Penetrating shaft unit structure

A unit structure, through-shaft technology, used in transmission parts, belts/chains/gears, mechanical equipment, etc., can solve problems such as poor lubrication, oil leakage from oil seals, extended assembly cycle, etc., and achieve reliable connection and simple combined structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

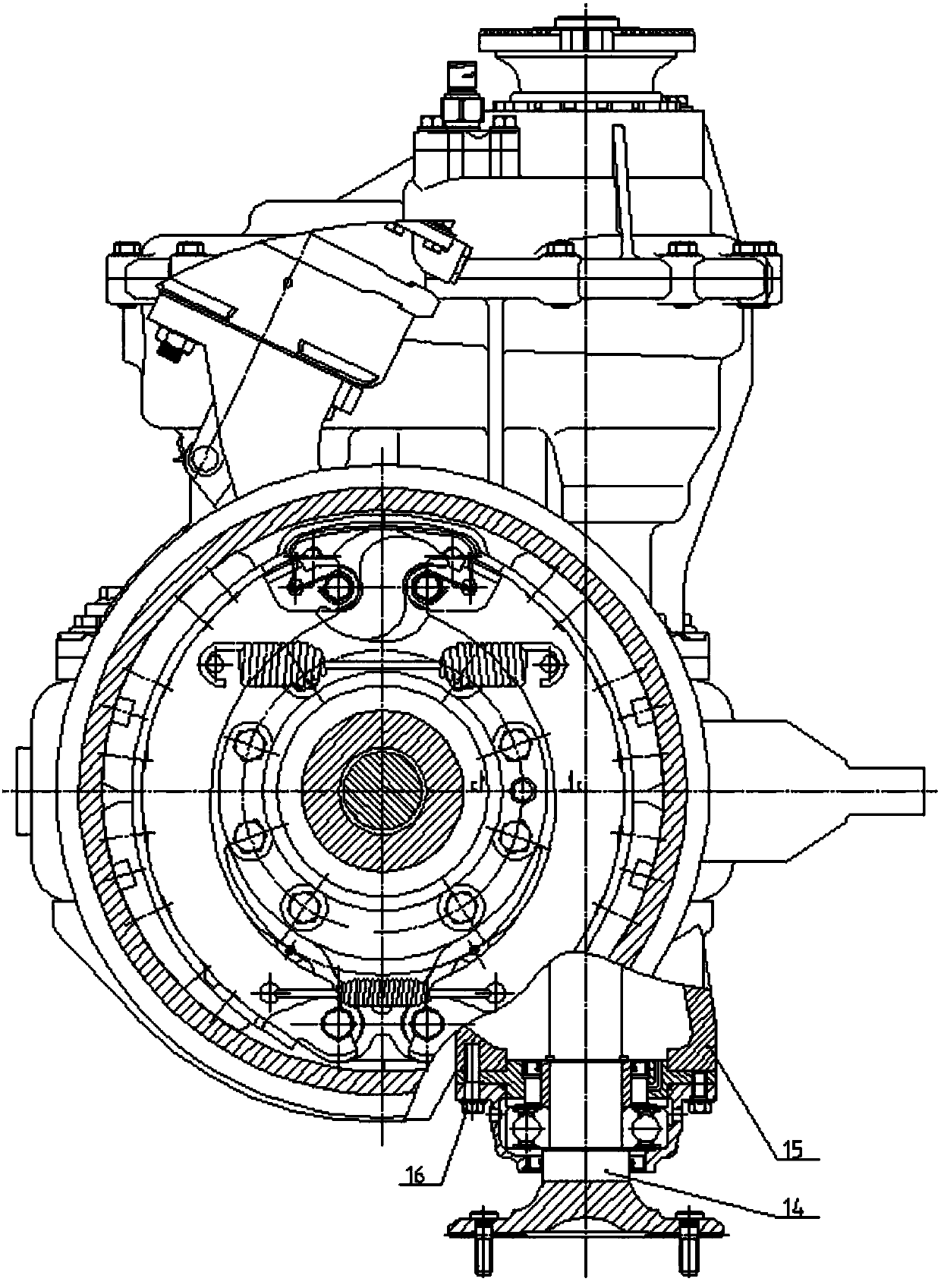

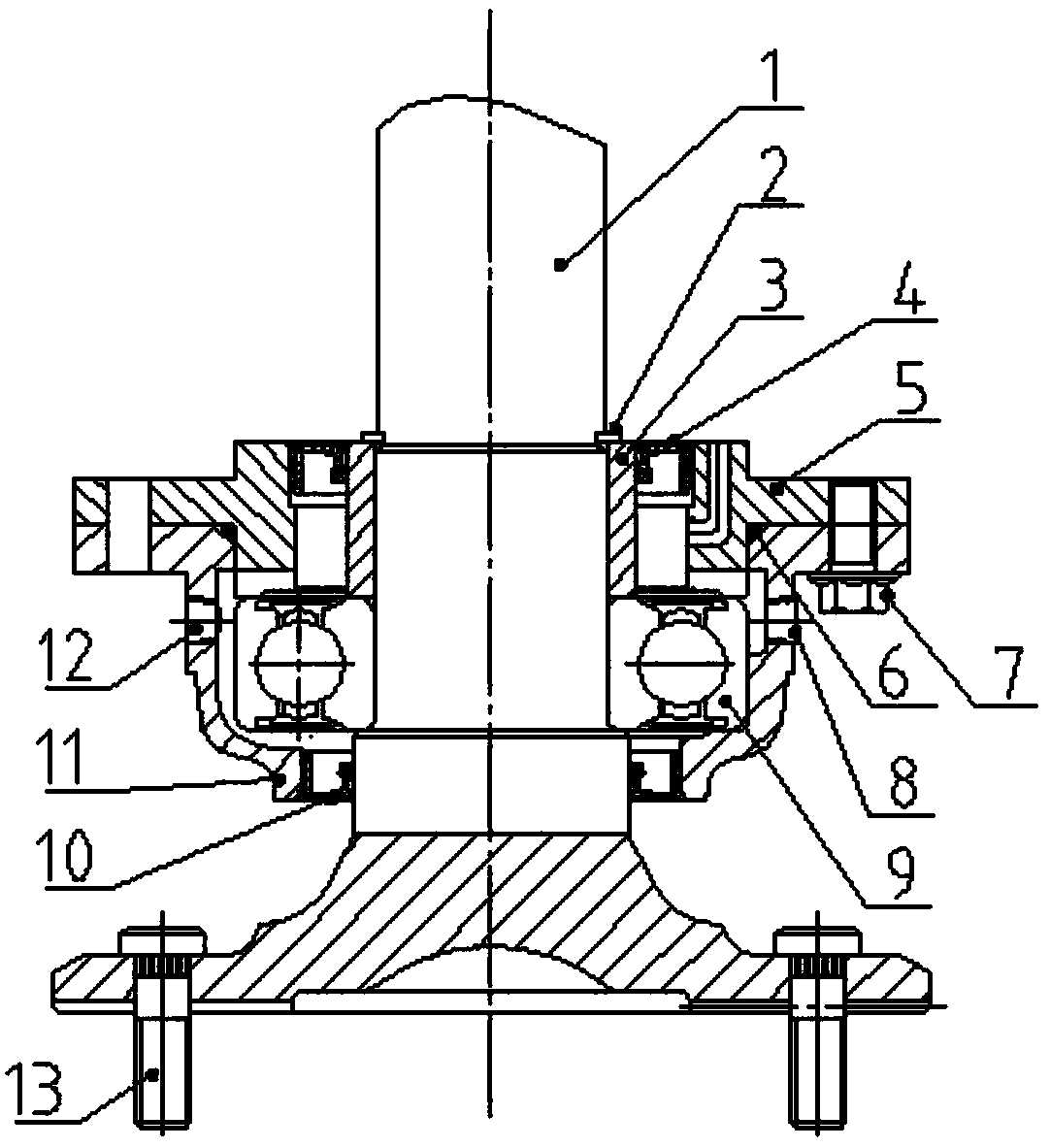

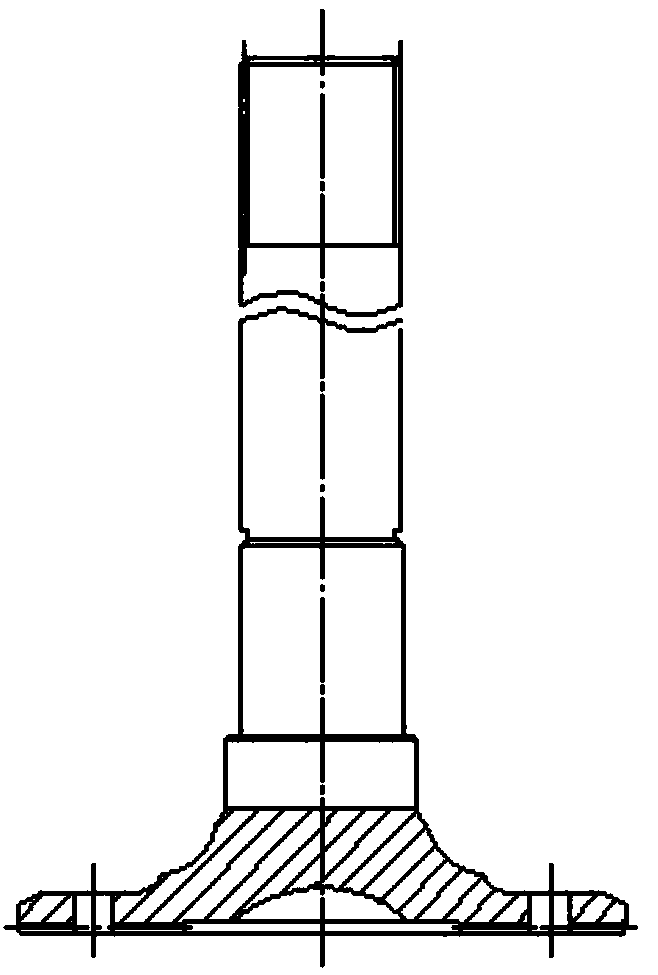

[0022] refer to figure 1 , figure 2 , a through-shaft unit structure, the through-shaft unit 14 is a symmetrical structure, including a through-shaft 1, a snap ring 2, a retaining ring 3, a first oil seal 4, an oil seal seat 5, an O-ring 6, a first bolt 7, Filling plug 8, bearing 9, second oil seal 10, bearing seat 11, oil drain plug 12, second bolt 13.

[0023] The left and right sides of the lower end of the through shaft 1 are connected to the transmission shaft through the second bolt 13; the second oil seal 10 is arranged in the pin circular hole on the lower end surface of the bearing seat 11; the bearing 9 is arranged The large circular hole on the upper end surface of the bearing seat 11 is positioned axially with the end surface of the large circular hole; the oil drain plug 12 is threadedly connected to both sides of the bearing seat 11; the inner hole of the retaining ring 3 Interference fit with the outer diameter of the through shaft 1 to fix the inner ring of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com