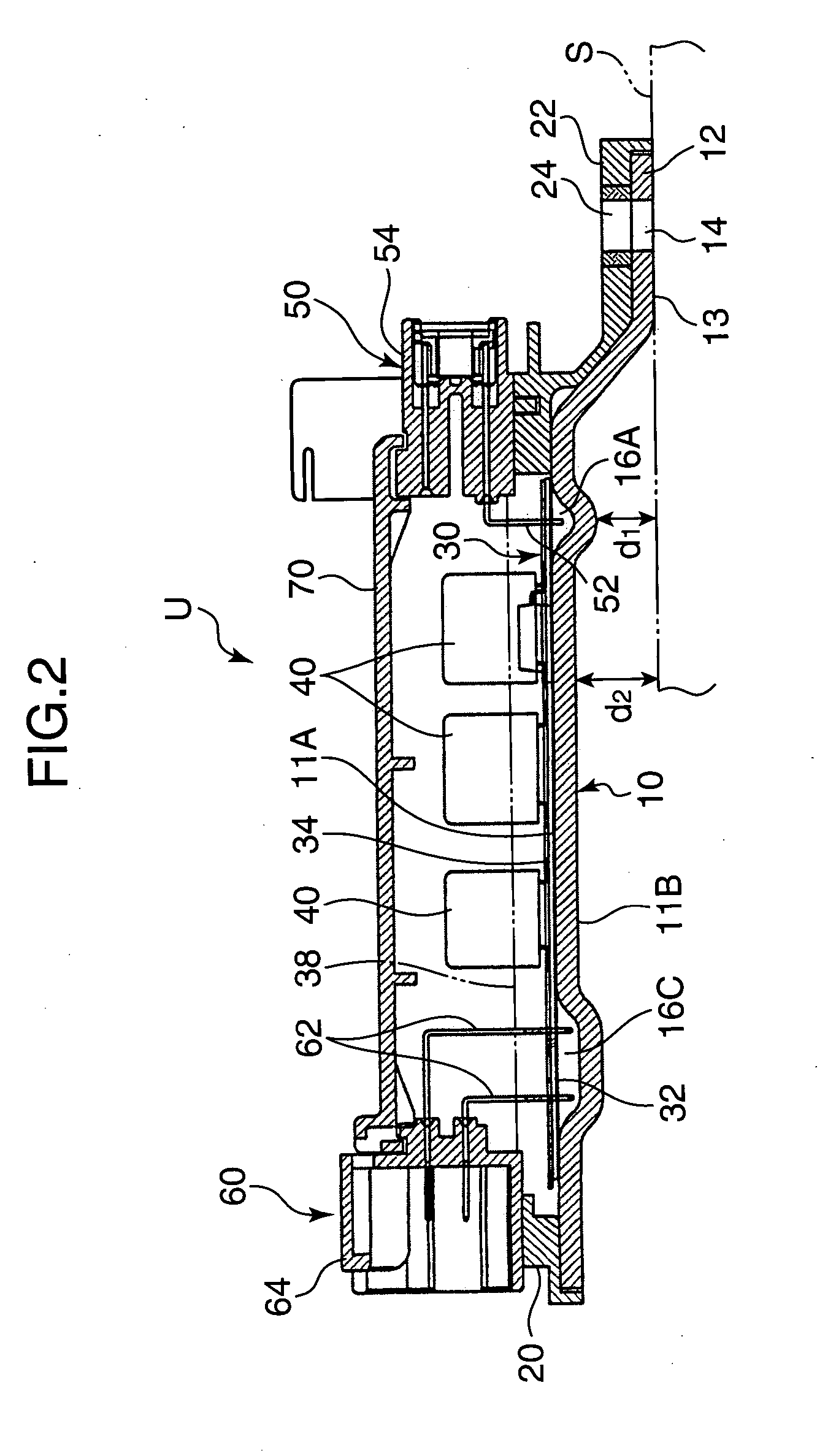

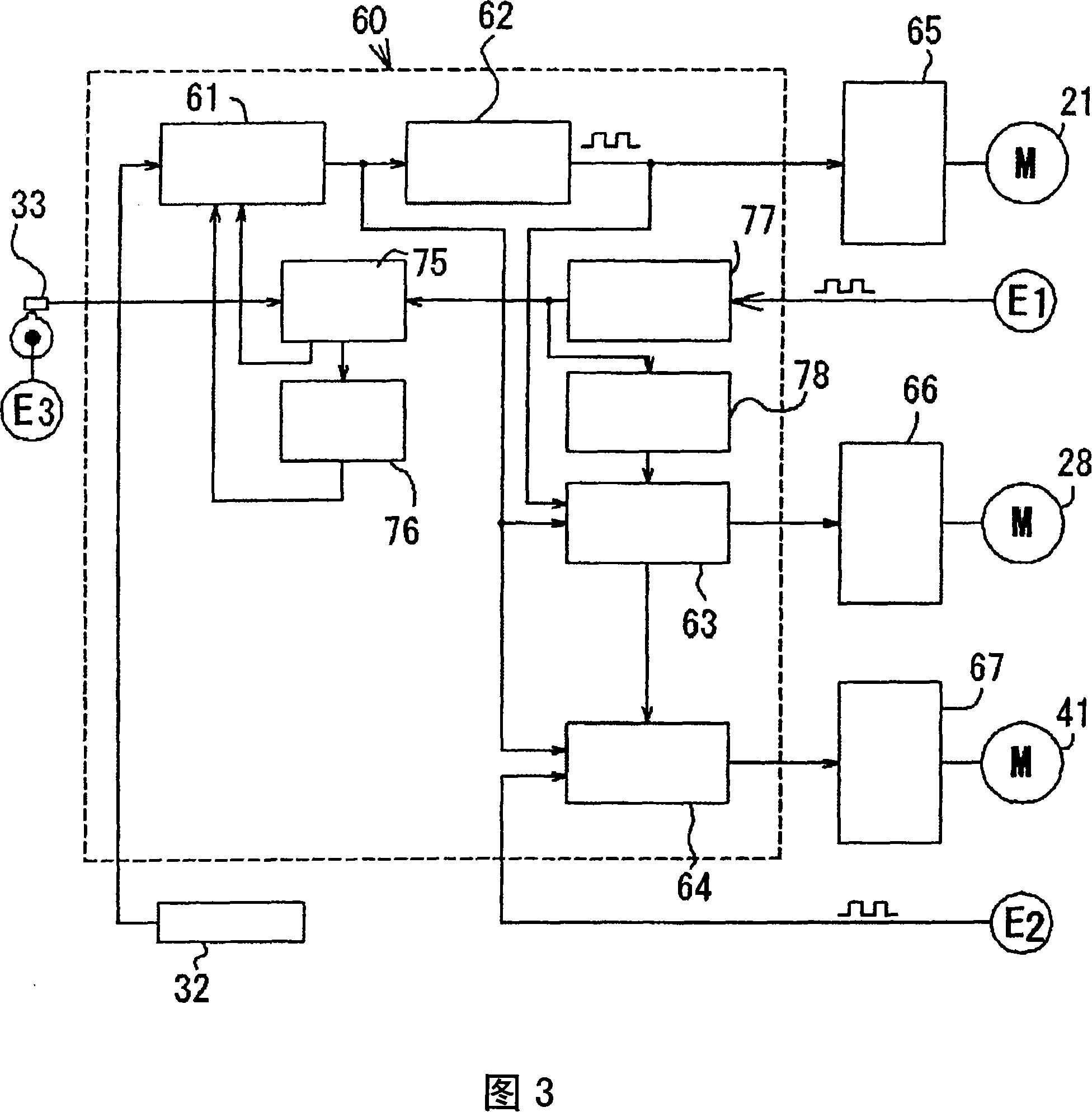

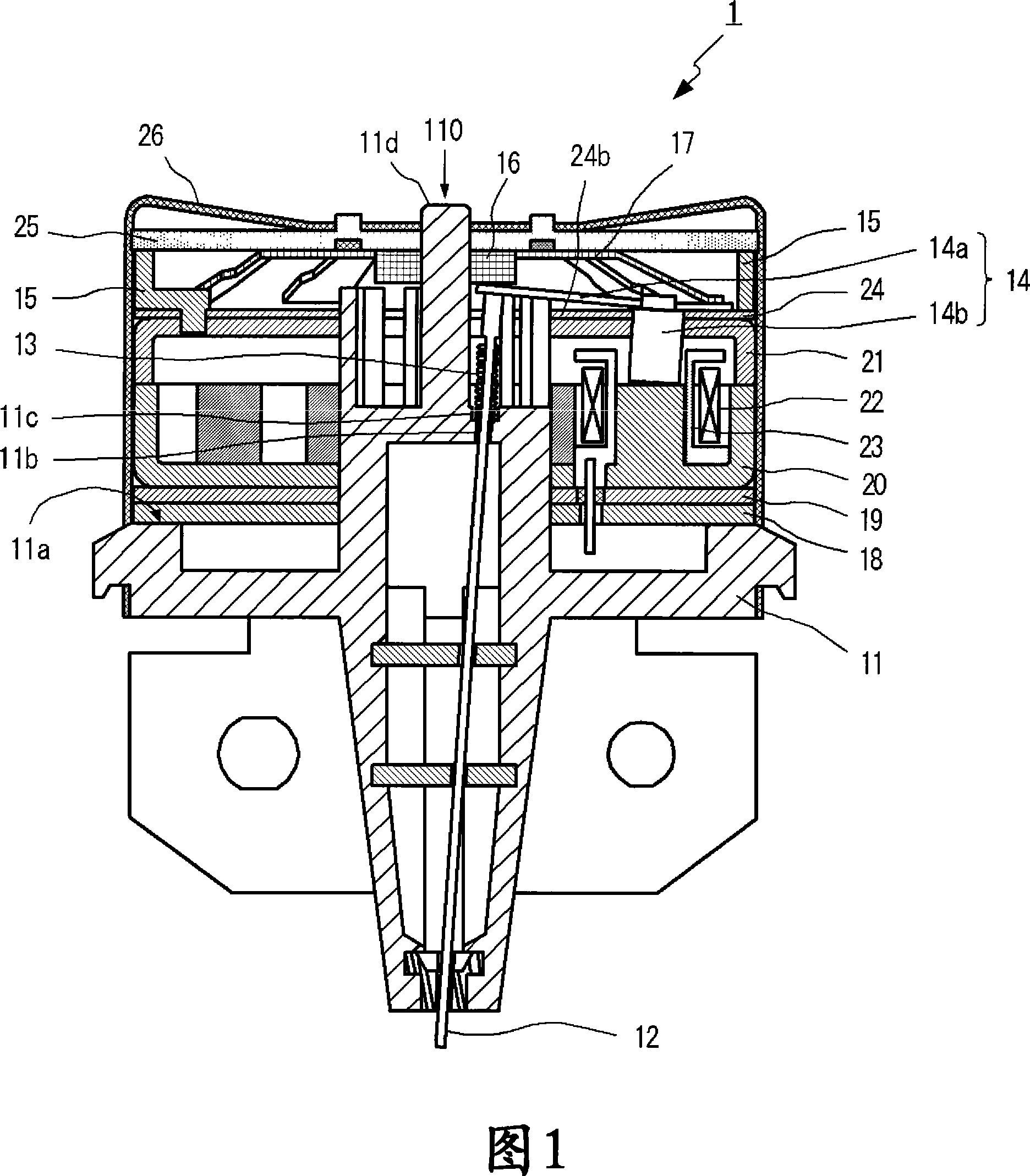

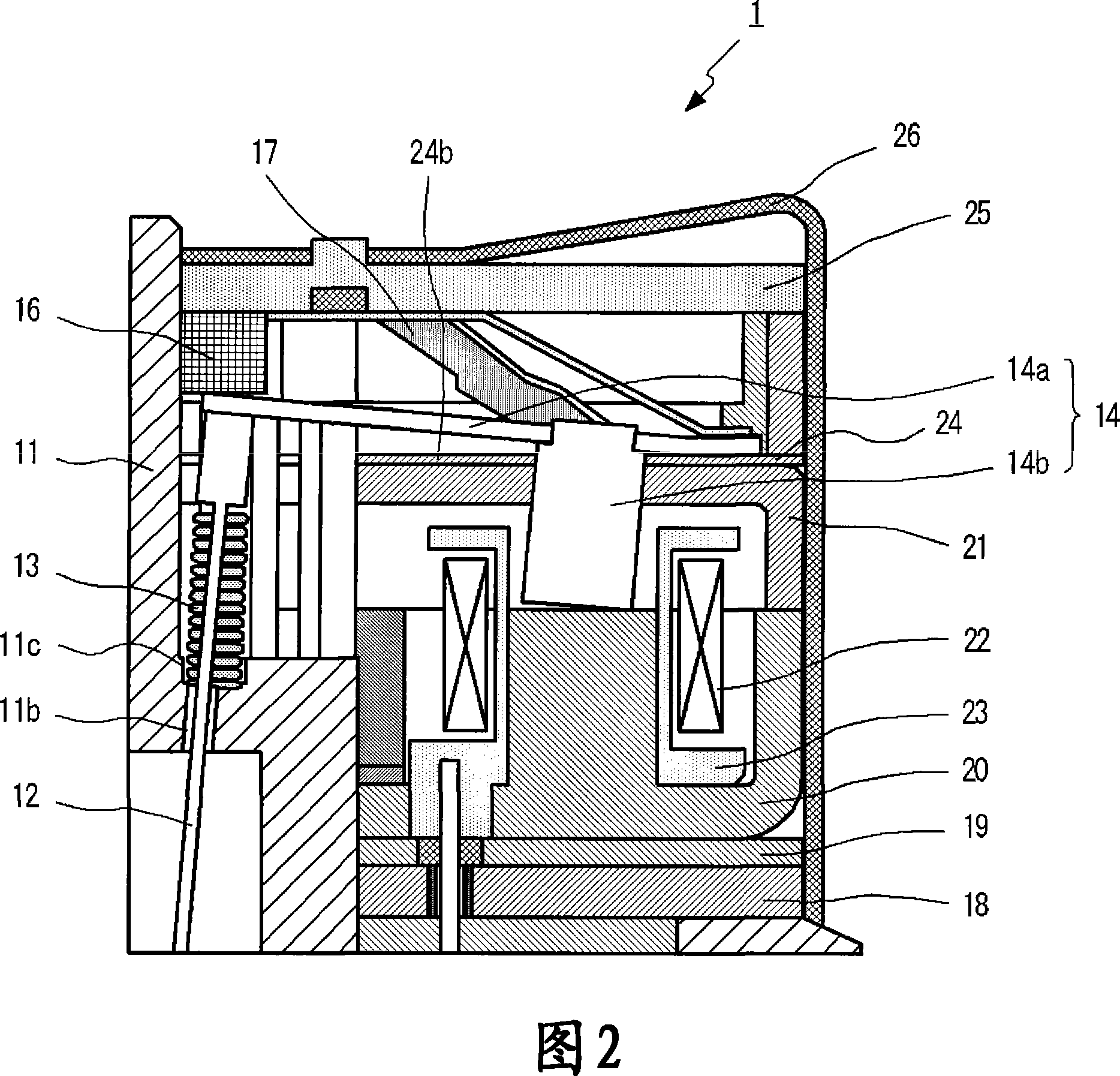

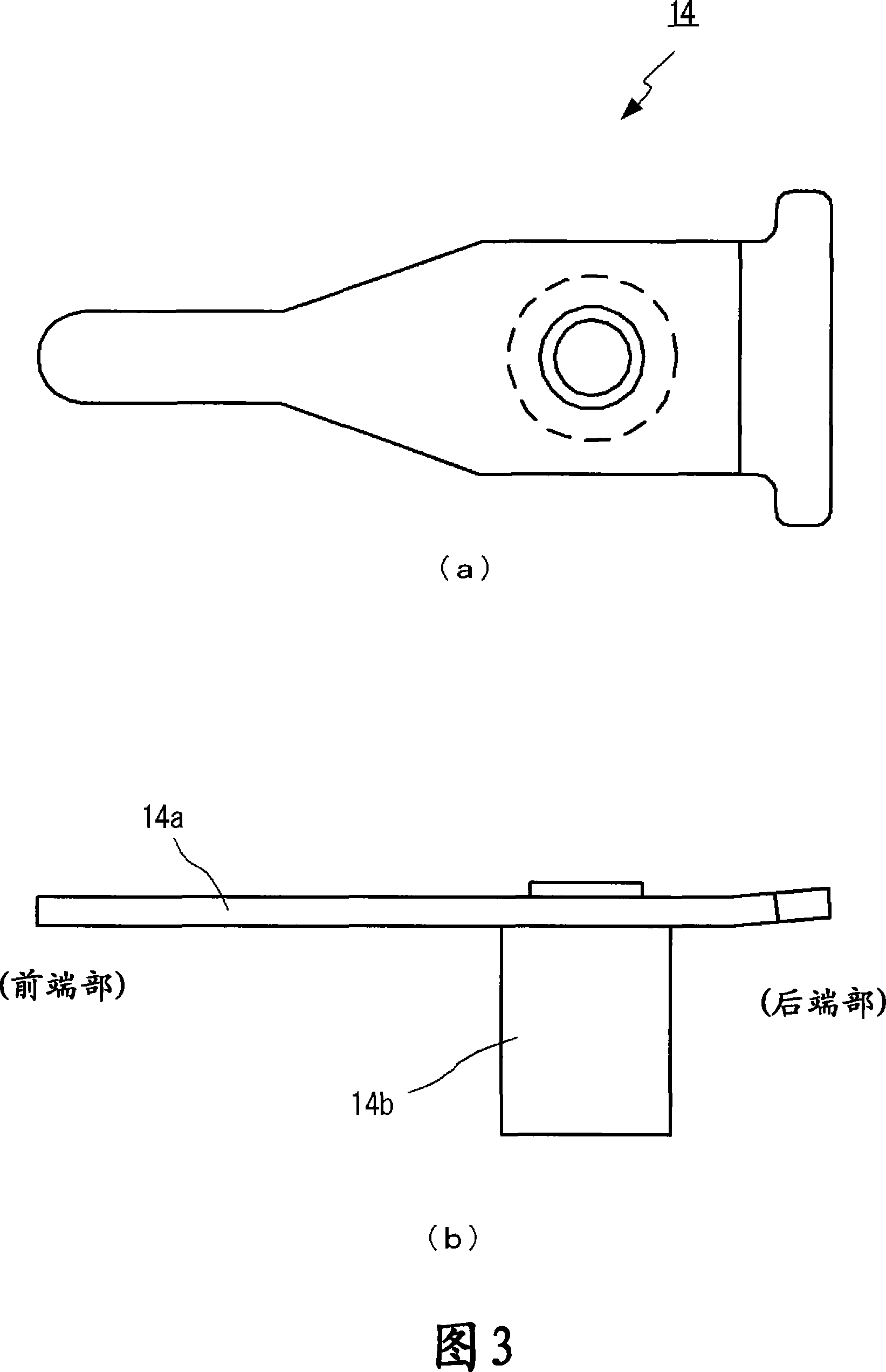

Mounting structure of on-vehicle circuit unit and on-vehicle circuit unit

ActiveUS8356762B2Improve cooling effectAvoid noiseAir-treating devicesRailway heating/coolingEngineeringBody surface

It is an object to effectively reduce minute clearances generated between a heat radiating member and a vehicle body and ensure good cooling performance while avoiding the occurrence of impact and noise caused by the vibration of a vehicle. A circuit unit U is mounted such that an outer surface 11B of the heat radiating member 10 to which the circuit body 30 is fixed faces a body surface S of the vehicle with a clearance. Preferably, the mounting part 12 fixed to the body of the vehicle is extended, the surface 13 of the mounting part 12 which is in contact with the body is positioned to be substantially parallel to the outer surface 11B of the heat radiating member and a step is provided in both surfaces 13, 11B. In a mounted state, the body and the outer surface 11B of the heat radiating member are facing each other in a substantially parallel state and a clearance is formed between the body and the outer surface of the heat radiating member over the entire area excluding the mounting part 12.

Owner:AUTONETWORKS TECH LTD +2

Mounting structure of on-vehicle circuit unit and on-vehicle circuit unit

ActiveUS20060289664A1Improve cooling effectAvoid noiseAir-treating devicesRailway heating/coolingEngineeringMechanical engineering

It is an object to effectively reduce minute clearances generated between a heat radiating member and a vehicle body and ensure good cooling performance while avoiding the occurrence of impact and noise caused by the vibration of a vehicle. A circuit unit U is mounted such that an outer surface 11B of the heat radiating member 10 to which the circuit body 30 is fixed faces a body surface S of the vehicle with a clearance. Preferably, the mounting part 12 fixed to the body of the vehicle is extended, the surface 13 of the mounting part 12 which is in contact with the body is positioned to be substantially parallel to the outer surface 11B of the heat radiating member and a step is provided in both surfaces 13, 11B. In a mounted state, the body and the outer surface 11B of the heat radiating member are facing each other in a substantially parallel state and a clearance is formed between the body and the outer surface of the heat radiating member over the entire area excluding the mounting part 12.

Owner:AUTONETWORKS TECH LTD +2

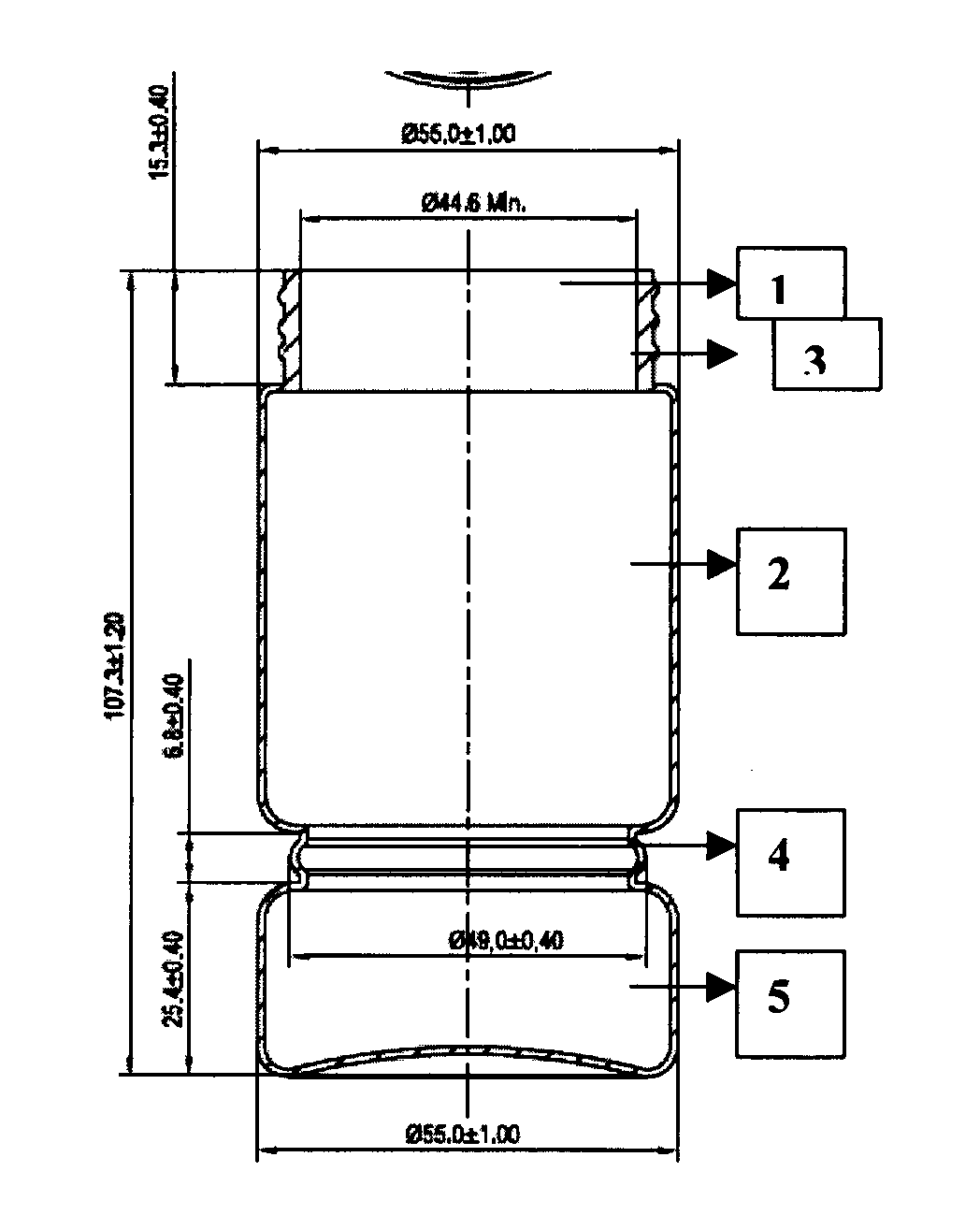

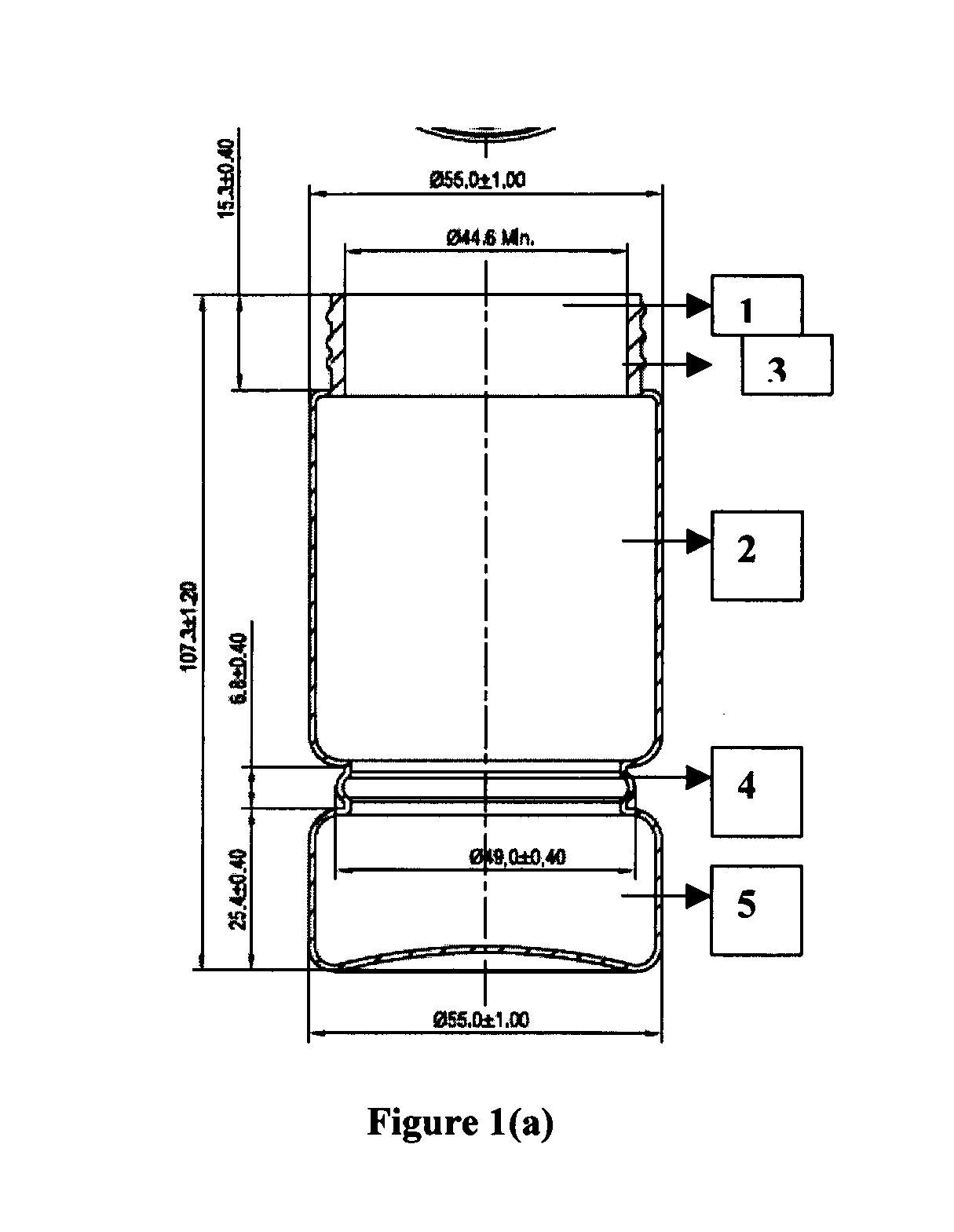

Desiccant container

InactiveUS20130213828A1Effectively and efficiently removes moistureAvoid enteringPharmaceutical containersMedical packagingDesiccantEngineering

Owner:LUPIN LTD

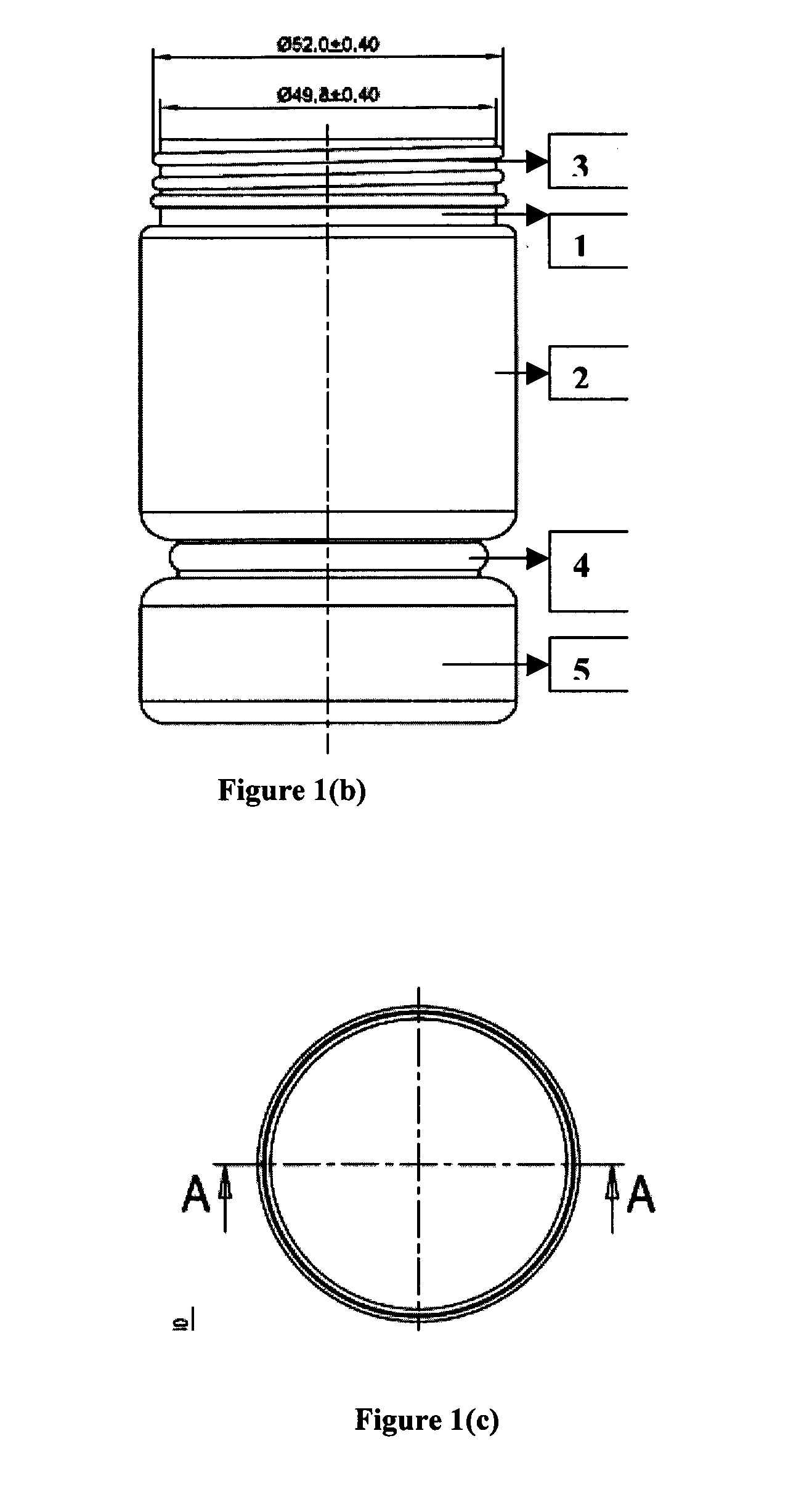

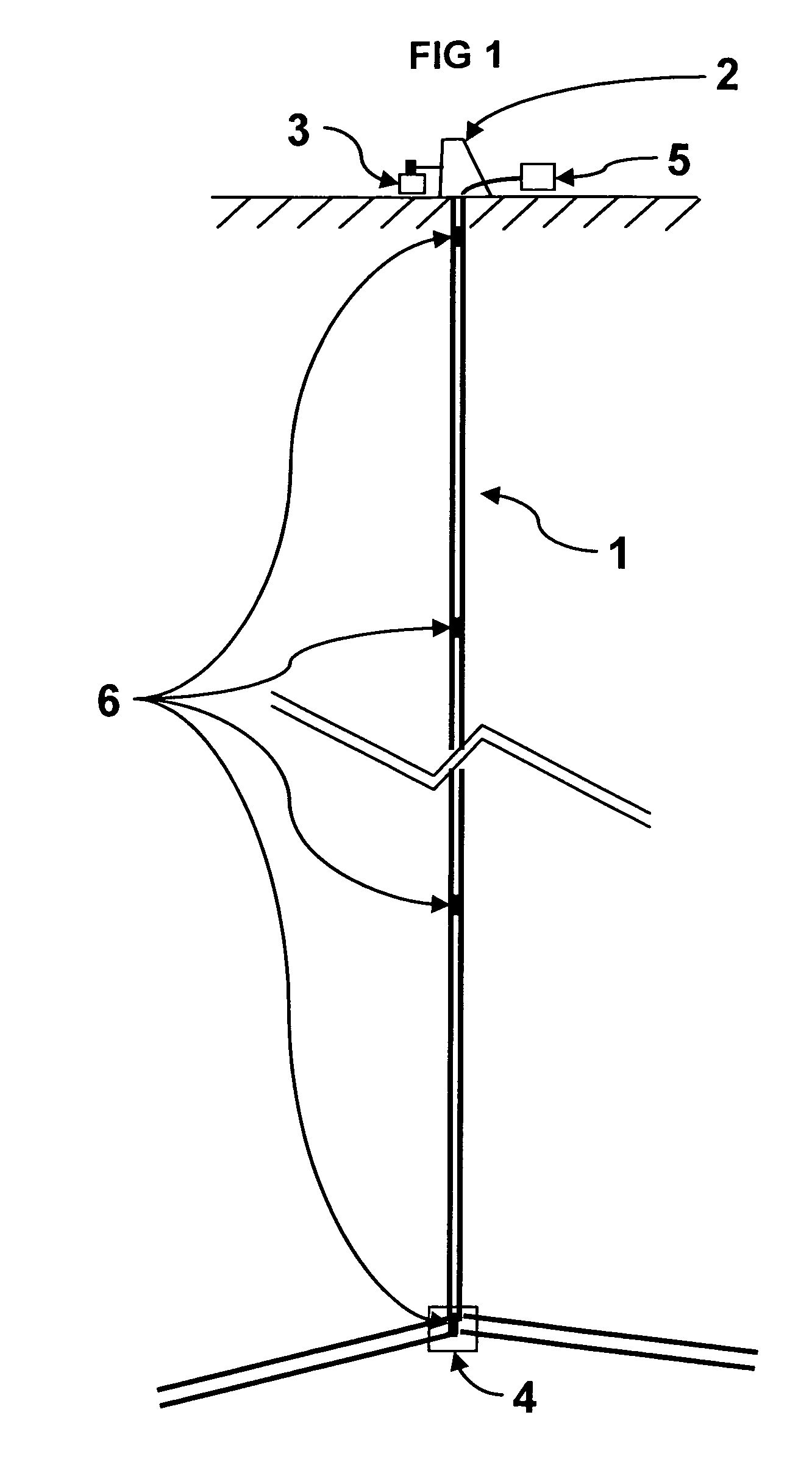

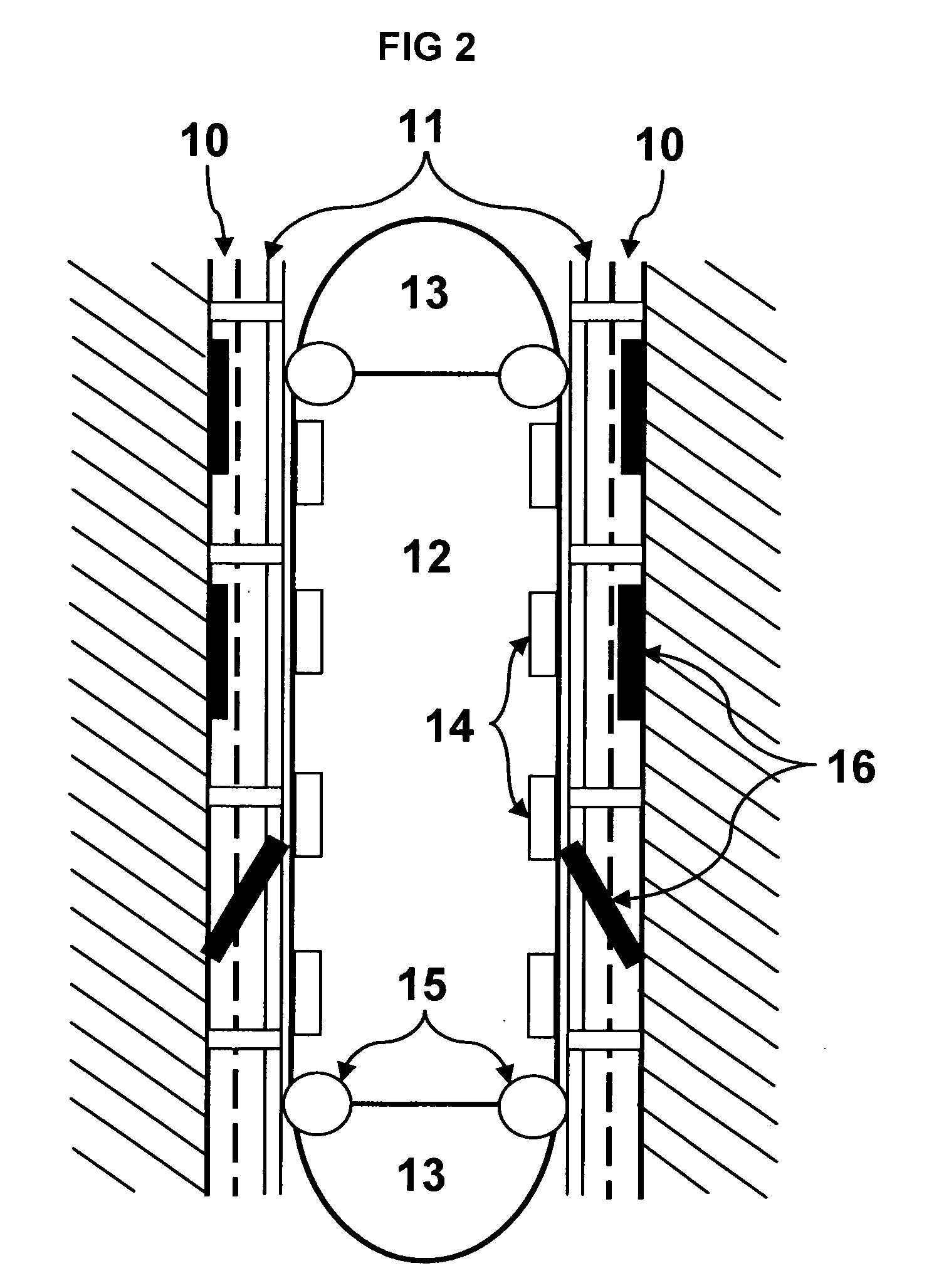

Transportation of underground mined materials utilizing a magnetic levitation mass driver in a small shaft

InactiveUS20100276253A1Improve efficiencyEasy to transportElevatorsBuilding liftsLevitationHeadframe

A conveyance system that utilizes an electromagnetic levitation motor acting as a mass driver to transport mined materials via a small shaft wherein multiple small skips are in transit simultaneously and which allows for return of the skips via the same route wherein the mass driver is used as a braking mechanism. The system also includes guideways to keep the skips in the correct position during transit, a safety system to prevent skips from falling back during a power failure, a system for feeding the skips to the mass driver at the lower end, and a headframe system for capturing skips at the upper end, unloading them, and feeding them back to the mass driver for the descent to the bottom.

Owner:ASHLEY KEVIN JOHN

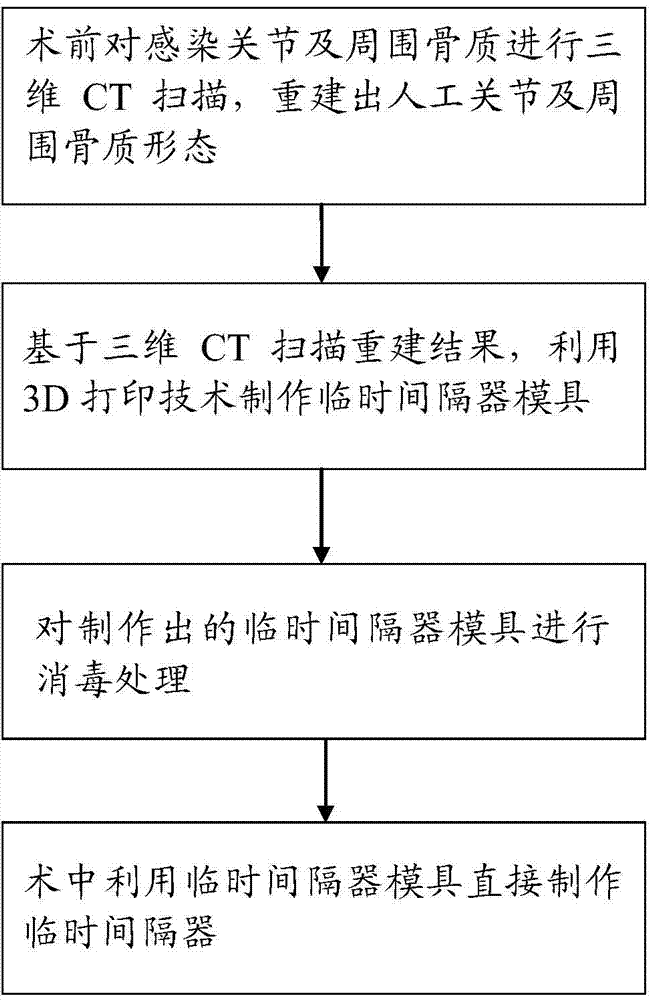

Manufacturing method of temporary spacer in artificial joint replacement operation

InactiveCN104490492ANot suitable for deformationEasy to useJoint implantsThree dimensional ctArtificial joints

The invention discloses a manufacturing method of a temporary spacer in an artificial joint replacement operation. The manufacturing method of the temporary spacer is used when the infection condition occurs after operation, and comprises the following steps that before infection operation, the injection joint and peripheral bone are subjected to three-dimensional CT (computed tomography) scanning, and the artificial joint and peripheral bone form is reestablished; on the basis of the 3D (three-dimensional) CT scanning reestablishing result, a temporary spacer mold is manufactured by a 3D printing technology; the manufactured temporary spacer mold is subjected to disinfection treatment; in the infection operation process, the temporary spacer is directly manufactured by utilizing the manufactured temporary spacer mold. The manufacturing method of the temporary spacer in the artificial joint replacement operation has the advantages that medical workers can conveniently and directly manufacture the temporary spacer according to the mold manufactured before operation, the temporary spacer more conforms to the local joint form, after the temporary spacer is placed, the proper gap and tension can be properly maintained, and the generation of joint capsule soft tissue contracture and disuse bone mass loss during the interval between two operations is avoided.

Owner:BEIJING CHUNLIZHENGDA MEDICAL INSTR

A kind of stage-by-stage solid culture method of Beauveria bassiana

InactiveCN102286385AReduce the chance of contaminationImprove ventilation performanceFungiMicroorganism based processesHyphomycetesFungal mycelium

The invention provides a method for carrying out solid culturing on beauveria bassiana by stages, which is characterized in that the beauveria bassiana solid culturing process is divided into two stages, i.e. a mycelium growing stage and a sporulating stage; in the mycelium growing stage, a closed fermenting mode is adopted and a liquid strain is inoculated with a solid culture material in a closed container to carry out culturing; and in the sporulating stage, the solid culture material on which mycelia full grow is taken out in a buckled mode and an open fermenting mode is adopted. The method for carrying out solid culture on the bassiana, which is provided by the invention, has simple process and does not need complex equipment. The fermenting period of the method is shortened to 6 to 7 d from 10 to 14 days in the prior art. The production efficiency is greatly improved. Meanwhile, the requirement on the environment humidity is low. The probability of the mixed fungi pollution is obviously reduced. The production cost is low. The method is easy to control and has high success rate. The product quality is stable. The method can be applied to laboratory production, can be used asthe preferred scheme of upgrading of technology of masses of small and medium bassiana manufacturers and has obvious social and economic benefits.

Owner:FUJIAN ACAD OF FORESTRY

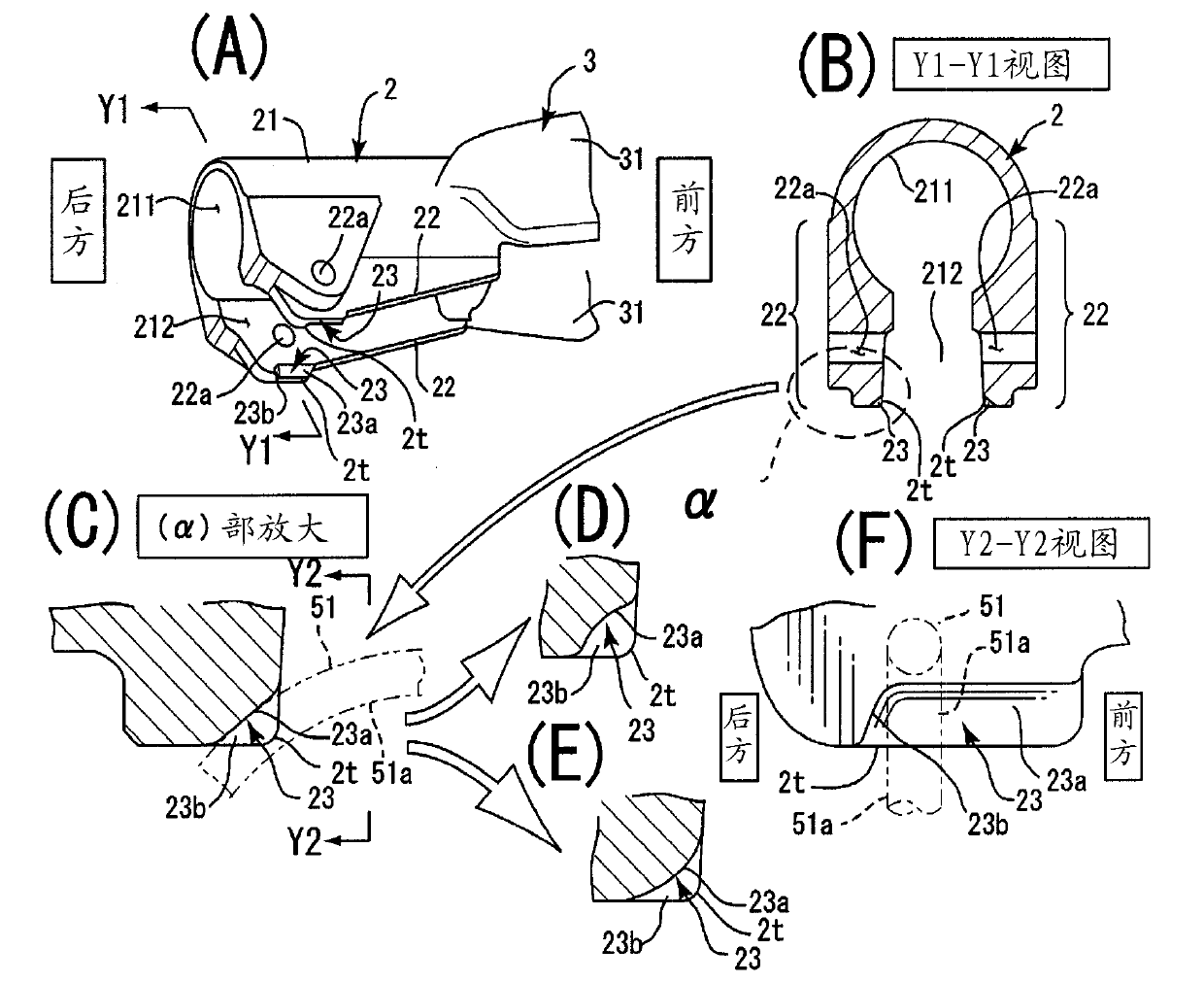

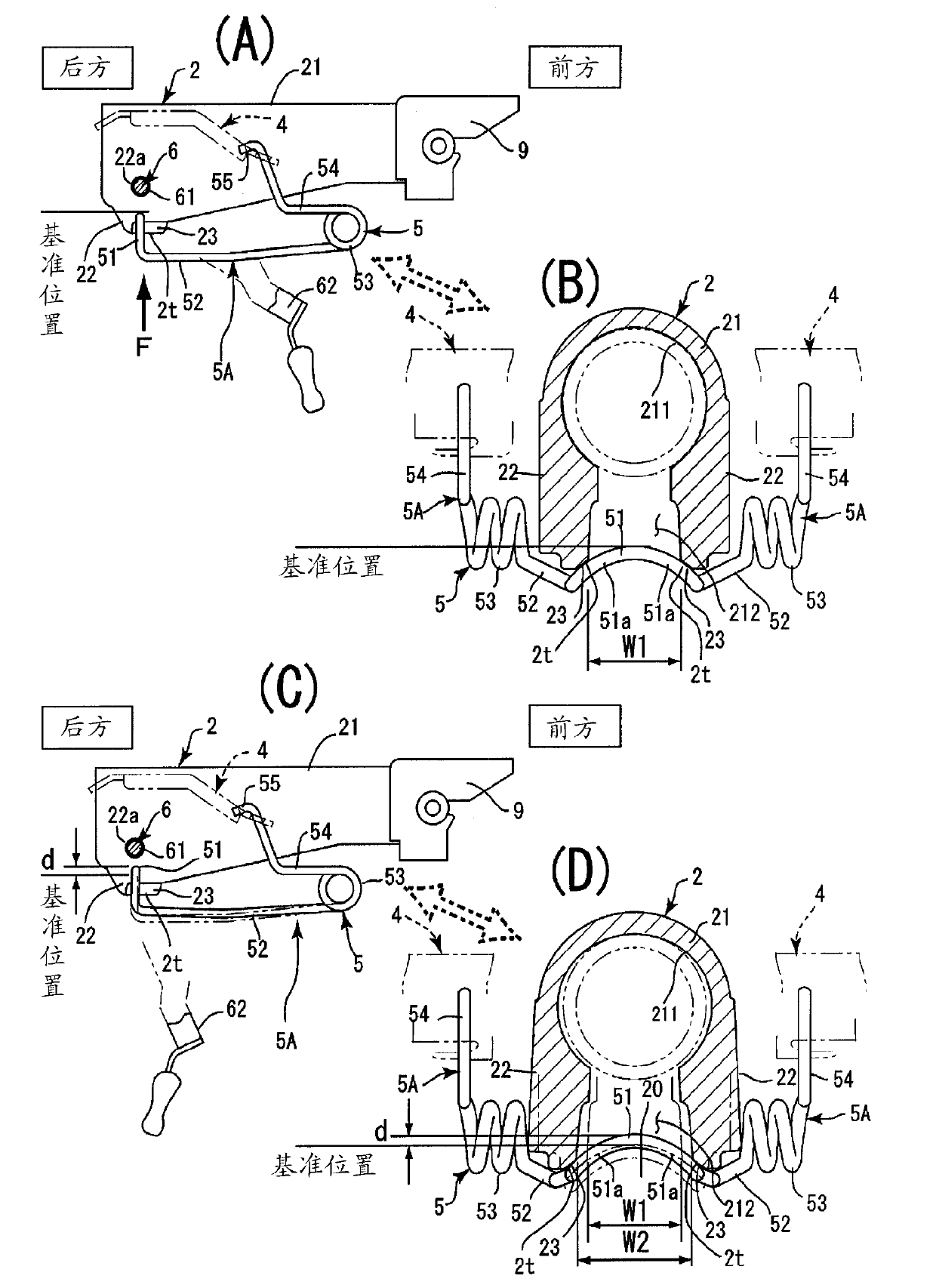

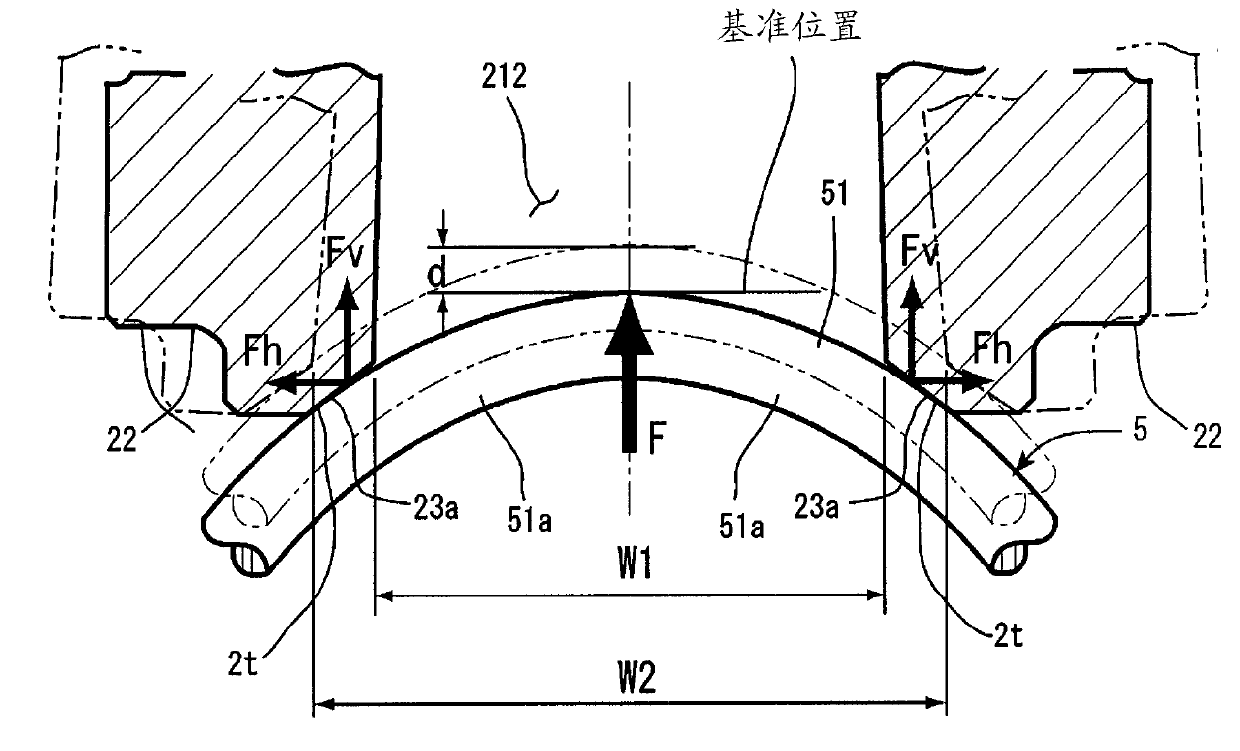

Steering device

InactiveCN102627119AAppropriate clearanceImproved telescoping operabilitySteering columnsEngineeringFastener

A steering device includes an outer column including fastening pieces formed to face each other at both sides, in the width direction, of a slot portion formed at either of a lower side or an upper side of an embracing body portion along an axial direction thereof, a fixed bracket clamping the outer column, a fastener that fastens the outer column and the fixed bracket, an inner column, and a pushing member having an expanding shaft portion. The two fastening pieces of the embracing body portion are connected by the fastener so that the two fastening pieces can be expanded and contracted, and the expanding shaft portion is elastically biased in an axial center direction of the outer column so as to abut on end zones of the slot portion and expand the two fastening pieces.

Owner:YAMADA SEISAKUSHO KK

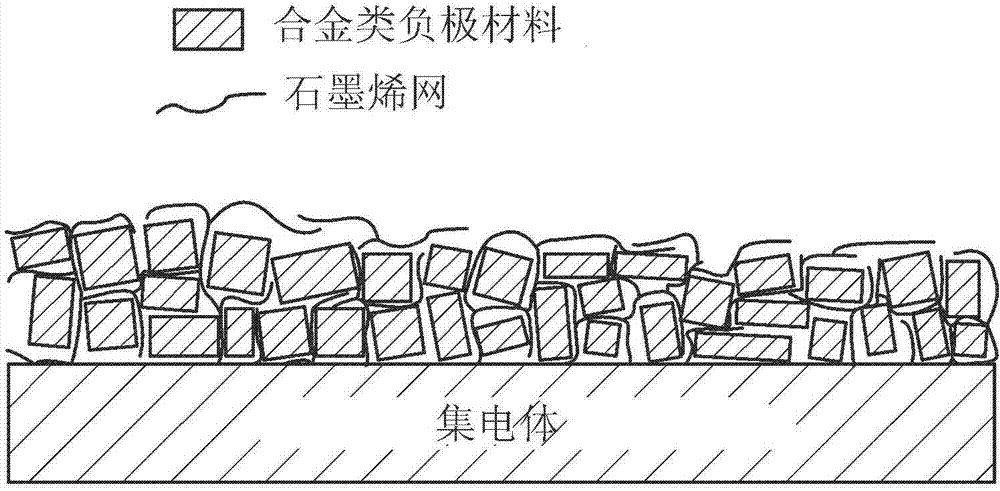

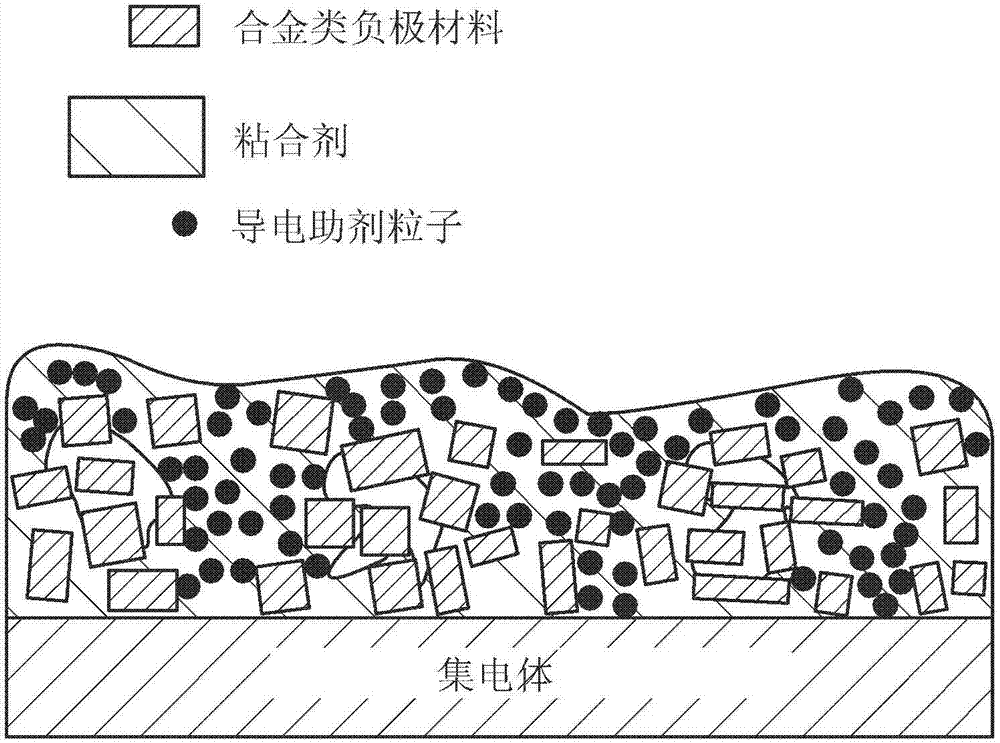

Power storage device and method of manufacturing the same

ActiveCN102810672AAvoid breakingInhibit deteriorationFinal product manufactureNon-aqueous electrolyte accumulator electrodesCarbon filmLithium

The invention provides a power storage device and a method of manufacturing the same. One embodiment of the invention provides a lithium-ion secondary battery with suppressed degradation of battery characteristics due to a volume change of alloy-based negative electrode material particles in charging. A negative electrode comprises an alloy-based negative electrode material particle or an alloy-based negative electrode material whisker the surface of which is covered by a carbon film including 1 to 50 graphene layers obtained by reducing graphene oxide. For the carbon film, strong sp<2 >bonds between molecules are substantially parallel to a silicon surface so that the carbon film can be prevented from being broken even when the alloy-based negative electrode material swells and the silicon can be prevented from being broken as well. In addition, the formed carbon film has an appropriate gap and can stretch with the swelling of the alloy-based negative electrode material, and furthermore, such a gap allows lithium ions to pass through. Besides, the carbon film also can prevent the alloy-based negative electrode material from reacting with electrolyte.

Owner:SEMICON ENERGY LAB CO LTD

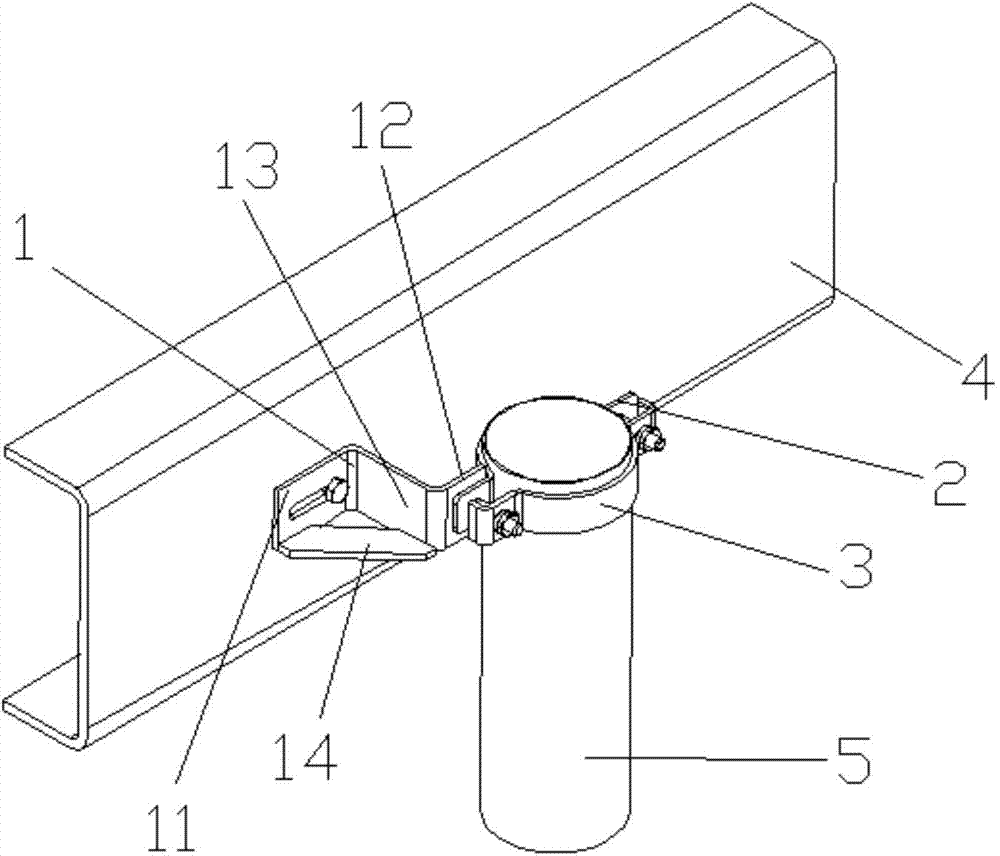

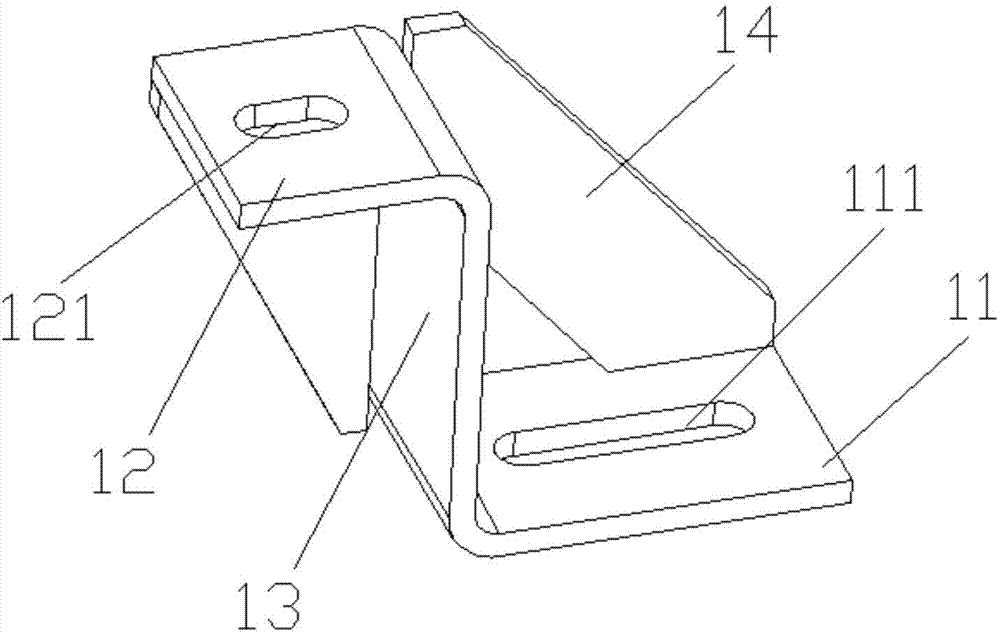

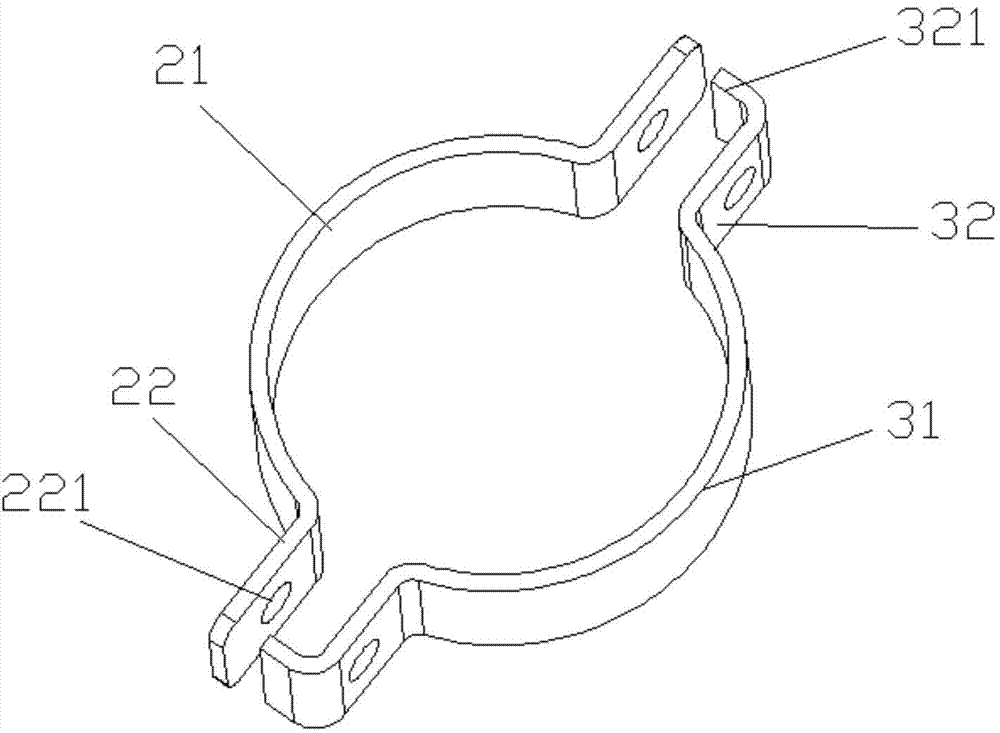

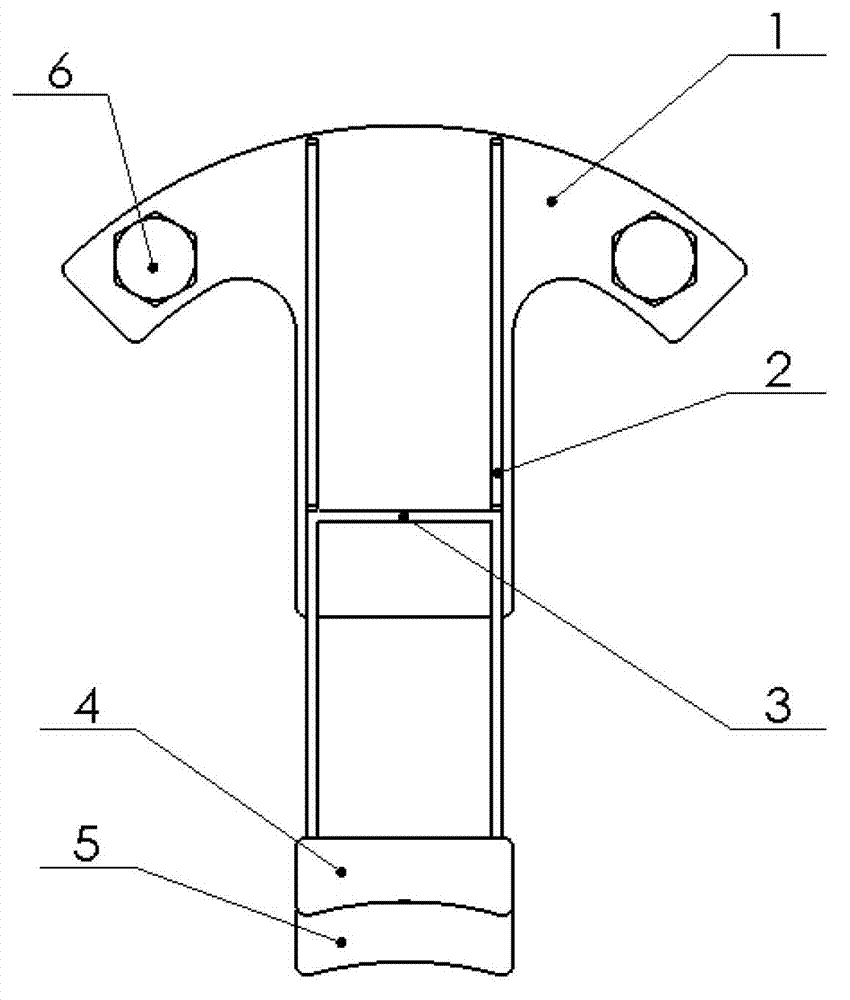

Inter-cooling pipe fixing device

InactiveCN104727930AIncrease stiffnessHigh strengthInternal combustion piston enginesEngine componentsMating connectionVehicle frame

The invention discloses an inter-cooling pipe fixing device. The inter-cooling pipe fixing device comprises a Z-shaped connecting support, a first semicircular hoop and a second semicircular hoop. The Z-shaped connecting support comprises a first installation face connected with a vehicle frame in a matched mode, a second installation face connected with the first semicircular hoop in a matched mode and a connecting face for connecting the two installation faces. A first long-strip hole is formed in the first installation face, and a second long-strip hole is formed in the second installation face; the first semicircular hoop is formed by a first clamping part and two first tightly-clamping parts, and installation holes are formed in the two first tightly-clamping parts respectively; the second semicircular hoop is formed by a second clamping part and two second tightly-clamping parts, installation holes are formed in the two second tightly-clamping parts respectively, and the second tightly-clamping parts are connected with the first tightly-clamping parts through bolts. By means of the inter-cooling pipe fixing device, the support structure is optimized, the rigidity and the strength of the support structure are improved, and it is guaranteed that pipe fixing is firm, reliable and durable.

Owner:NANJING GOLDEN DRAGON BUS

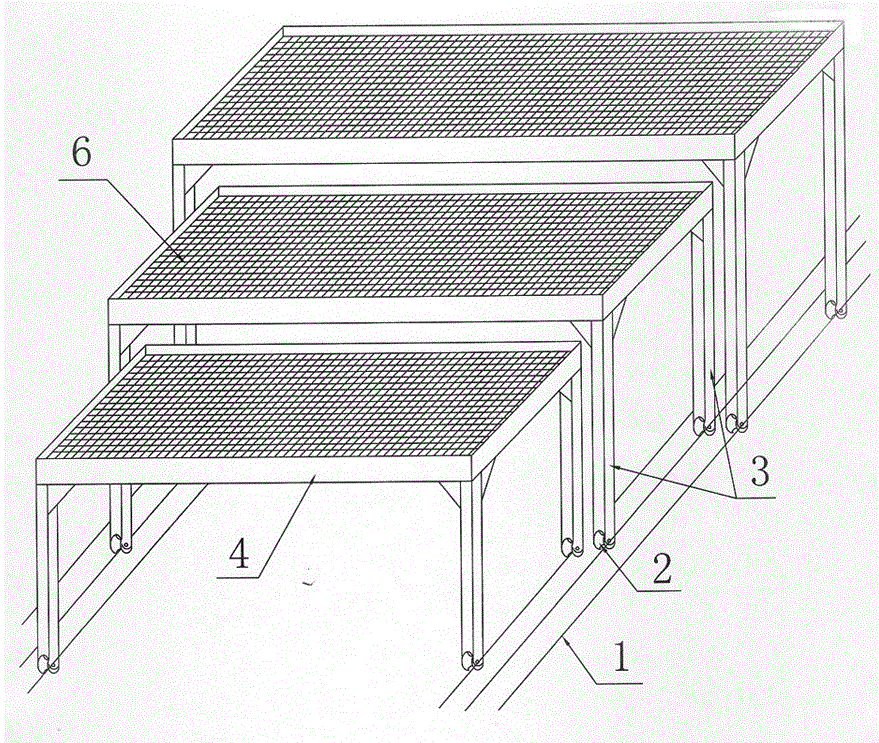

Track type multilayer moving silkworm stand

InactiveCN106818654ARealize automatic separationReduce labor intensityAnimal husbandryEngineeringPulley

The invention discloses a track-type multi-layer mobile silkworm stand, which includes a track, a pulley, a column and several silkworm platforms, and the several silkworm platforms can be nested on the same facade in turn, and each silkworm platform is composed of four columns Support, each silkworm platform includes a silkworm platform frame, a silkworm seat mesh and a silkworm sand tray, the silkworm sand tray is movably connected with the silkworm platform frame, and a pulley is provided at the bottom of each column, and the track is matched with the pulley to realize The movement of each silkworm platform. Each layer of silkworm platform of the present invention can be removed separately for feeding operation, and can realize automatic separation of silkworm excrement, facilitate sand removal, reduce labor intensity of silkworm rearing, and improve production efficiency.

Owner:海宁市蚕桑技术服务站

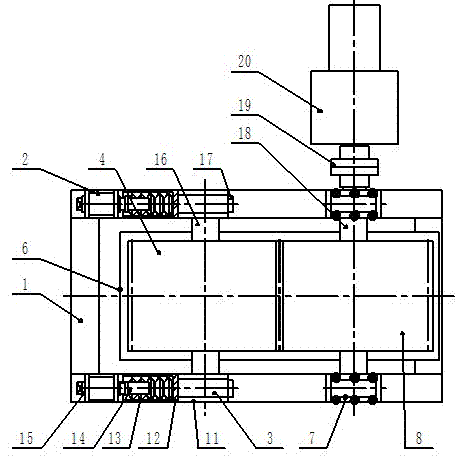

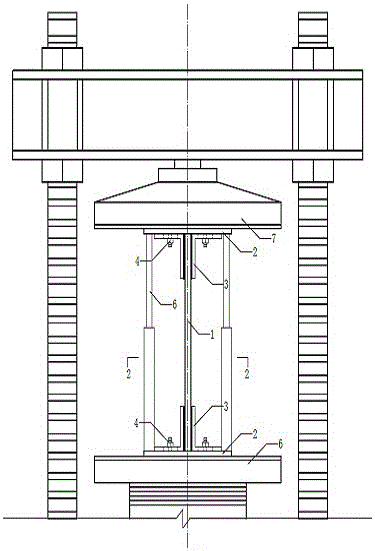

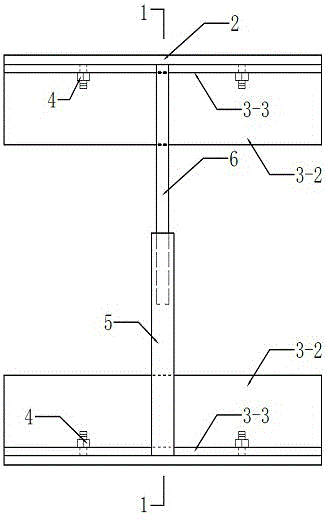

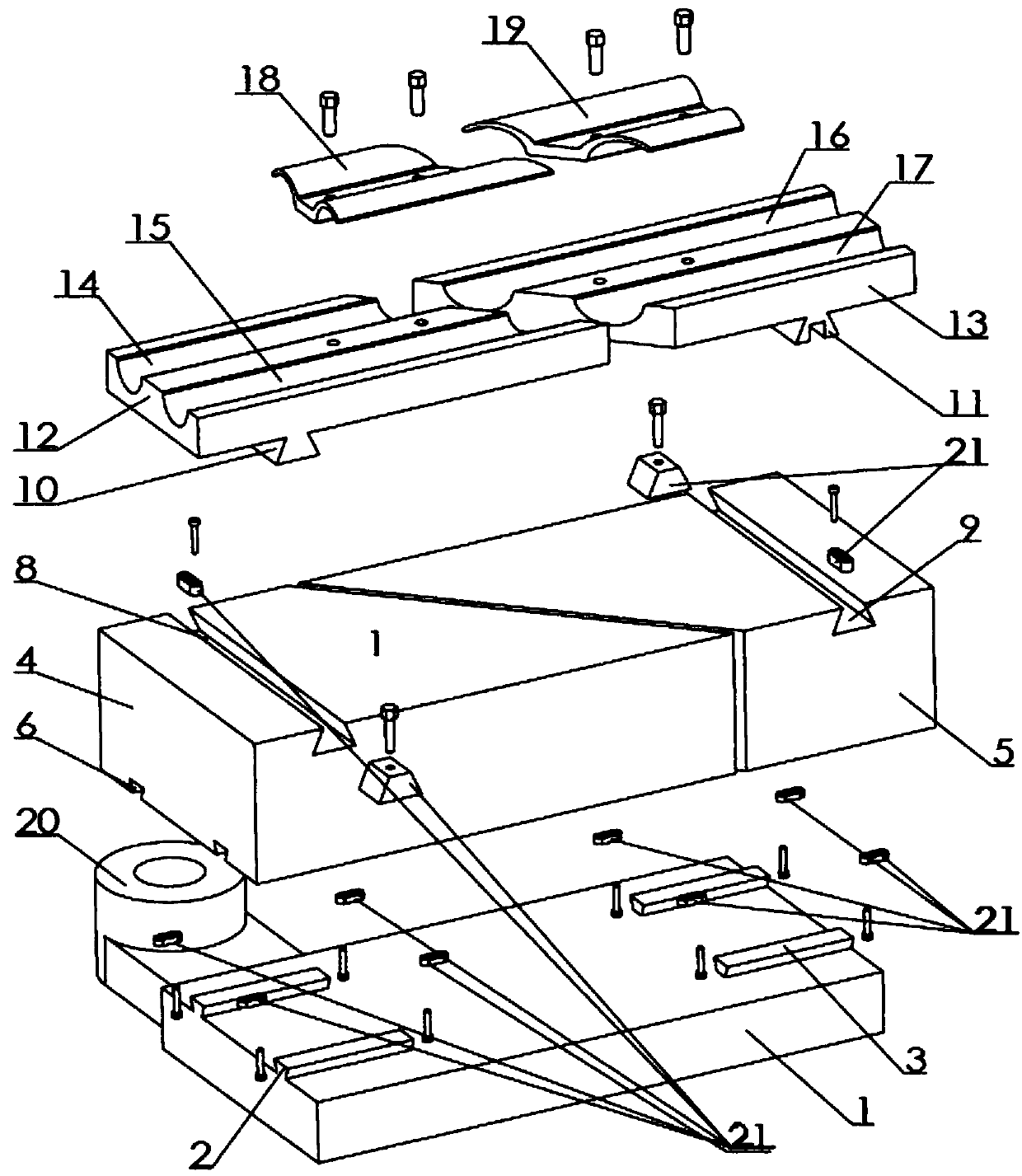

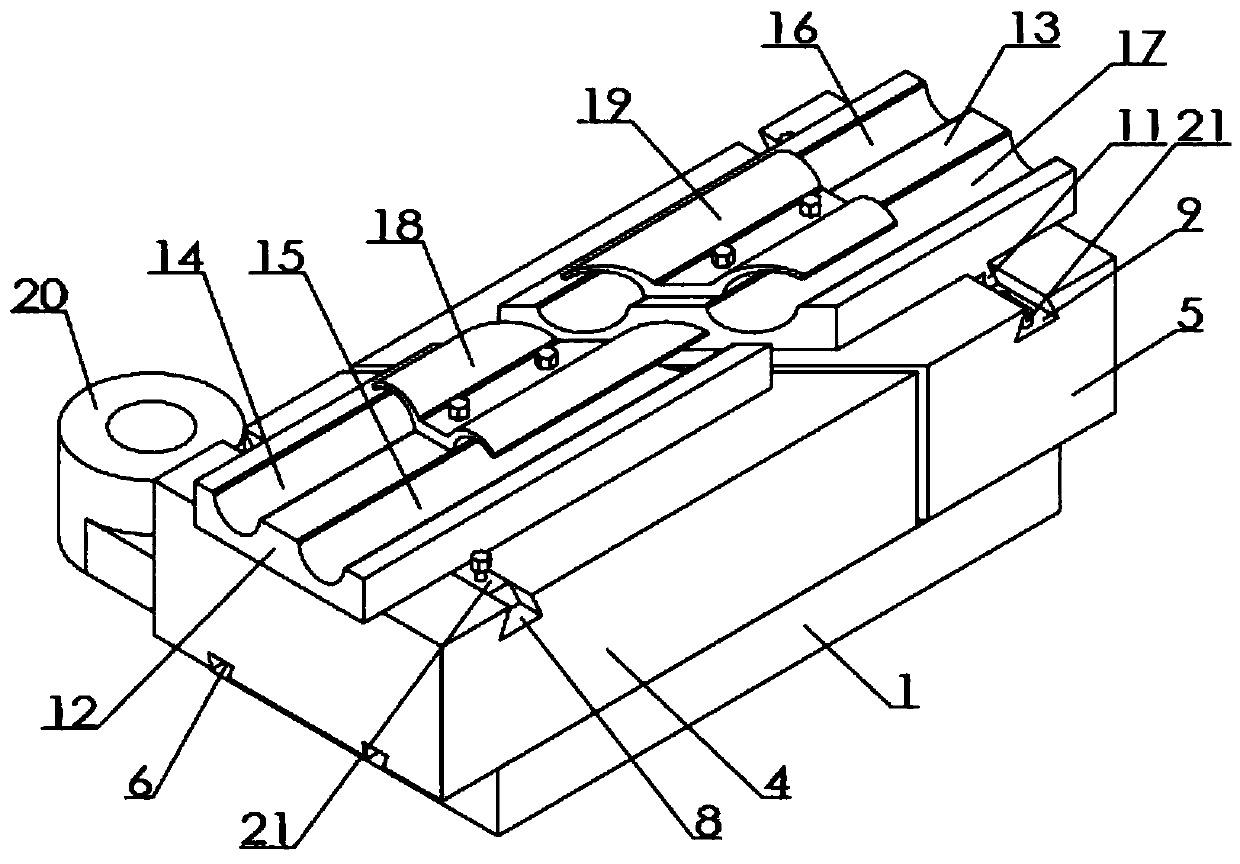

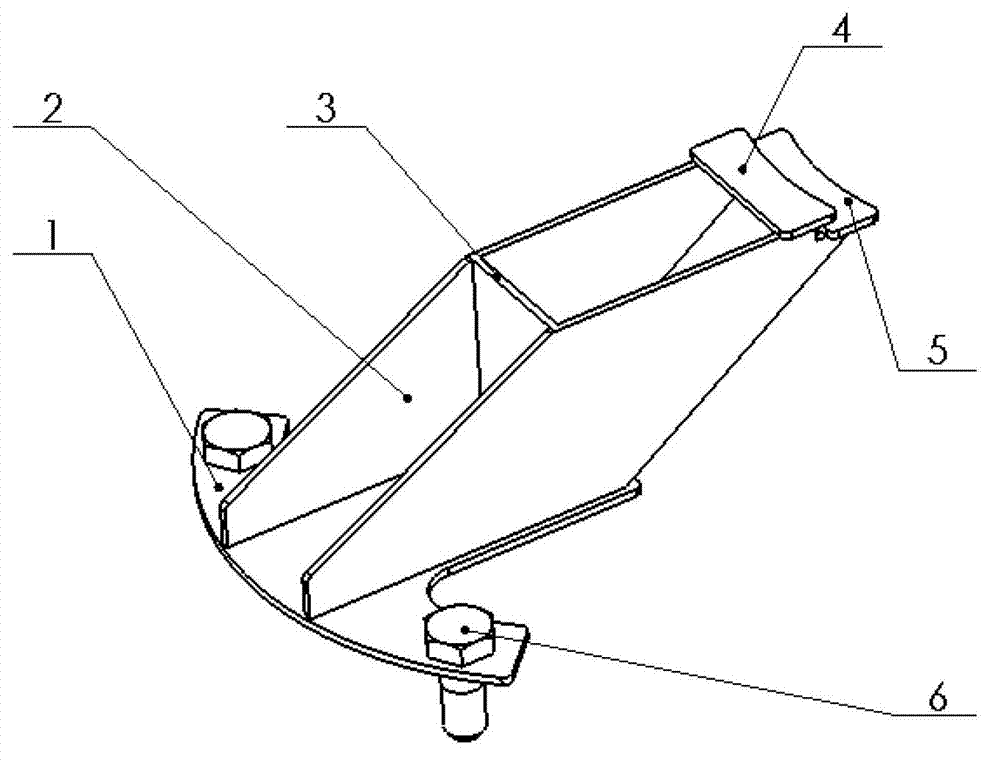

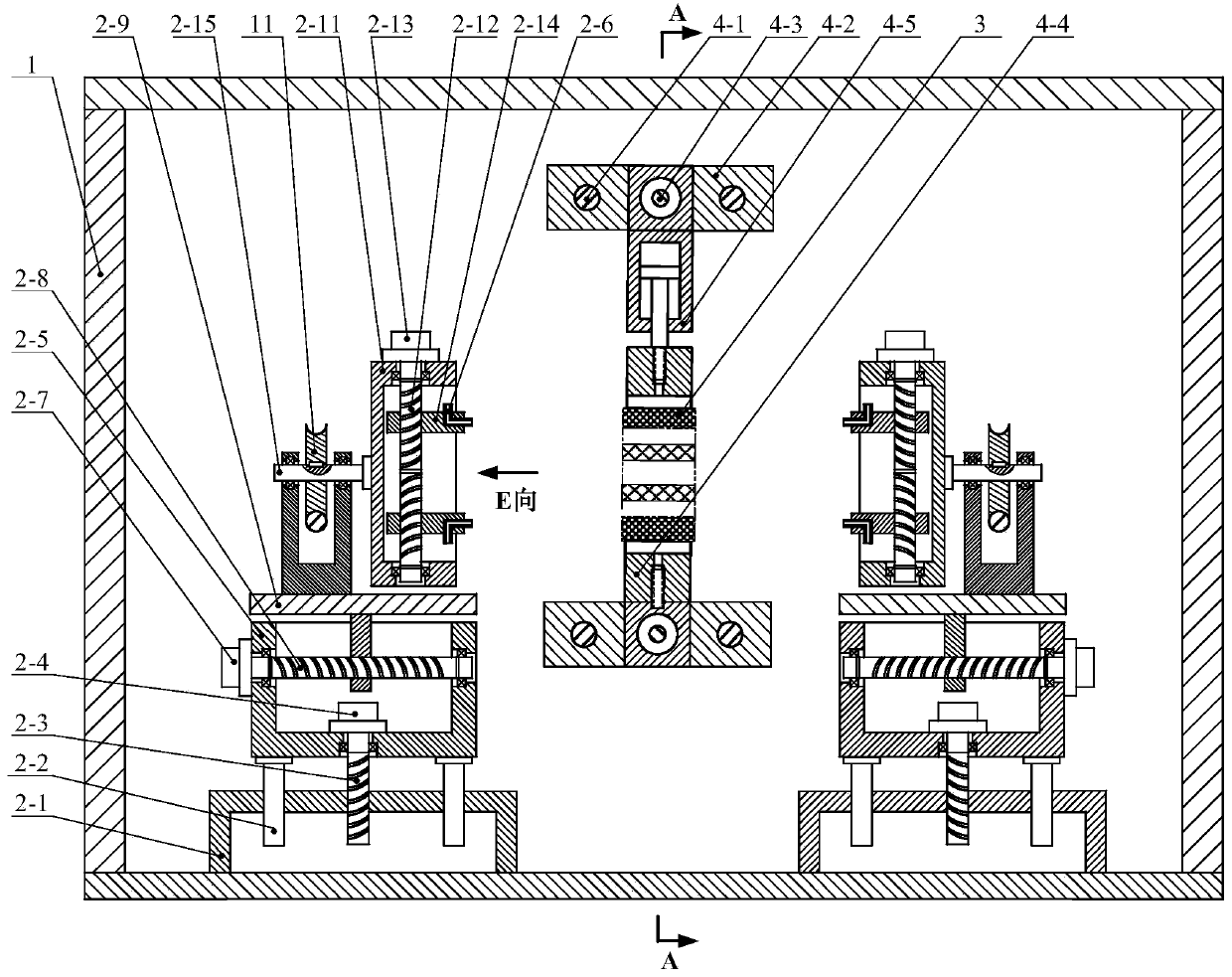

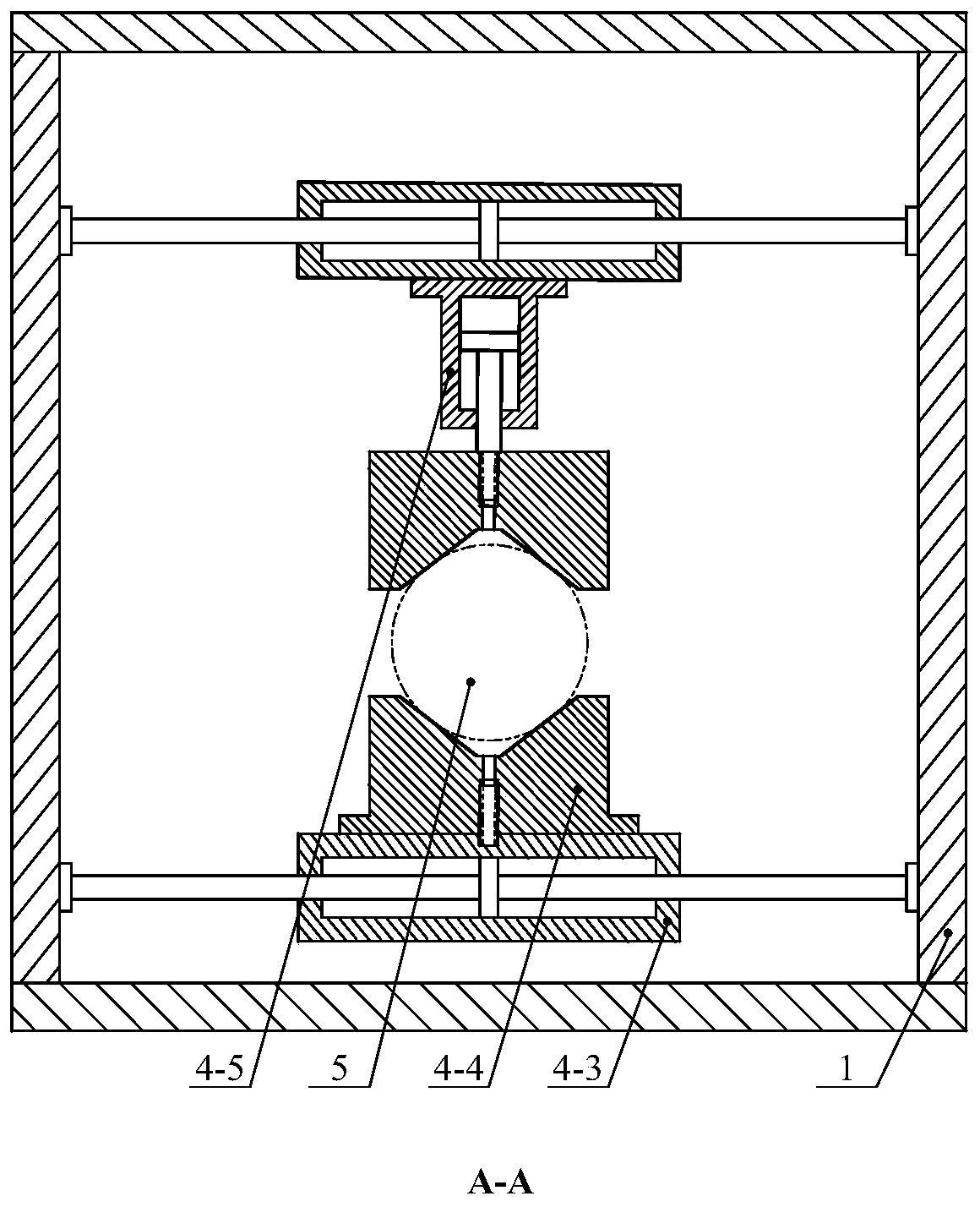

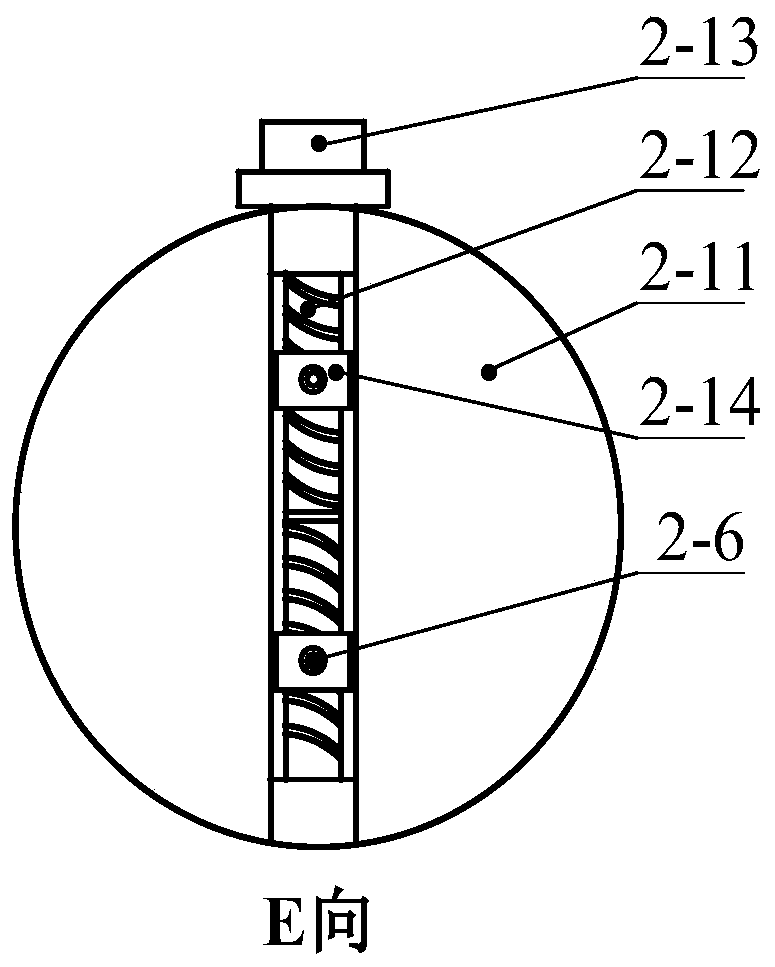

Experimental device for axial compression experiments of plates

ActiveCN106840853AAppropriate clearanceMaterial strength using tensile/compressive forcesAxial compressionEngineering

The invention provides an experimental device for axial compression experiments of plates. The device comprises end plates, a clamping device, a locking device, an upper supporting rod and a lower supporting rod. During the experiments, section centroids of compressed faces and bottom faces of plate samples are overlapped with centers of end faces of the upper end plate and the lower end plate, the upper supporting rod is inserted into the lower supporting rod, the clamping device is adjusted, the locking device is tightened, and a clamping plate of the clamping device closely contacts with the plate samples. The requirements of plate samples with different heights and thicknesses can be met by adjusting the upper supporting rod, the lower supporting rod and the clamping device. The experimental device is simple to manufacture, convenient to operate and high in reusing rate and can be widely applied to the axial compression experiments of the plates, the plate samples can be vertically fixed, and constraint of the designed experimental device on ends of the plate samples cannot interfere in experimental results.

Owner:SICHUAN UNIV

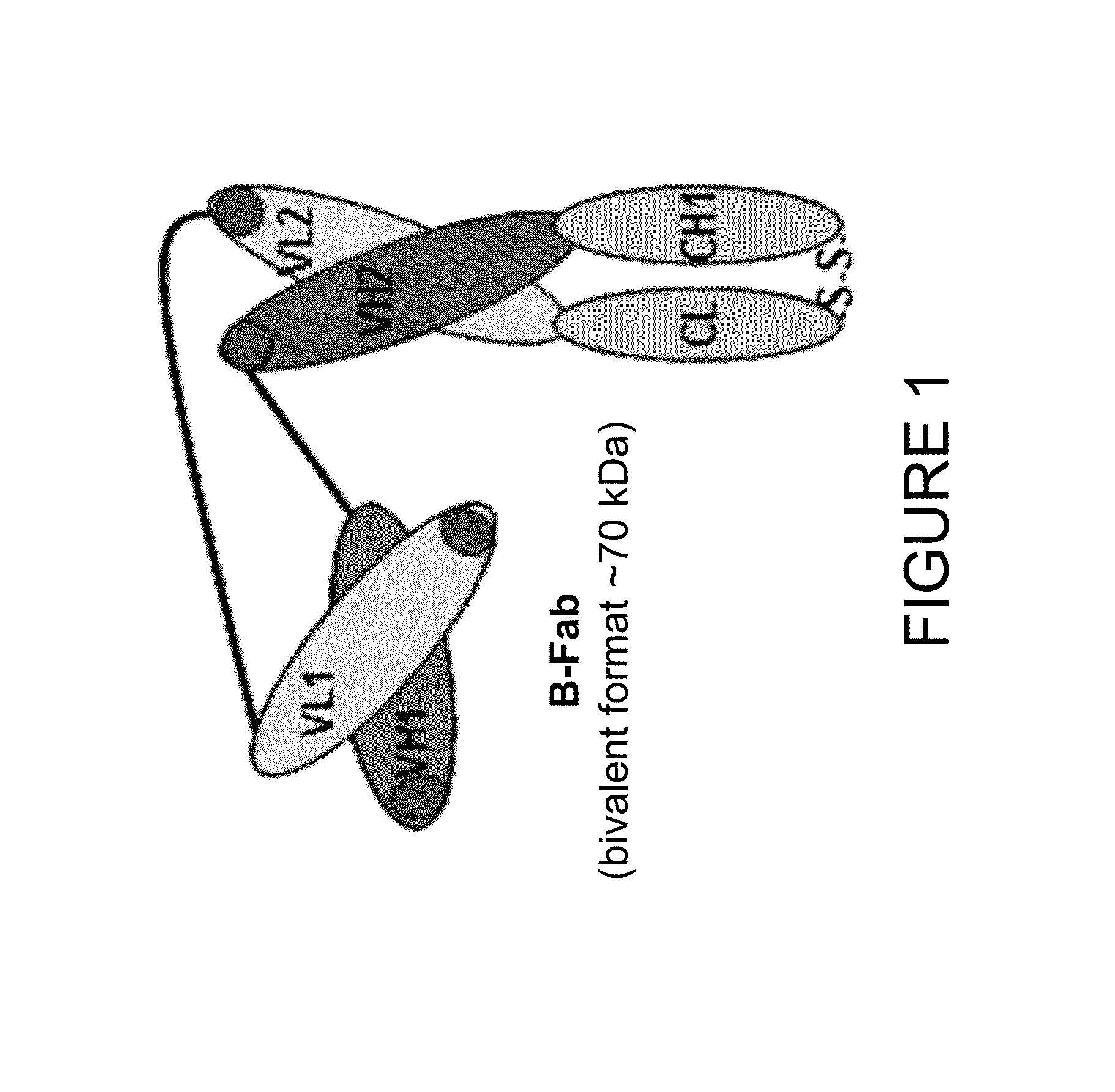

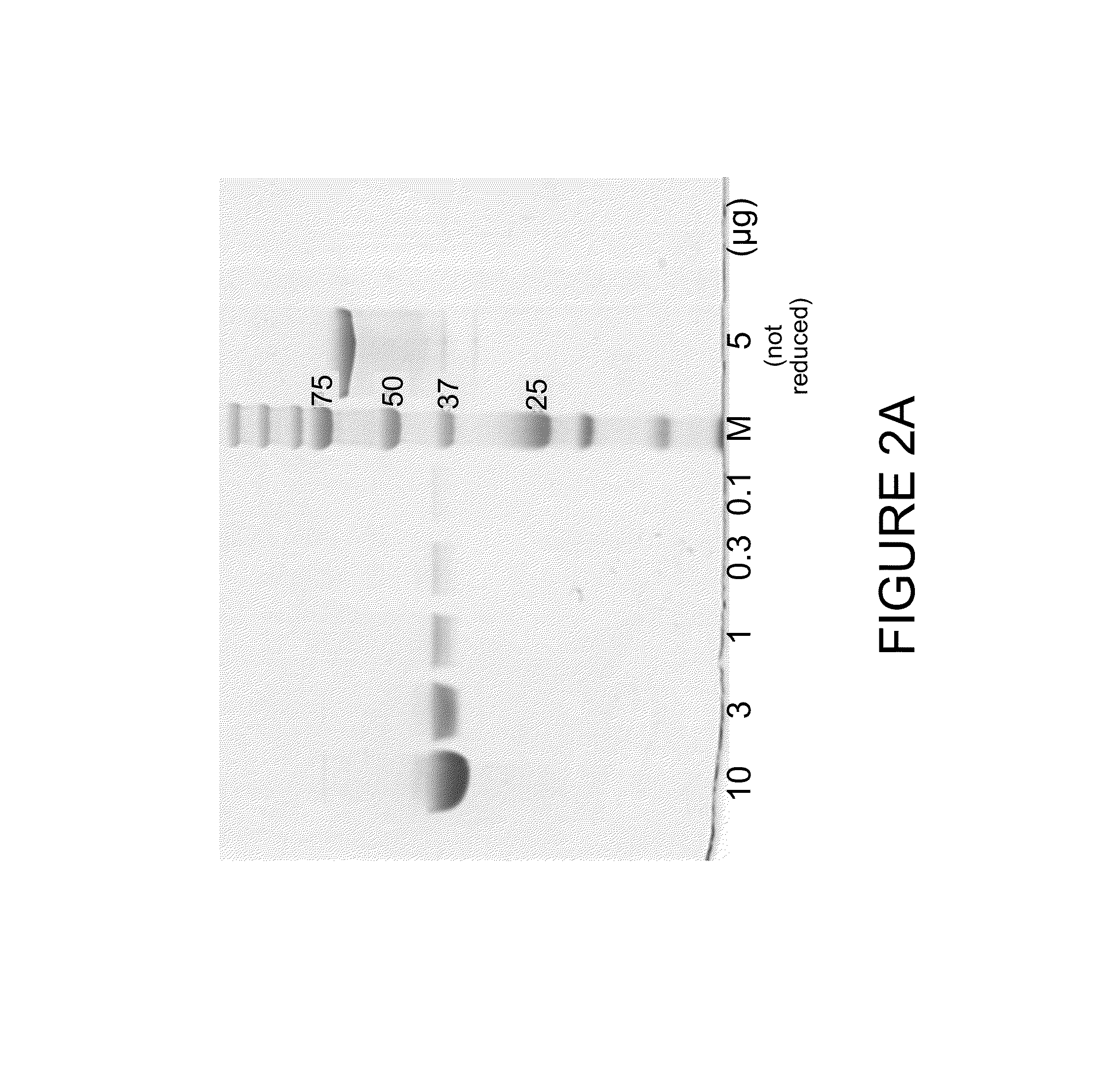

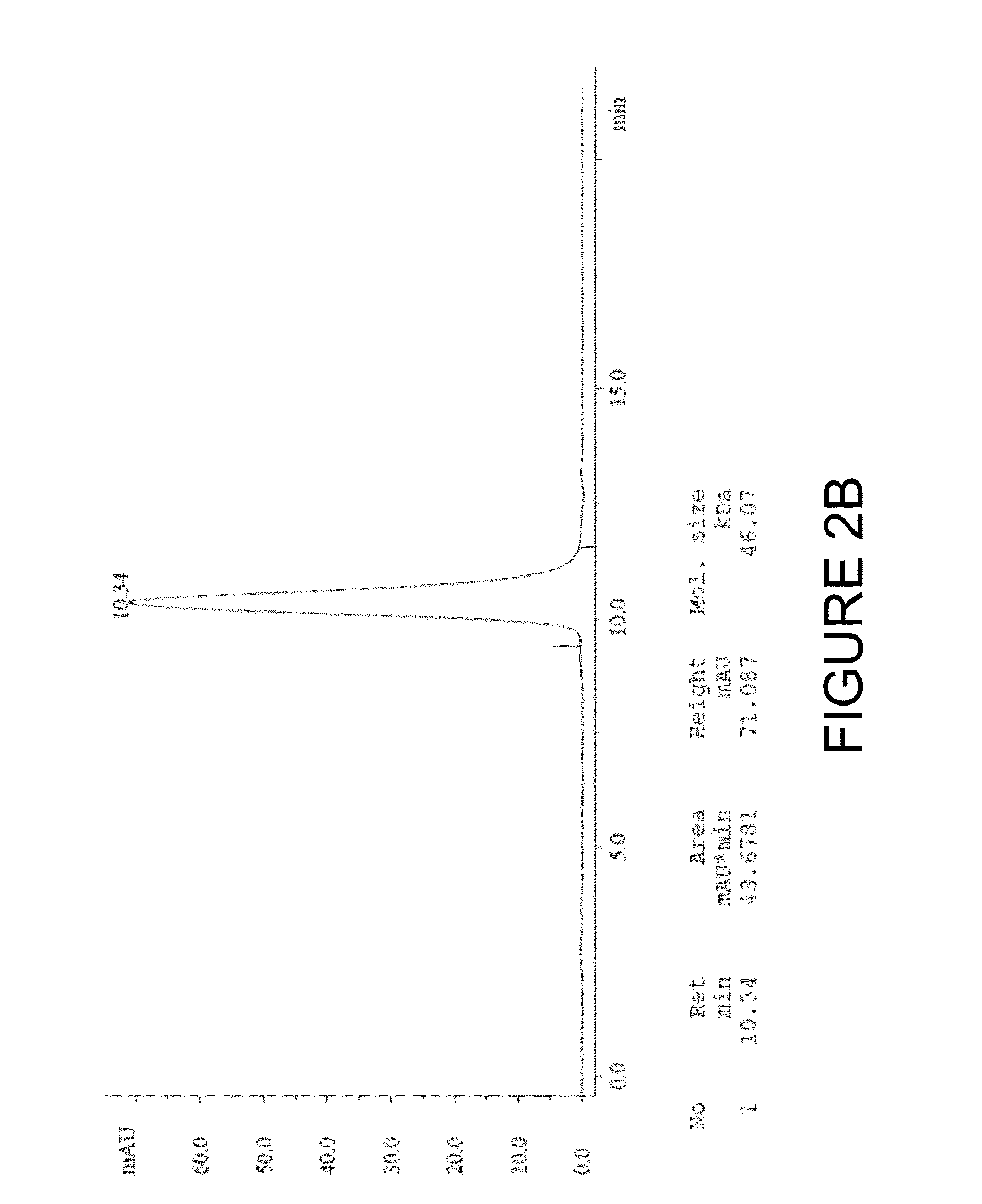

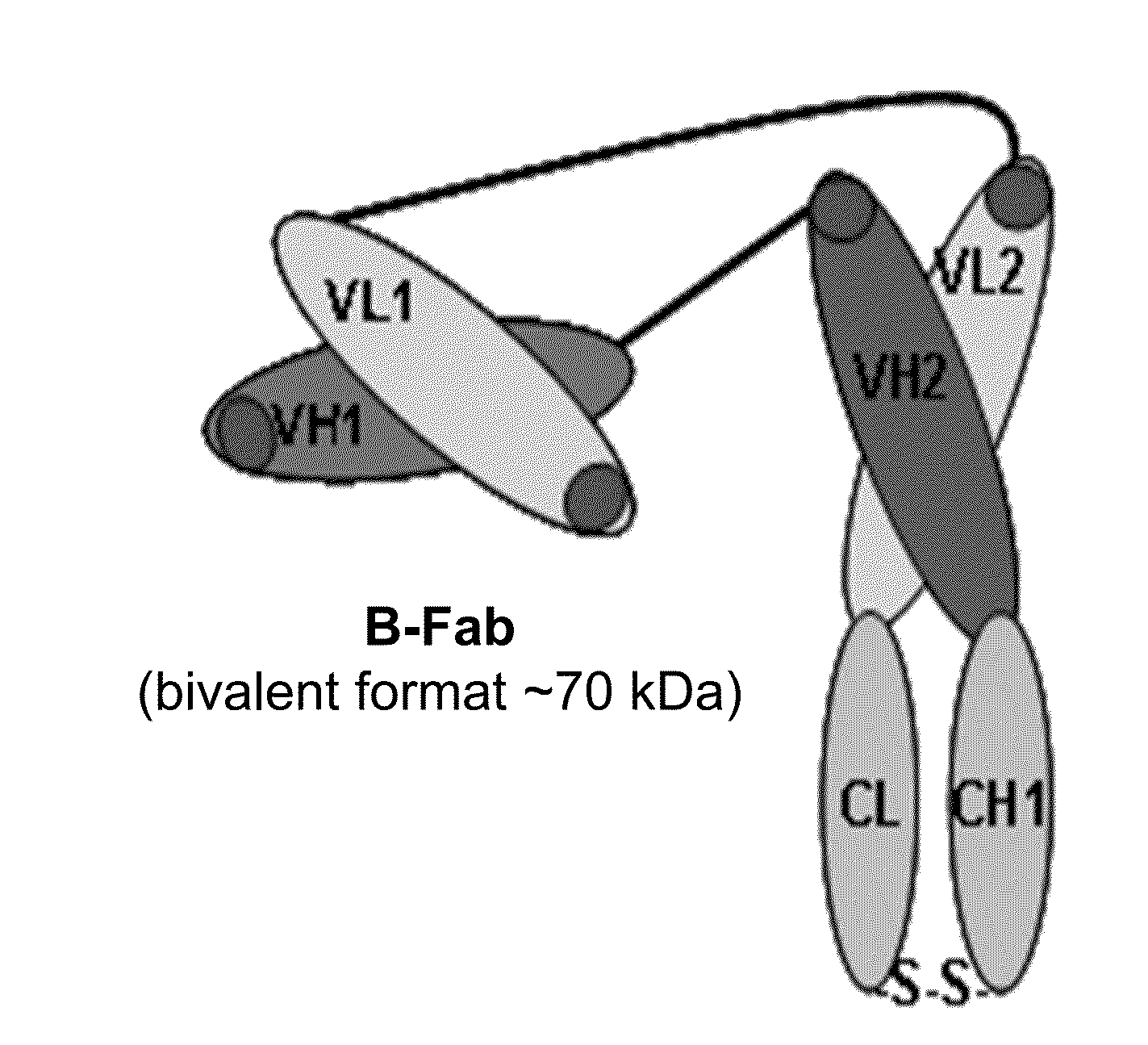

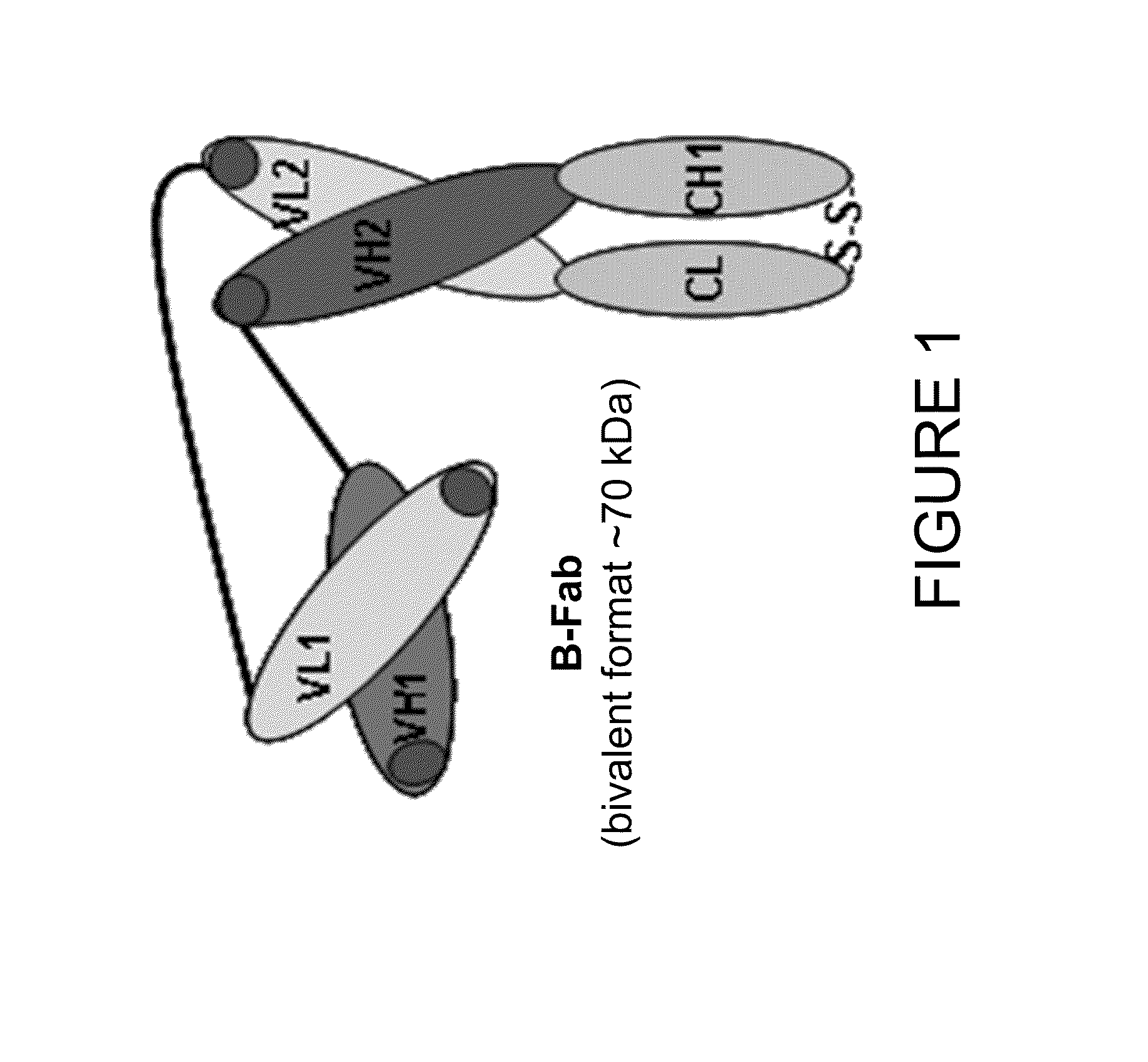

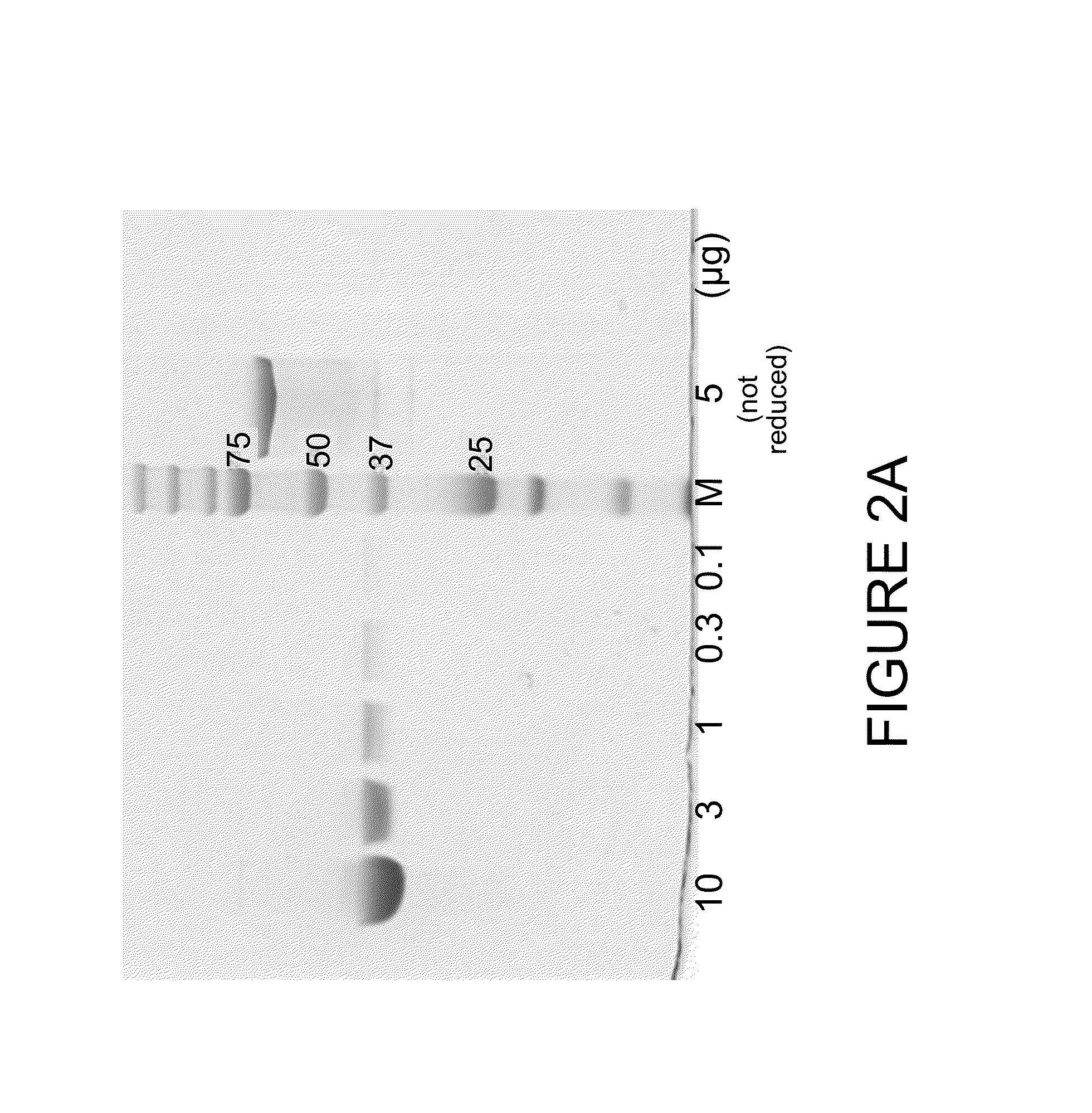

Immuno imaging agent for use with antibody-drug conjugate therapy

ActiveUS20140256916A1Easy to stratifyFacilitates early evaluationFermentationPlant genotype modificationMedicineImaging agent

The invention relates to a companion diagnostic antibody-like binding protein based on the humanized monoclonal antibody, DS6, to be used as diagnostic tool for in vivo detection and quantification of the tumor-associated MUC1-sialoglycotope, CA6.

Owner:SANOFI SA

Meat stuffing preparation device

The invention discloses a meat stuffing preparation device, comprising a rack, a first cylindrical roller, a first conical roller, a second cylindrical roller, a second conical roller and a storage box, wherein the first cylindrical roller, the first conical roller, the second cylindrical roller and the second conical roller are the same in length; spike bulges are evenly distributed in the circumferences of the first cylindrical roller, the first conical roller, the second cylindrical roller and the second conical roller; the first cylindrical roller and the second cylindrical roller are arranged on the left half part; the first cylindrical roller is arranged above the second cylindrical roller; the first conical roller and the second conical roller are arranged on the right half part; the first conical roller is arranged above the second conical roller; the inner side of the left half part and the inner side of the right half part are inclined planes which are inclined downwards; the first conical roller and the first cylindrical roller are positioned at the same height; the second conical roller and the second cylindrical roller are positioned at the same height; a gap between the first conical roller and the first cylindrical roller is greater than a gap between the second conical roller and the second cylindrical roller; the storage box is arranged below the second cylindrical roller and the second conical roller. According to the scheme, the meat stuffing with different specifications can be formed; and different tastes of people are met.

Owner:CHONGQING GUANGHENG FOOD DEV

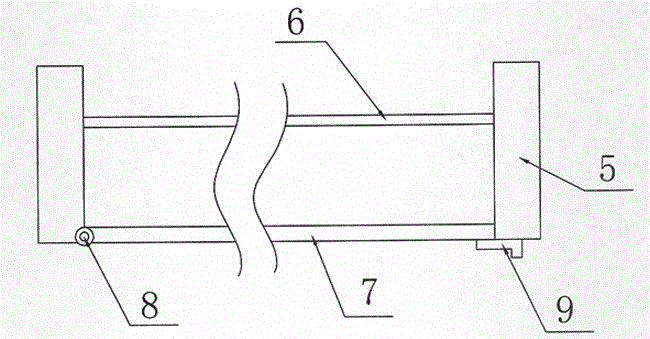

Straight pipe butt welding auxiliary device

InactiveCN107695722AAppropriate clearanceFirmly connectedWelding/cutting auxillary devicesAuxillary welding devicesButt weldingStraight tube

The invention discloses a straight pipe butt welding auxiliary device, which is characterized in that a left base block and a right base block are arranged on the upper part of the platform, a left guide groove matching with the left guide rib is arranged under the left base block, and a left base block is arranged under the right base block. The right guide groove matched with the right guide rib, the left base block and the right base block are respectively provided with a left guide groove and a right guide groove in the front and back direction, and the left guide groove and the right guide groove pass through the left slider and the right slider respectively The block is connected with a left positioning block and a right positioning block. The left positioning block is provided with a left front positioning groove and a left rear positioning groove extending in a left and right direction distributed before and after. The right rear positioning groove, the interface is neat and the gap is appropriate, and the interface after welding is tilted and connected firmly, and the quality is higher.

Owner:CHONGQING GUANGJI IND

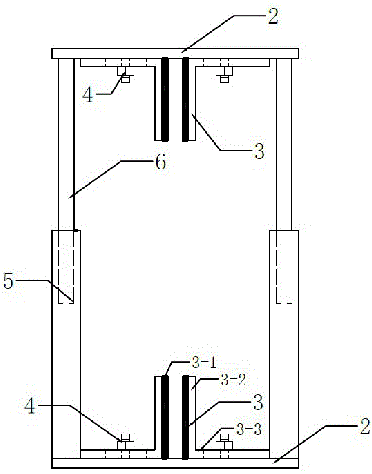

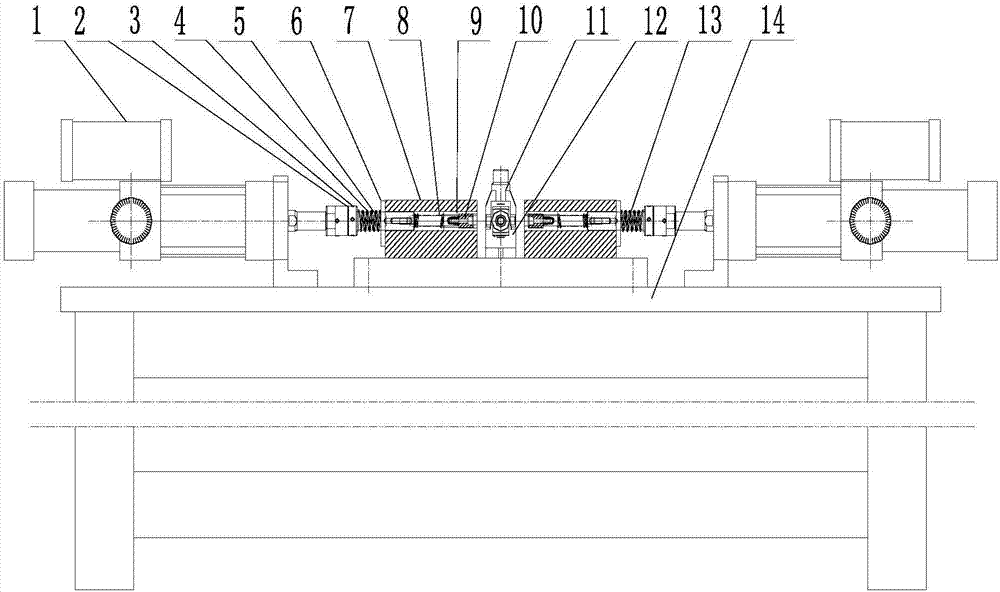

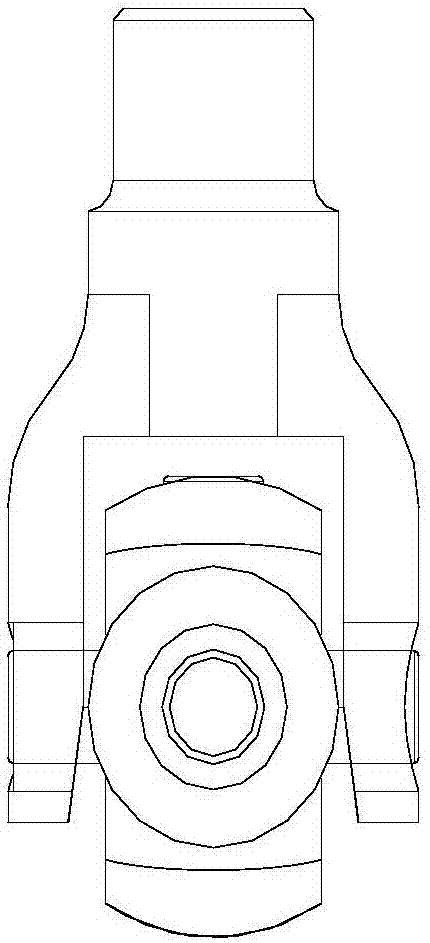

Riveting machine and method for cross joints

InactiveCN106925681AConsistent depthAppropriate clearanceMetal-working feeding devicesPositioning devicesNeedle roller bearingUniversal joint

The invention provides a riveting machine and method for cross joints, belongs to the field of universal joint assembly, and particularly relates to the technical field of riveting machines for the cross joints. Unclamping cylinders are arranged on the left side and the right side of the upper end of a bottom plate correspondingly. A positioning block is arranged on the middle portion between the two unclamping cylinders. Fixing blocks are arranged on the left side and the right side of the positioning block correspondingly. A connection rod, a positioning sleeve and a rivet joint are arranged on the fixing block located on the left side, wherein a spring is arranged on the left side of each connection rod and is arranged on one push rod in a sleeving manner, a regulation nut and a locking nut are arranged on the left side of the push rod, and a telescopic spring is arranged on the portion, on the right side of the fixing block on the right side, of the other push rod. A yoke workpiece is clamped on the positioning block. By means of the riveting machine and method, the aims of achieving uniform riveting depths and matching of the cross joints and needle bearing clearance and greatly improving the production efficiency are achieved.

Owner:JIANGSU CCVI BEARING

Straw briquetting machine

InactiveCN106003802AAdjustable dry humiditySolve the blockageShaping pressPulp and paper industryControl switch

The invention discloses a straw briquetting machine. The straw briquetting machine comprises a water tank, water injection nozzles, a machine body, a rotating column, an electric heating ring, molds, control switches, weight sensors, chassis, discharge holes, an electric motor, a first rotating shaft, a base, a press roll, a second rotating shaft, a buckle, a sliding groove, a conveyor belt and a feeding inlet; the water tank is installed on the top of the machine body, the water injection nozzles are arranged on the lower portion of the water tank, the feeding inlet is formed in the upper right portion of the machine body, the conveyor belt is arranged at the feeding inlet, the molds are installed on the lower portion inside the machine body, the chassis are arranged at the bottoms of the molds, the control switches and the weight sensors are installed on the chassis, and discharge holes are formed in the lower potions of the chassis. The straw briquetting machine is provided with the electric heating ring, the full-automatic electric heating device can adjust humidity of materials, and the difficulties that the materials are blocked and failed in molding are solved; meanwhile, the top of the machine body is provided with the water tank and the water injection nozzles, on one hand, water adding is convenient, and on the other hand, after the work is completed, water can be sprayed to the interior of the machine body through the water injection nozzles to clean the machine.

Owner:朱德苹

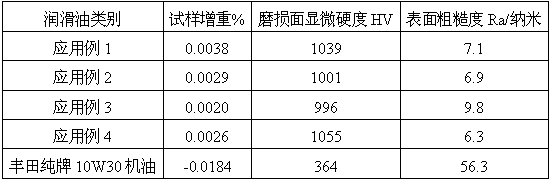

Antiwear agent used for lubricating oil, and preparation method thereof

The invention relates to an antiwear agent used for lubricating oil, and a preparation method thereof, and belongs to the field of lubricating oil. The antiwear agent used for self-repairing lubricating oil is composed of, by mass, 30 to 70 parts of a lubricating oil base oil, 5 to 10 parts of h-BN nanosheet, 5 to 10 parts of nanometer graphene, 3 to 5 parts of aluminium hydroxide, 0.5 to 5 partsof boron oxide, 1 to 2 parts of dispersing agent 155, 1 to 2 parts of a fatty amine polyoxyethylene ether, and 1 to 5 parts of succimide. The antiwear agent used for lubricating oil is capable of prolonging the service life of lubricating oil, reducing wear loss of friction pairs, prolonging the service life of friction pairs, avoiding deposition of greasy filth and carbon formation effectively, and avoiding blocking.

Owner:大连圣多教育咨询有限公司

Objective lens assembling and adjusting method for fusion type telescope

The invention provides an objective lens assembling and adjusting method for a fusion type telescope. The objective lens assembling and adjusting method for the fusion type telescope comprises the steps that machining of the excircle and the end face of a lens barrel is conducted by using the center line of a main shaft of a machining lathe as the datum line, and abrasive machining of a gap between a lens frame and the lens barrel is conducted by using the stability of an auto-collimation image of an auto-collimation goniometer as the datum. The dimensional accuracy of the lens frame and the lens barrel is guaranteed through the machining process, the concentricity of an objective lens is guaranteed without the need for selective assembly of the lens frame and the lens barrel, and therefore the imaging quality of the fusion type telescope is improved.

Owner:SHANDONG NORTH OPTICAL & ELECTRONICS

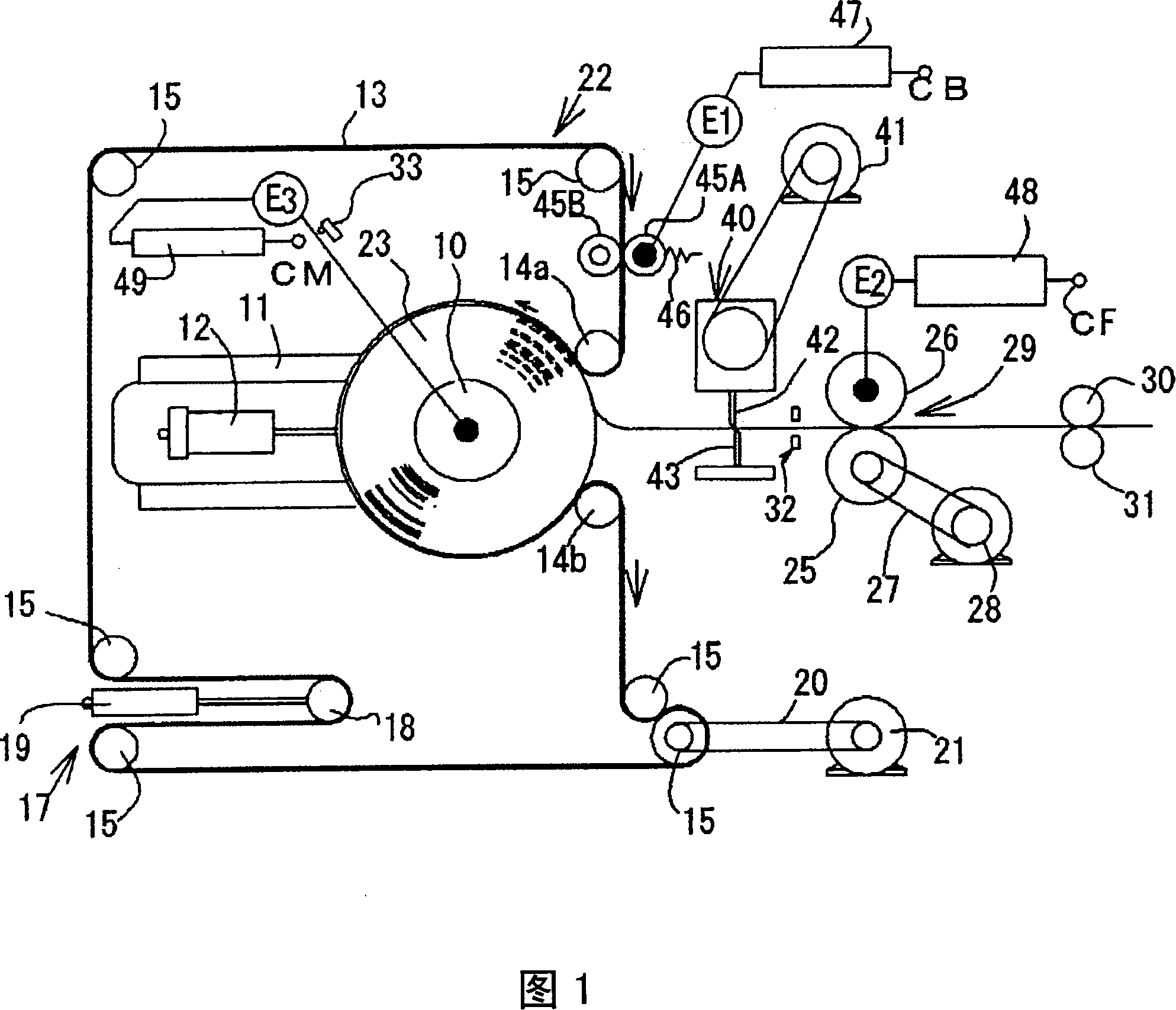

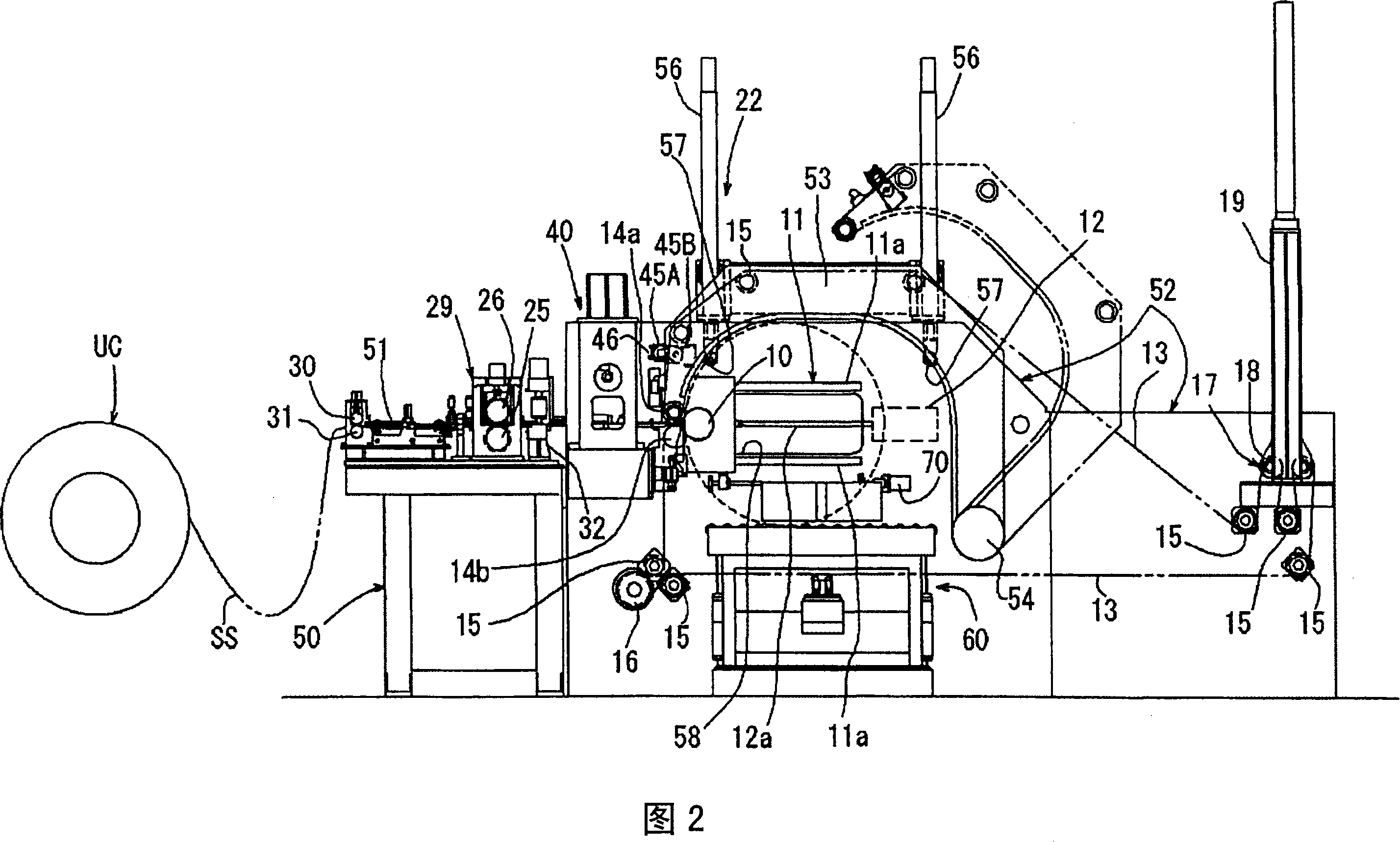

Device for producing iron core

InactiveCN101090031AAccurate calculation of lengthImprove qualityTransformers/inductances magnetic coresInductances/transformers/magnets manufactureMetal stripsButt joint

The invention relates to a winding core manufacturing device, comprising: coiling device (22) for winding the metal strip (SS) between winding frame (10) and coiling strips (13) to wind the winding core (23); metal strip supplying machine (29) for sending the metal strip to supply roller (25); clipper (40) installed between the coiling device and metal strip supplying machine and cutting the metal strip without stopping it. The metal strip supplying machine is controlled to send metal strip at the speed equal to coiling speed of metal strip of the coiling device. When the metal strip supplying machine supples the metal strip of preset length, the said metal strip is cut by clipper for unit metal strip to continuously wind the winding core. The cut length is calculated based on the thickness of metal strip calculated by strip length of each revolution of the winding frame. Therefore, the invention can produce a number of iron core of high quality with proper clearance between each butt-joint part or lapping amount.

Owner:DAIHEN CORP

Immuno imaging agent for use with antibody-drug conjugate therapy

ActiveUS20140255305A1Facilitates stratification and early evaluationShort exposure timeHybrid immunoglobulinsRadioactive preparation carriersMedicineImaging agent

The invention relates to a companion diagnostic antibody-like binding protein based on the humanized monoclonal antibody, DS6, to be used as diagnostic tool for in vivo detection and quantification of the tumor-associated MUC1-sialoglycotope, CA6.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV +1

Print head of printer and gap spacer used for the print head

InactiveCN101242959AGuaranteed clearanceAppropriate clearancePrintingEngineeringMechanical engineering

Owner:SEIKO PRECISION INC

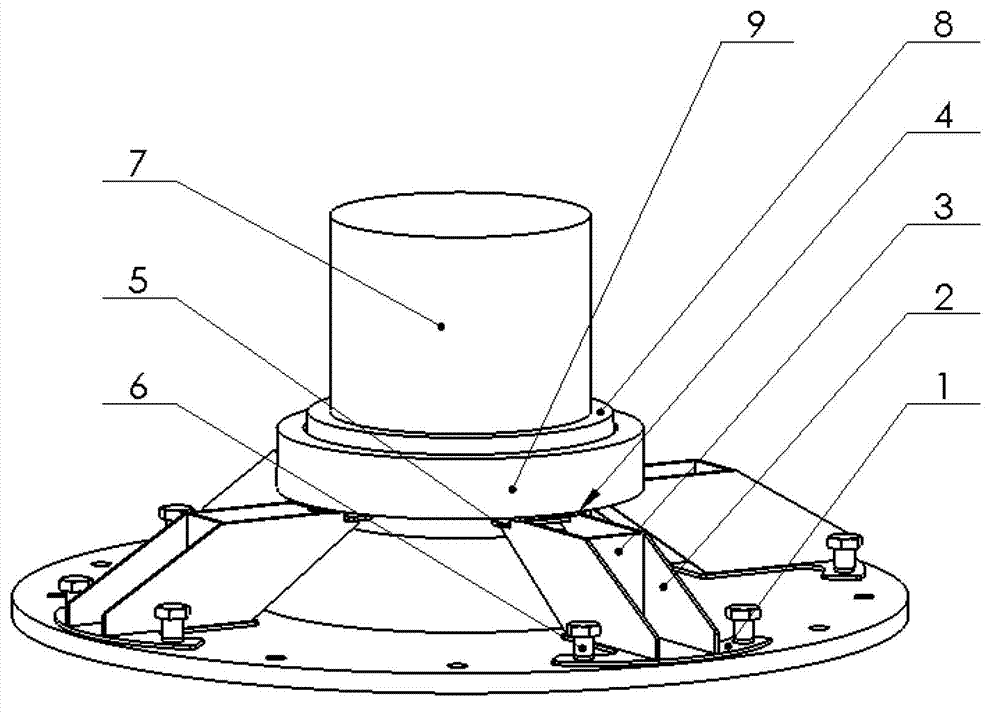

Assembling tool for bearing and main shaft of permanent magnet direct-driven wind driven generator

ActiveCN102886754ACombination structure is simpleLow manufacturing costWork holdersWind drivenWind force

The invention relates to an assembling tool for a bearing and a main shaft of a permanent magnet direct-driven wind driven generator, which comprises a bottom plate, a positioning plate and a supporting body, wherein the lower end of the supporting body is fixedly connected with the bottom plate and the upper end of the supporting body is fixedly connected with the positioning plate. The assembling tool is applied to assembly between a spherical self-aligning roller bearing, an adjusting sleeve and the main shaft of the large permanent magnet direct-driven wind driven generator, and can provide positioning to assemble the bearing to an appointed position of the main shaft and obtain an appropriate bearing play. The tool is simple in structure, low in manufacturing cost, simple to use and beneficial to adjustment, and can ensure the demands of assembly effectively to meet the technical effect needed.

Owner:GUODIAN UNITED POWER TECH

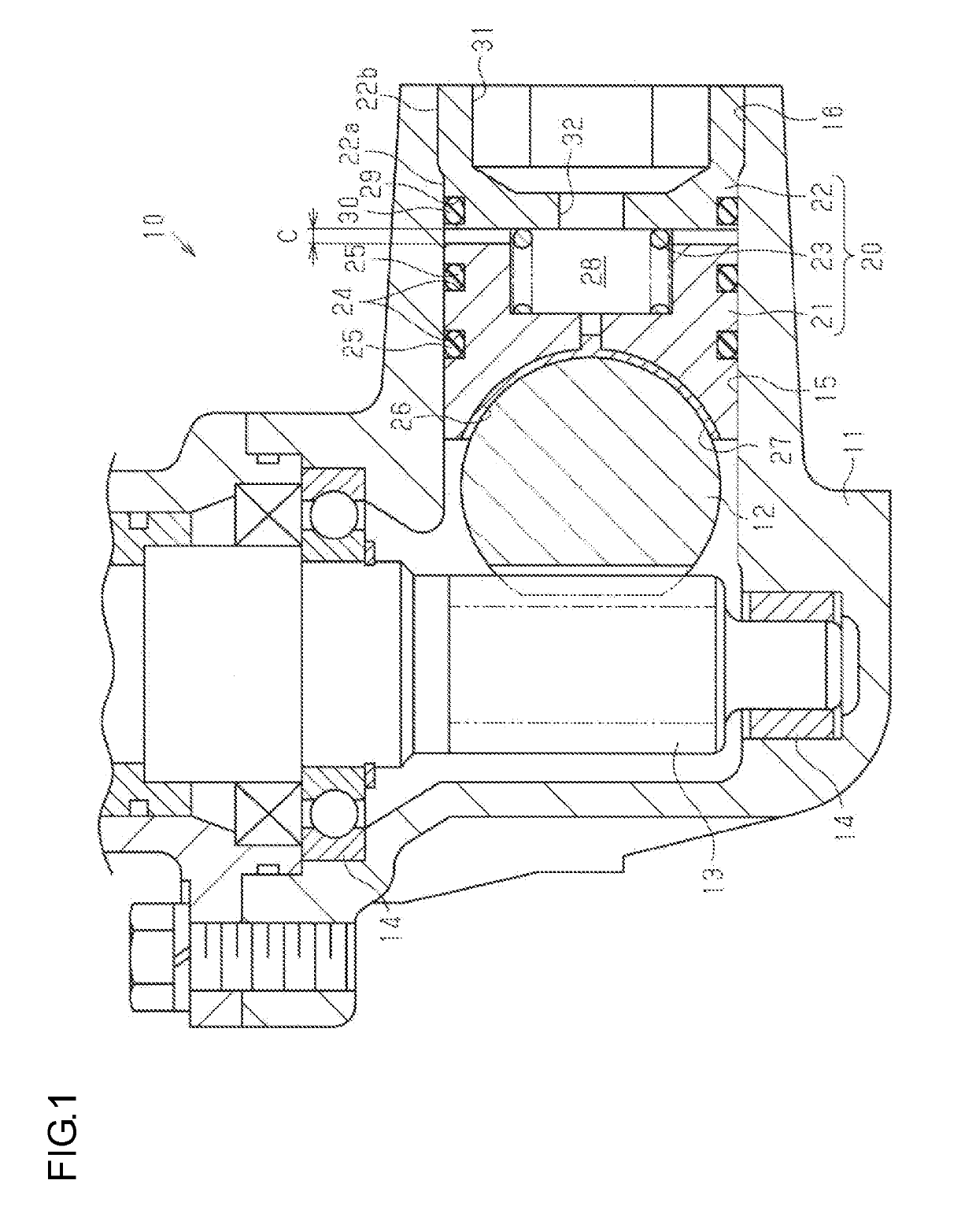

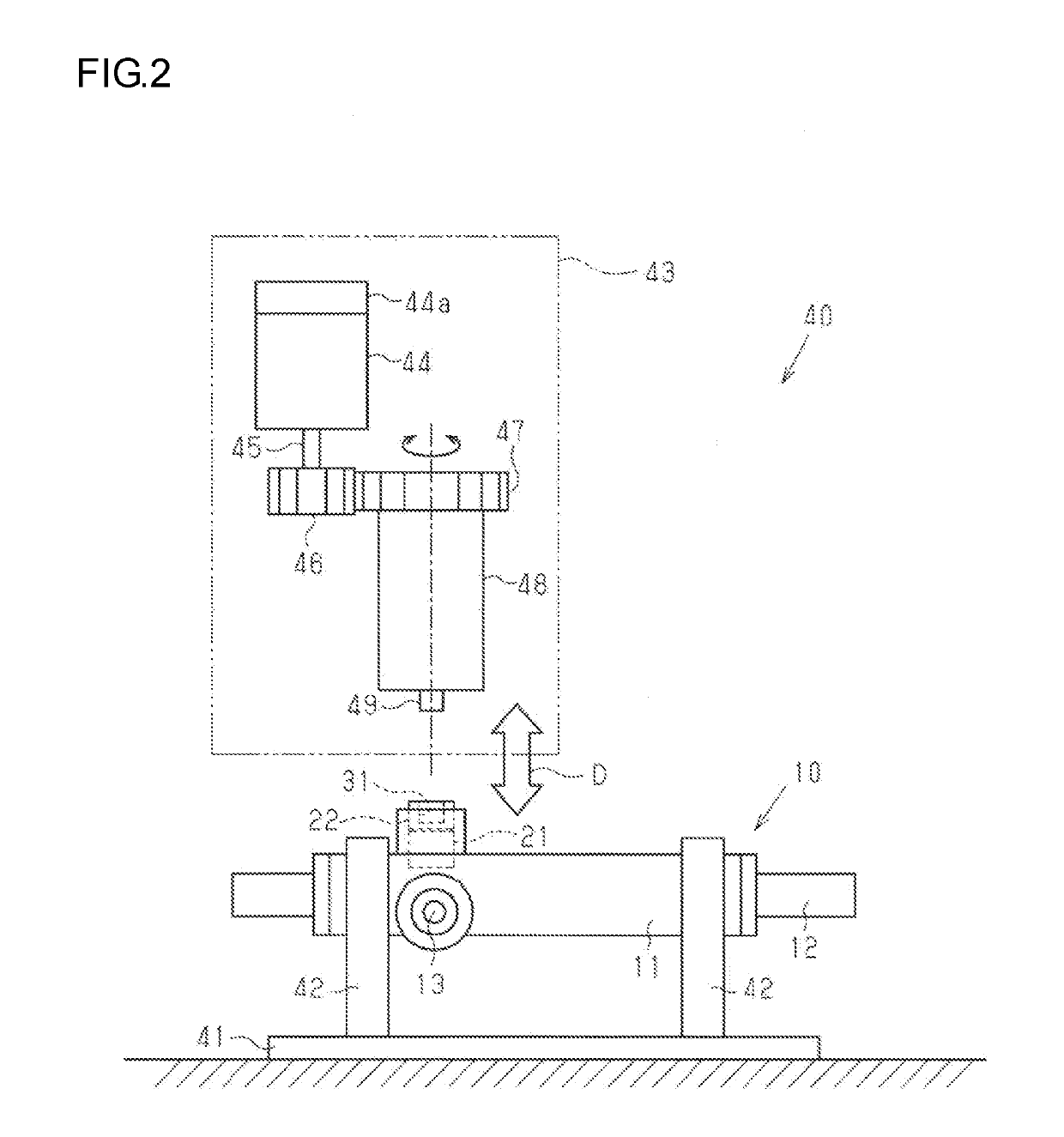

Method for adjusting steering system and adjustment apparatus for steering system

A method for adjusting a steering system and an adjustment apparatus for a steering system are provided which allow a clearance between a support yoke and a yoke plug to be appropriately set. When a yoke plug is loosened which has been temporarily fastened to a degree that a support yoke is subjected to elastic compressive deformation, the yoke plug is loosened to a position where a clearance C between the support yoke and the yoke plug reaches a target clearance using, as a reference, a position where a rate of a change in an axial position of the yoke plug with respect to an angular position of the yoke plug increases rapidly.

Owner:JTEKT CORP

Bearing double-sided grease injecting machine and grease injecting method thereof

ActiveCN110285309AImprove grease injection efficiencyImprove grease injection accuracy and uniformityBearing componentsConduits/junctionsEngineeringNozzle

The invention discloses a bearing double-sided grease injecting machine and a grease injecting method thereof. An existing bearing double-faced grease injecting machine cannot realize double-sided synchronous fast grease injecting. The bearing double-sided grease injecting machine comprises a machine frame, a grease injecting module and a feeding and clamping mechanism, wherein the grease injecting module is composed of two single-sided grease injecting mechanisms; the two single-sided grease injecting mechanisms are correspondingly arranged on the two sides of the feeding and clamping mechanism; the feeding and clamping mechanism comprises a sliding assembly and a clamping assembly; and the single-side grease injecting mechanism comprises a grease injecting lifting machine seat, a grease injecting lifting driving assembly, a grease injecting transverse machine seat, a grease injecting mounting table, a grease injecting transverse movement driving assembly, a swing shaft, a grease injecting tank body, a swing driving assembly, a grease injecting sliding block, a grease injecting nozzle and a bidirectional driving assembly. According to the bearing double-sided grease injecting machine, the grease injecting module adopts a technical means of vertically clamping bearings and synchronously injecting grease on two sides, and the grease injecting efficiency is improved, and meanwhile, the rotary grease injecting is carried out by 180 degrees, so that the grease injecting precision and uniformity are improved.

Owner:杭州电子科技大学安吉智能制造技术研究院有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com