Assembling tool for bearing and main shaft of permanent magnet direct-driven wind driven generator

A technology for wind turbines and assembling tooling, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problem of high cost, and achieve the effects of convenient use, convenient adjustment and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

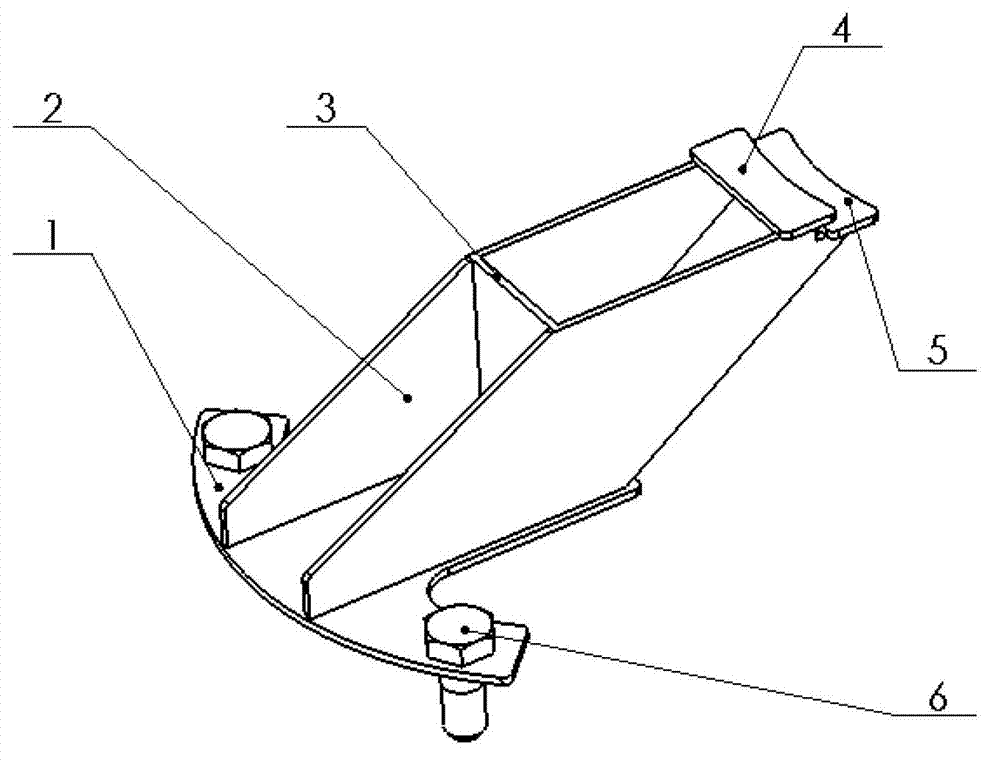

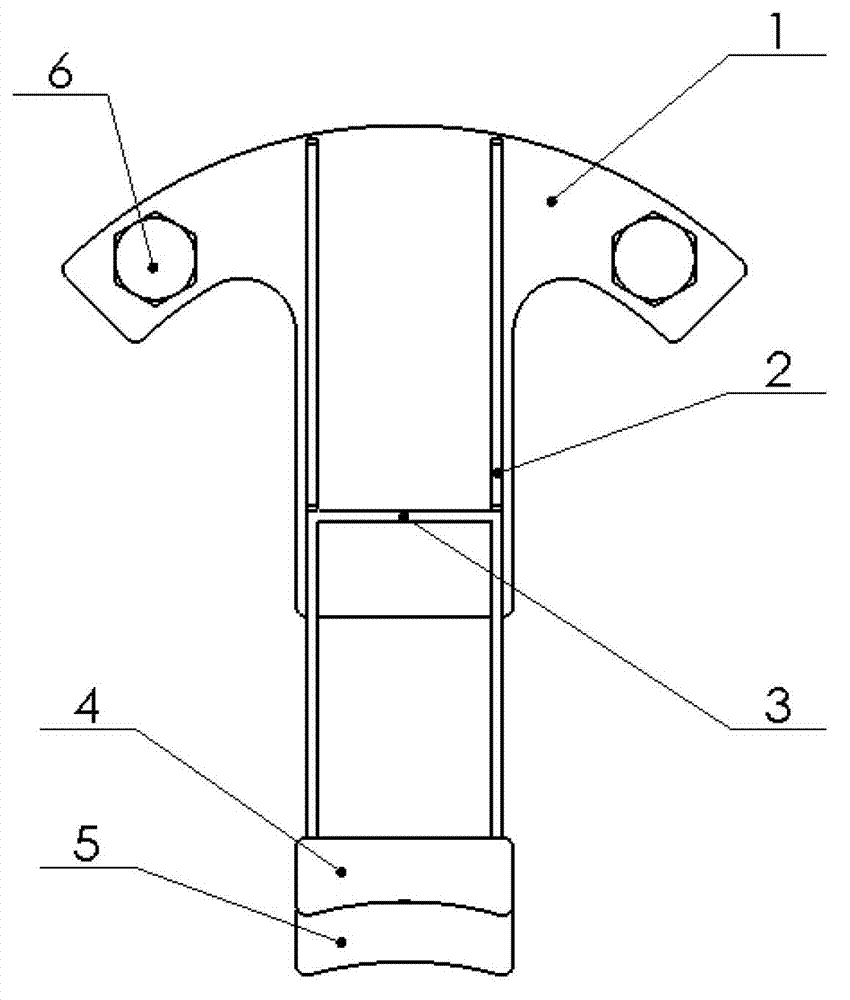

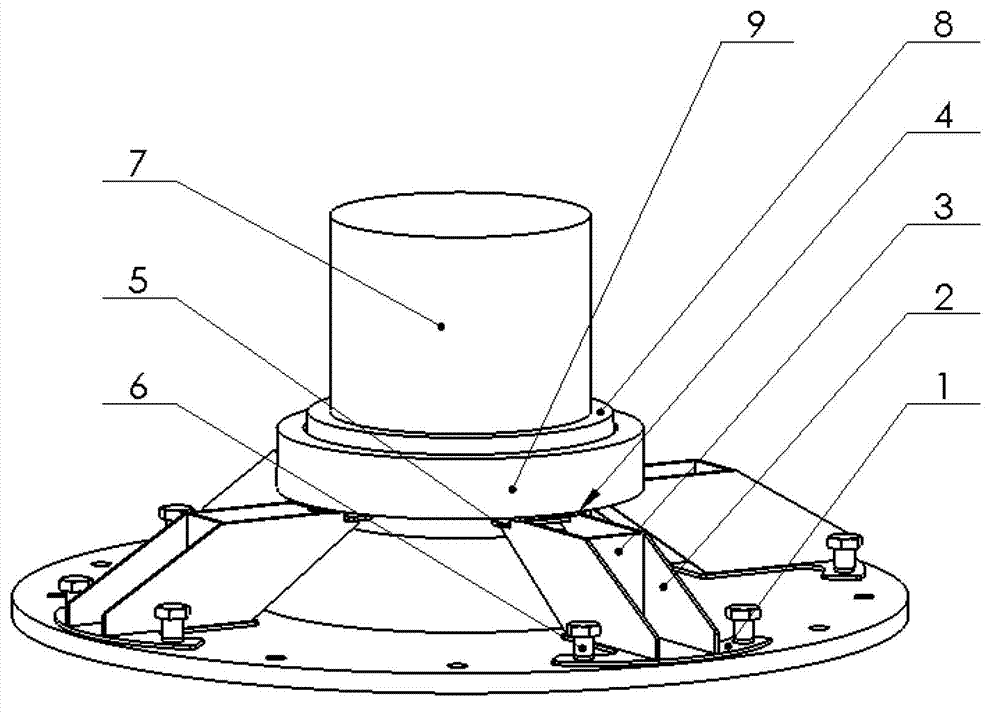

[0020] see figure 1 , figure 2 As shown, the bearing and main shaft assembly tool of the permanent magnet direct drive wind power generator of the present invention includes a base plate, a positioning plate, and a support body whose lower end is fixedly connected to the base plate and whose upper end is fixedly connected to the positioning plate.

[0021] More specifically, the bottom plate 1 preferably has an arc-shaped outer edge, and more than two installation through holes are symmetrically provided at both ends of the arc. The support body includes a pair of side plates 2 and a support plate 3 fixed between the two side plates 2, and the overall height of the support body is adapted to the axial position of the bearing to be assembled. The positioning plate includes upper and lower single-side arc plates, wherein the arc edges of the upper and lower single-side arc plates are all facing the inside of the assembly tool, and the upper single-side arc plate 4 is located a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com