Railway pier and beam combining structure suitable for multi-span long coupling and large expansion and contraction quantity beams on two sides

A technology of expansion and contraction, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as poor ride comfort, too large bridge piers, and low bridge rigidity, and achieve strong terrain adaptability, improved overall layout, and good adaptability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0020] To build a flat road-rail bridge in a certain place, the bridge includes a long-connected large-scale beam section structure with a length of 400-600m, and according to the existing technology, the long-linked large-scale beam section is transitioned by building a transition span containing two piers There are problems of too many piers and high cost. This embodiment provides a new type of transition structure connecting long-connected and large-scale beams on both sides.

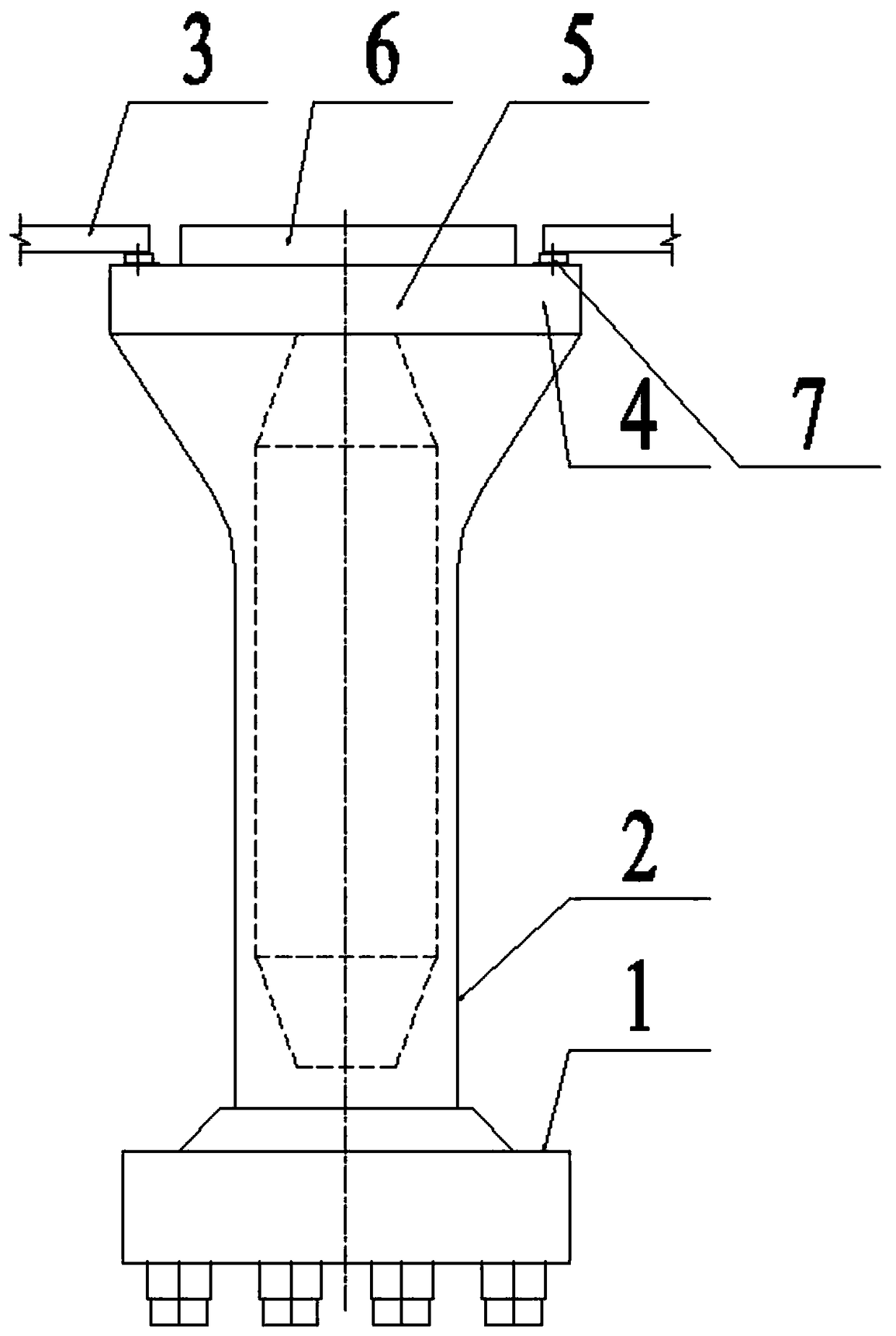

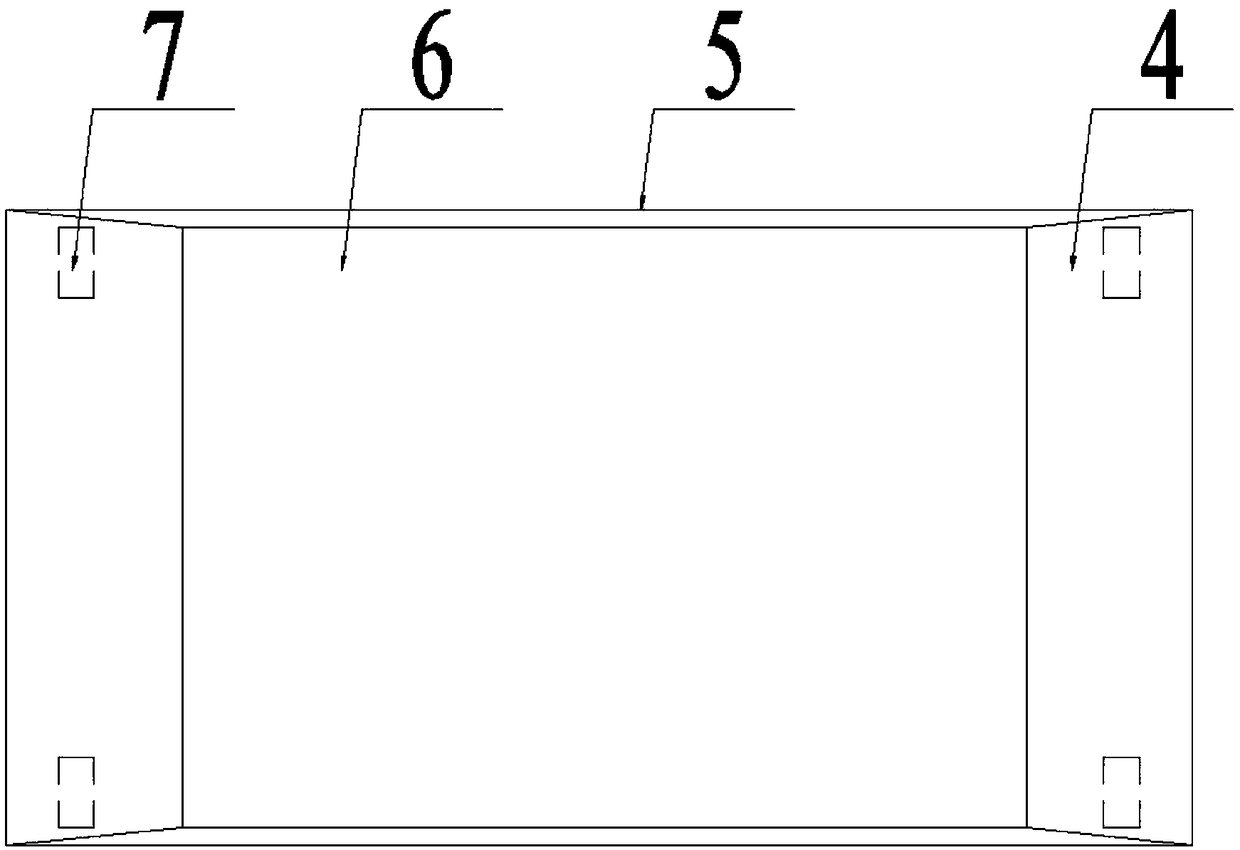

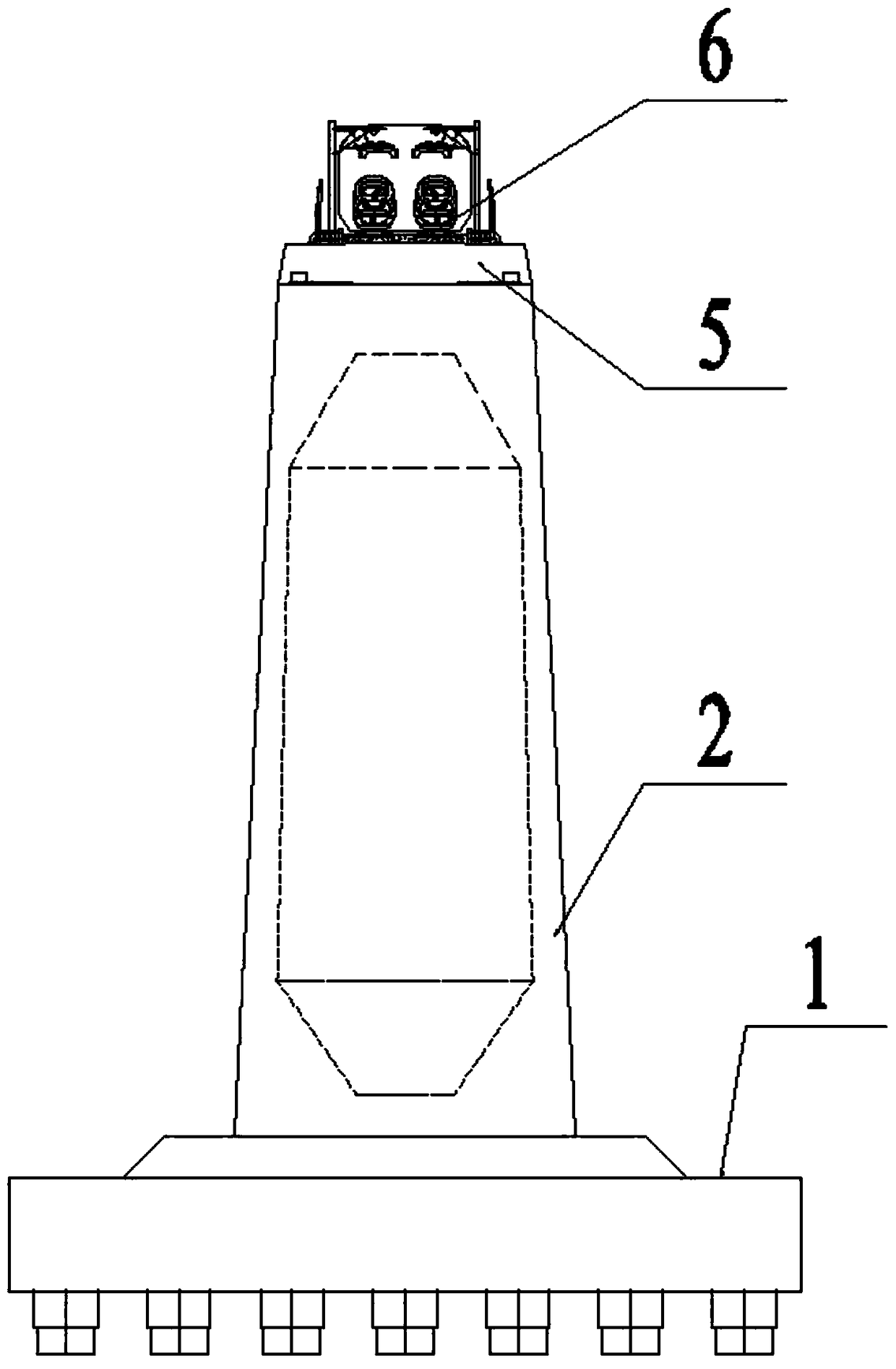

[0021] Such as Figure 1~3 , a pier-beam combination structure suitable for railway bridges with long-connected and large-scale expansion on both sides. The joint expansion beam 3 includes a cap 1 and a bridge pier 2 located on the cap 1 , and a pier-beam joint section and a beam portion 6 are arranged on the bridge pier 2 .

[0022] Such as figure 1 As s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com