Power storage device and method of manufacturing the same

A technology of electric storage device and manufacturing method, which is applied in the direction of electrolyte storage battery manufacturing, final product manufacturing, non-aqueous electrolyte storage battery, etc., and can solve problems such as poor conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

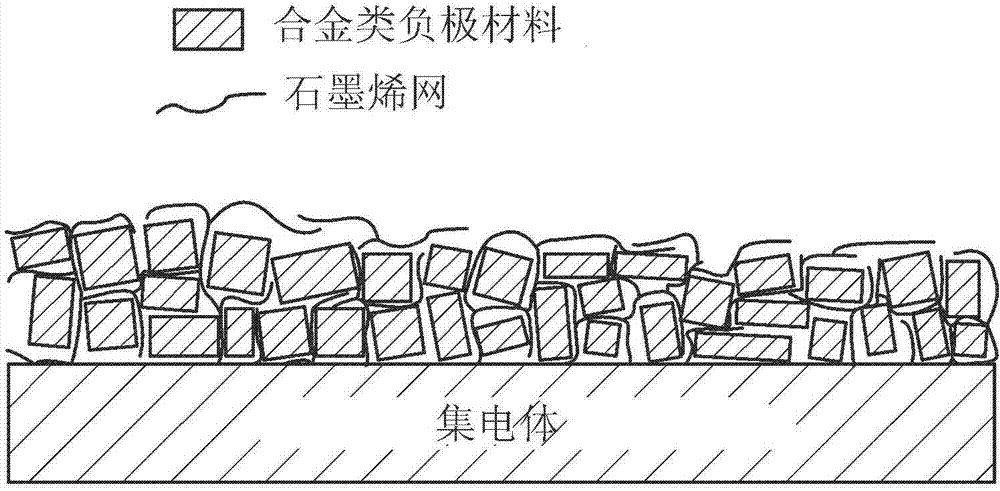

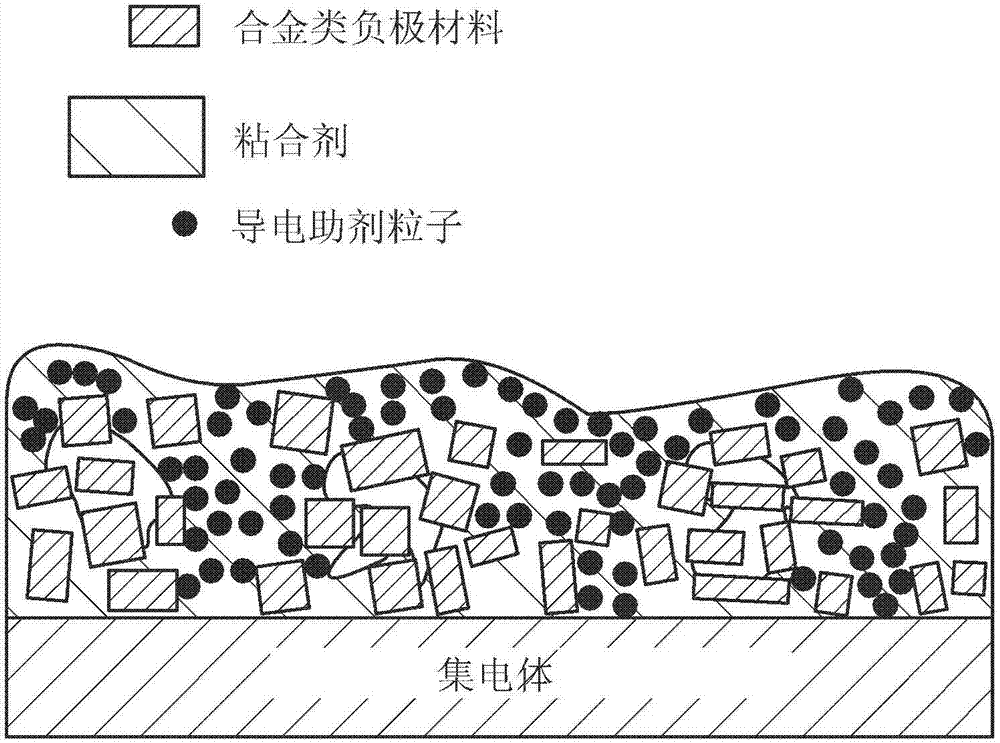

[0094] In this embodiment, an example in which silicon is used as an alloy-based negative electrode material and a carbon film composed of 1 to 50 graphene layers is formed on the surface of silicon particles will be described. First, graphite oxide is produced by oxidizing graphite, and ultrasonic vibration is applied to the graphite oxide to obtain graphene oxide. For details, refer to Patent Document 2. In addition, commercially available graphene oxide can also be used. In order to obtain graphene oxide from graphite, the following steps are preferably performed.

[0095] First, graphite oxide such as flaky graphite is oxidized to obtain graphite oxide. Graphite oxide is formed when some parts of graphite are oxidized and combined with functional groups such as carbonyl, carboxyl, and hydroxyl groups. The crystallinity of graphite is destroyed, and the distance between graphenes becomes larger. Therefore, separation between layers is likely to occur by ultrasonic treatm...

Embodiment approach 2

[0122] In this embodiment, an example in which a carbon film composed of 1 to 50 graphene layers is formed on the surface of a silicon active material layer formed on a current collector will be described. First, graphene oxide is dispersed in a solvent such as water or NMP. The solvent is preferably a polar solvent. The concentration of graphene oxide can be set at 0.1 g to 10 g per 1 L.

[0123] The entire current collector including the silicon active material layer was immersed in the above solution, pulled out, and then dried. In addition, a layer made of a highly conductive material such as copper may be formed in advance on the surface of the silicon active material layer. In addition, heating is performed at a temperature of 150° C. or higher, preferably 200° C. or higher, in a reducing atmosphere such as vacuum or an inert gas (nitrogen or a rare gas, etc.). Through the above steps, a carbon film composed of 1 to 50 graphene layers can be formed on the surface of t...

Embodiment approach 3

[0127] In this embodiment, another example in which a carbon film composed of 1 to 50 graphene layers is formed on the surface of a silicon active material layer formed on a current collector will be described. Similar to Embodiment 2, graphene oxide is dispersed in a solvent such as water or NMP. The concentration of graphene oxide can be set at 0.1 g to 10 g per 1 L.

[0128] The current collector formed with the silicon active material layer was placed in a solution in which graphene oxide was dispersed to use it as a positive electrode. In addition, a layer made of a highly conductive material such as copper may be formed in advance on the surface of the silicon active material layer. In addition, put the conductor that becomes the negative electrode in the solution, and apply an appropriate voltage (such as 5V to 20V) between the positive electrode and the negative electrode. Since a part of the ends of graphene sheets having a certain size in graphene oxide is capped w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com