Patents

Literature

43results about How to "Simplify Manufacturing Engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

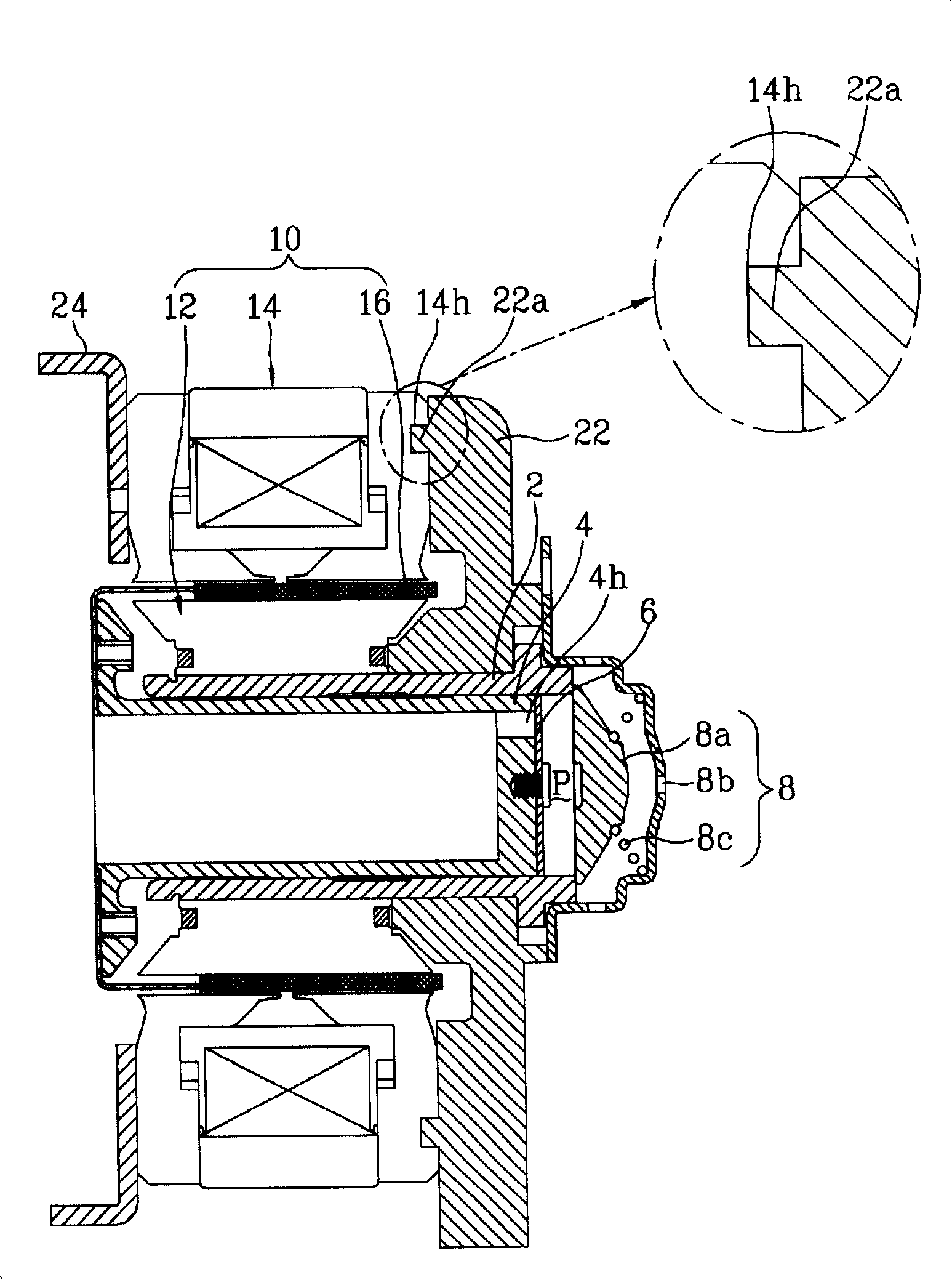

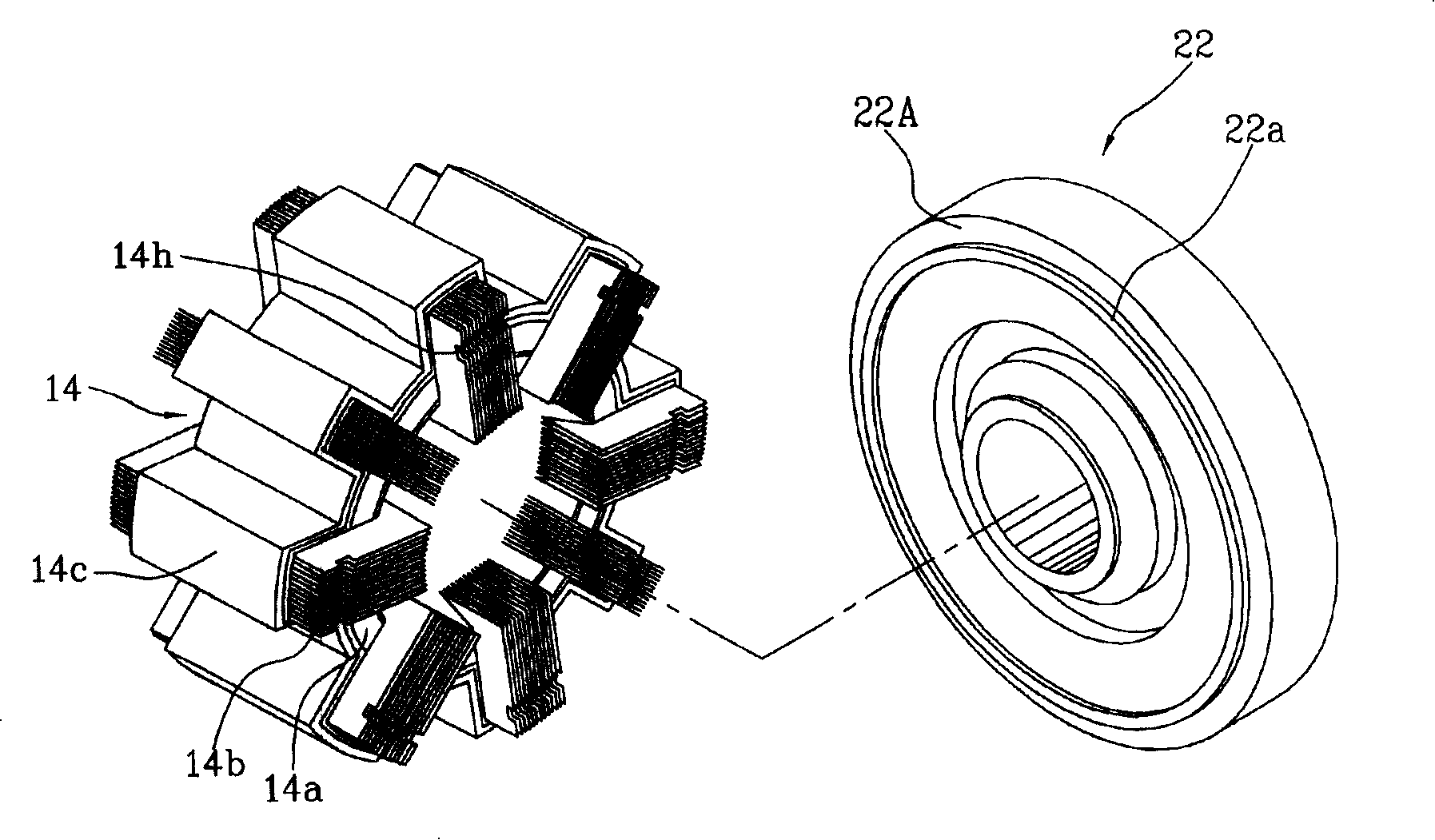

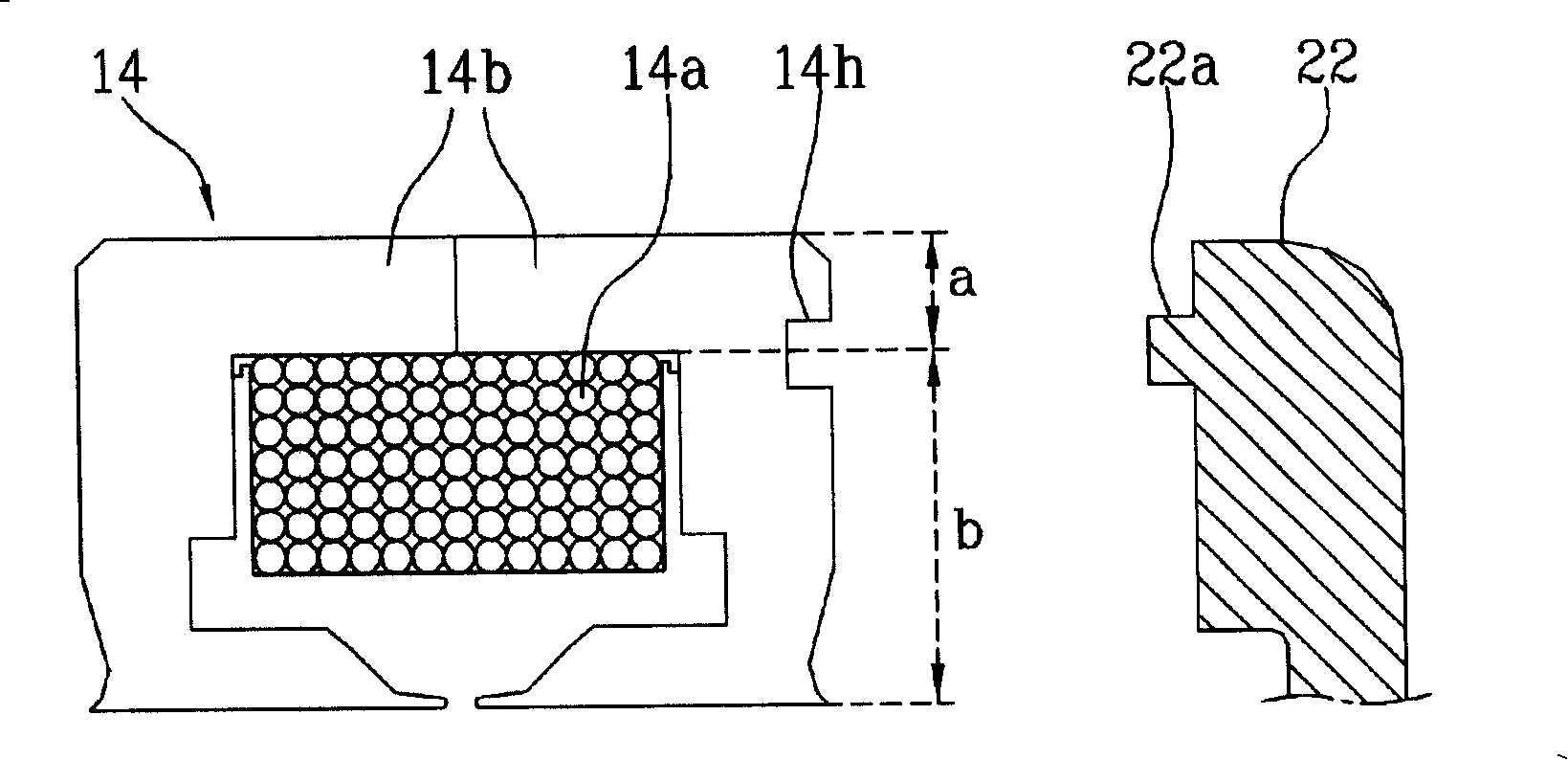

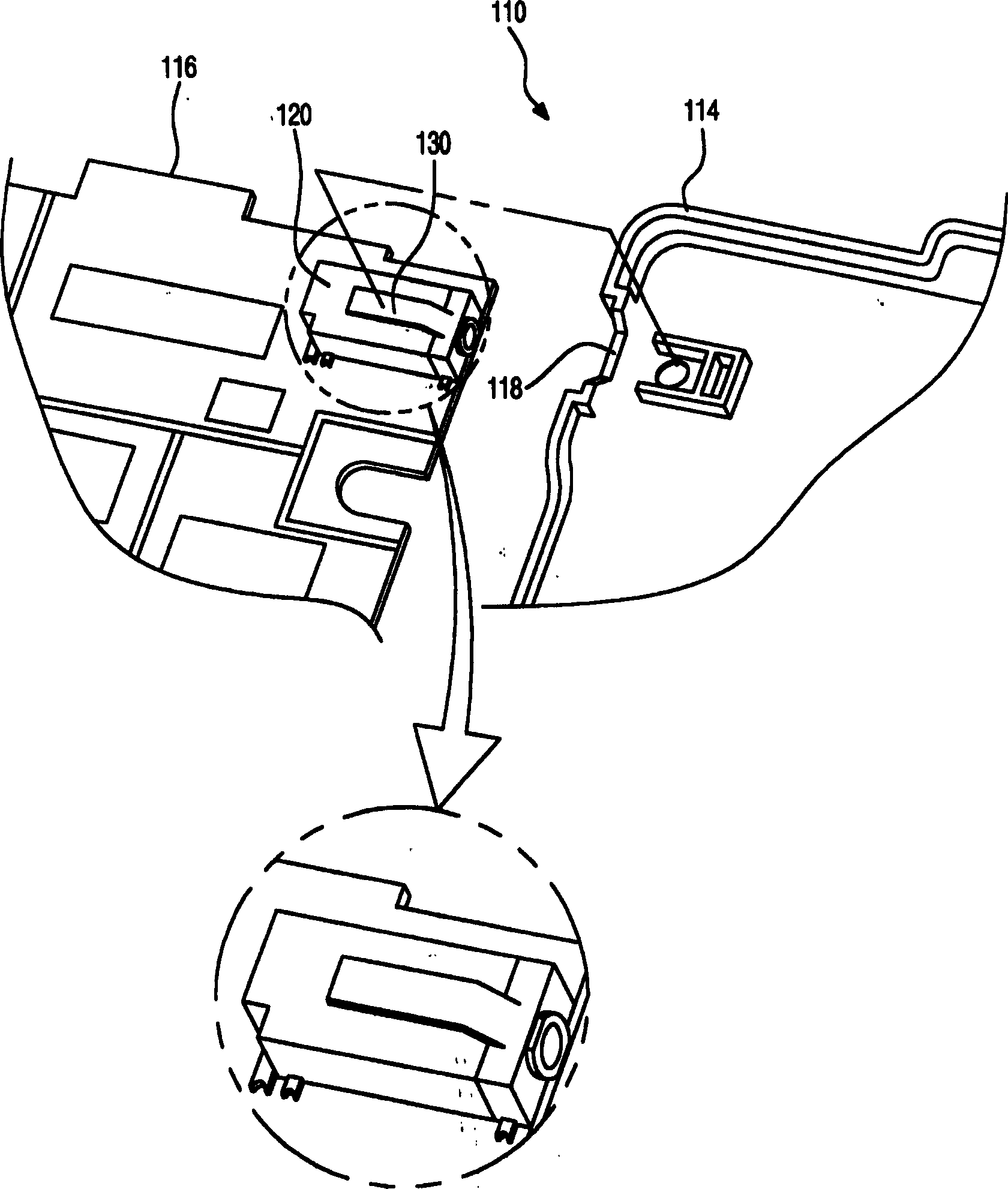

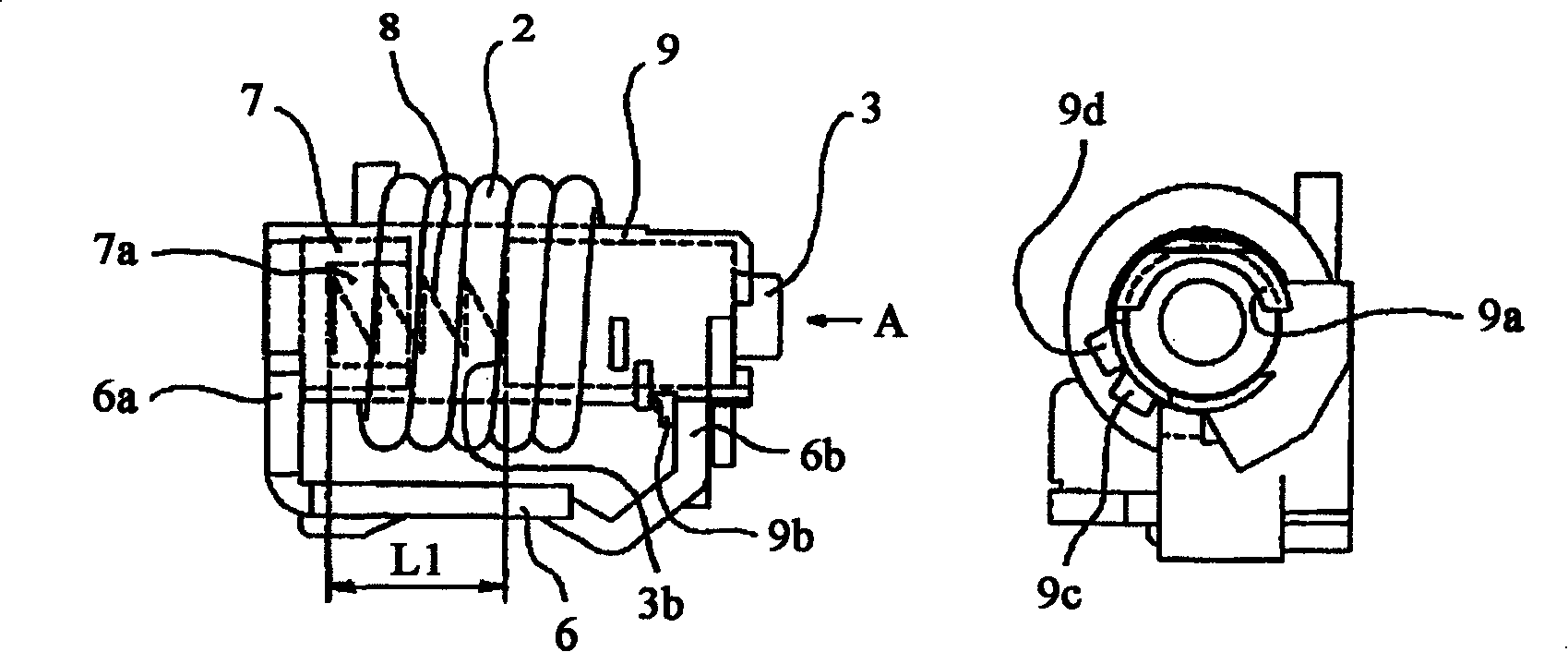

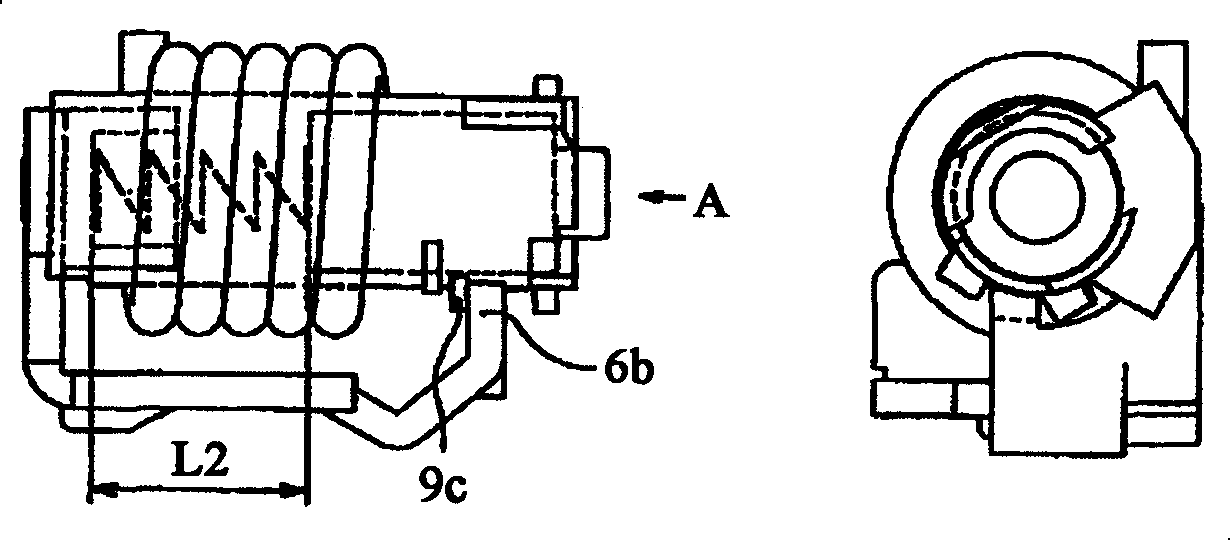

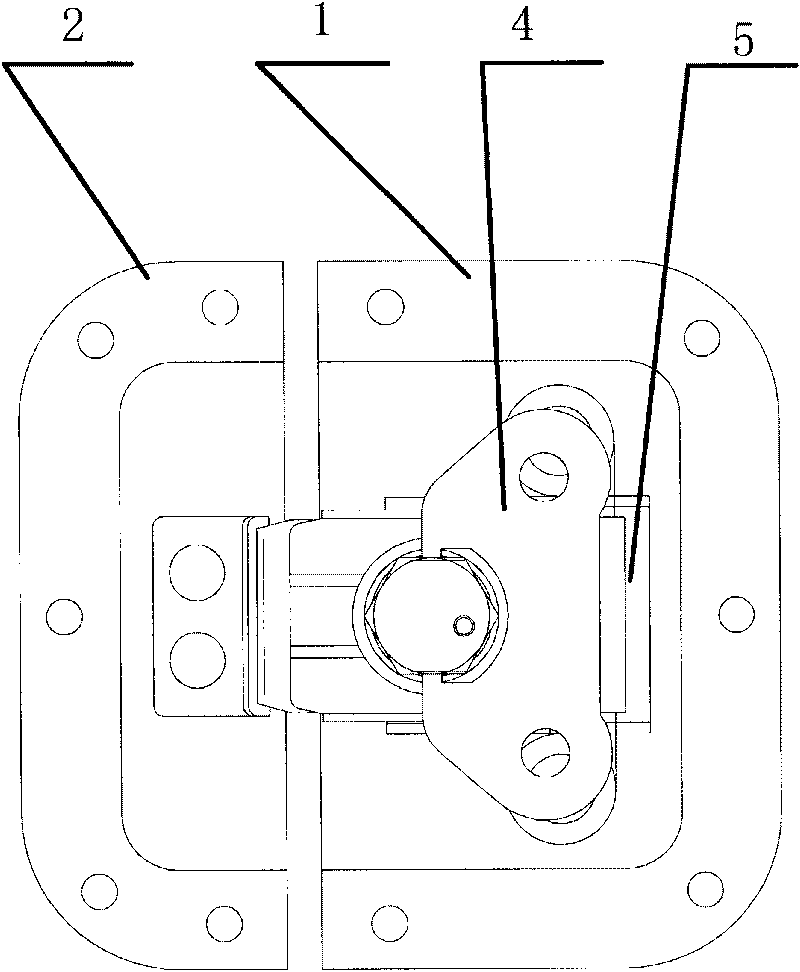

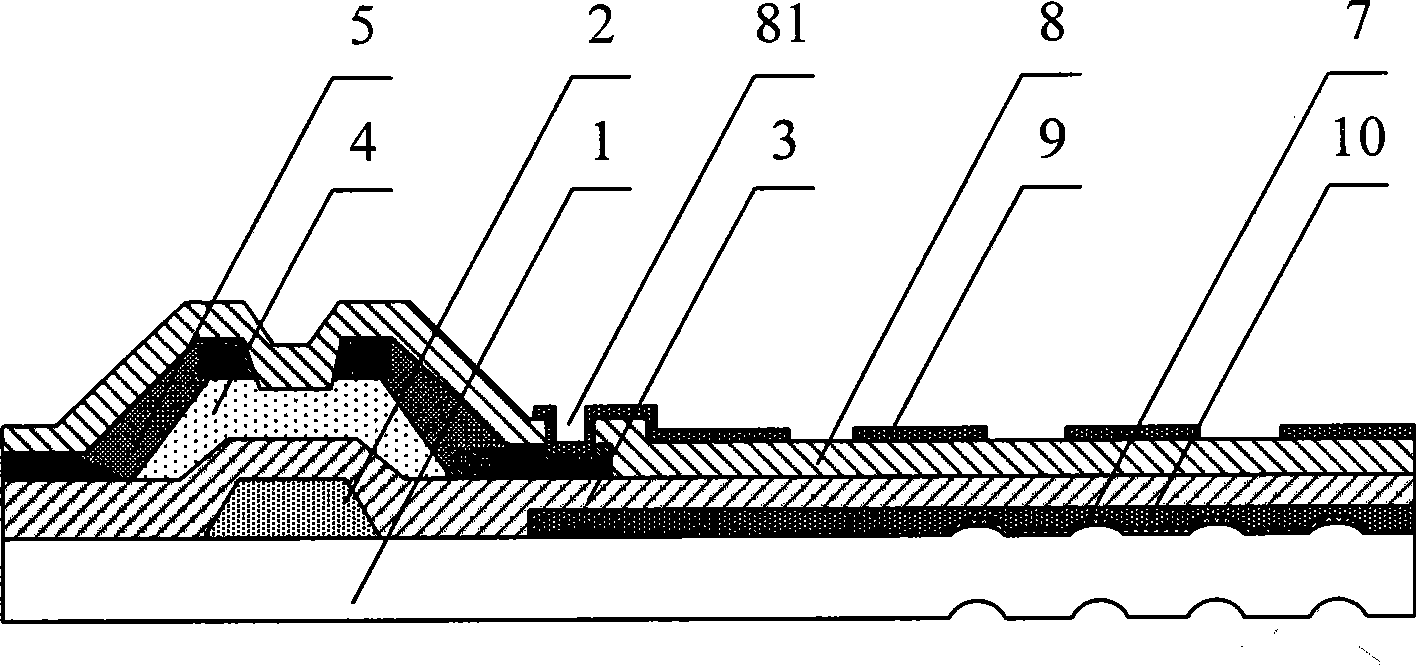

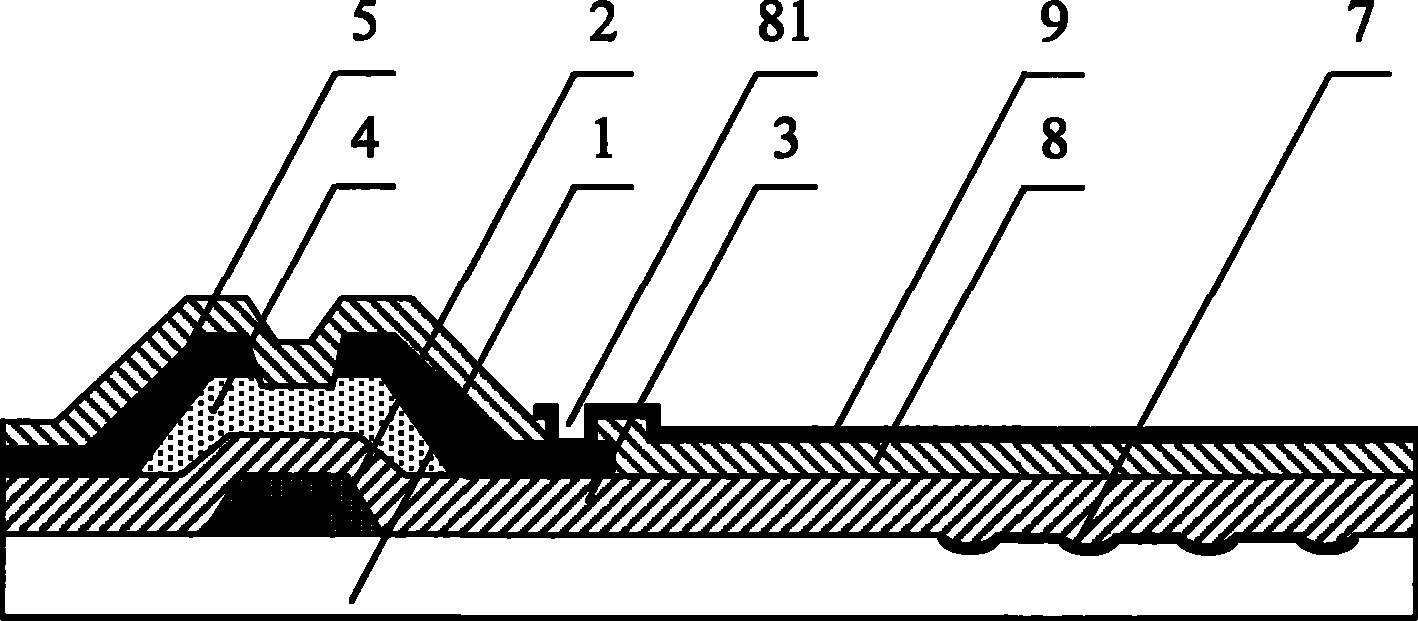

Electric machine fixation structure of linear compressor

InactiveCN101207318AEasy to fixImprove operational reliabilityMagnetic circuit stationary partsPumpsElectric machineLinear compressor

The invention provides a linear motor fixed structure of a linear compressor; the structure comprises a cylinder, a piston, an inner stator, an outer stator, a permanent magnet, a supporting projection that supports one end of the outer stator and projects out of one surface of a main frame and a motor cover that supports the other end of the outer stator and is fixed on the main frame, wherein, the number of the supporting projection that projects out of one surface of the main frame is one or more. The invention has the effects that: in the linear motor fixed structure of the linear compressor, when the other end on the axial direction of a coil group in the outer stator is supported on the motor cover, at least one supporting projection is supported in a straight-line-part section that is free from a coil winding in the coil group, so that the centralized gravity acts on a contact surface, thereby obtaining a linear motor that carries out the fixed linear compressor much more stably. The invention not only can improve the operation reliability of the motor, but also can simplify the production process and improve the production since the coil group is not provided with a fixed groove.

Owner:TAIZHOU LG ELECTRONICS REFRIGERATOR CO LTD

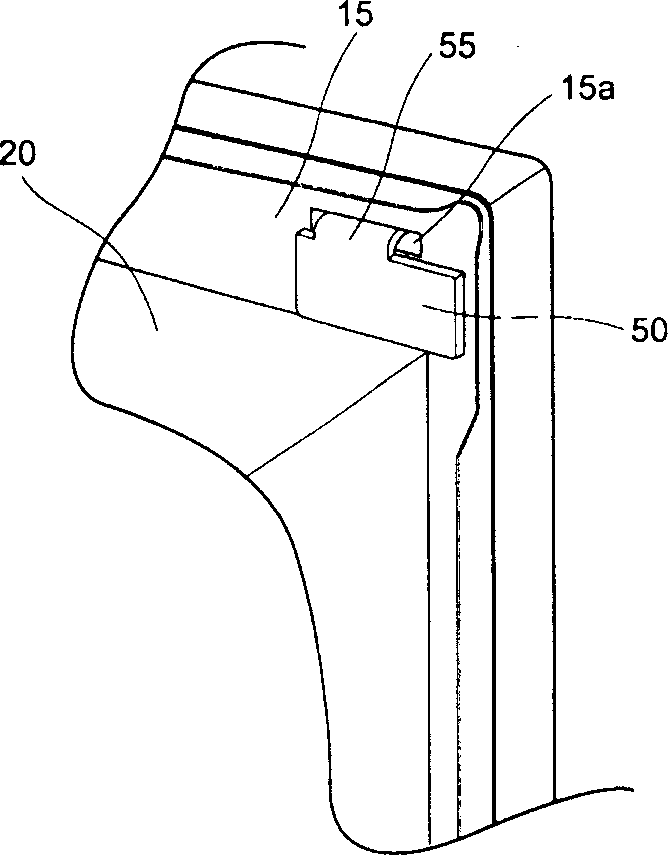

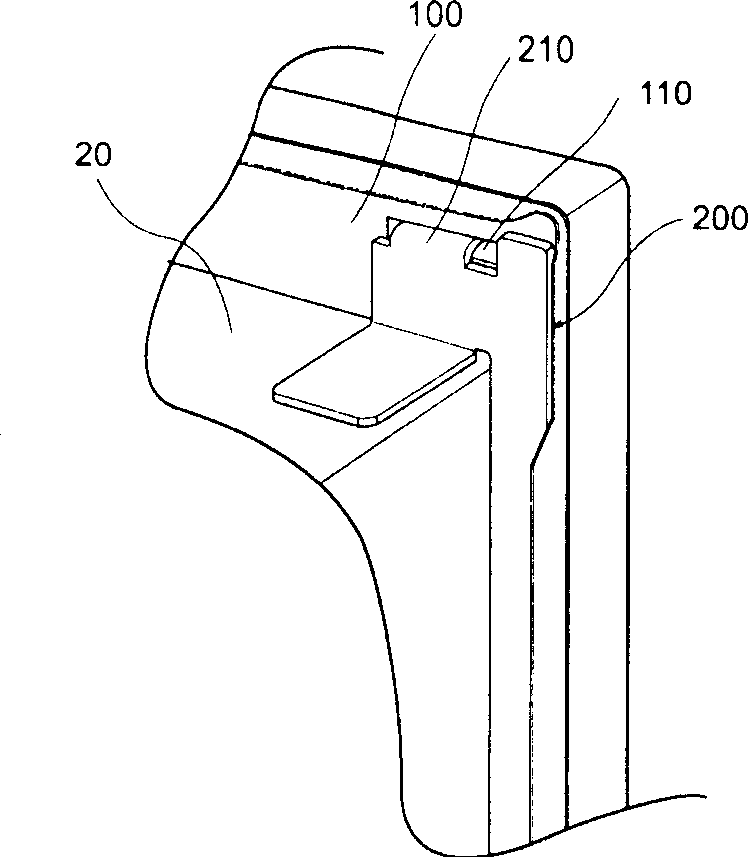

Static removing structure of mobile communication terminal

InactiveCN1794903AEliminate static electricitySimplify Manufacturing EngineeringElectrical apparatus contructional detailsTransmissionComputer terminalEngineering

The invention relates to a static elimination structure of a mobile communication terminal, which installs a conductive plate-shaped spring on one side of a charging jack or one side of an earphone jack, so that the static electricity flowing on the terminal shell passes through the conductive plate-shaped spring. spring and eliminate by connecting to ground at the charge jack or headphone jack. The present invention is characterized in that it includes an elastic member, which is fixed on one side of the above-mentioned charging jack so that it is close to the bottom surface of the terminal shell coated with a conductive substance and has elasticity, and is formed of a conductive substance, so that the flow is Static electricity on the bottom surface of the terminal shell is transmitted to the ground terminal through the charging jack, and the outer surface of the charging jack is formed of conductive material. In addition, the static electricity flowing on the terminal case is eliminated by the conductive plate spring fixed on the side of the charging jack or the earphone jack, so there is no need for a separate manufacturing process for eliminating static electricity. In addition, the manufacturing process is simplified, thereby reducing manufacturing costs and reducing defective assembly.

Owner:LG ELECTRONICS (CHINA) R&D CENT CO LTD

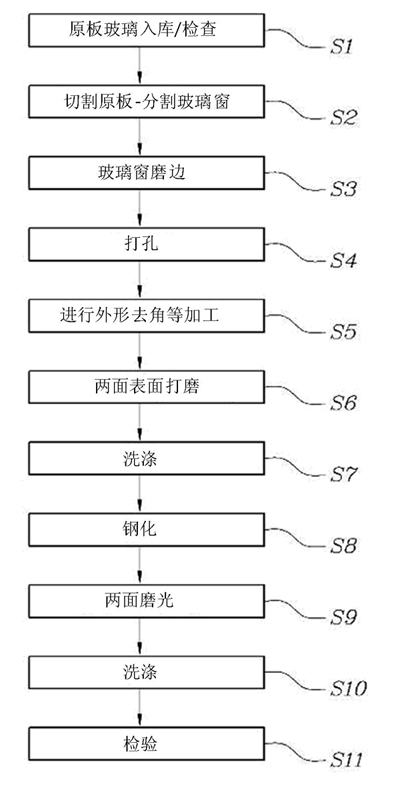

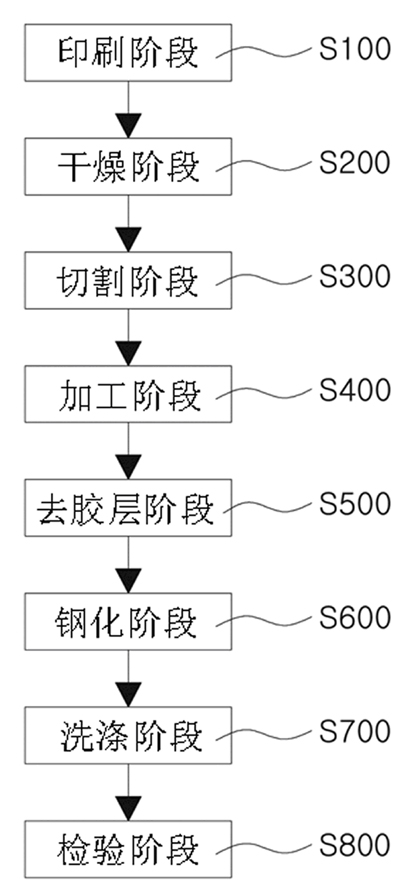

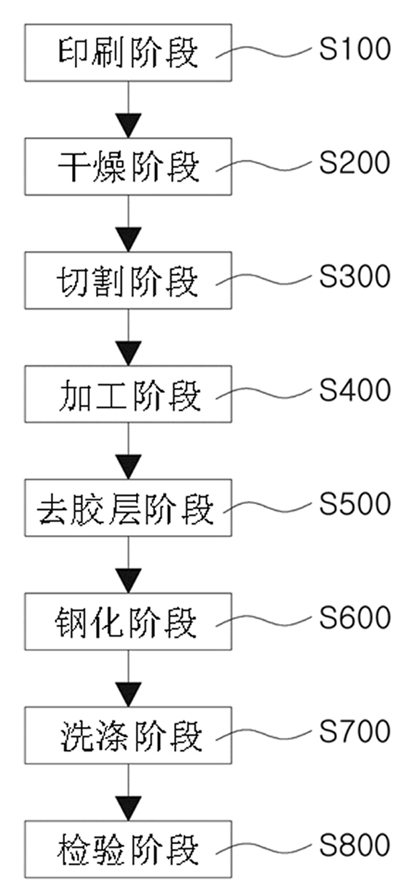

Manufacturing method of strengthed glass for touch panel

InactiveCN102001820AAvoid scratchesAvoid stickingGlass tempering apparatusGlass productionCutting glassEngineering

The invention relates to a manufacturing method of strengthened glass for touch panel, comprising: a step of printing on an glass plate with masking ink; a step of drying the printed glass plate; a step of cutting the dried glass plate in a uniform size; a step of processing the cut glass to have hole or groove; a step of removing printed masking ink; a step of strengthening the glass; a step of washing the strengthened glass; and a step of testing the washed glass. The method mainly uses the masking ink to prevent scratch on the strengthened glass and has features of simple manufacturing project, relative low cost and relative strong competitive powder.

Owner:李起松

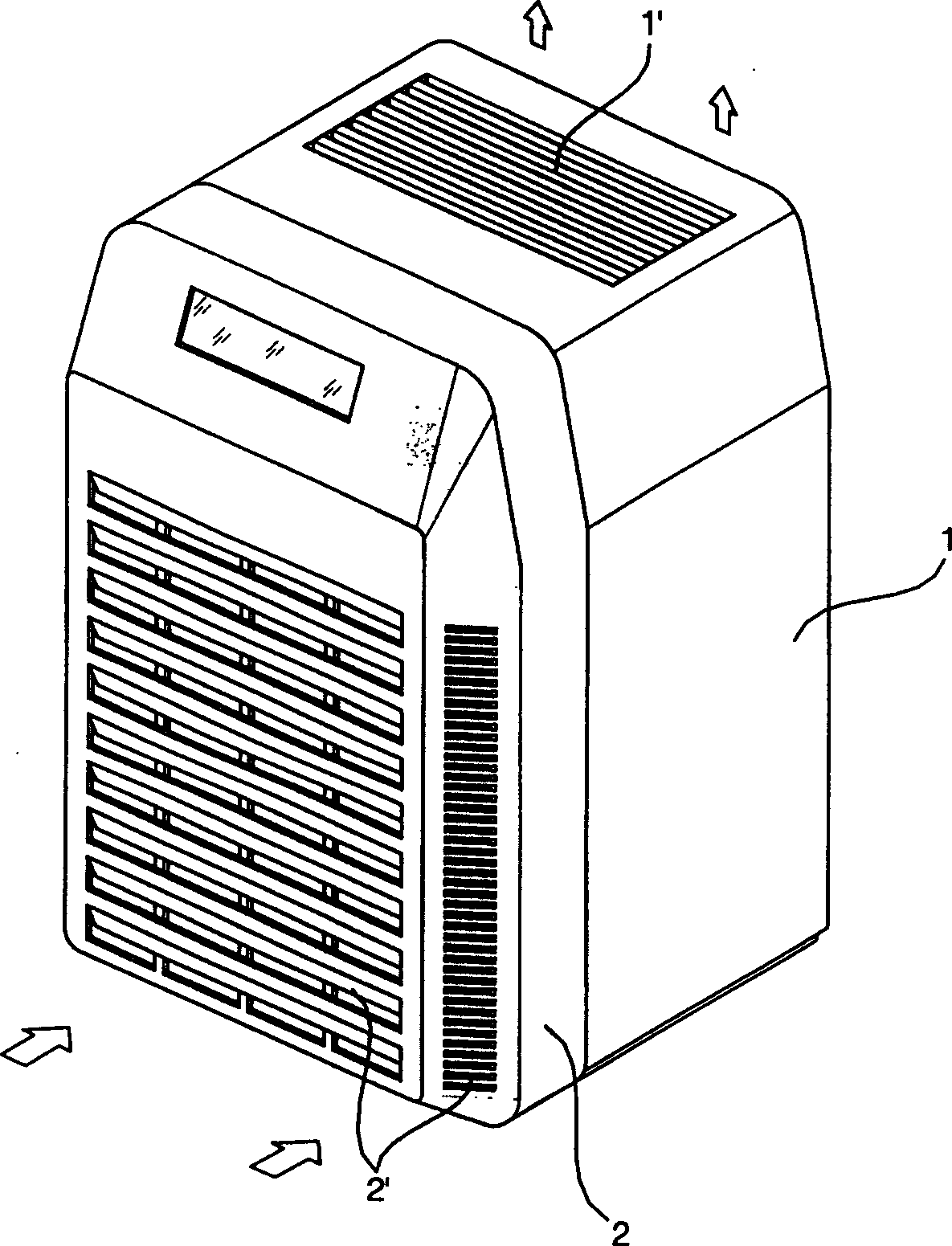

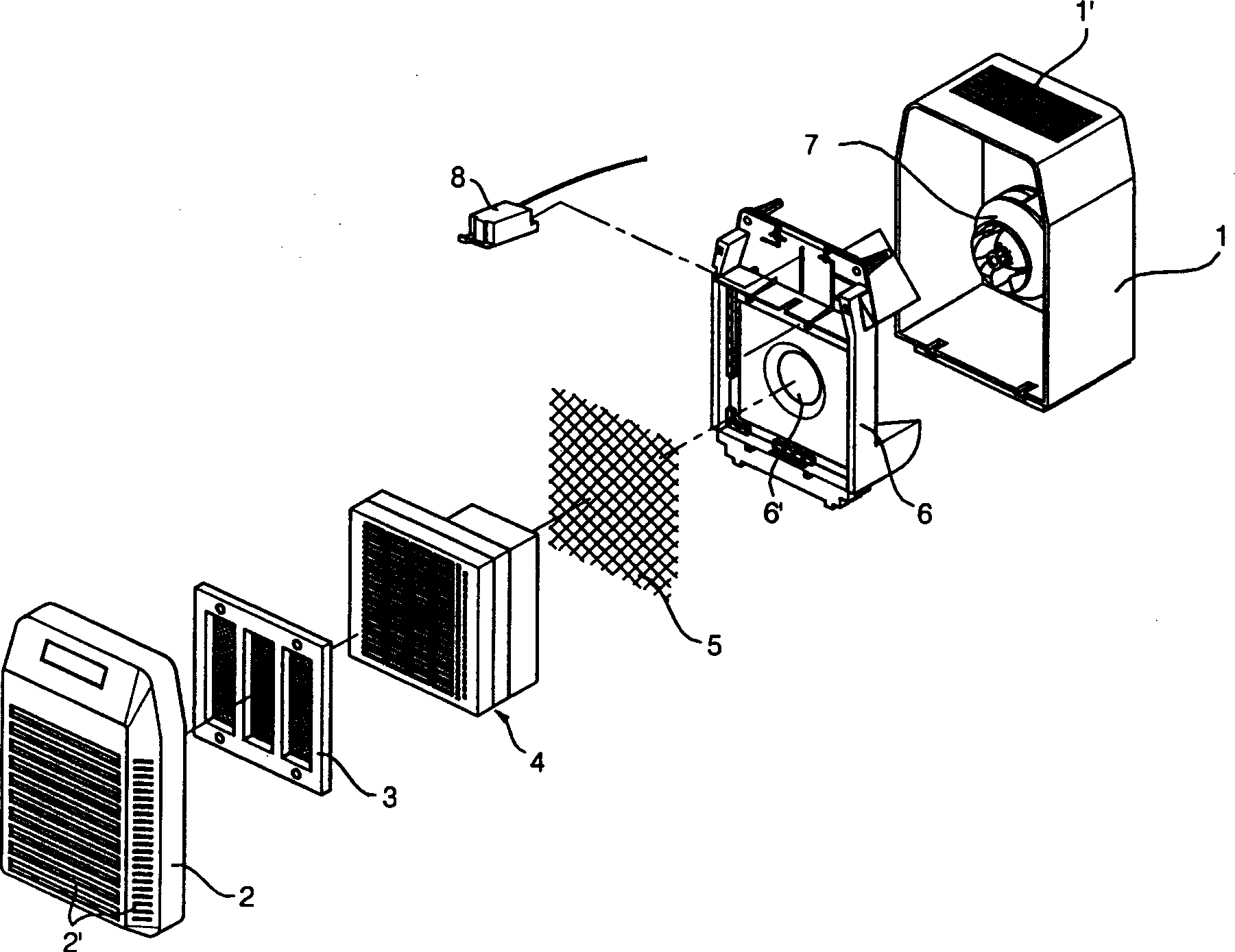

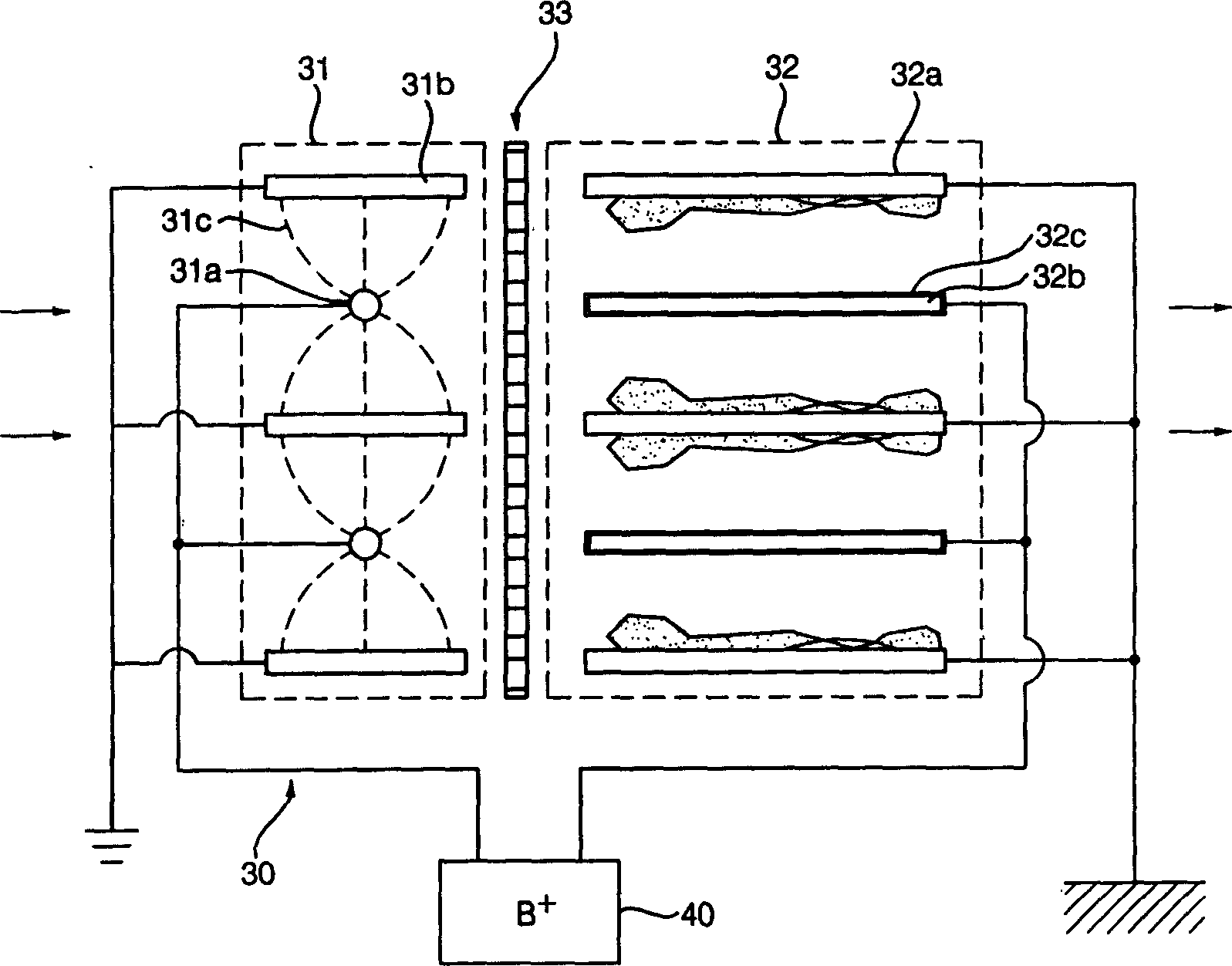

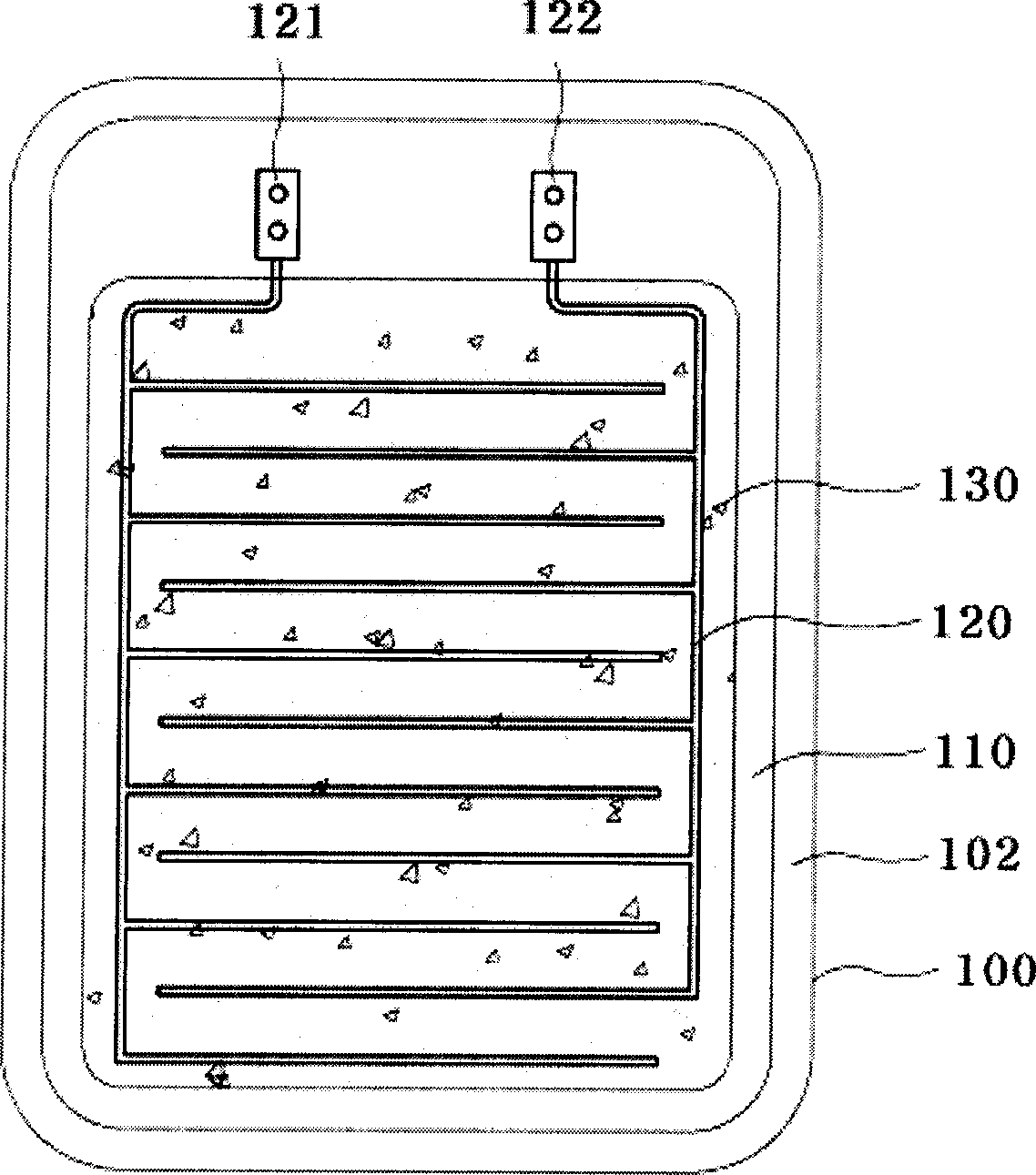

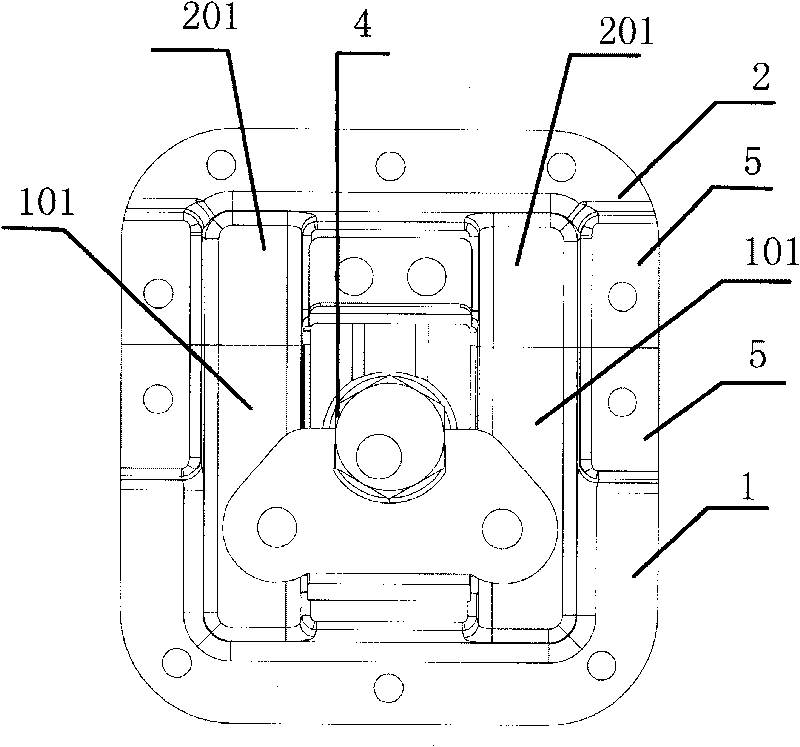

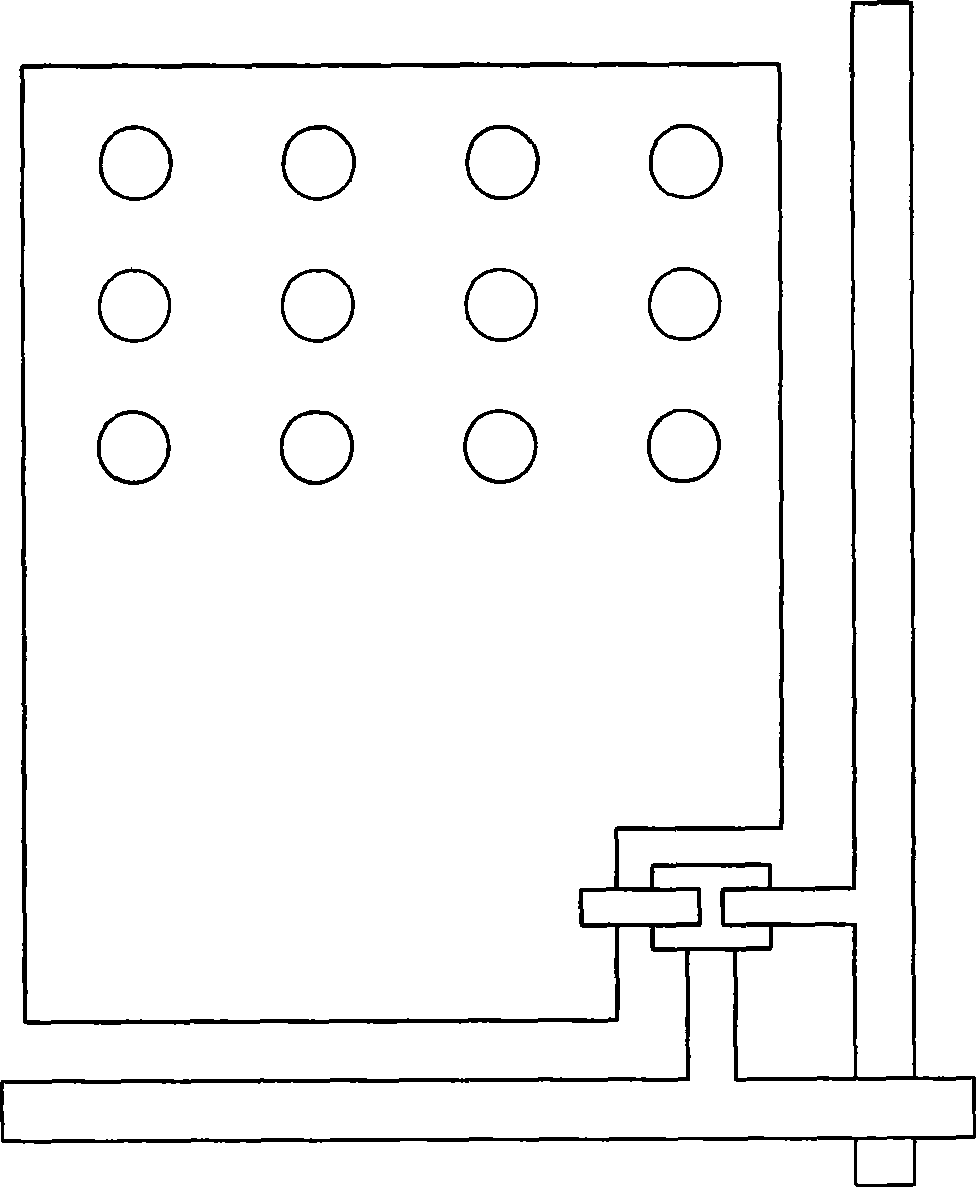

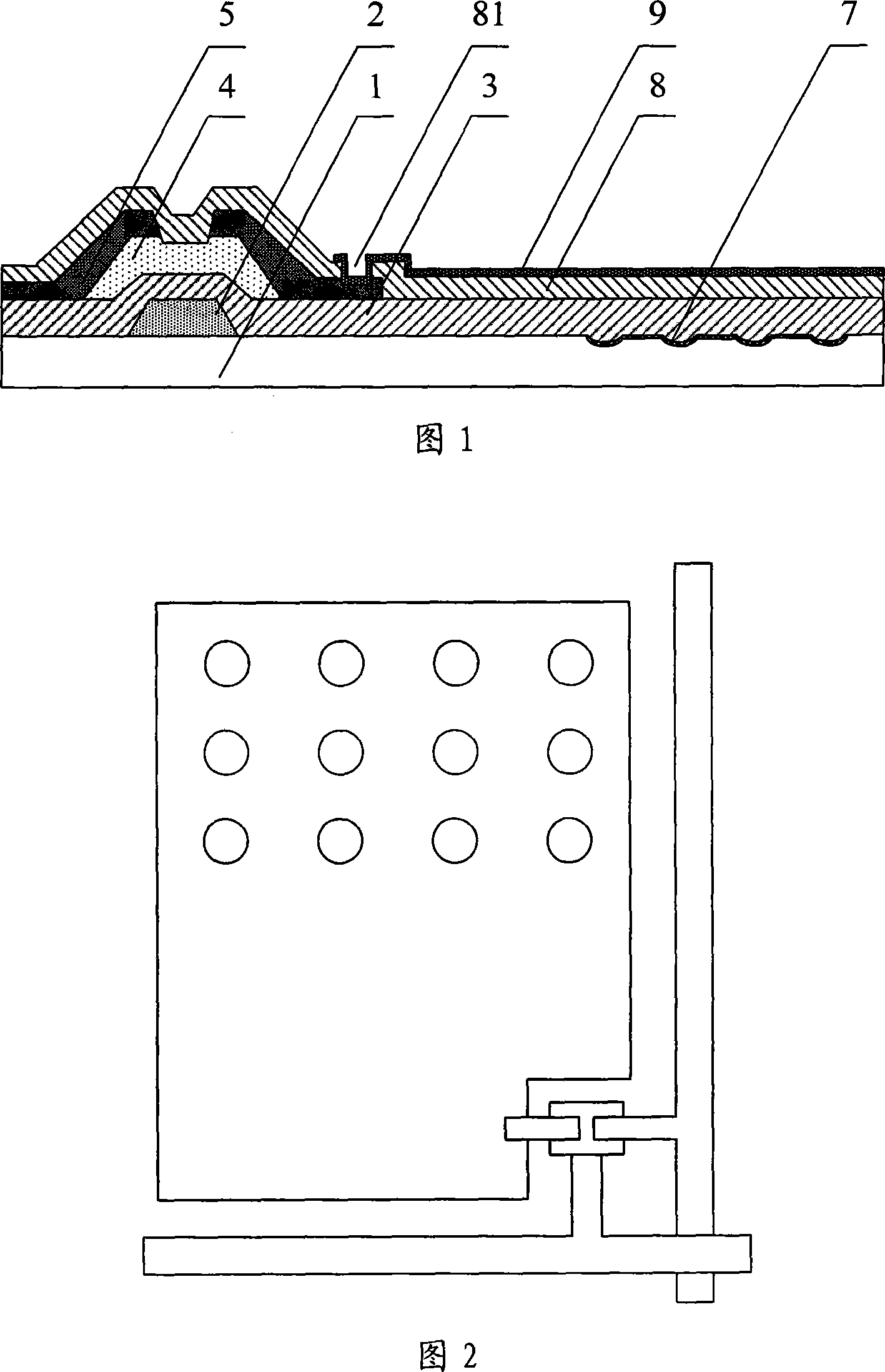

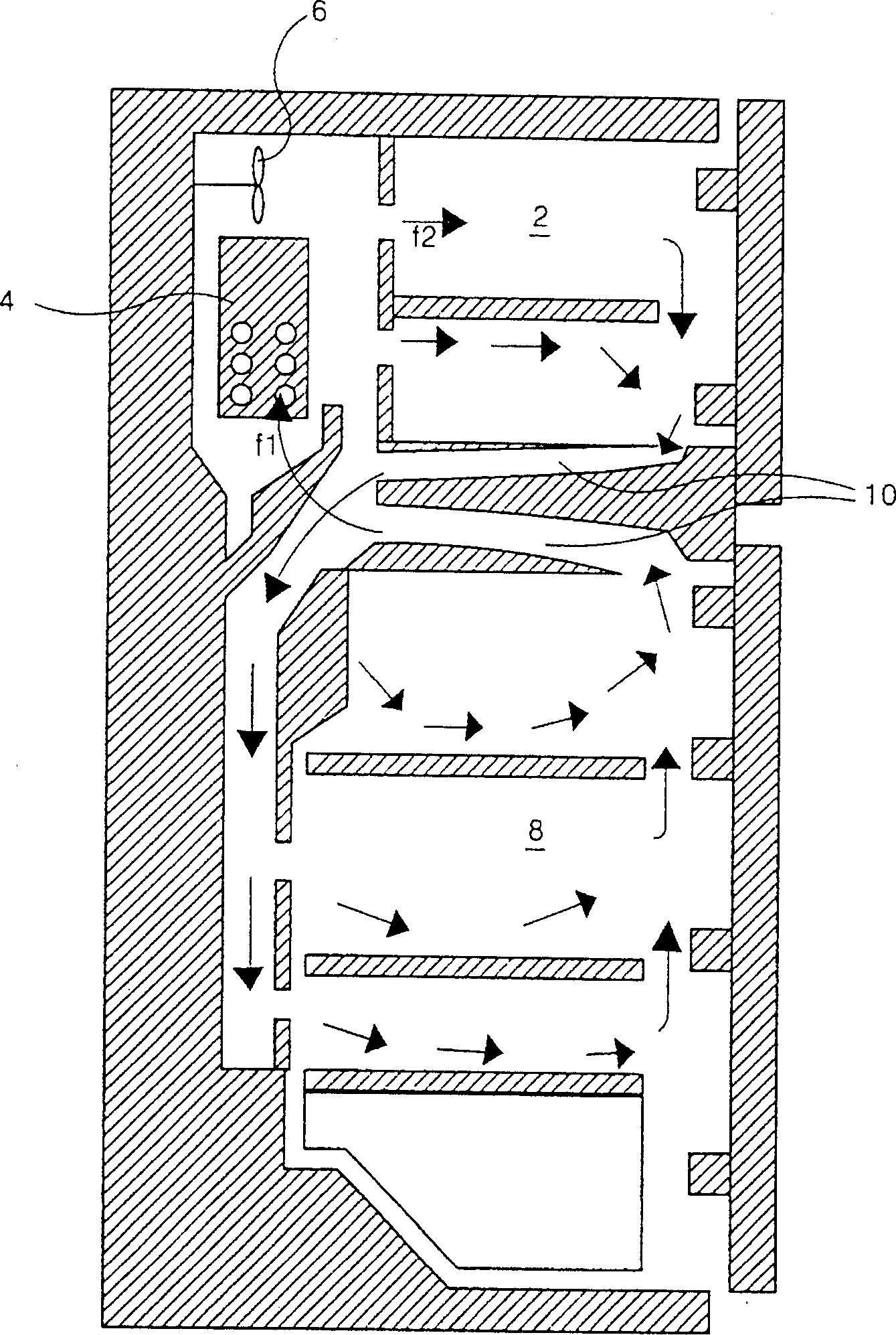

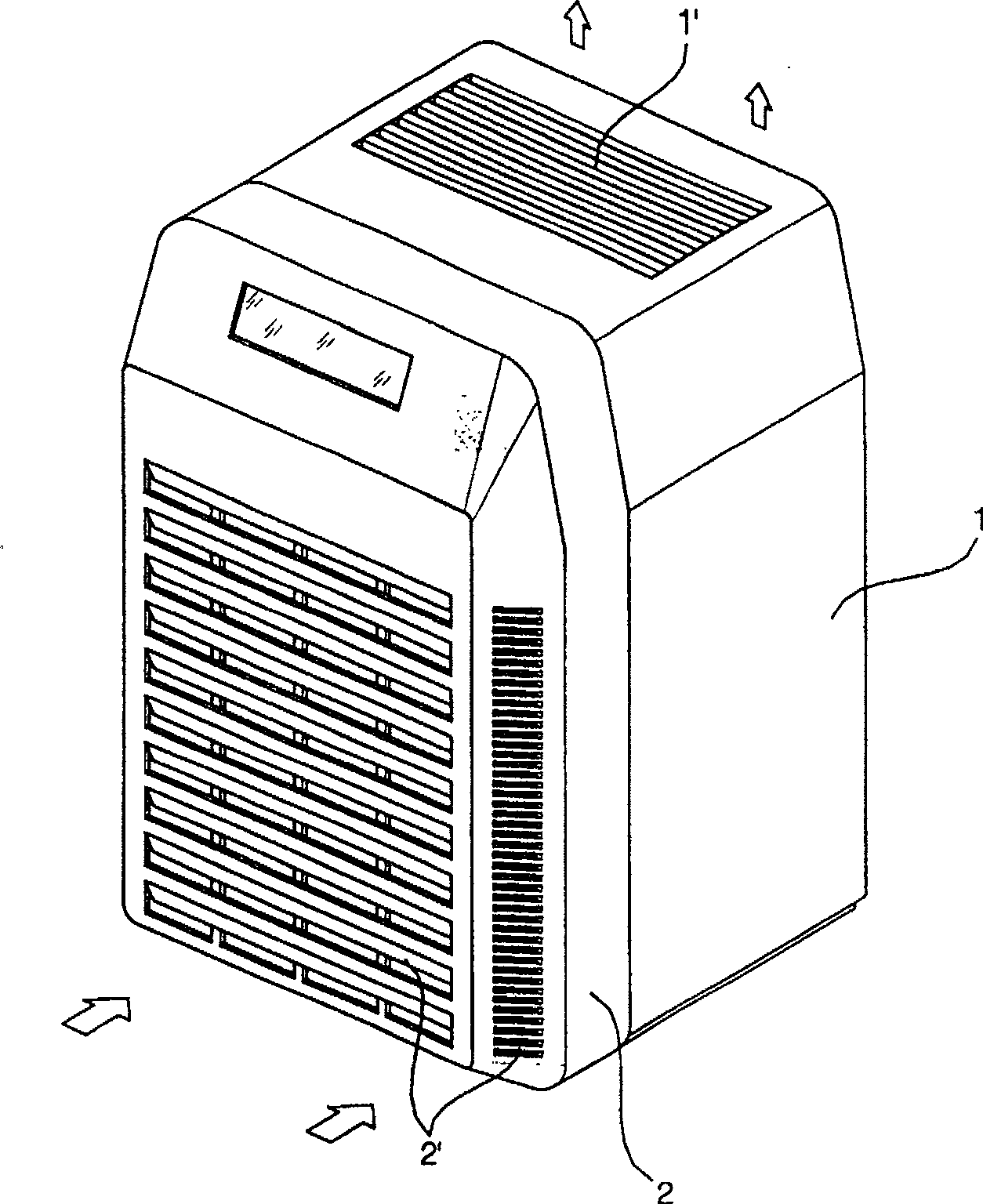

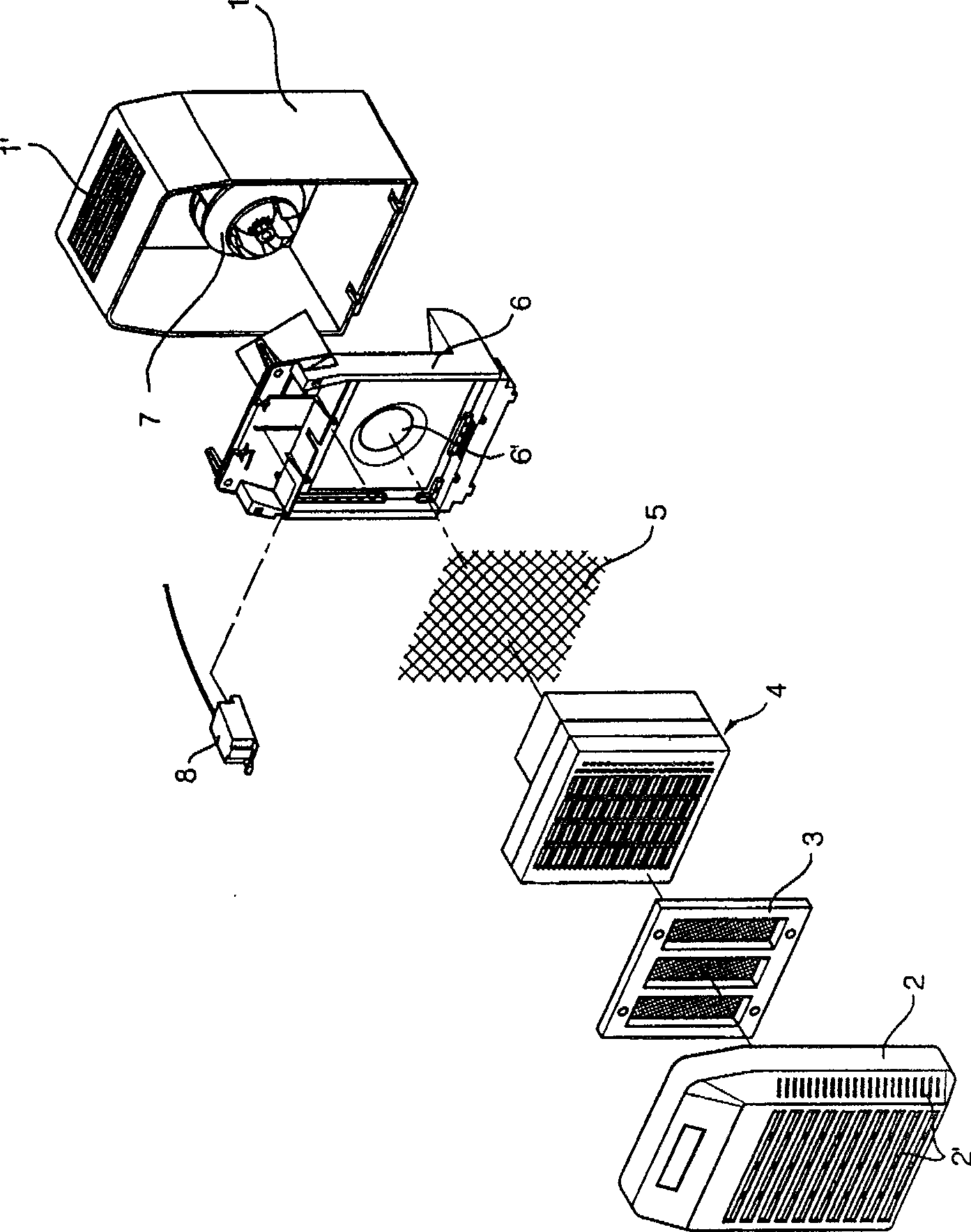

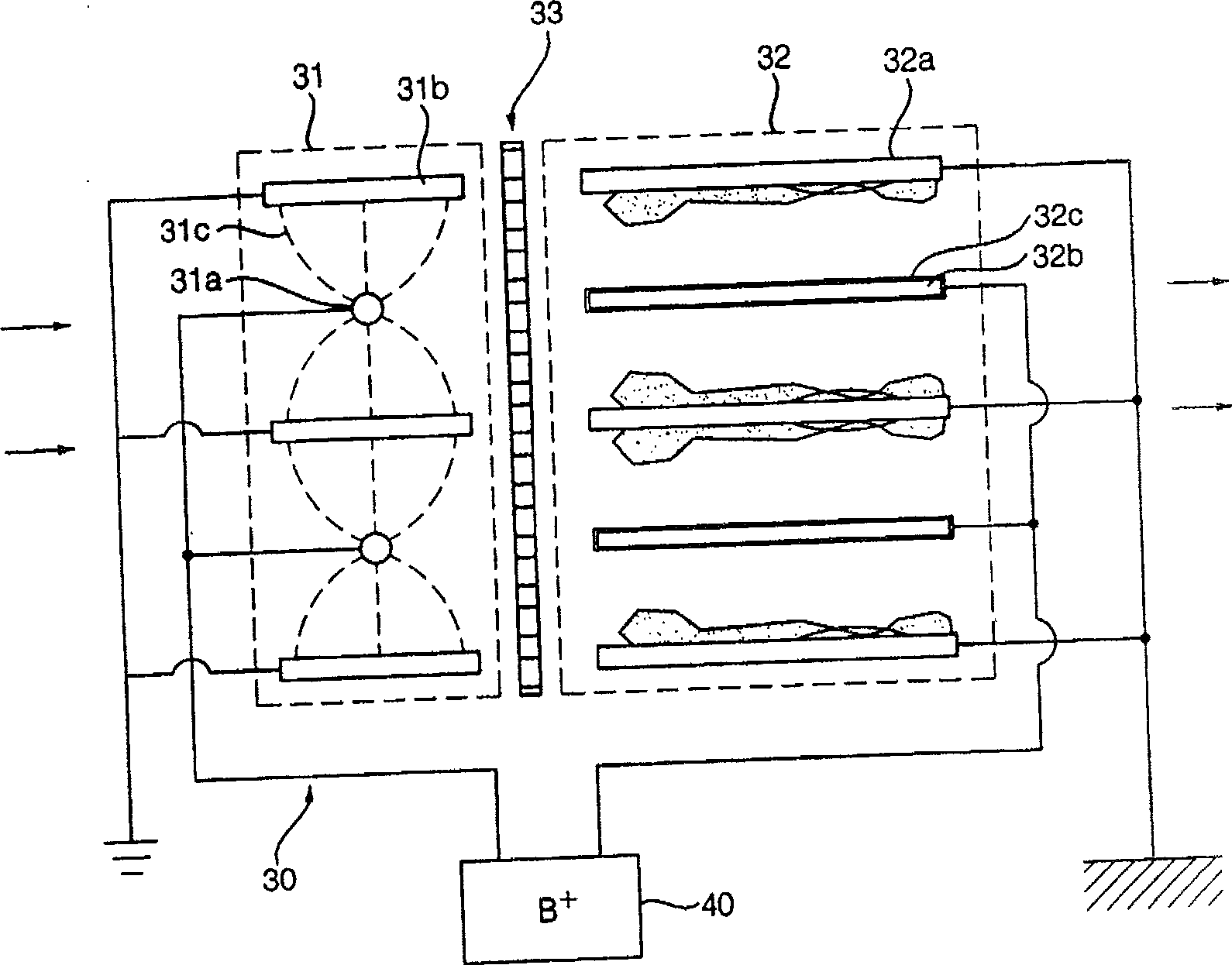

Electronic dust-collecting filter of air purifier

InactiveCN1541774AImprove freshness efficiencySimplify Manufacturing EngineeringCombination devicesLighting and heating apparatusElectricityHigh voltage

The electronic dust collecting filter for air purifier includes ionizing part, collector and metal net. The ionizing part charges fine dust in air passing through by means of high voltage; the collector is set behind the ionizing part and connected to earth line to adsorb charged dust; and the metal net is set between the ionizing part and the collector and connected to earth line. The electronic dust collecting filter for air purifier in the said structure has simple production process and raised air purifying efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

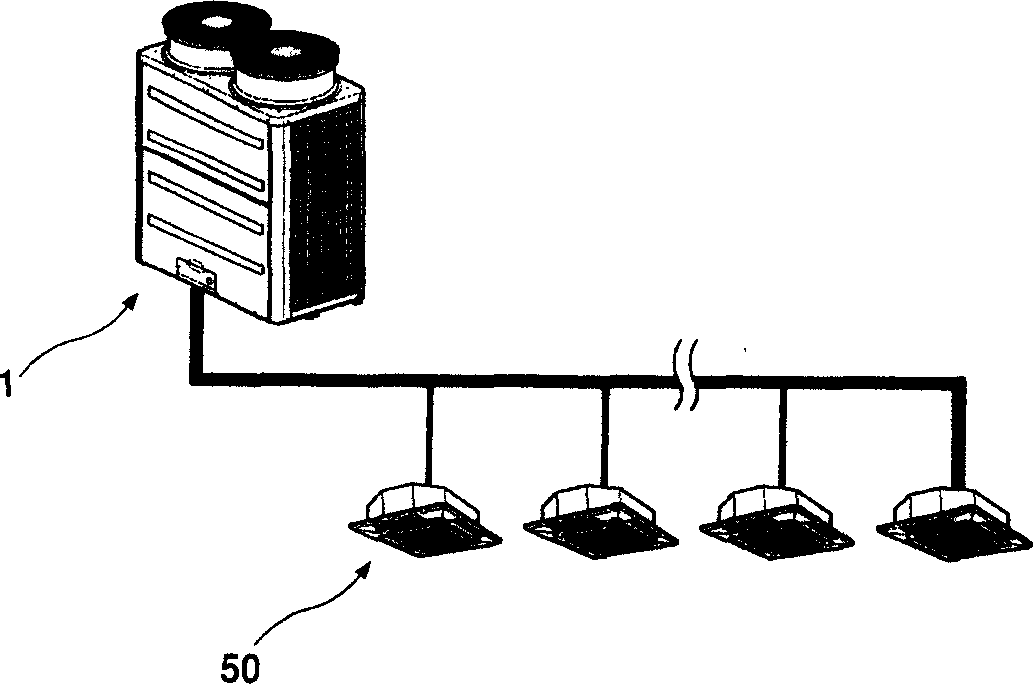

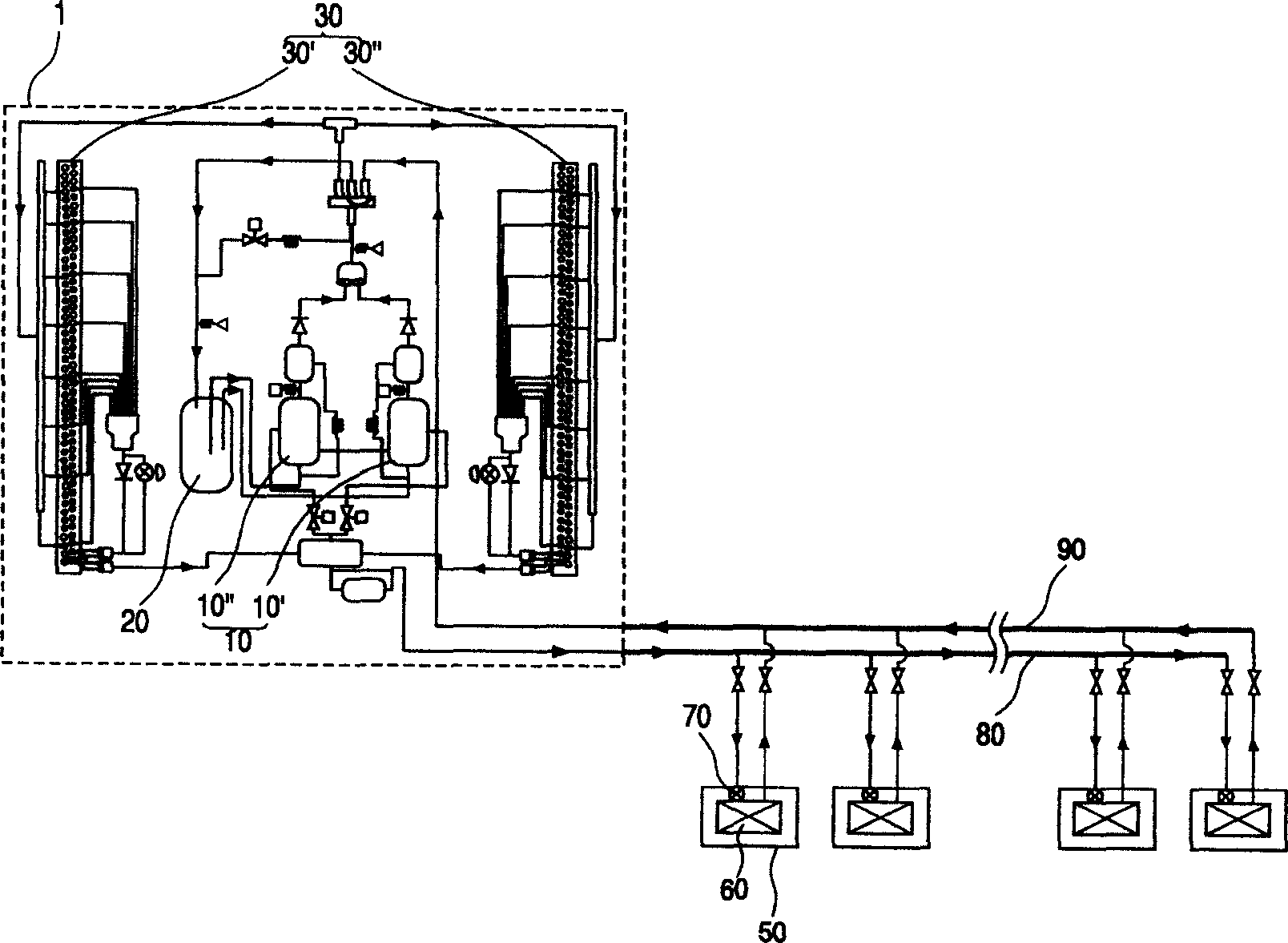

Oil distributing device for air conditioner

InactiveCN1752670AImprove oil separation efficiencySimple structureRefrigeration componentsEngineeringCentrifugal force

The present invention discloses an oil separator of air conditioner. It includes external shell which is used for forming appearance, refrigerant discharge tube which is extended into the interior of external shell, one side of said refrigerant discharge tube is equipped with an oil-separating fan, the oil-separating fan is set in the interior of external shell, and can be rotated to produce vortex flow, the refrigerant in the external shell interior can be passed through the refrigerant discharge tube and discharged, the side face of the external shell is equipped with refrigerant supply tube, said refrigerant supply tube can supply refrigerant to the interior of the external shell, the oil-separating fan can be rotated by utilizing refrigerant discharged from refrigerant supply tube so as to separate the lubricating oil from refrigerant.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

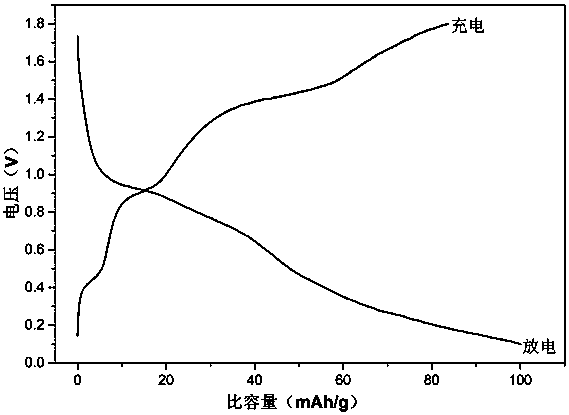

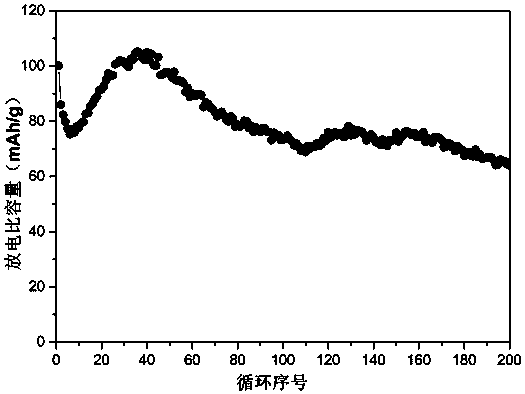

Independent self-supporting positive electrode material and preparation method thereof, and aluminum ion battery and preparation method thereof

InactiveCN109786725AAvoid the influence of internal resistanceEliminate the influence of internal resistanceFinal product manufactureCell electrodesAluminum IonInternal resistance

The invention relates to the field of aluminum ion batteries, and discloses an independent self-supporting positive electrode material and a preparation method thereof, and an aluminum ion battery anda preparation method thereof. The aluminum ion battery comprises a positive electrode, a negative electrode, a diaphragm and an ionic liquid electrolyte, wherein the positive electrode is a non-adhesive material prepared by growing cobalt sulfide on a conductive carbon substrate. The battery is characterized in that the positive electrode of the battery is a composite of the cobalt sulfide and the conductive carbon matrix, and is an independent self-supporting material without an adhesive, thereby avoiding the problem of battery internal resistance caused by the adhesive. The aluminum ion battery has many advantages of being low in price, stable in circulation, wide in voltage window, clean and environmentally friendly, high in safety and the like, and can be applied to various fields such as electronic industries, communication industries, energy reserves and the like.

Owner:JIANGSU UNIV +1

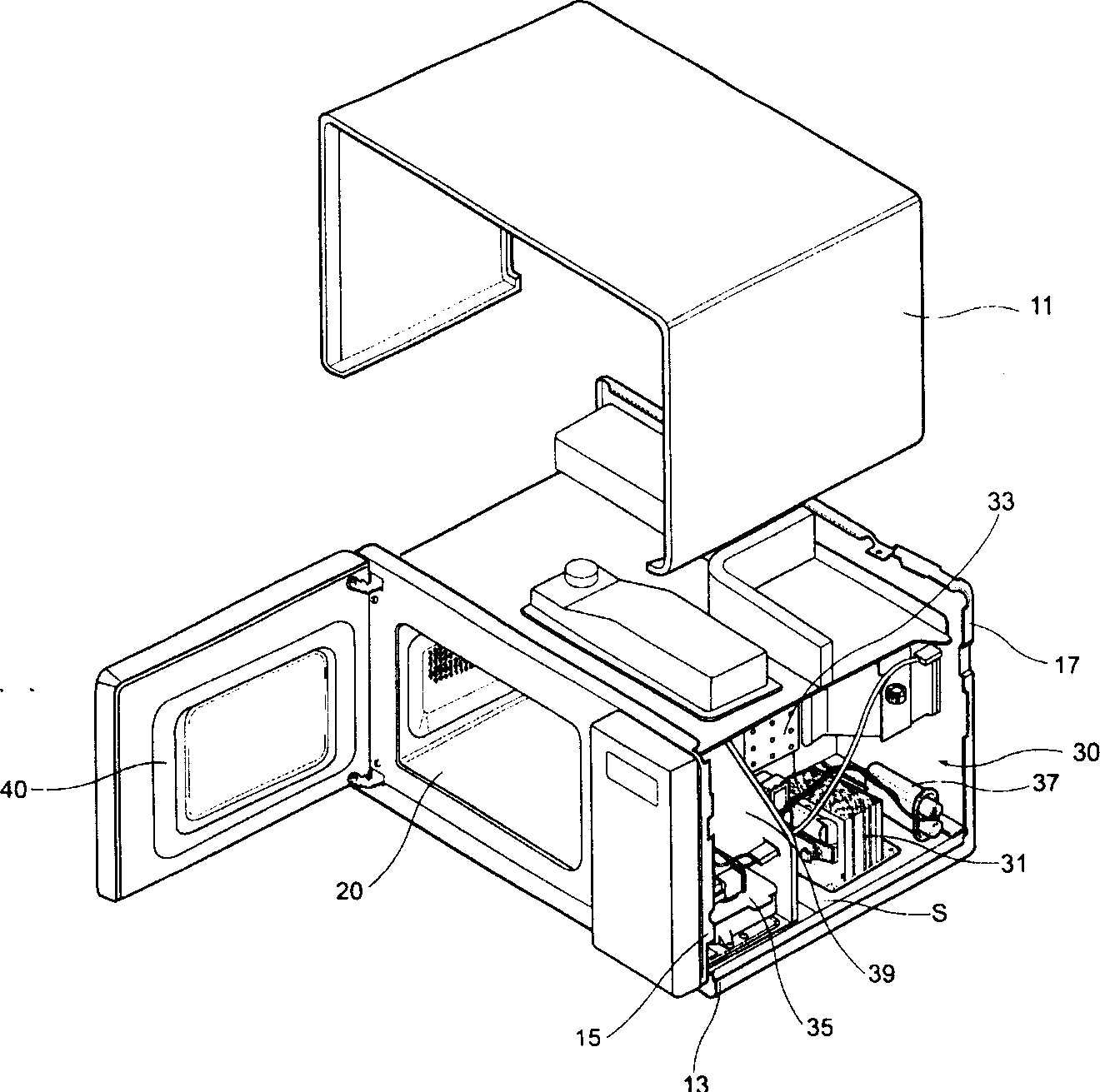

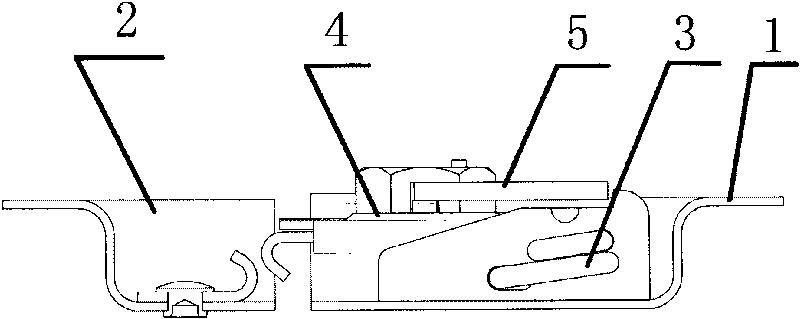

Hinge assembly structure for microwave oven door

InactiveCN1752548AAvoid bendingSimple structureDoors for stoves/rangesDomestic stoves or rangesMicrowave ovenEngineering

The present invention relates to hinge component of microwave oven door. It includes upper side hinge which is positioned in the front of oven cavity and hinge-fixed on the upper end of the oven door, lower side hinge which is hinge-fixed on the lower end of oven door and bend-preventing rib which is positioned on the back of front panel and is connected with upper side hinge and lower side hinge, and the above-mentioned uppe side hinge, lower side hinge and bend-preventing rib are integrally formed, so that they can not be deformed, and can prevent deformation of front panel.

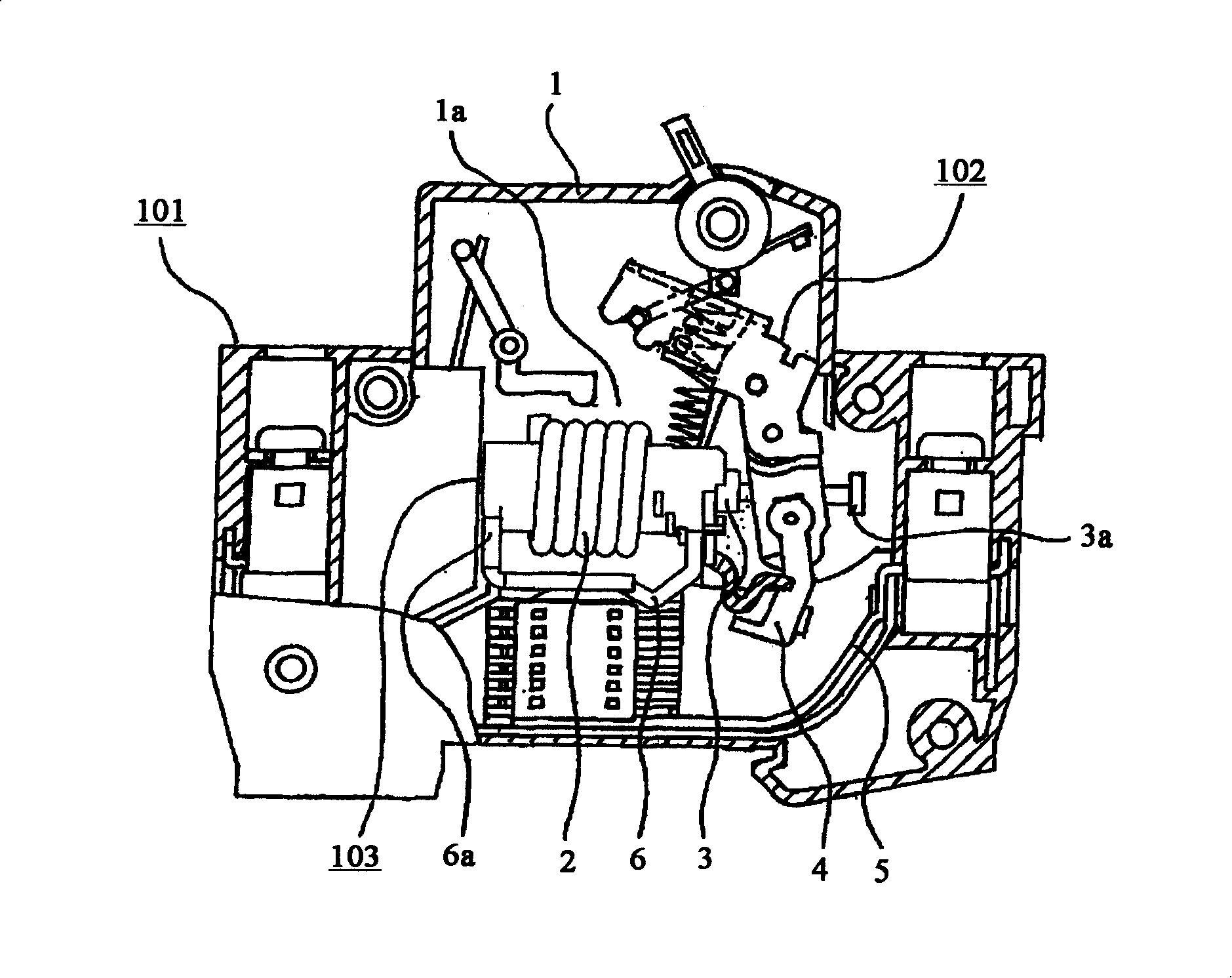

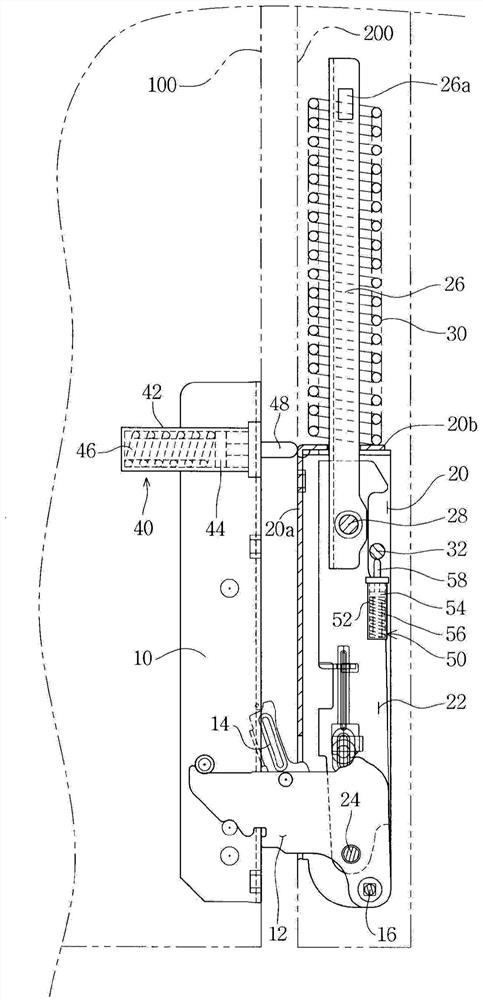

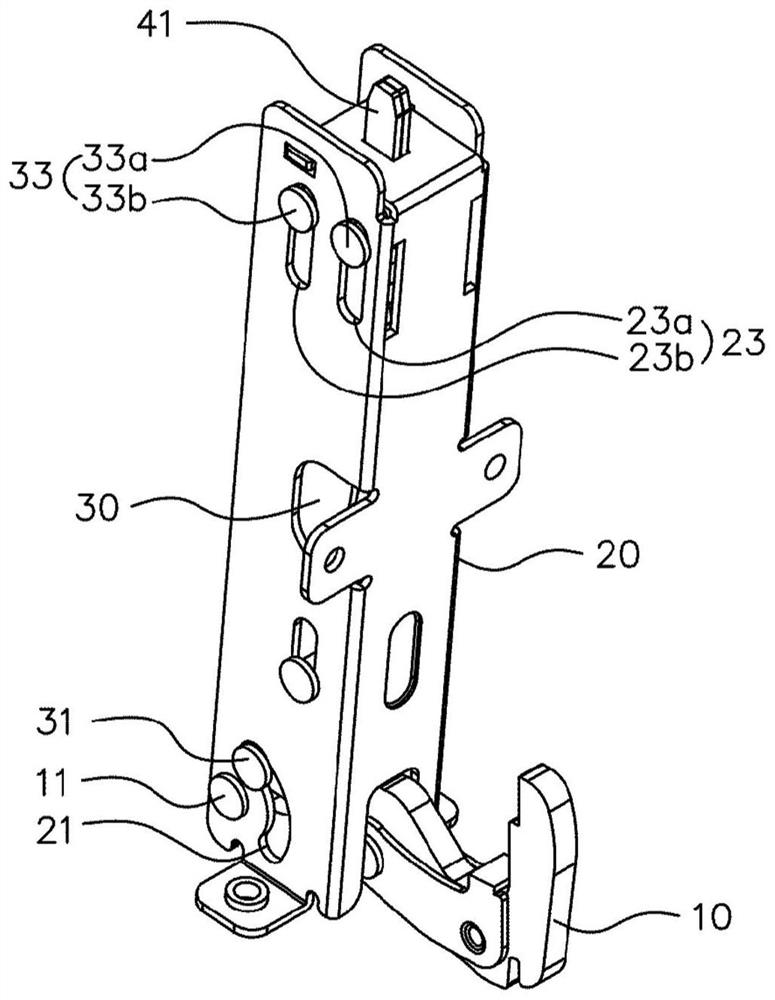

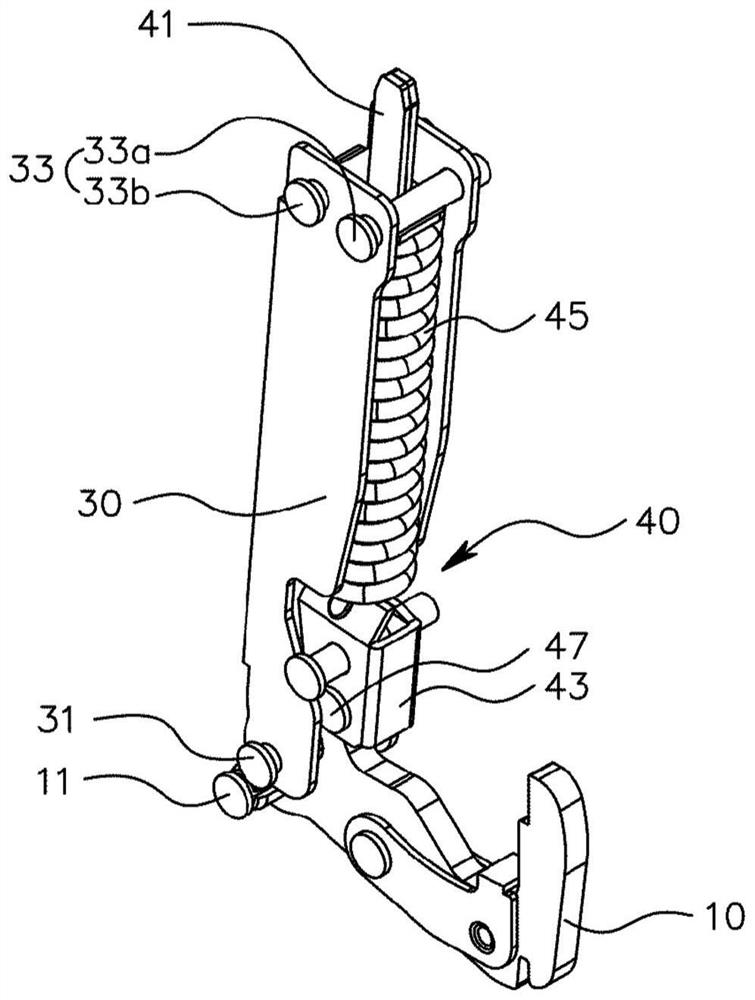

Electrical circuit breaker electromagnetical tripping apparatus

InactiveCN101211723ASimplify Manufacturing EngineeringProtective switch operating/release mechanismsCircuit breakerEngineering

The invention aims at obtaining an electromagnetic tripping device for circuit breaker, which can reduce the kinds of the thrust springs and simultaneously corresponds to various instant tripping current values. The invention is made the coil rack of the guide rail of a spring between a movable core and a fixed core and can rotate with the axis of the movable core as the rotation center, and simultaneously is clamped with another vertical plate of a magnetic yoke through a ladder-shaped process arranged on the external peripheral of the coil rack so as to ensure that the initial length of the spring is changed.

Owner:MITSUBISHI ELECTRIC CORP

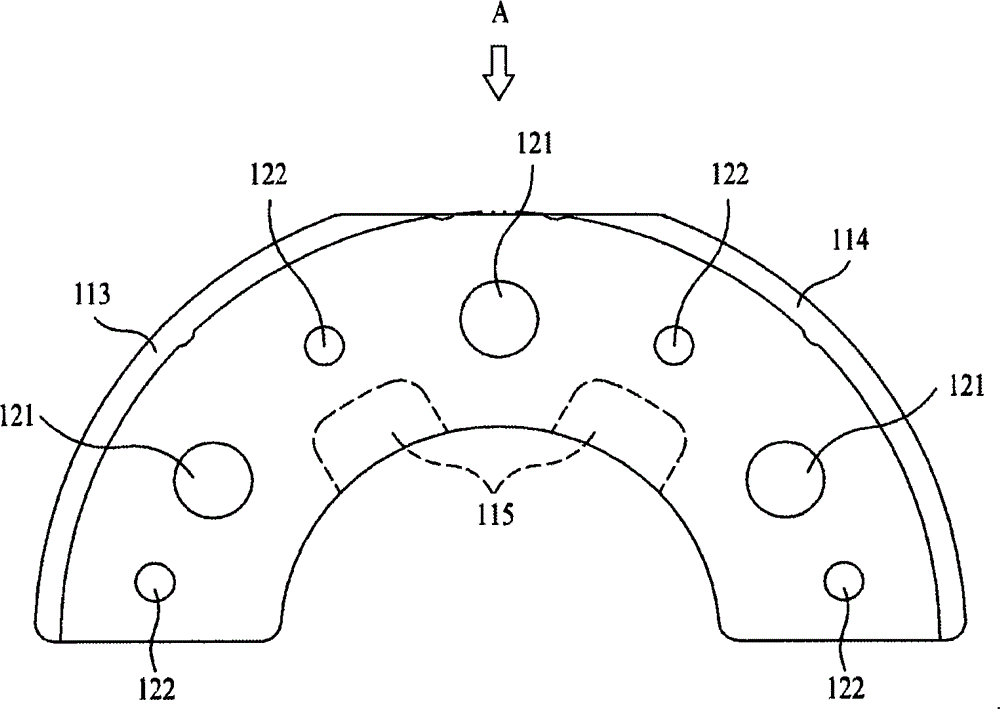

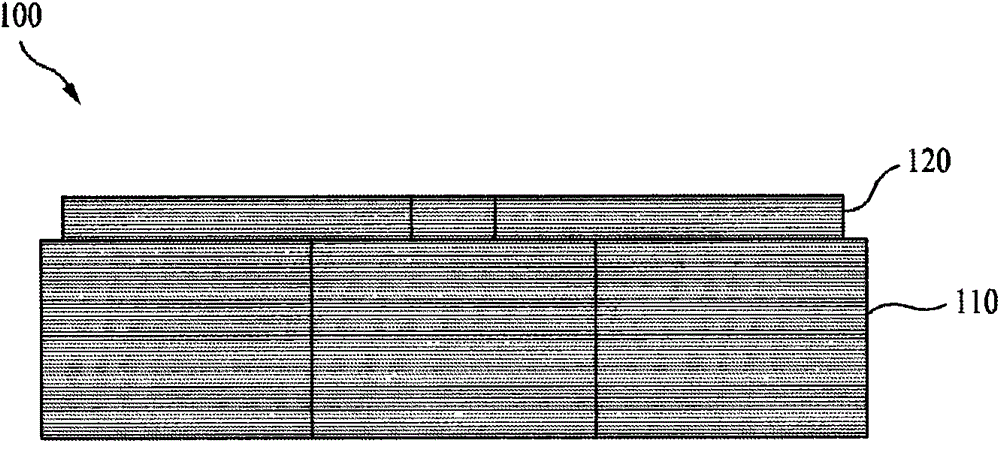

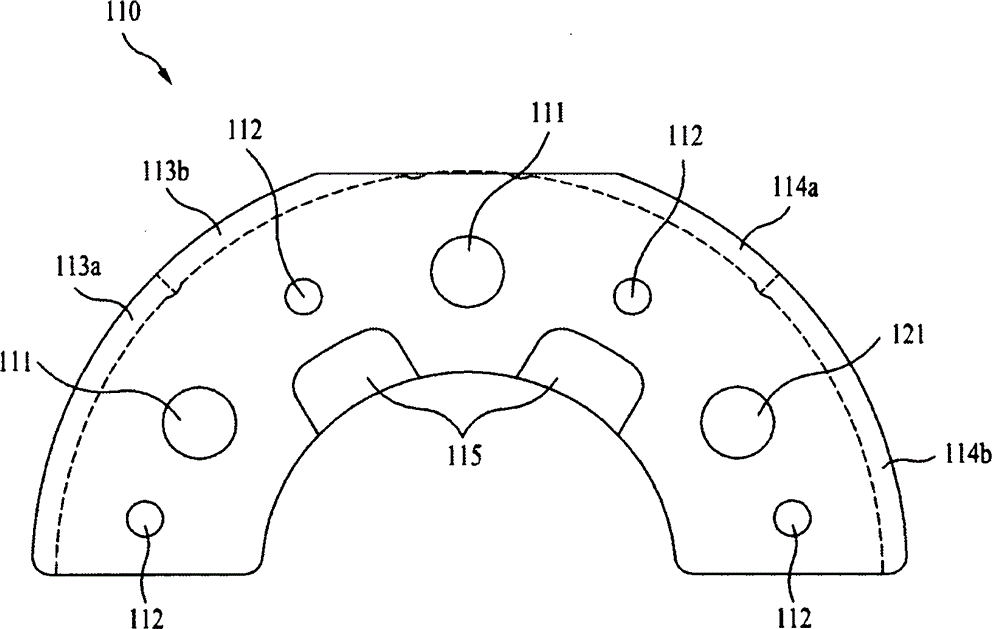

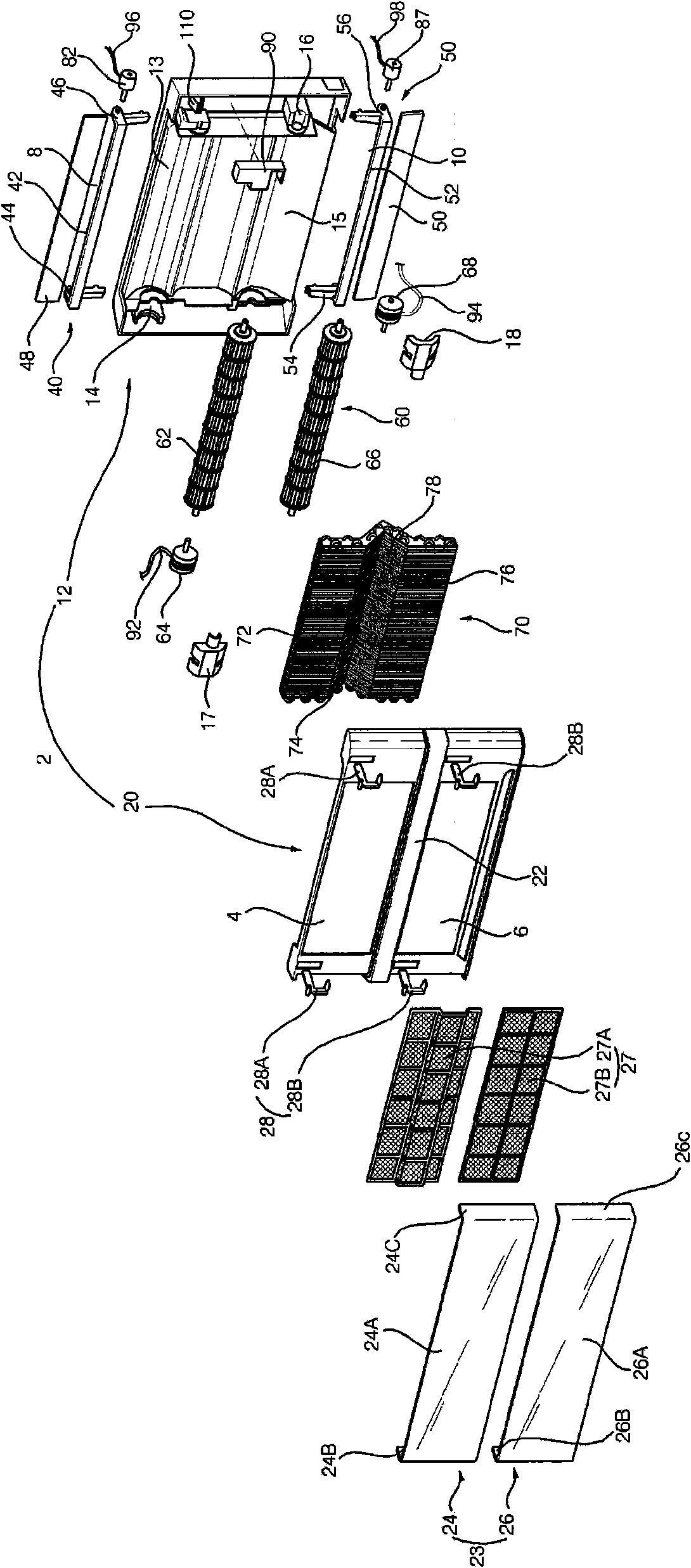

Apparatus and method for manufacturing weight balancing core of motor with at least two materials laminated

ActiveCN104014627AReduce manufacturing costsSimplify Manufacturing EngineeringShaping toolsManufacturing stator/rotor bodiesSheet steelEngineering

A manufacturing device of a weight balancing core of a motor according to the present invention is made of: a base material steel sheet which is sequentially supplied to an upper side of a die of a lower mold by one pitch at a time and is punched with first and second base materials; a first punch which is installed on an upper mold and forms an exclusive borehole of the first base material on the base material steel sheet; a second punch which is installed on one side of the first punch and punches an outer circumference part which is a size differential portion of the first and second base materials; a fourth punch which is installed on one side of the second punch and forms a common borehole of the first and second base materials; a fifth punch which is installed on one side of the fourth punch and forms embossing of the first and second base materials; a blanking punch which is installed on one side of the fifth punch and shears the first and second base materials; and a schedule ring which is installed on a lower side of the die of the lower mold corresponding to the blanking punch and has an internal diameter in which the first base material is inserted.

Owner:HANGNAM CO LTD

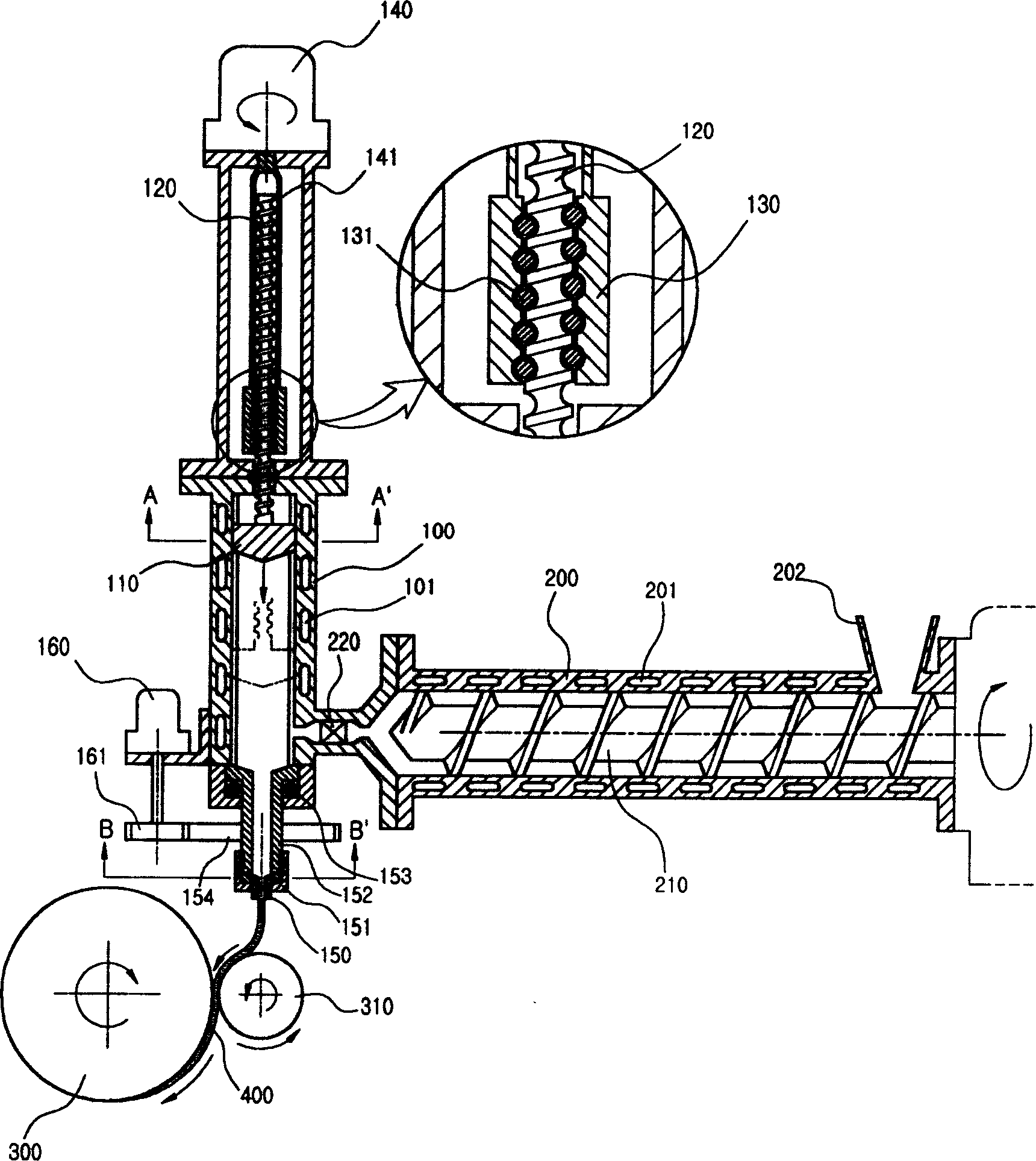

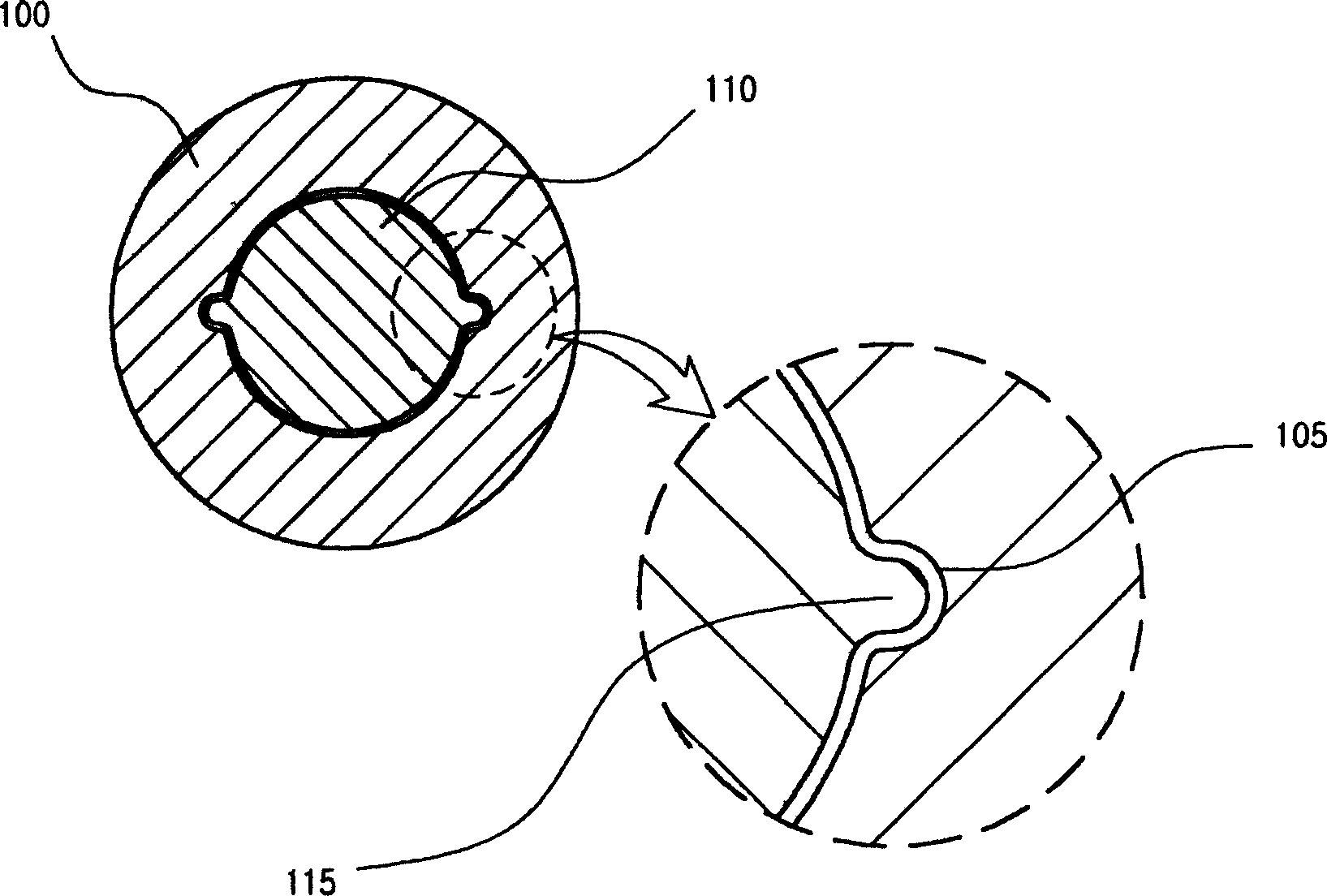

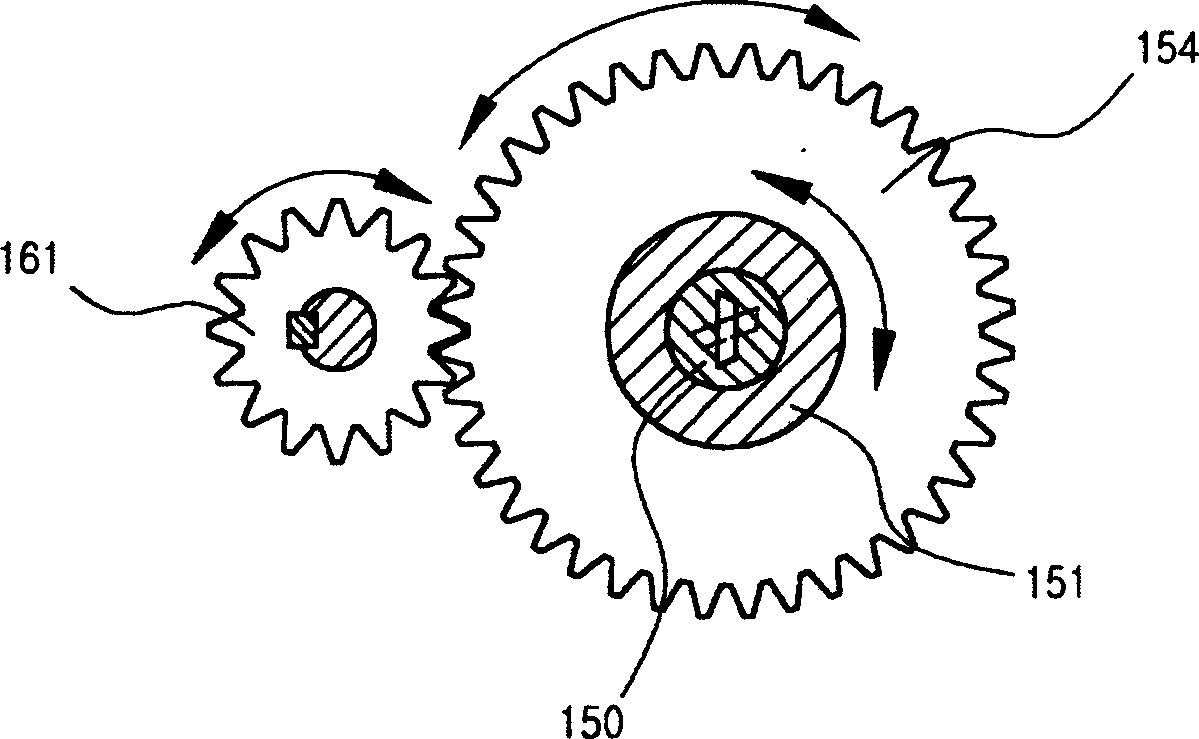

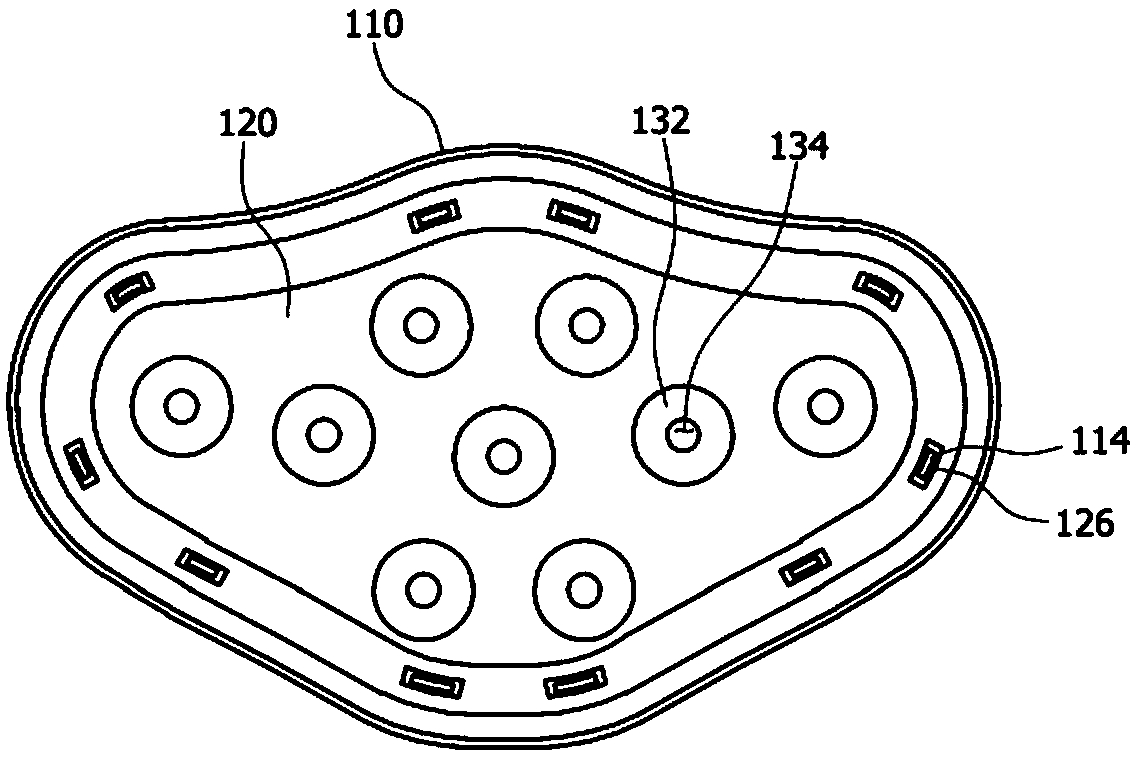

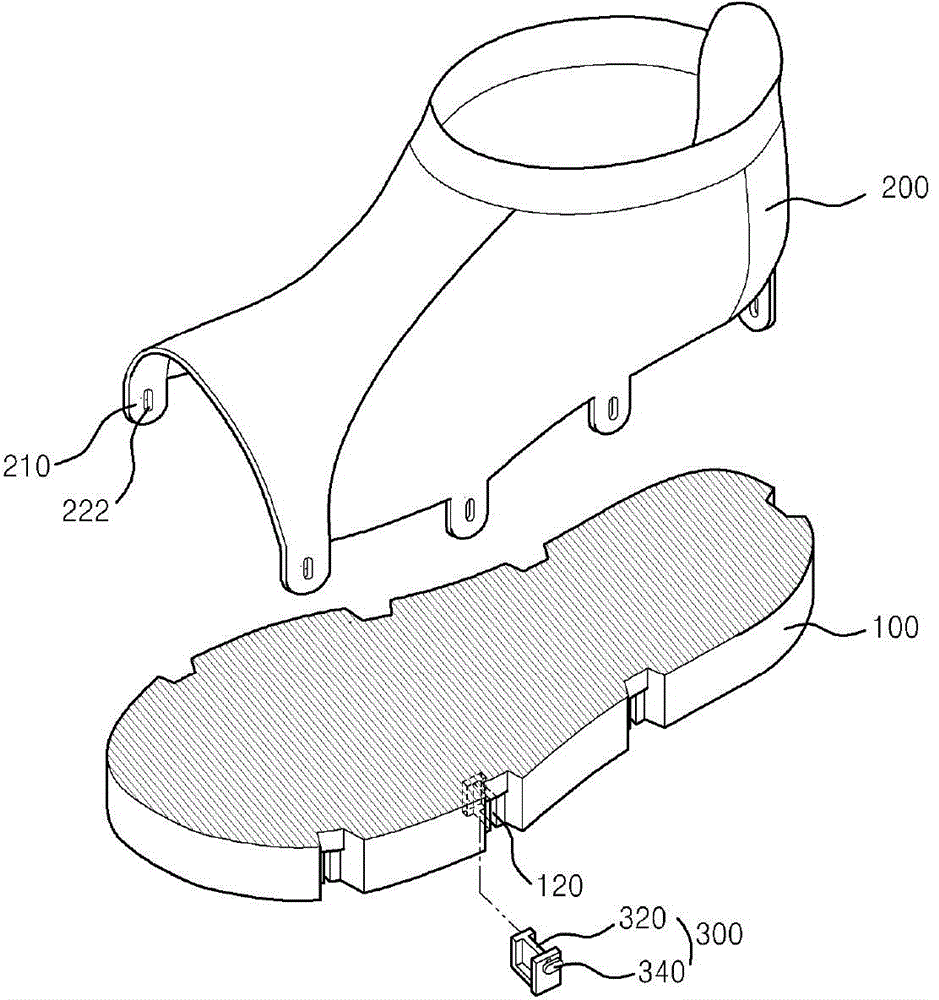

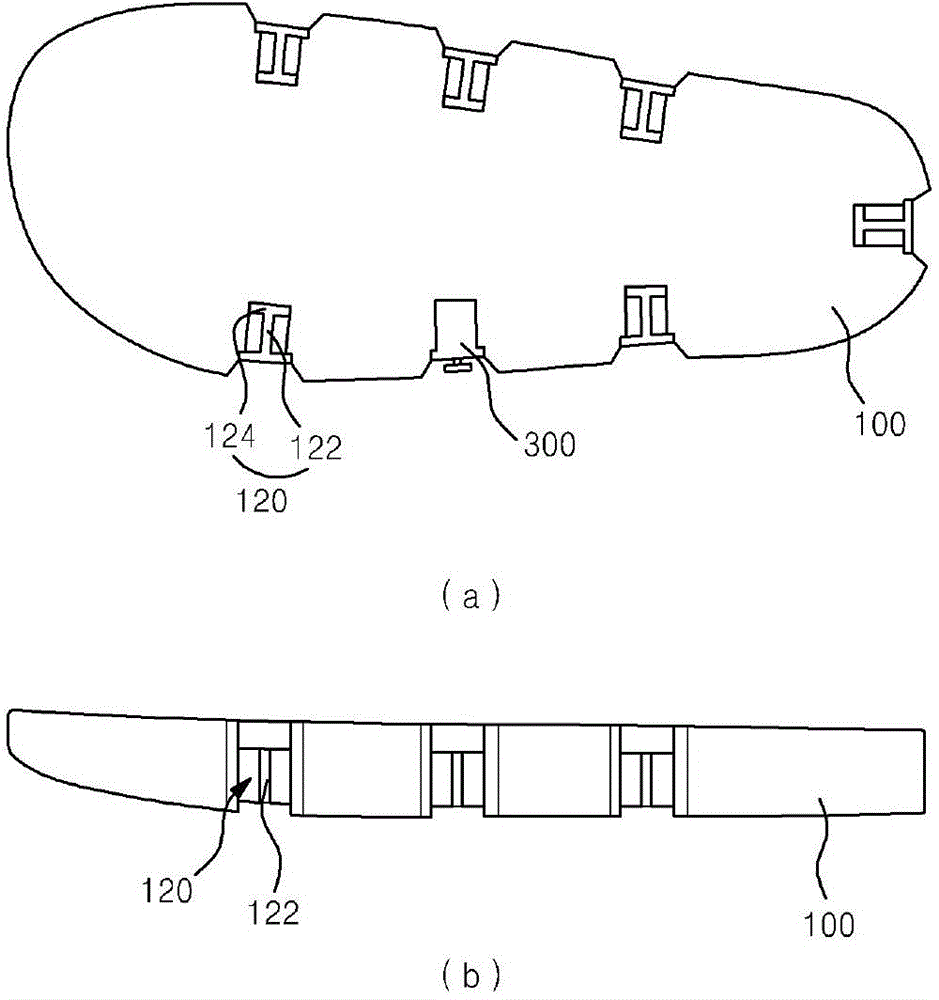

Tire making machine

InactiveCN1524682ASimplify Manufacturing EngineeringBuilding roofsTents/canopiesEngineeringCheck valve

A tire forming machine is provided to enable extrusion of raw materials and a winding operation to be performed simultaneously and to achieve a high-quality tire by a precise forming work without using toxic materials such as a releasing agent or an adhesive agent, which simplifies a tire manufacturing process and reduces an overall operation time, thereby increasing the manufacture and preventing environmental pollution while reducing the manufacturing cost. The tire forming machine comprises: an injection cylinder(200) having a built-in injection screw(210) and a heater(201); an extrusion cylinder(100) connected to the injection cylinder(200) via a check valve(220), and having a nozzle(150) rotated by a rotation motor(160), and a nozzle chuck(152) connected to the extrusion cylinder(100) via a bearing(153) and connected to the rotation motor(160) via a nozzle gear(154) and a rotation gear(161); a piston(110) reciprocating vertically inside the extrusion cylinder(100) and installed so as not to rotate; a transfer screw(120) having one end fixedly connected to the piston(110); a transfer nut(130) fitted into the transfer screw(120) and rotated by a driving motor(140); a ball(131) installed between the transfer screw(120) and the transfer nut(130); and a winding roller(300) on which a rubber ribbon(400) is wound after being extruded and formed.

Owner:株式会社宇星机工

Electric heating mirror and its producing method

InactiveCN1859816AEliminate issues that reduce durabilityNo damageTransparent/reflecting heating arrangementsConductive pattern formationElectricityEvaporation

The present invention relates to electrical heating mirror and manufacturing method. It contains forming insulating layer on glass metal surface or using electrical conductivity printing ink printing according to specified electricity line and drying, parallel connection current input terminal, through printing or covering or evaporation coating to form safety film, series connection current input terminal, then forming electrical heating mirror.

Owner:文登太成电子有限公司

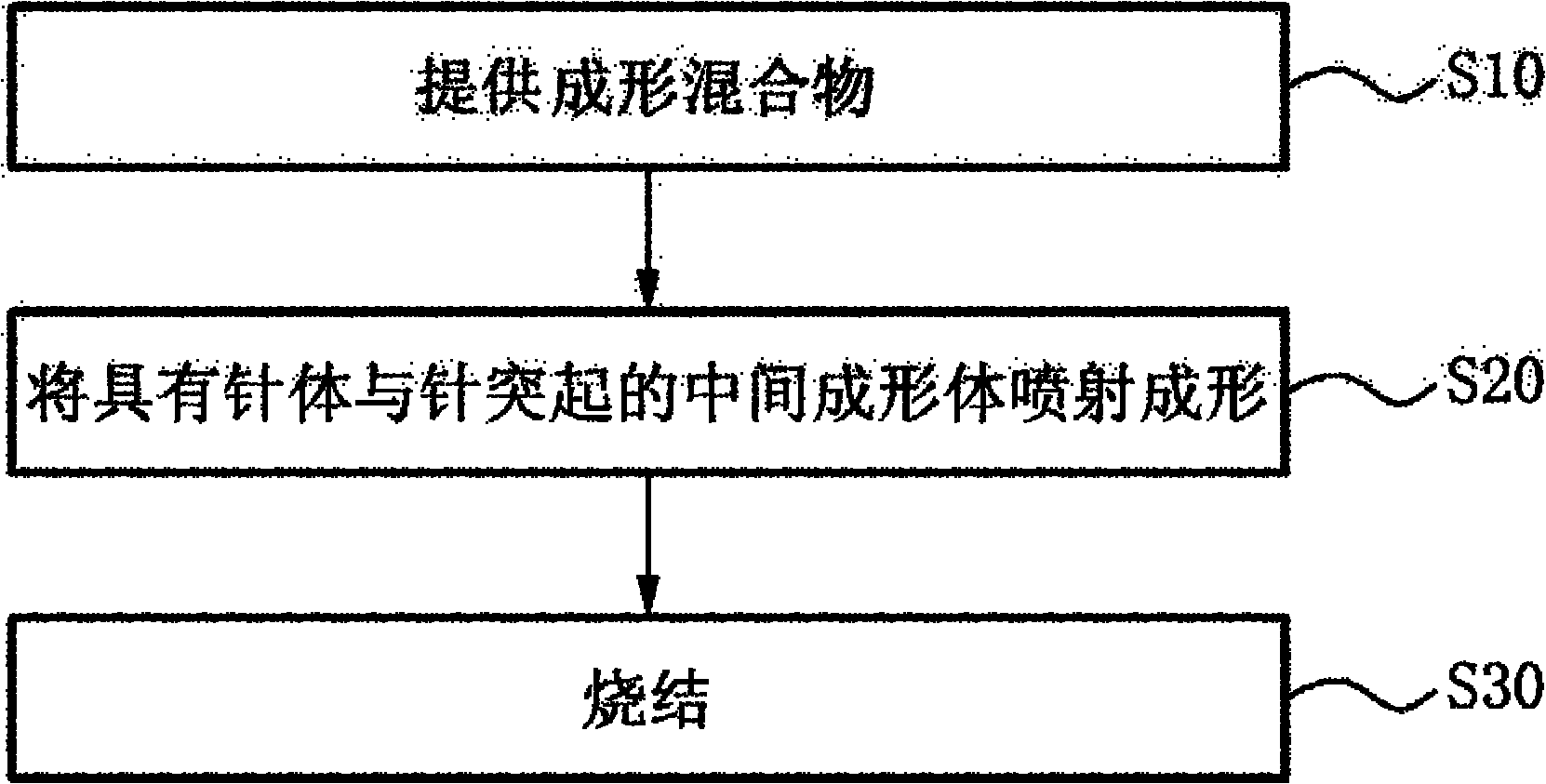

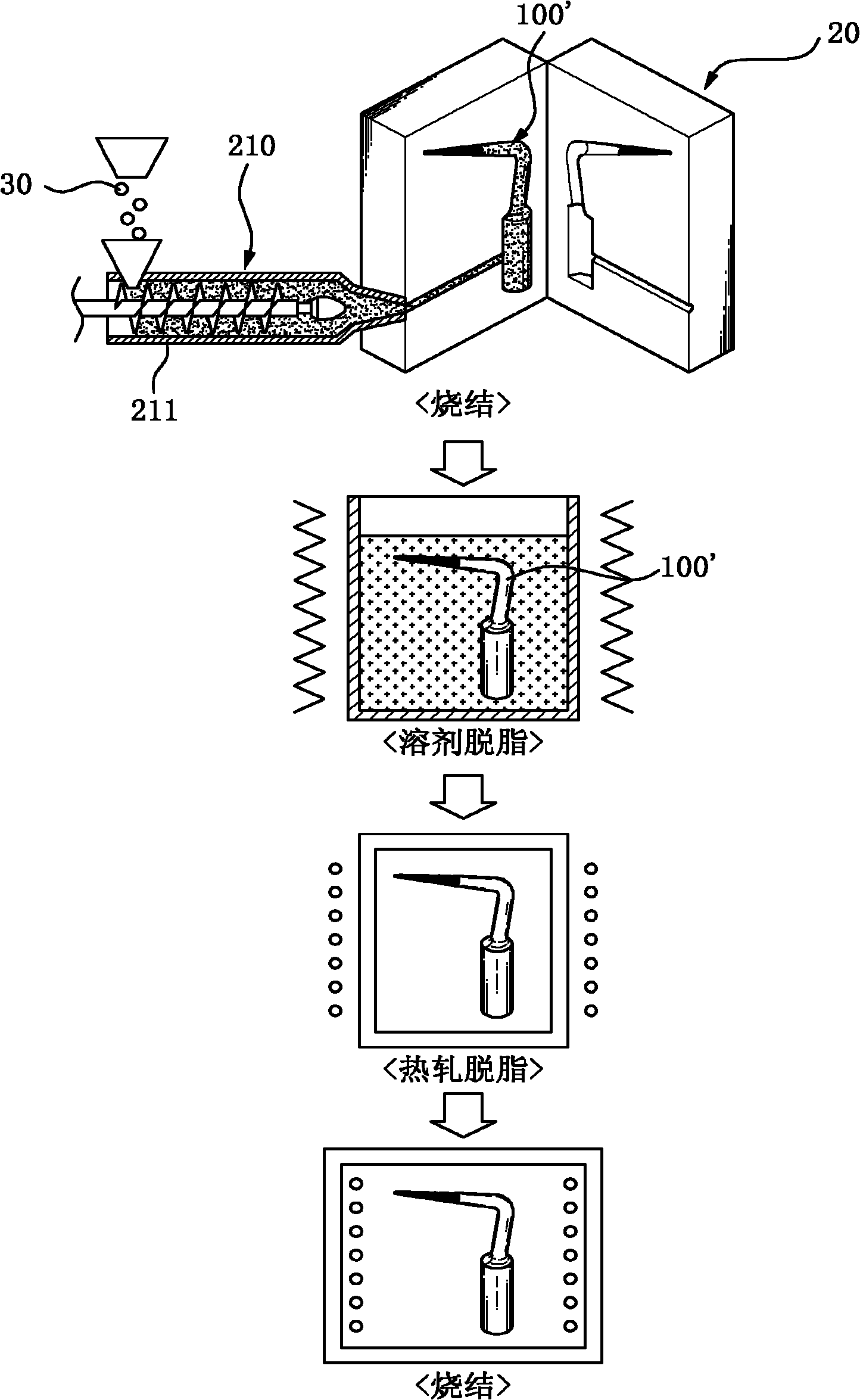

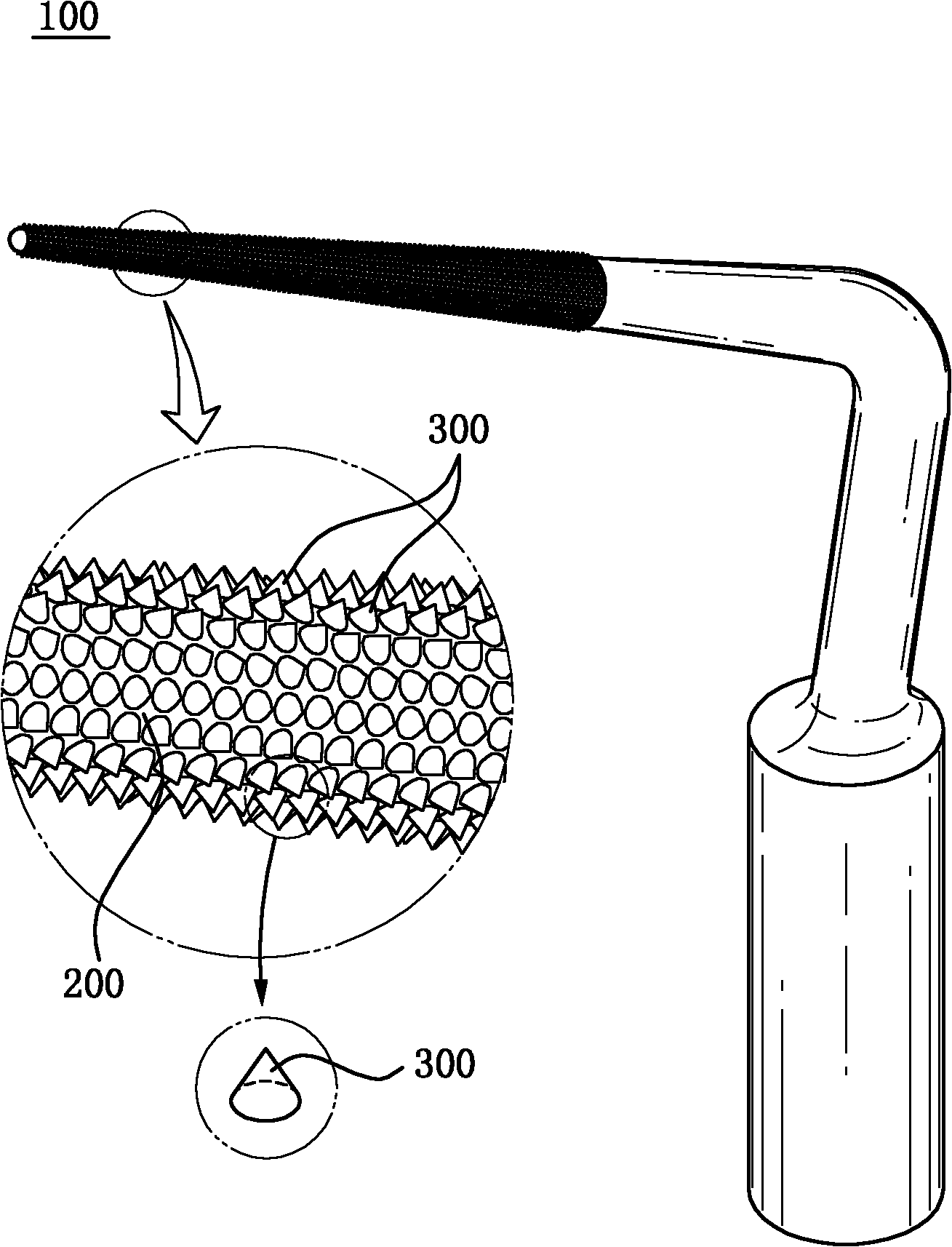

Ultrasonic wave syringe needle for dental department and medical treatment and manufacture method thereof

ActiveCN102018582AReduce manufacturing costSimplify Manufacturing EngineeringSurgeryDentistrySyringe needleBiomedical engineering

The invention provides an ultrasonic wave syringe needle for a dental department and medical treatment and a manufacture method thereof, wherein the durability and reliability of the ultrasonic wave syringe needle can be improved, and the ultrasonic wave syringe needle is easy to manufacture. The manufacture method of the ultrasonic wave syringe needle for the dental department and the medical treatment comprises the following steps: ejecting shaped mixture comprising powder to manufacture a middle shaping body, wherein the middle shaping body comprises a syringe body and a plurality of syringe bulges, and the syringe bulges are integrated on the surface of the syringe body and form a bulge; and sintering the middle shaping body.

Owner:赛搭泰克公司 +1

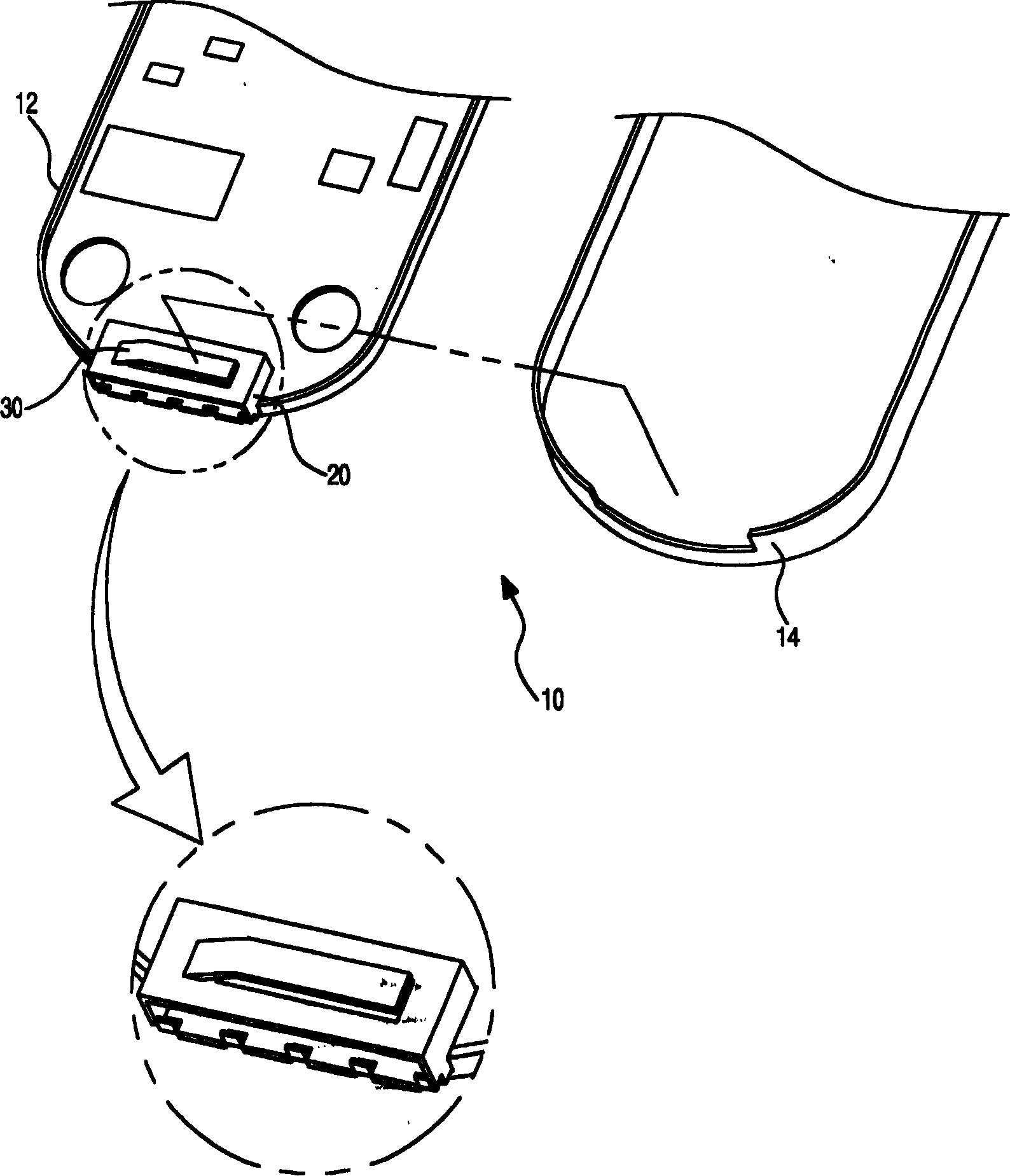

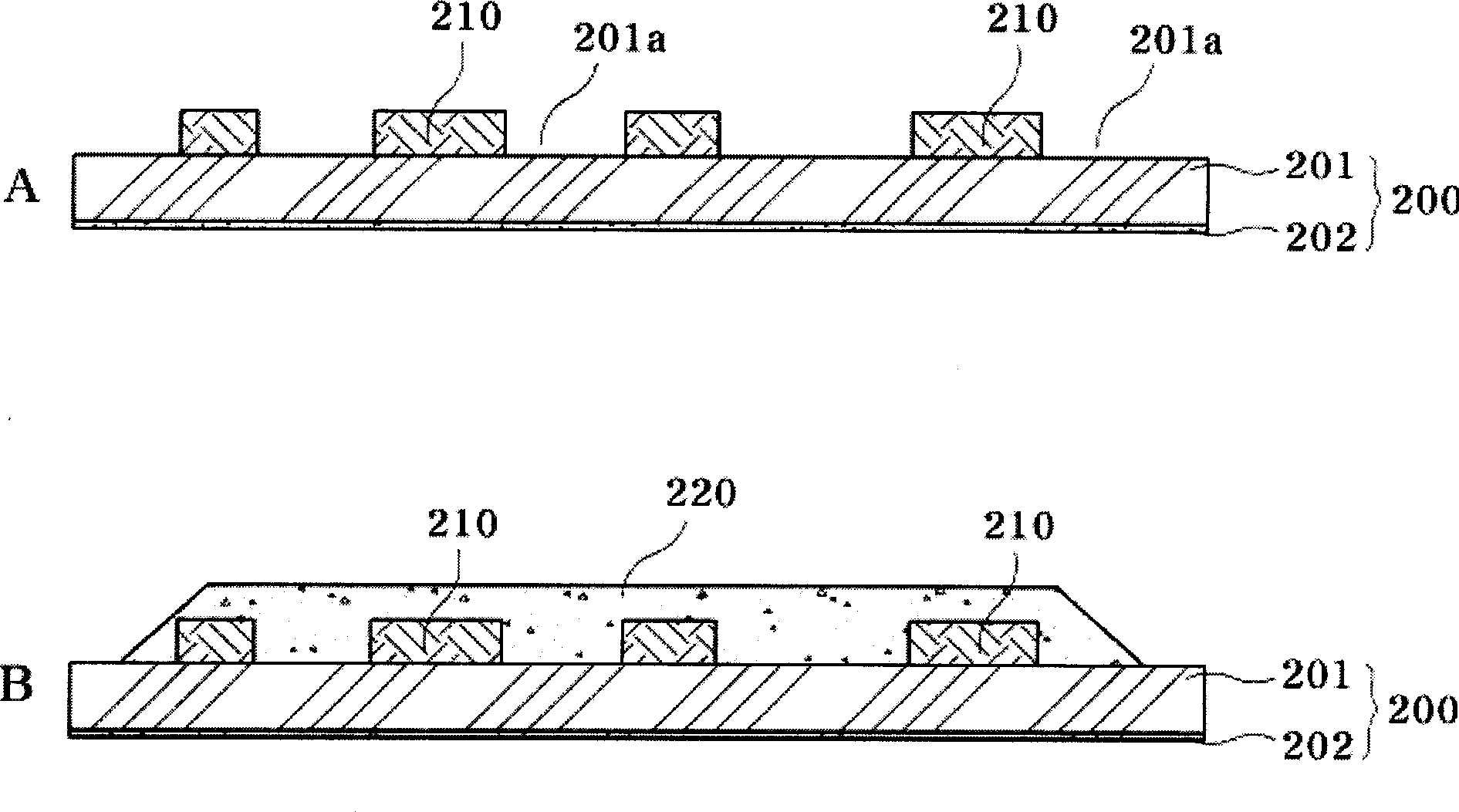

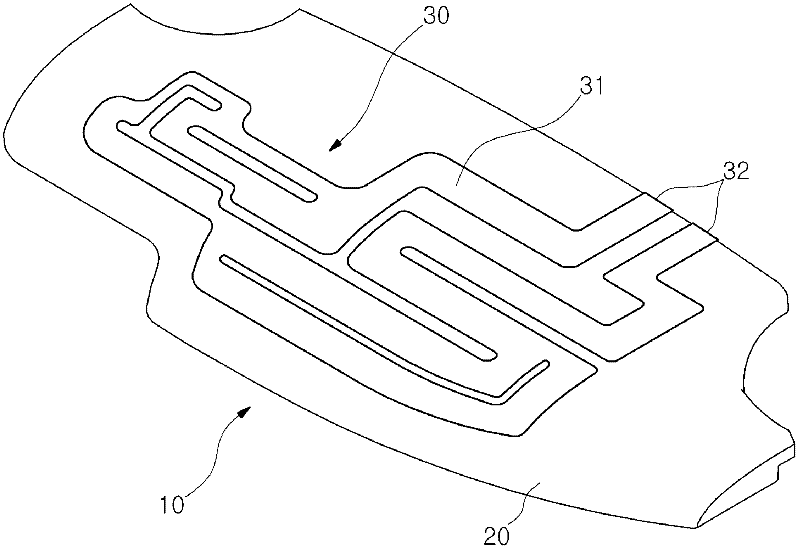

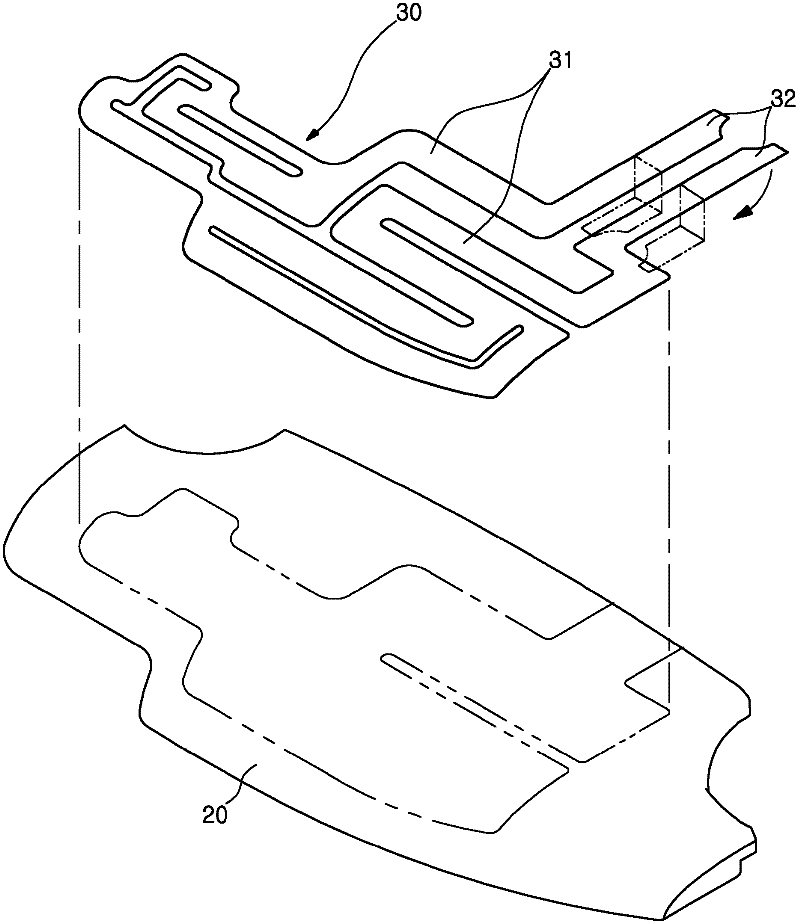

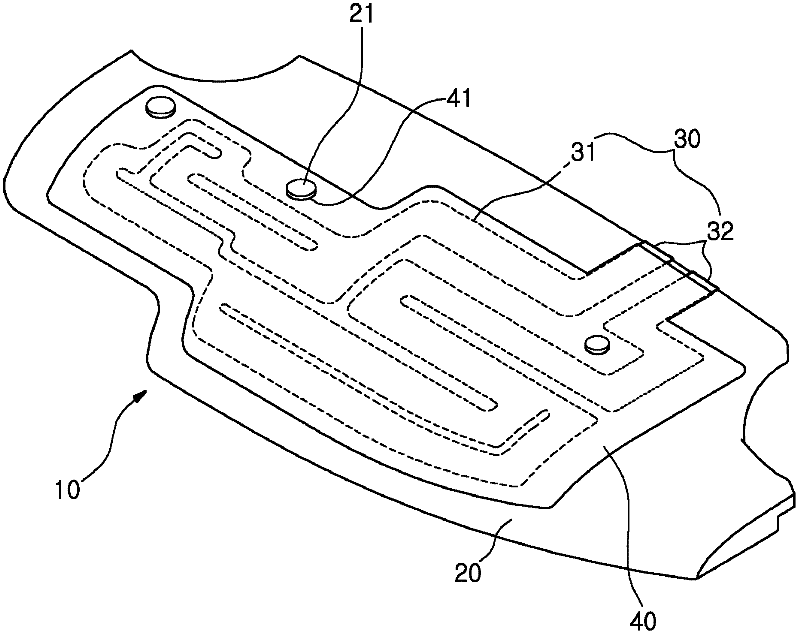

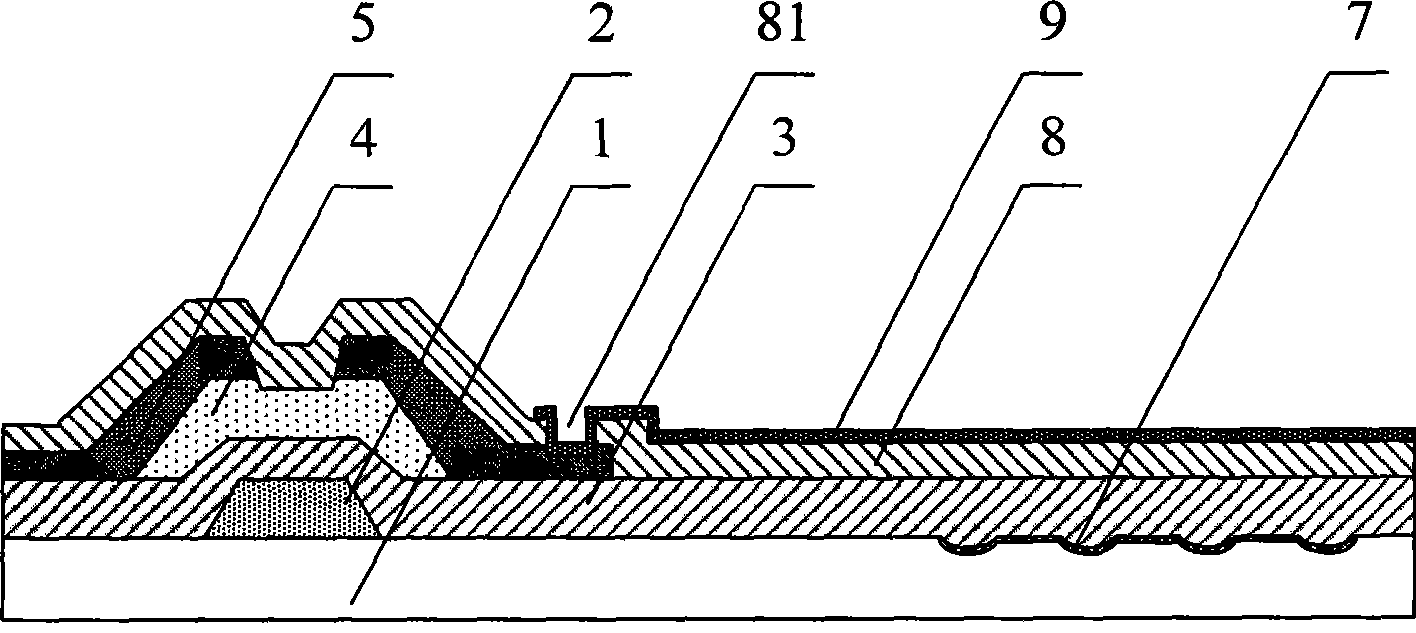

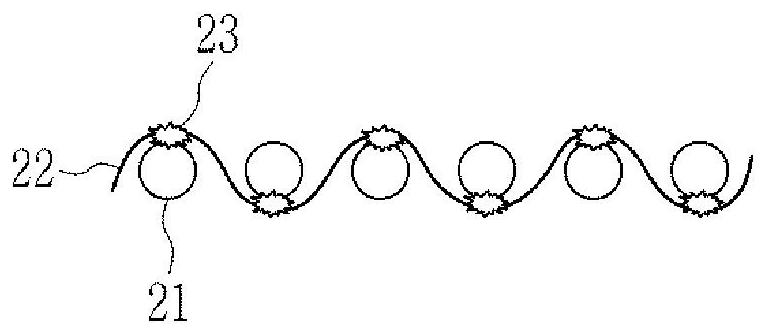

Mobile communication terminal intenna using a electrically conductive film and the manufacturing method thereof

InactiveCN102544683ASimplify Manufacturing EngineeringReduce manufacturing costAntenna supports/mountingsRadiating elements structural formsCopper foilElectrically conductive

An antenna for a radio communication terminal using a conductive film and a manufacturing method thereof are provided to drastically improve productivity and to offer convenience of manufacture by a simple manufacturing process and to reduce manufacture costs. An antenna main body(20) is composed of plastic. A thin film conductor(30) comprises antenna pattern(31) and a contacting portion(32). The antenna pattern is located in the front of the antenna main body. The thin film conductor is formed after punching a conductive film including copper foil consisting of conductive materials in order to form the antenna pattern and the contacting portion as one body. The thin film conductor is adhered in the antenna main body by adhesive.

Owner:卢东镐 +2

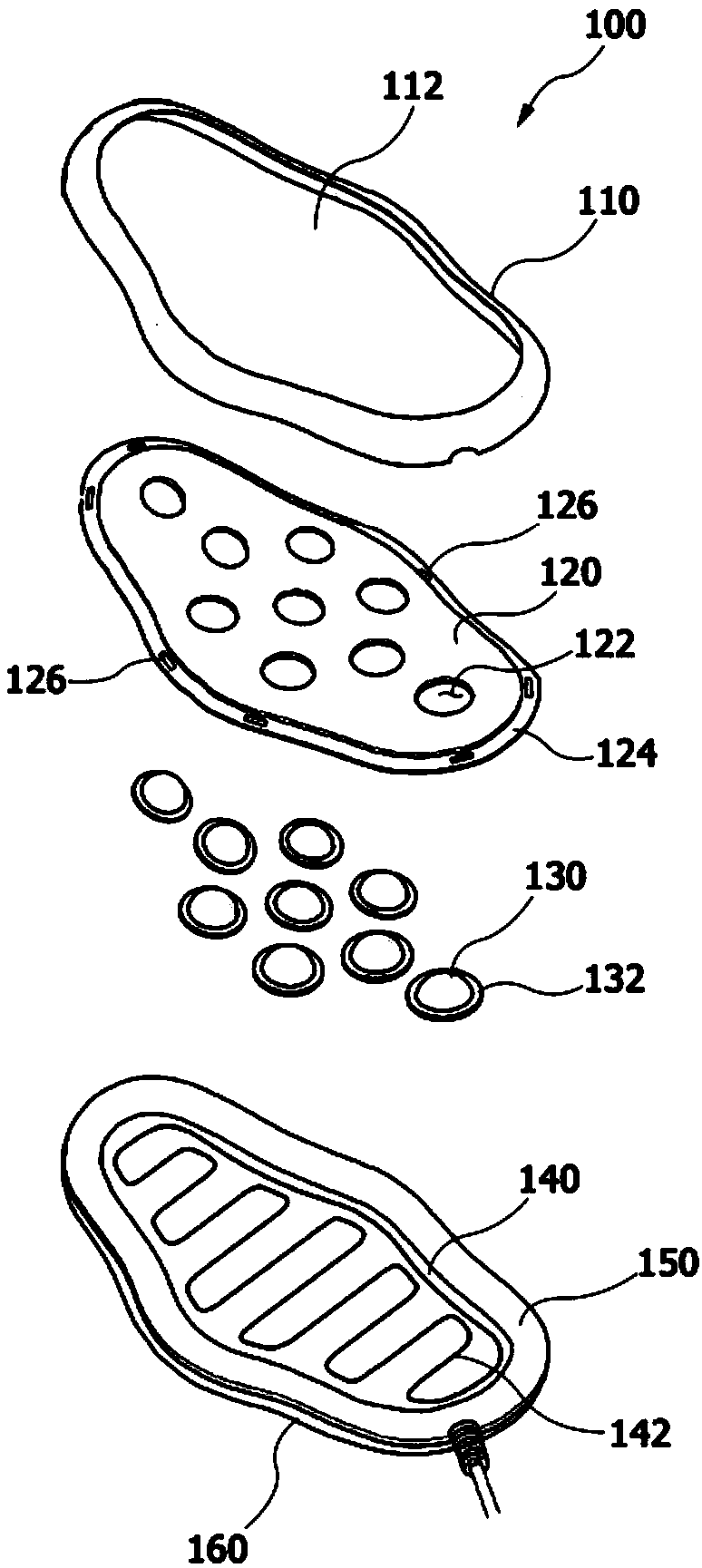

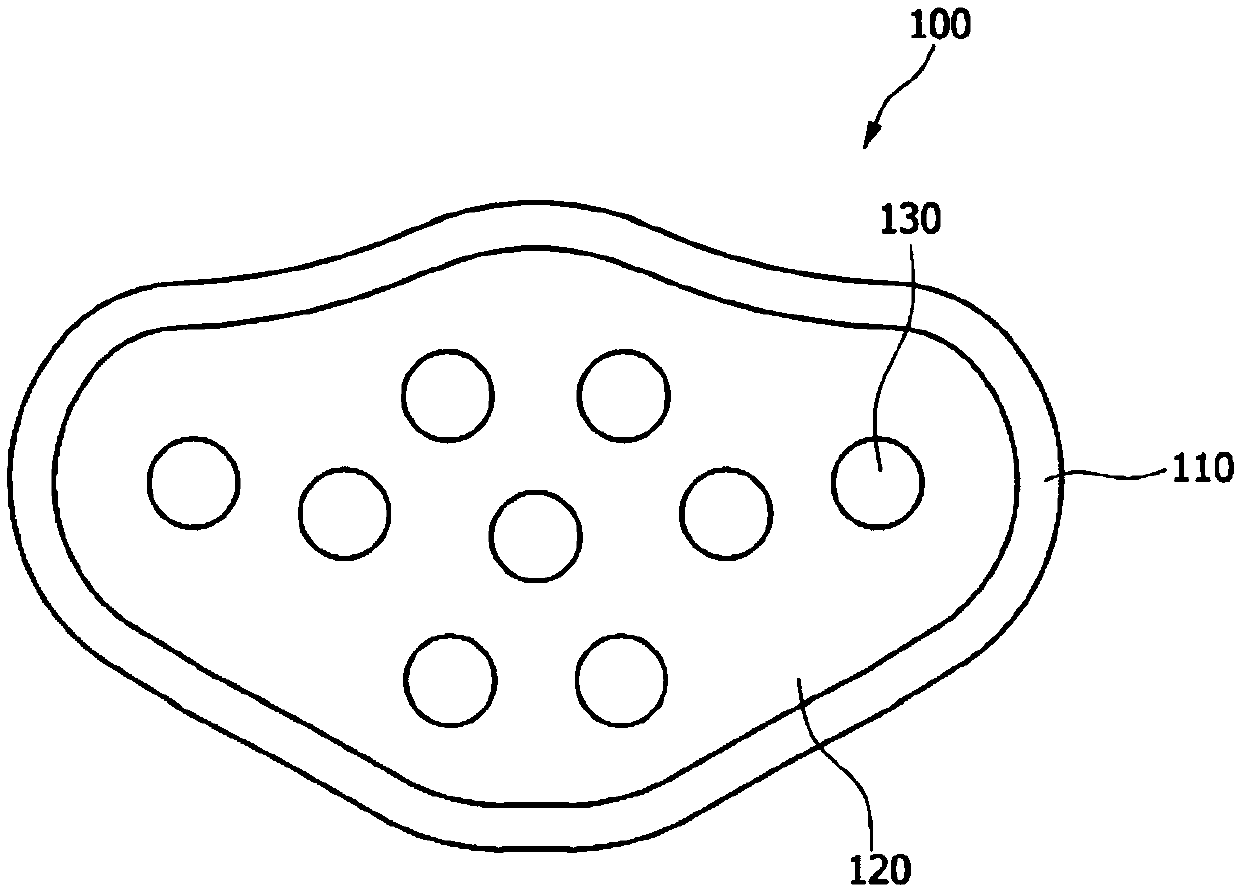

Thermo-therapeutic apparatus

ActiveCN110192971ACombination structure is simpleSimplify Manufacturing EngineeringDevices for heating/cooling reflex pointsDevices for pressing relfex pointsEngineeringCeramic

Owner:CERAGEM CO LTD

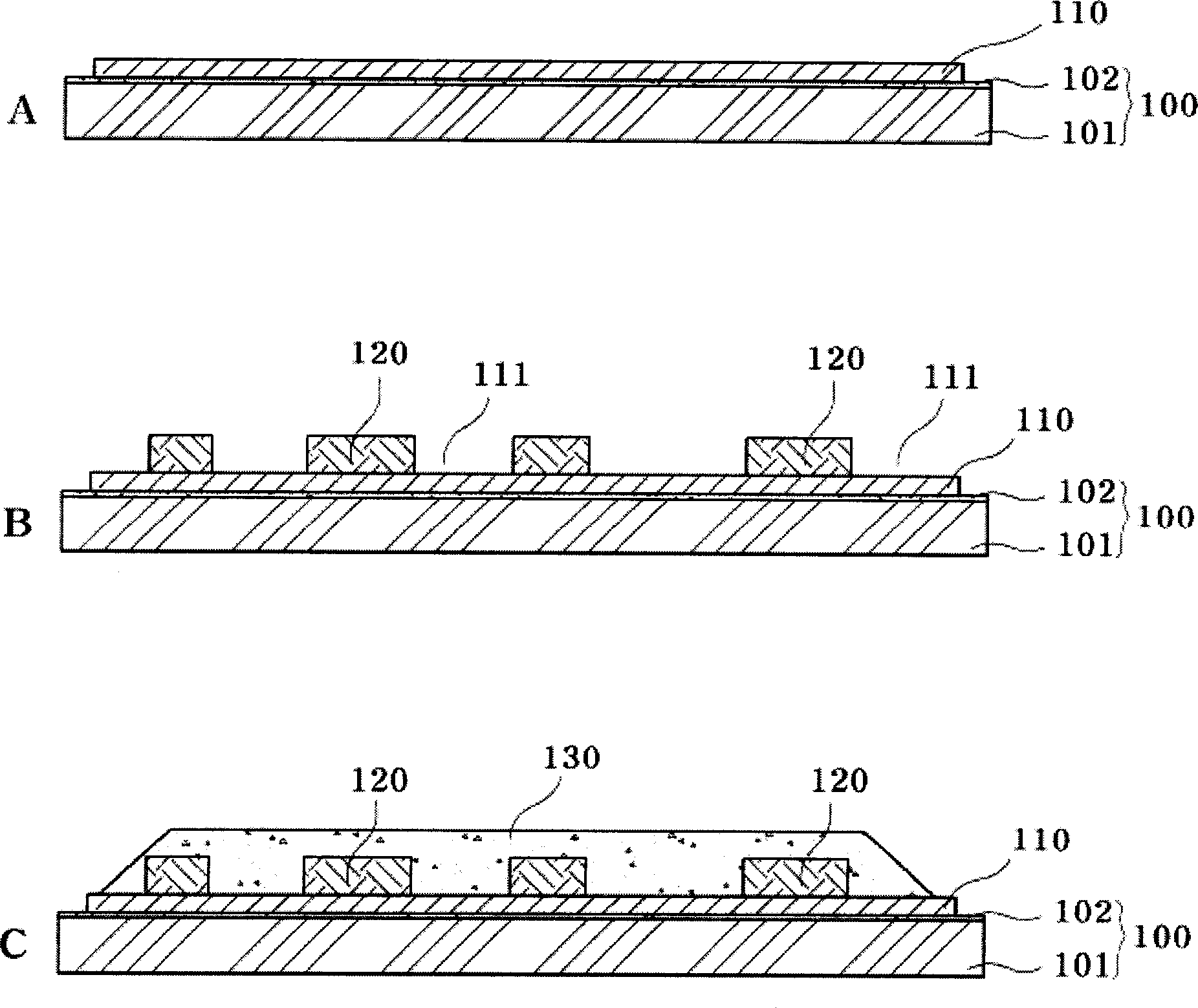

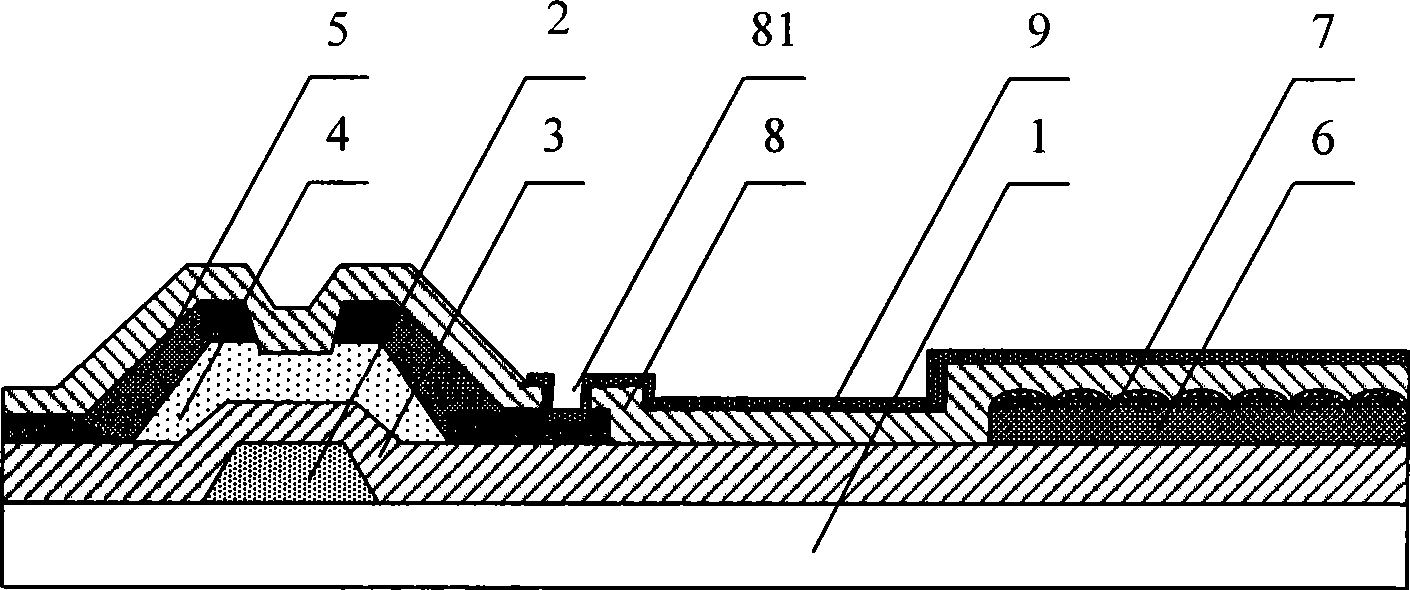

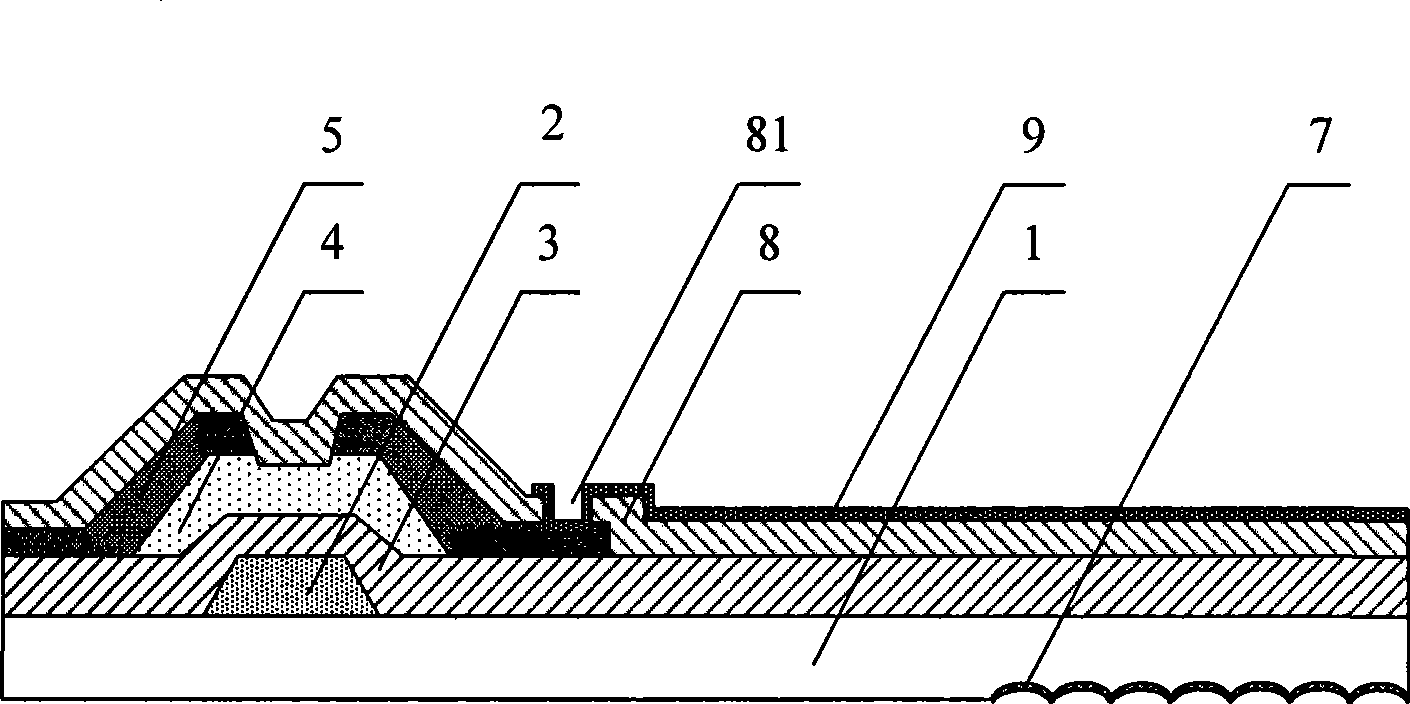

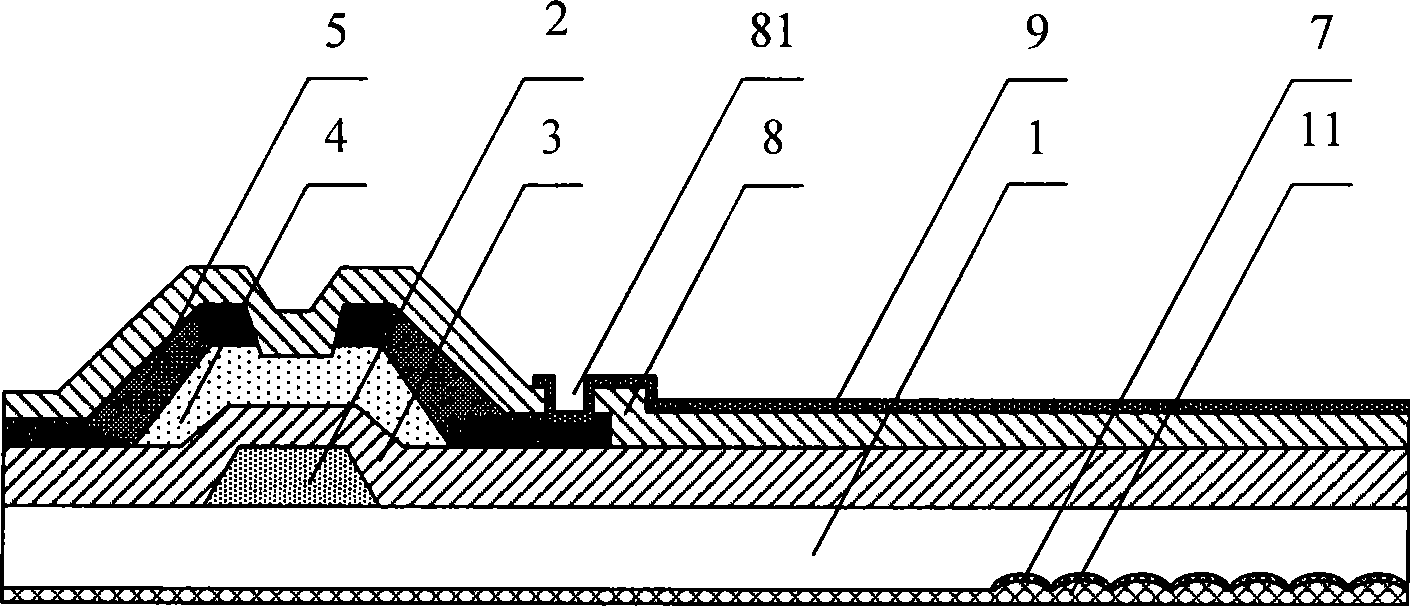

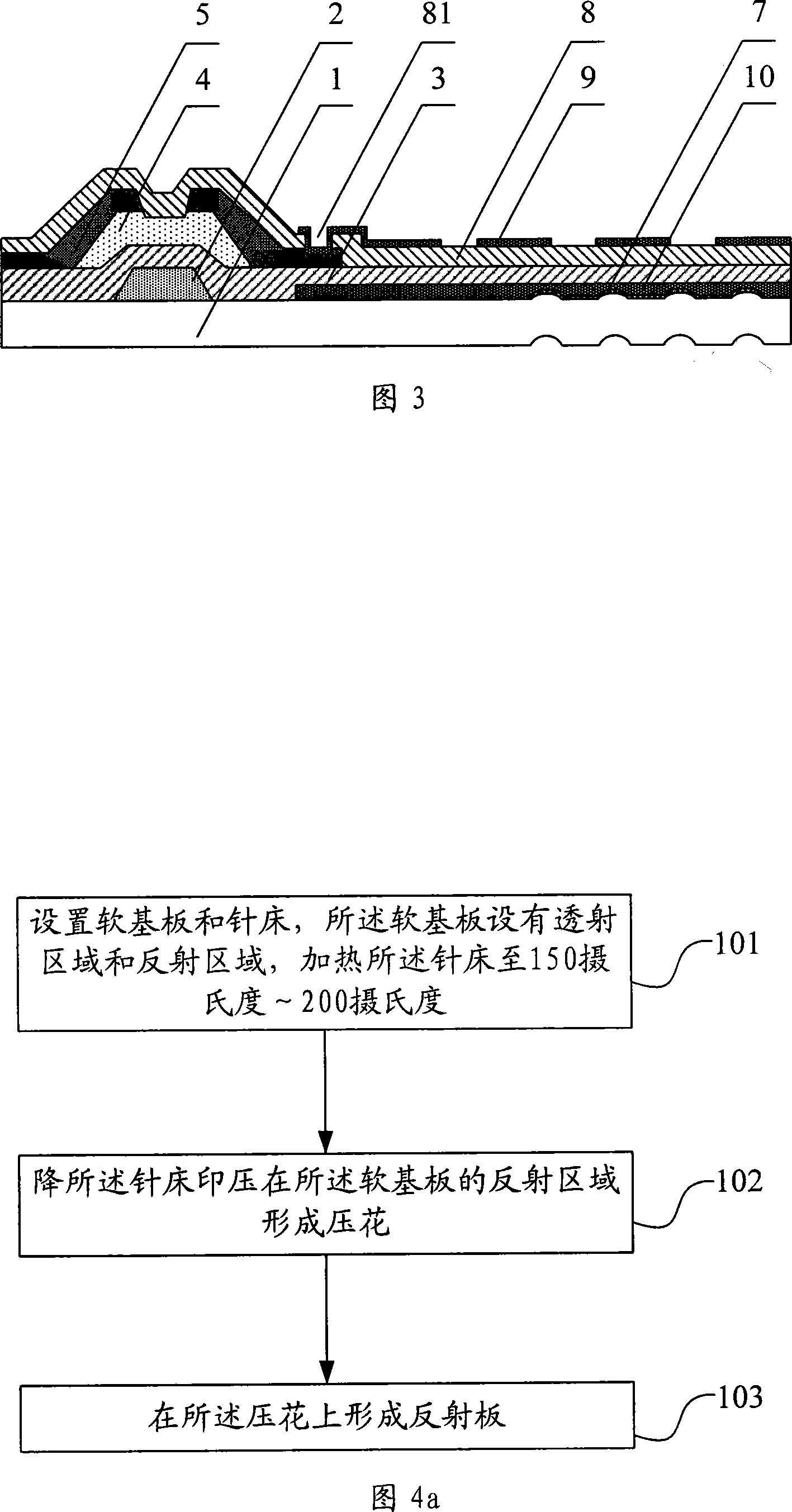

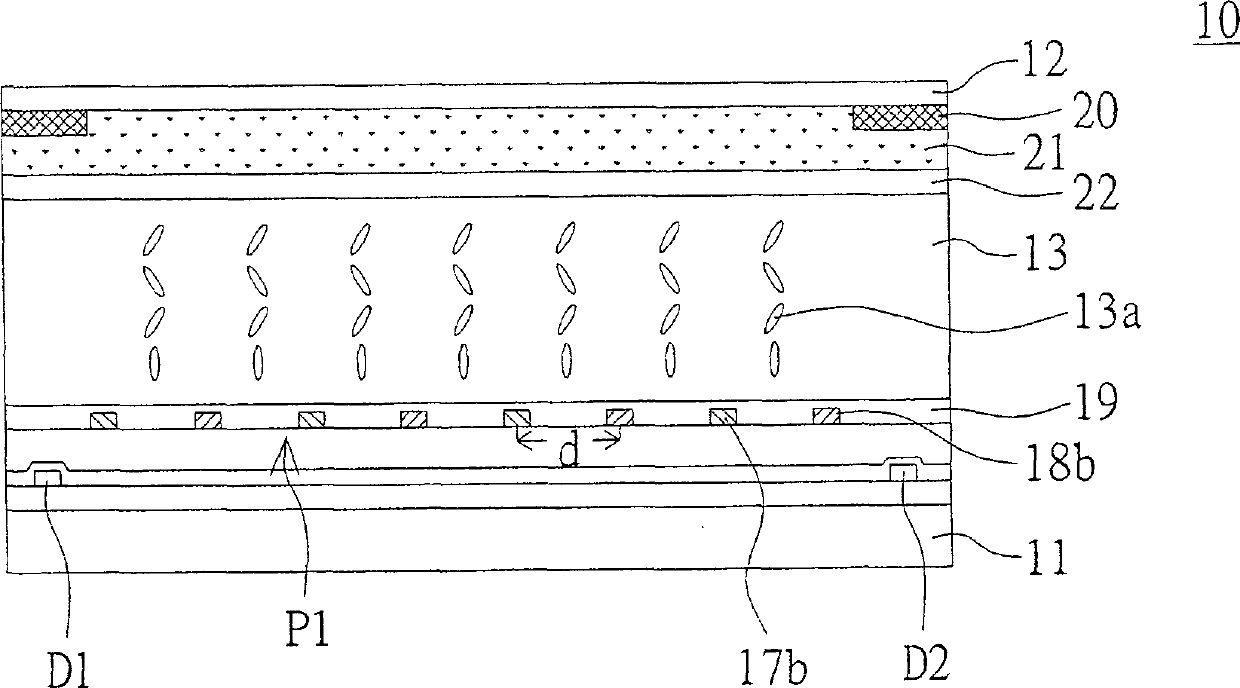

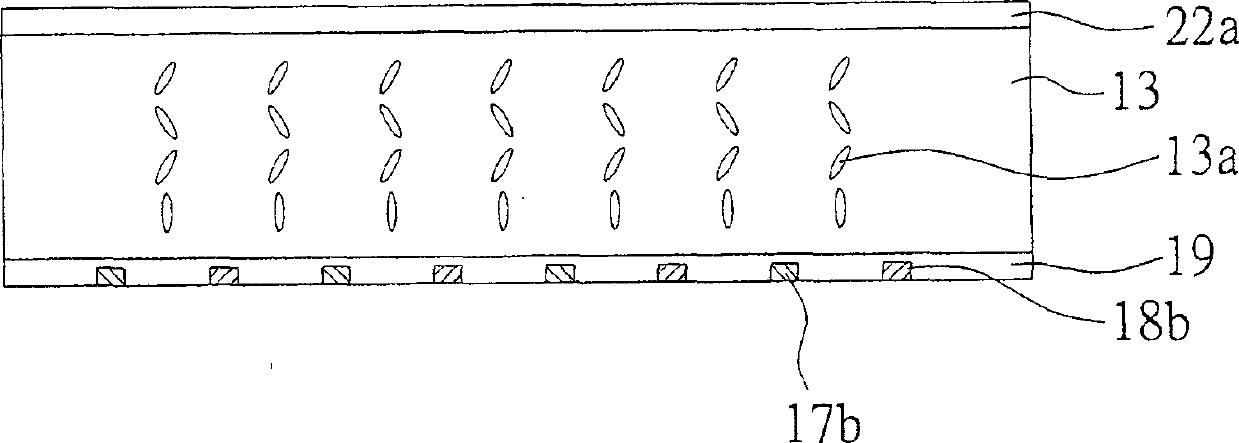

Reflection-permeation array substrate

The invention relates to an anti-penetration typed array substrate, comprising a glass substrate and an array mainbody; the glass substrate comprises a first surface and a second surface which face to each other; the first surface of the glass substrate forms an emboss which is provided with a reflection plate; the second surface of the glass substrate is provided with the array mainbody. The anti-penetration typed array substrate effectively solves the defect that the parameters of the existing anti-penetration typed array substrate such as thickness of resin layer, thickness of passivation layer, clearance of liquid crystal box and the like are difficult to be arranged during the design process and improves the quality of the liquid crystal display device.

Owner:K TRONICS (SUZHOU) TECH CO LTD +1

Butterfly lock

Owner:东莞市亿金金属制品有限公司

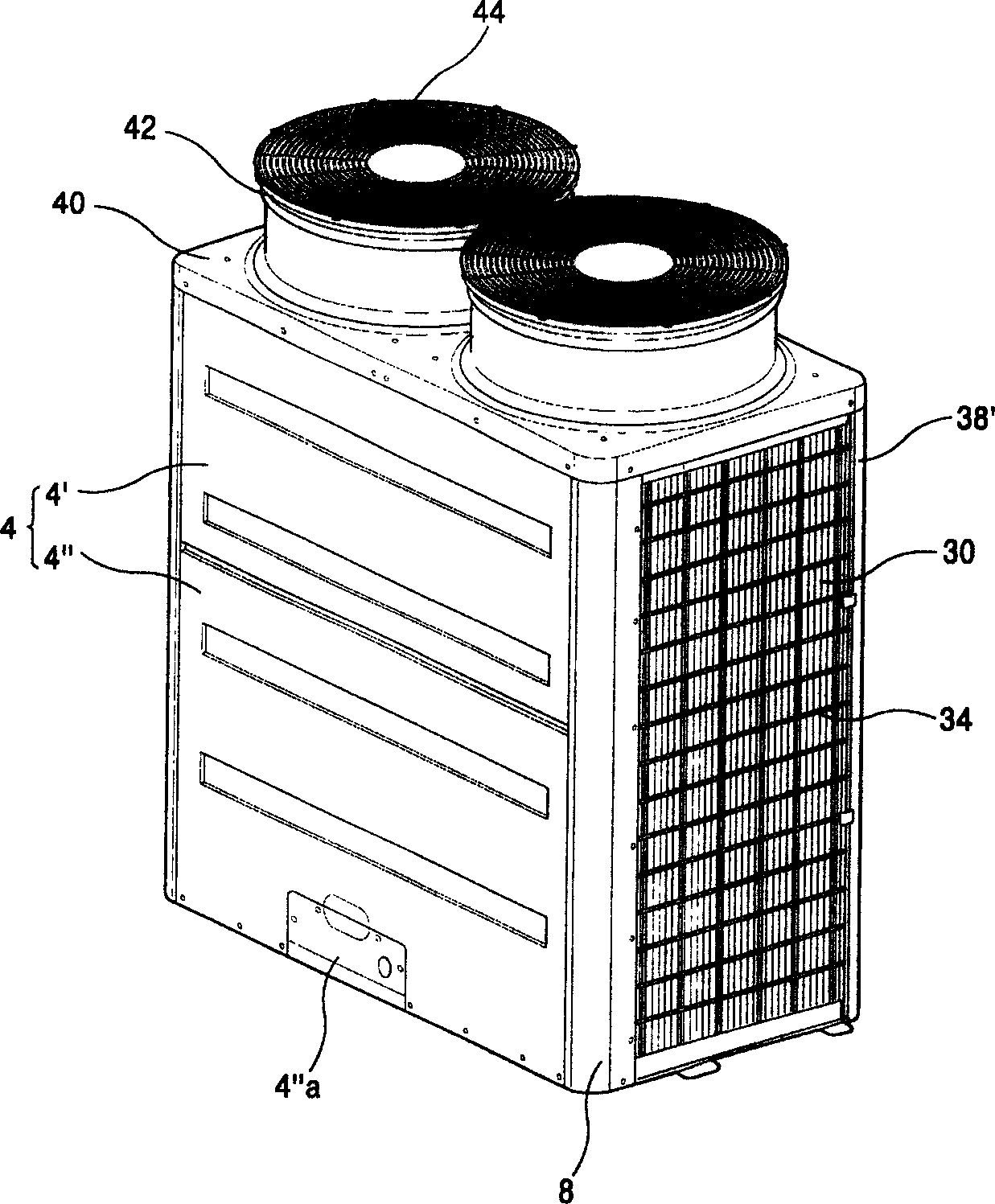

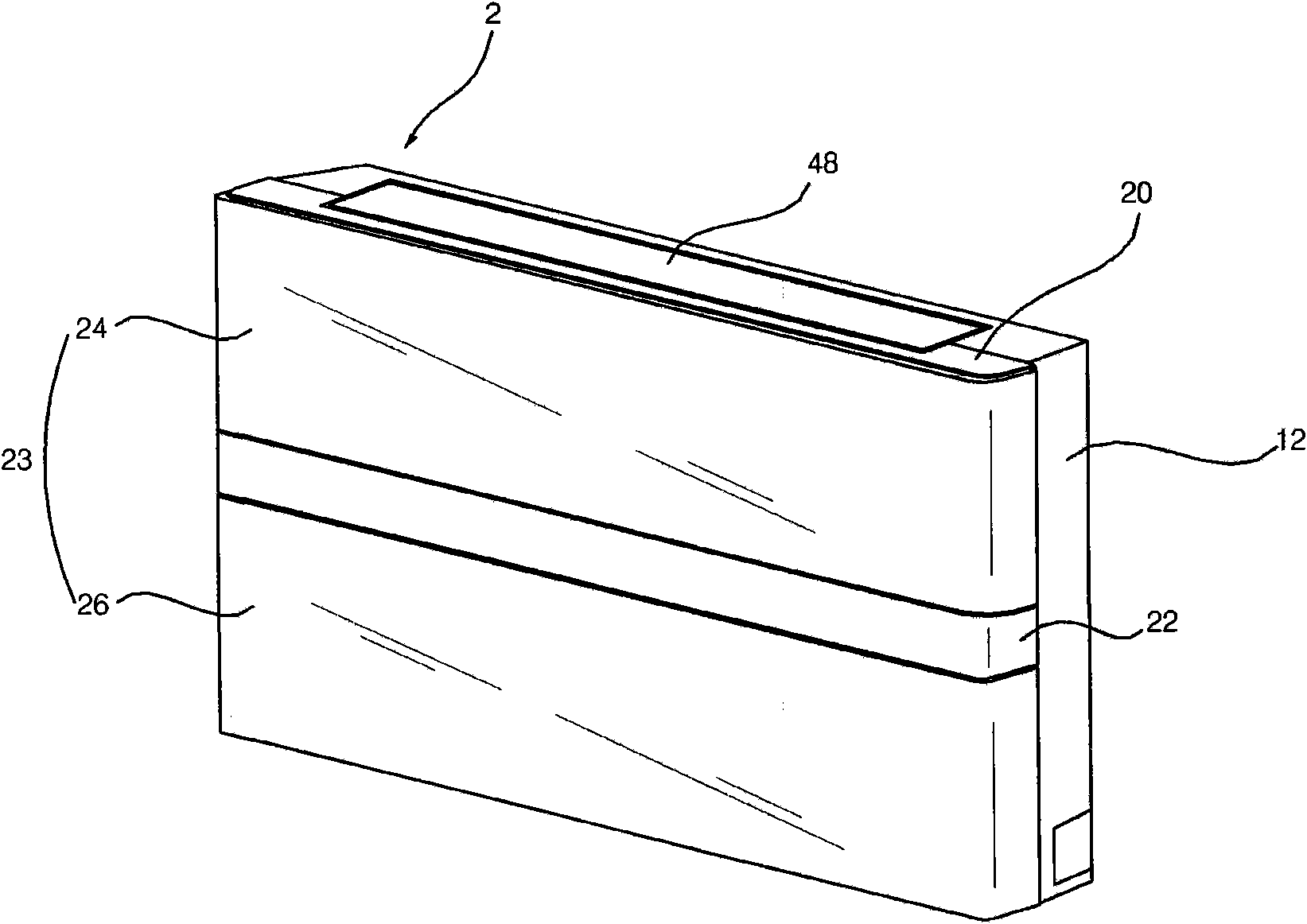

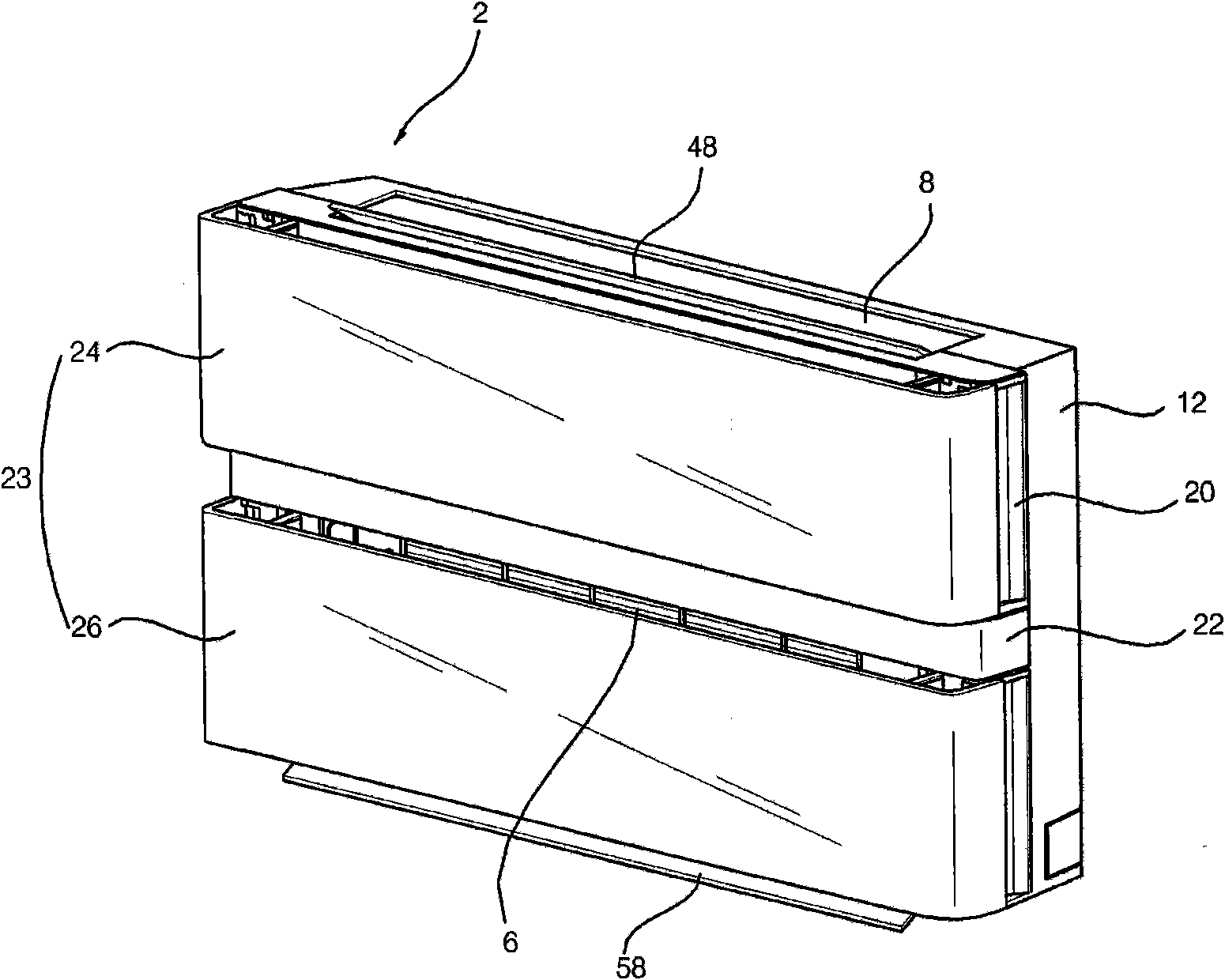

Air conditioner

InactiveCN101581469AConcise and effective arrangementFirmly connectedLighting and heating apparatusAir conditioning systemsControl theory

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

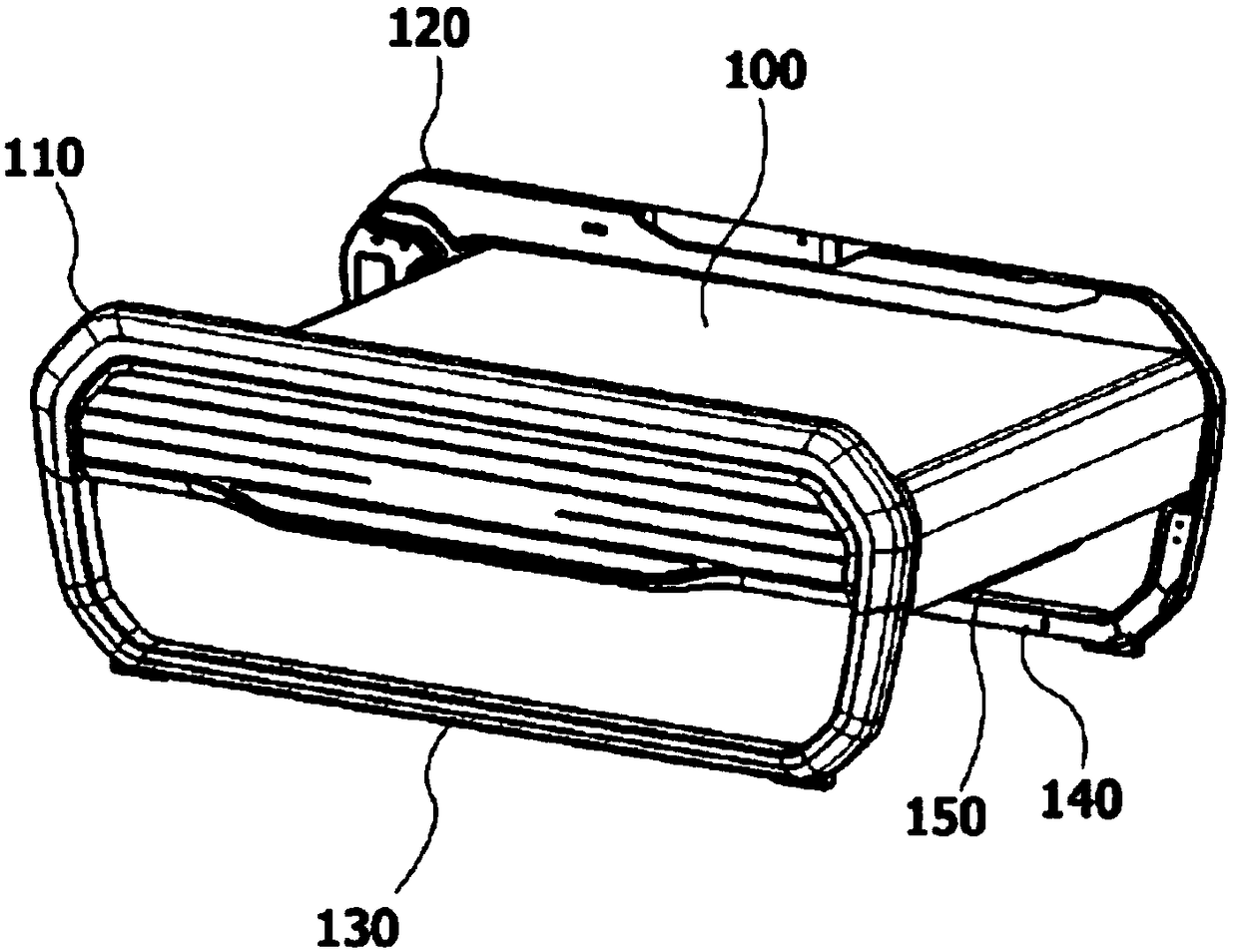

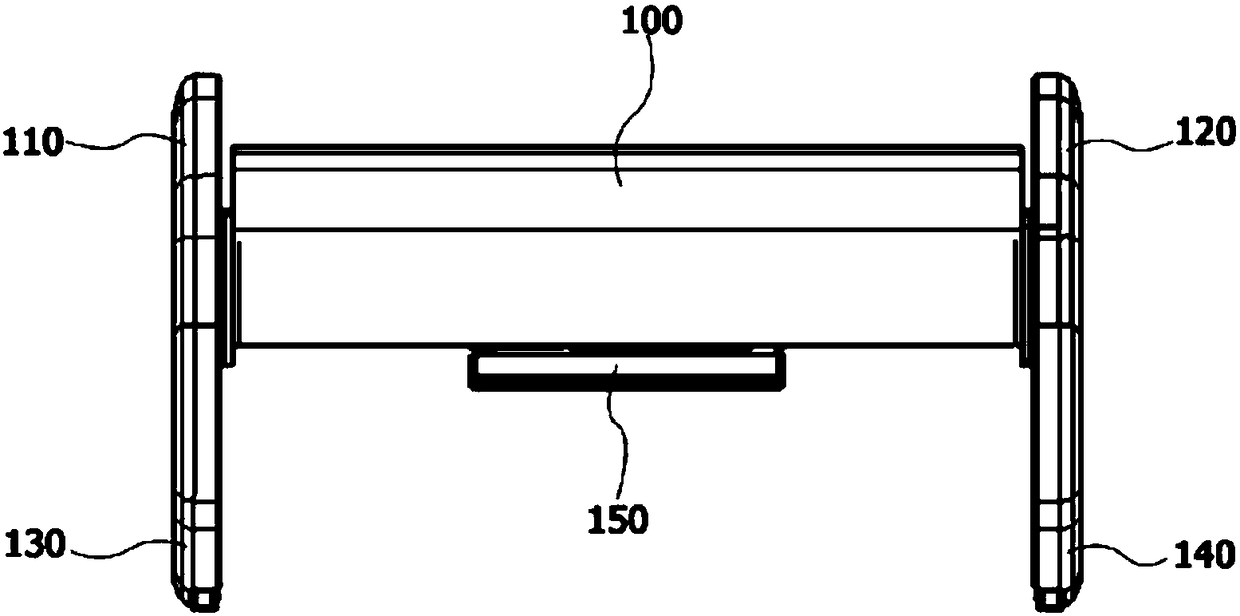

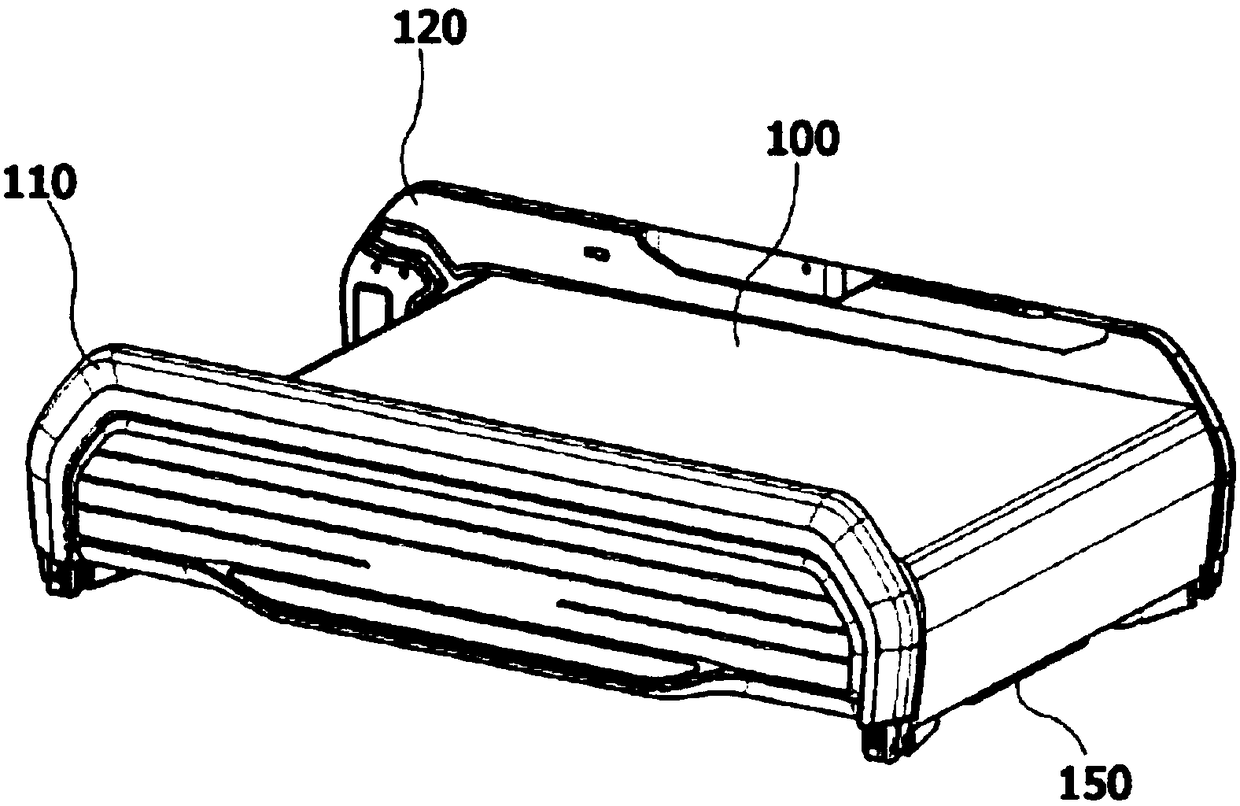

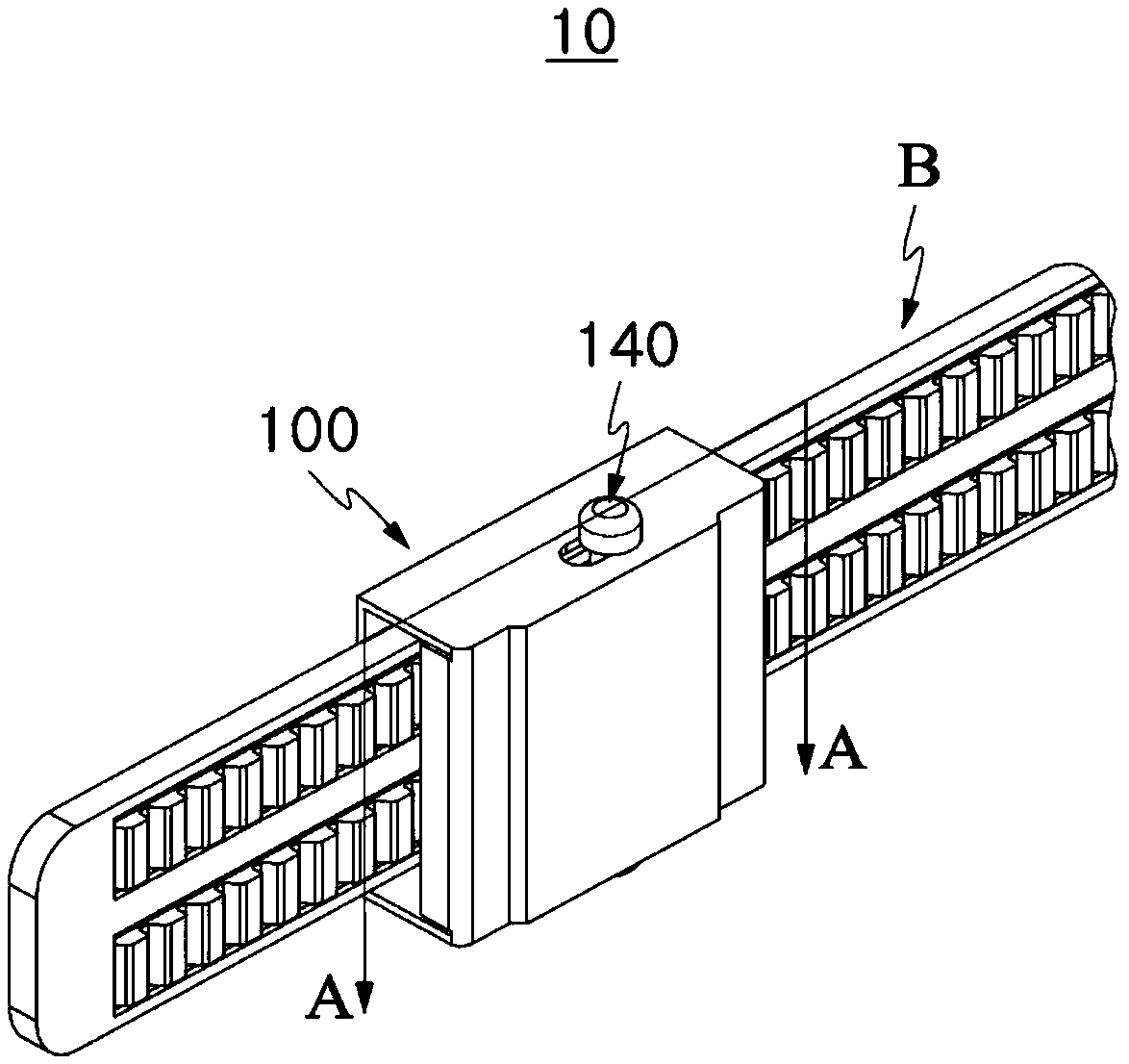

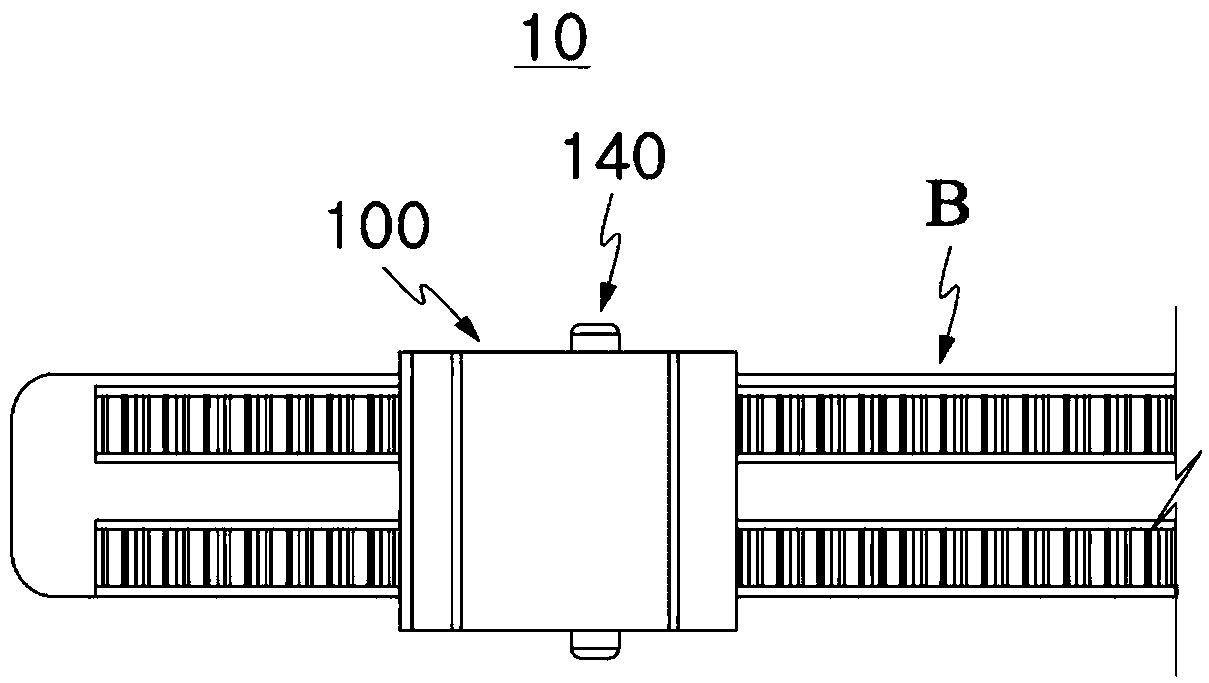

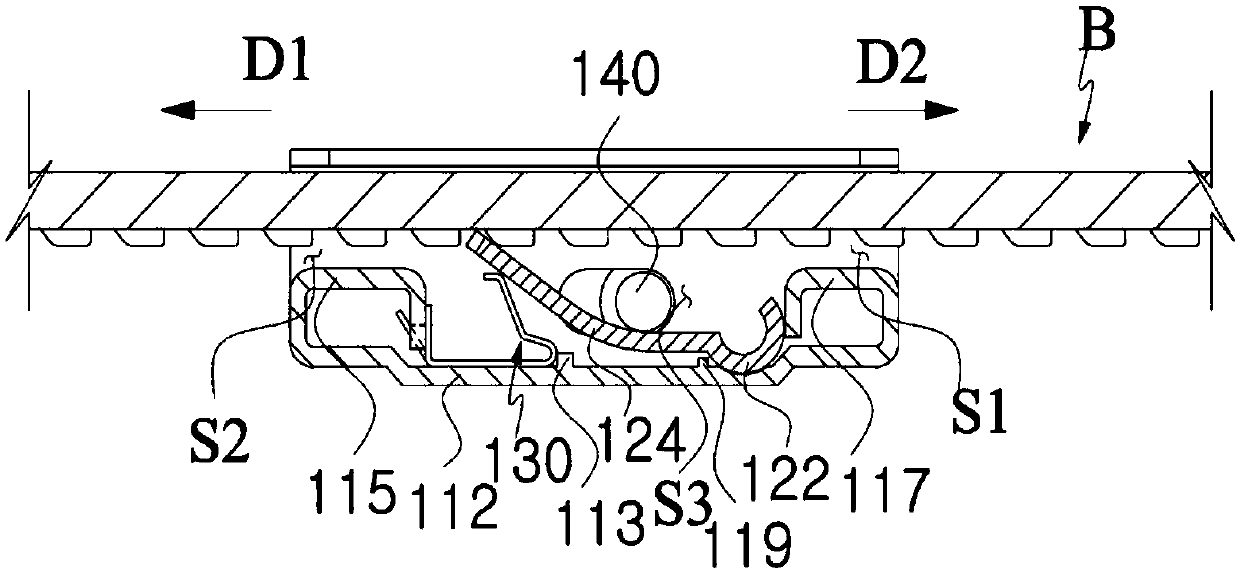

Thermotherapy Bed

ActiveCN108371588ASimplify Manufacturing EngineeringReduce manufacturing costsDevices for heating/cooling reflex pointsBedsEngineering

The present invention provides a thermotherapy bed comprising, in order to facilitate the storage and movement of the thermotherapy bed by maximizing space utilization and minimizing the volume of thethermotherapy bed: a bed main body in which a thermotherapy device is provided; side frames which are respectively connected to both side surfaces of the bed main body; and bed legs, which are respectively connected to the side frames, for supporting the bed main body, wherein the thermotherapy device is disposed in the center portion of the bed main body, thereby forming a step on the lower surface of the bed main body, and the bed legs are folded toward the inside of the bed main body so as to be received in spaces provided on both sides of the thermotherapy device.

Owner:CERAGEM CO LTD

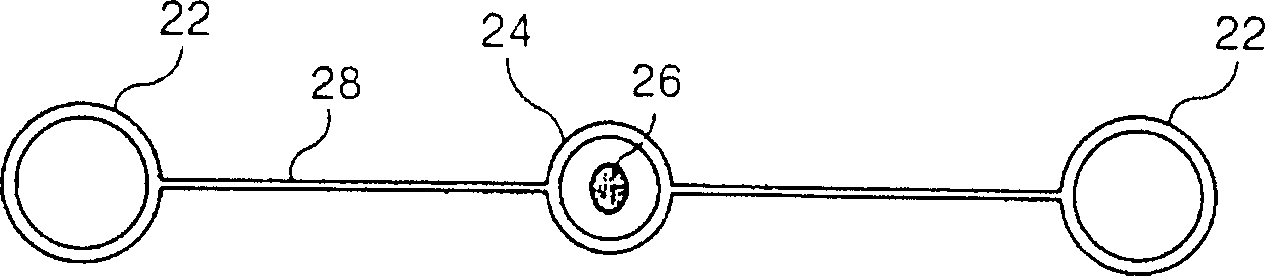

Band, control device, and band adjustment device

ActiveCN109688862AReduce in quantitySimplify Manufacturing EngineeringBucklesEngineeringElectrical and Electronics engineering

A control device according to an embodiment of the present invention is a device which allows a band to move freely in a first direction, but selectively in a second direction opposite to the first direction. The control device may comprise: a body part including an insertion space into which one end of the band is inserted and a discharging space through which the one end of the band having beeninserted into the insertion space is discharged; a band control part which: is disposed in an inner space of the body part in such a way as not to protrude toward an outside of the body part; can be switched between a first position and a second position with reference to a rotation shaft; and allows the band to move freely in the first direction while being in contact with the band when switchingtowards the first position and freely in the second direction while not being in contact with the band when switching towards the second position; and an external force transfer part which is disposed at a third position to place the band control part at the first position, and is switched from the third position to a fourth position while being in contact with the band control part, to allow theband control part to be switched from the first position to the second position.

Owner:柳良锡

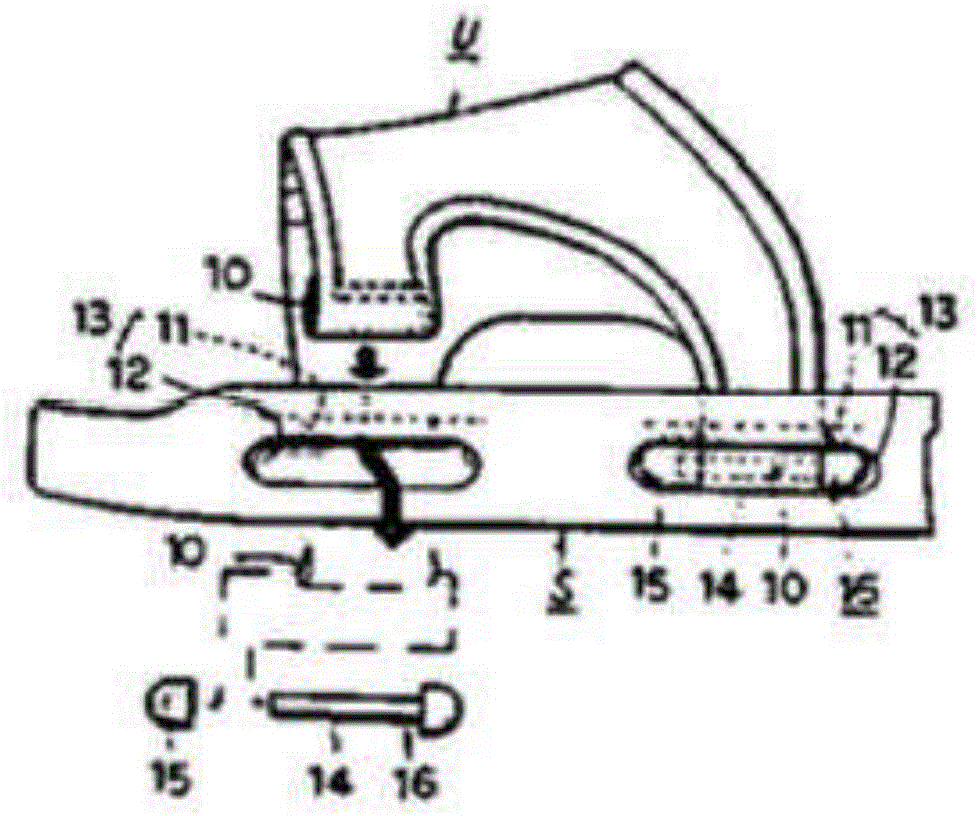

Door hinge

PendingCN114207236AReduce in quantityLow costDomestic stoves or rangesLighting and heating apparatusClassical mechanicsEngineering

Owner:胥元韩国株式会社

Sandal with replaceable upper outer leather

InactiveCN105286181AEasy to replaceSimplify Manufacturing EngineeringFootwearFastenerElectrical and Electronics engineering

The invention discloses a sandal with replaceable upper outer leather, comprising a bottom board, the upper outer leather and a strapping unit. Two sides of the bottom board are provided with a plurality of receiving holes. The upper portion of the bottom board is provided with the upper outer leather covering instep. The strapping unit comprises strapping ports disposed in correspondence with the receiving holes and used for joining with the receiving holes, and fasteners arranged outside the strapping ports and joining with two ends of the upper outer leather; each receiving hole comprises a guide-in channel formed from the upper side of the bottom face of the bottom board to the lower side of the bottom board, and a fastening channel communicated with an end of the guide-in channel and formed towards the length direction of the bottom board. The sandal according to the invention has simple manufacturing and has the upper outer leather simple to replace.

Owner:李沧敏

Reflection-permeation array substrate and method for manufacturing same

ActiveCN101398558AUniform gapOrderly rowsPhotomechanical apparatusNon-linear opticsPermeationNanotechnology

Owner:BOE TECH GRP CO LTD +1

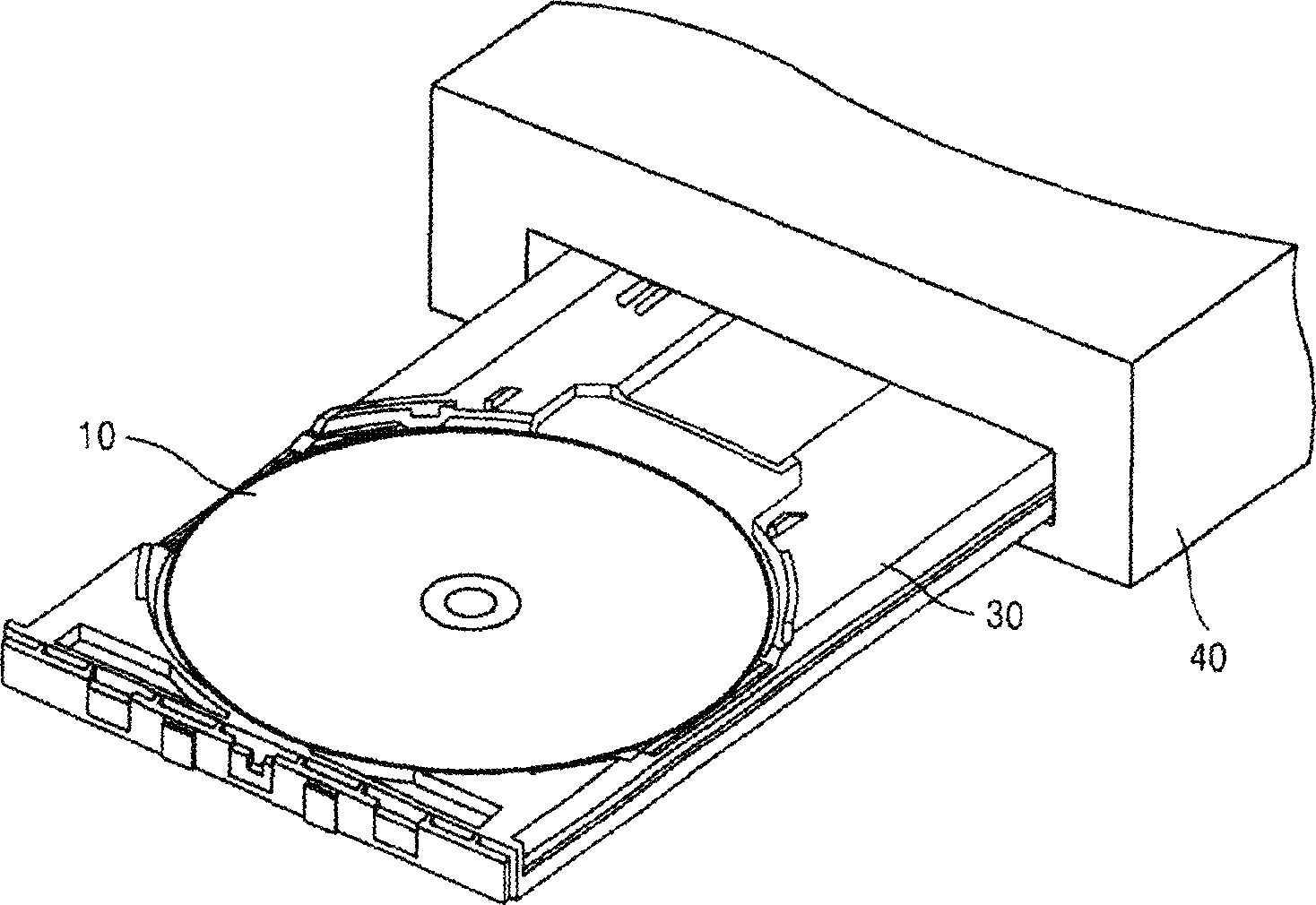

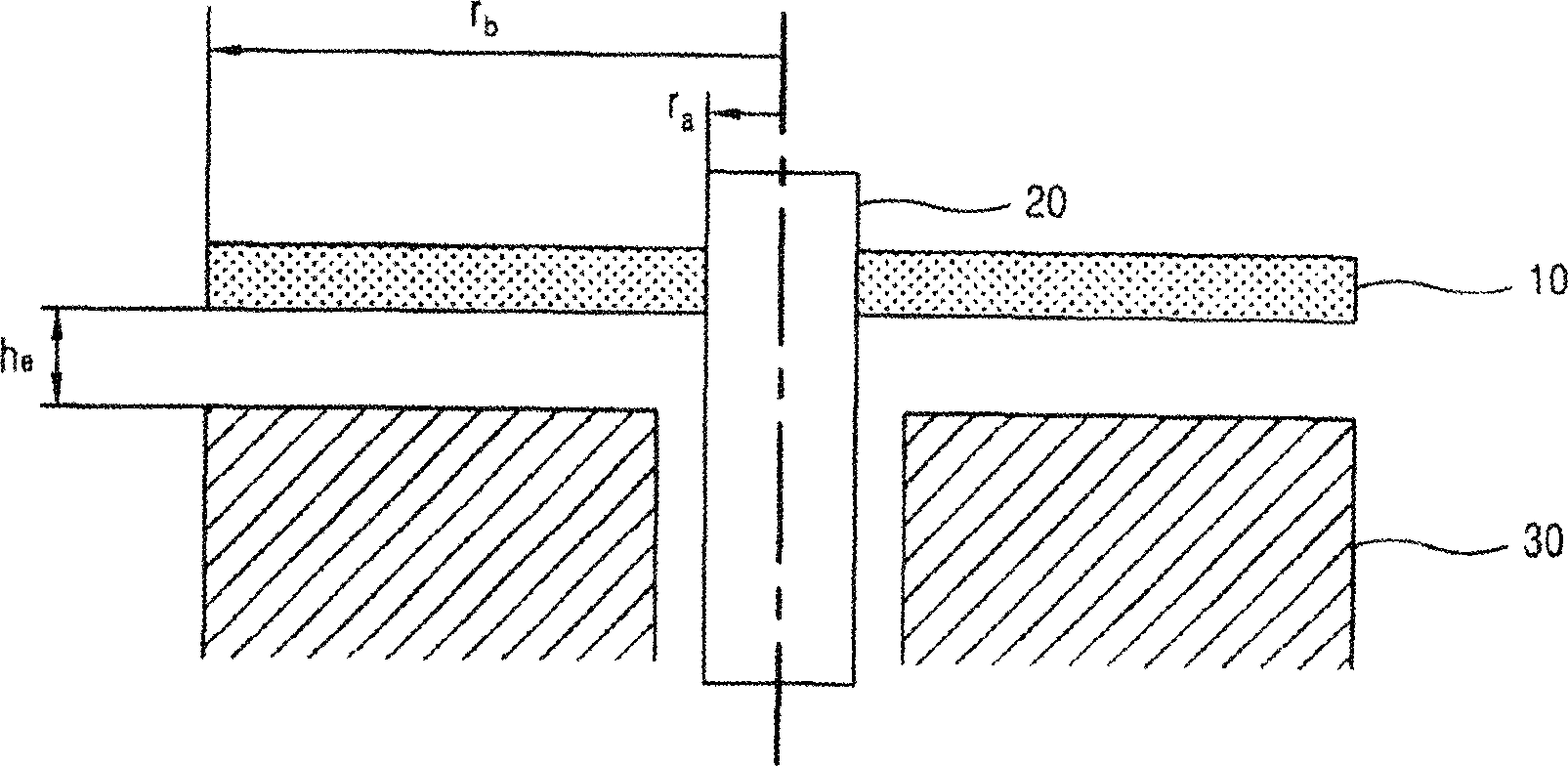

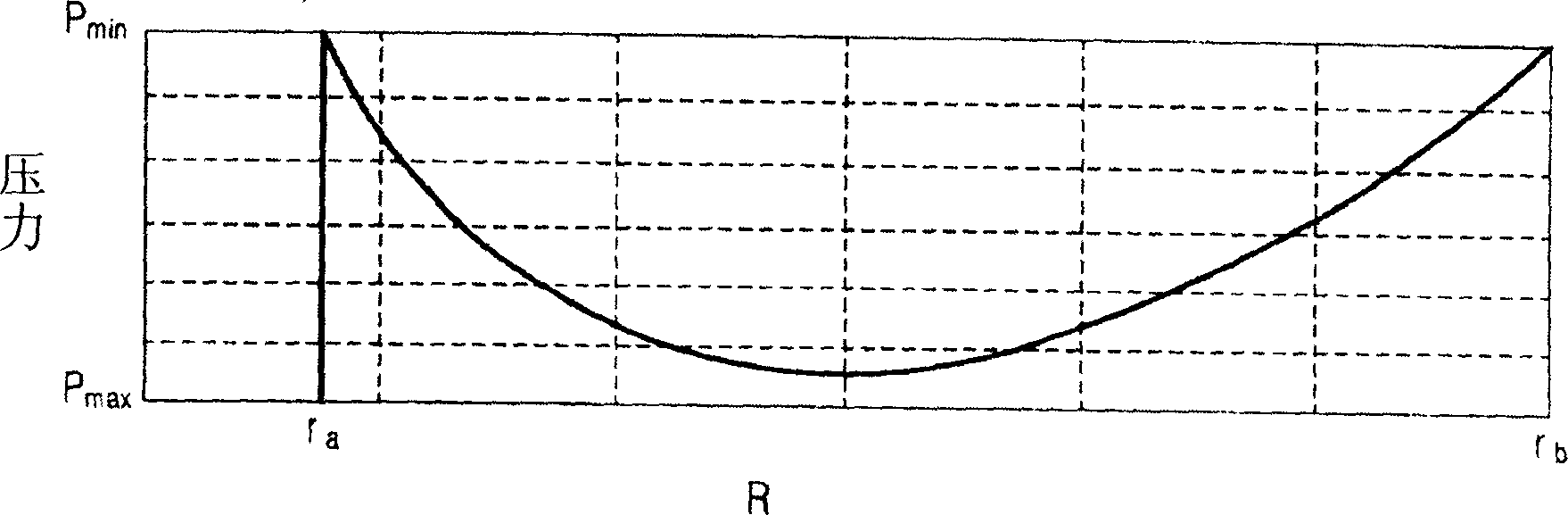

Optical disk driver with novel structure

InactiveCN1744220AStable driveGuaranteed credibilityRecord information storageEngineeringOptical disc

The optical drive includes following parts: telescopic tray for housing optical disk inside chassis; drive for driving optical disk on the tray; recording on optical disk rotated under action of drive or optical pick-up for playing optical information. In the drive, gap between bottom of the tray and lower surface of optical disk can be changed based on radius. Thus, when optical disk is rotated in high speed, pressure gradient occurred between bottom of the tray and lower surface of optical disk is minimized. The invention makes optical disk be driven more stable so as to guarantee creditability of recorded and played information.

Owner:LEJIN GUANGDIAN ELECTRONIC CO LTD SHANGHAI

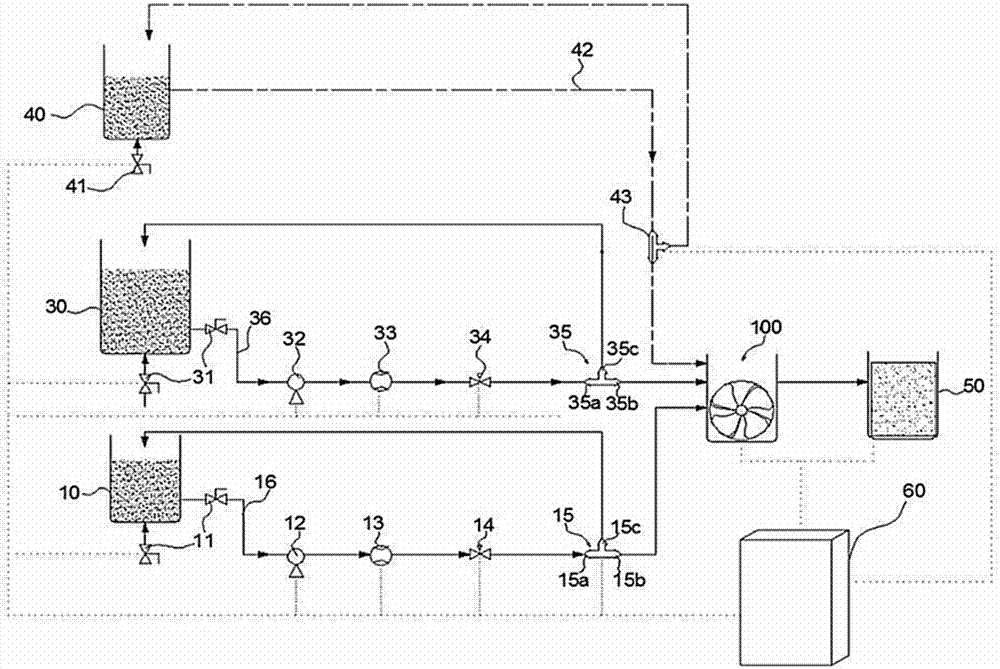

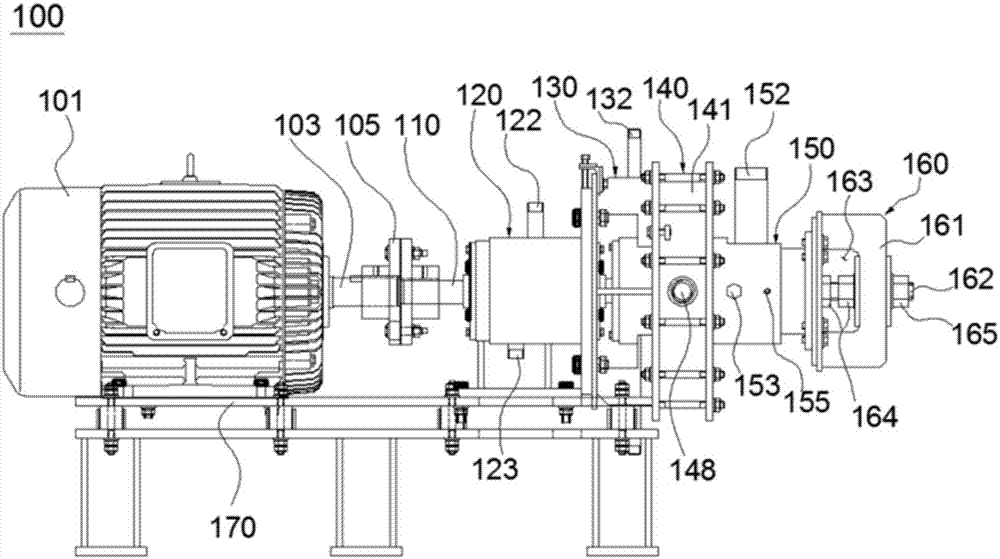

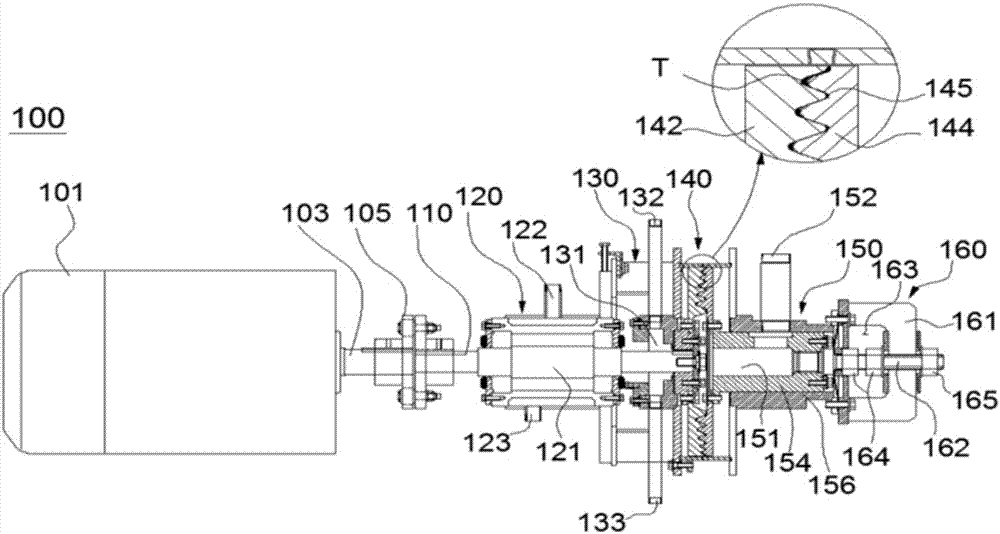

Fuel emulsion manufacturing device

ActiveCN106914161AImprove qualityBest mixing ratioFlow mixersMixing methodsEmulsionWater storage tank

The present invention belongs to the fuel emulsion manufacturing device field, especially to a fuel emulsion manufacturing device. The device comprises a raw material water storage tank (10), a raw material oil storage tank (30), metering pumps (32, 12), electronic control valves (35, 15) and a stirrer (100). The electronic control valves (35, 15) are arranged at the tail end of each raw material supply wire, the raw materials supplied by safety valves (24, 14) are supplied in a setting reference amount to the stirrer (100). When the setting condition is not accorded, the supplied raw materials are returned back to each raw material storage tank, and when the setting condition is accorded, the raw materials can supply to the stirrer (100); the stirrer (100) allows the introduced raw materials into the electronic control valves (35, 15) to allow the raw materials to mutually balance and mix. The installation is easy, the maintenance is convenient, the manufacturing time of the fuel emulsion is shortened, and lots of fuel emulsion can be produced.

Owner:MOOJIN MACHINETOOL

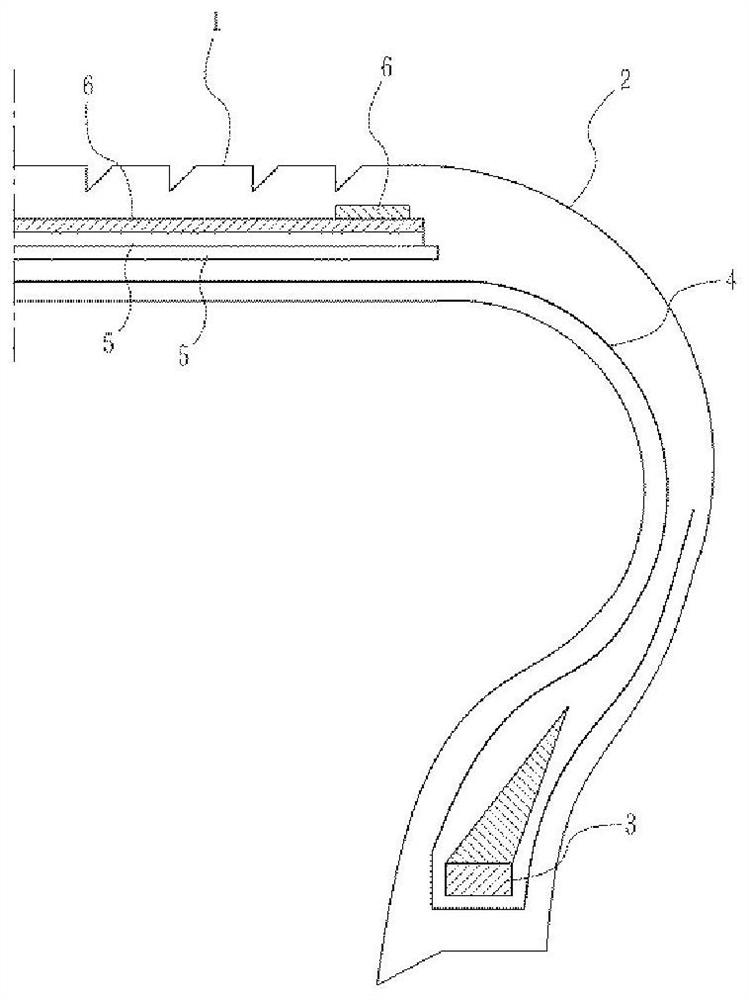

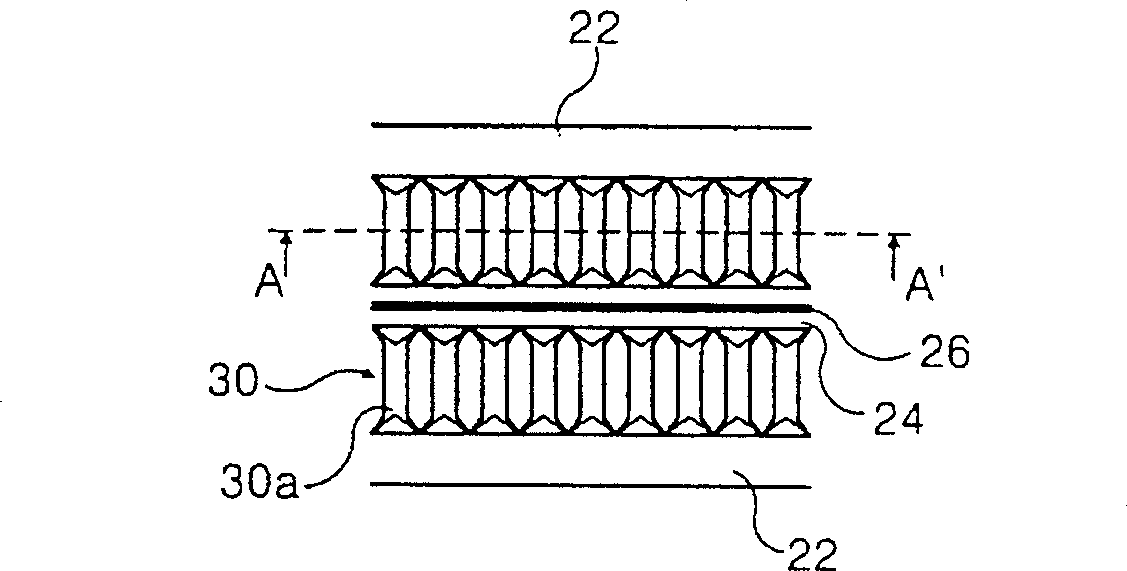

Tire comprising fabric strip

PendingCN112874244ASimplify Manufacturing EngineeringLow costSpecial tyresPneumatic tyre reinforcementsWeft yarnEngineering

The present invention relates to a tire comprising a fabric strip, the tire comprising, in a strip layer, a fabric strip composed of a plurality of warp yarns arranged parallel to each other and weft yarns woven from the warp yarns, the warp yarns being bonded to the weft yarns. According to the tire, the manufacturing engineering can be simplified, the cost in the manufacturing engineering is saved, the weight of the tire is reduced, and the fuel efficiency of the tire is improved by reducing the rotation resistance when the tire is used for driving.

Owner:HANKOOK TIRE & TECH CO LTD

Reflection-permeation array substrate and method for manufacturing same

ActiveCN101398558BOvercoming the problem of excessive difficulty in parameter settingOvercoming rising manufacturing costsPhotomechanical apparatusNon-linear opticsEngineeringMaterials science

Owner:BOE TECH GRP CO LTD +1

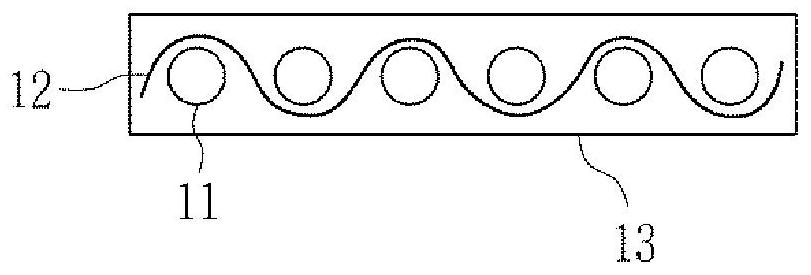

Double-refrigerant pipe evaporator with radiator for electric refrigerator

InactiveCN1435613AImprove heat exchange efficiencyBig spaceEvaporators/condensersRefrigerantHeat sink

An evaporator with dual cold medium pipe and grid radiator for refrigerator is characterized by that a grid radiator is between two cold medium pipes to form a whole and said radiator and pipes are bent by more than 2 segments. A defrost heater is under the evaporator. Its advantages are high cold volume and supplying speed, high heat exchanging efficiency, and high defrost effect.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

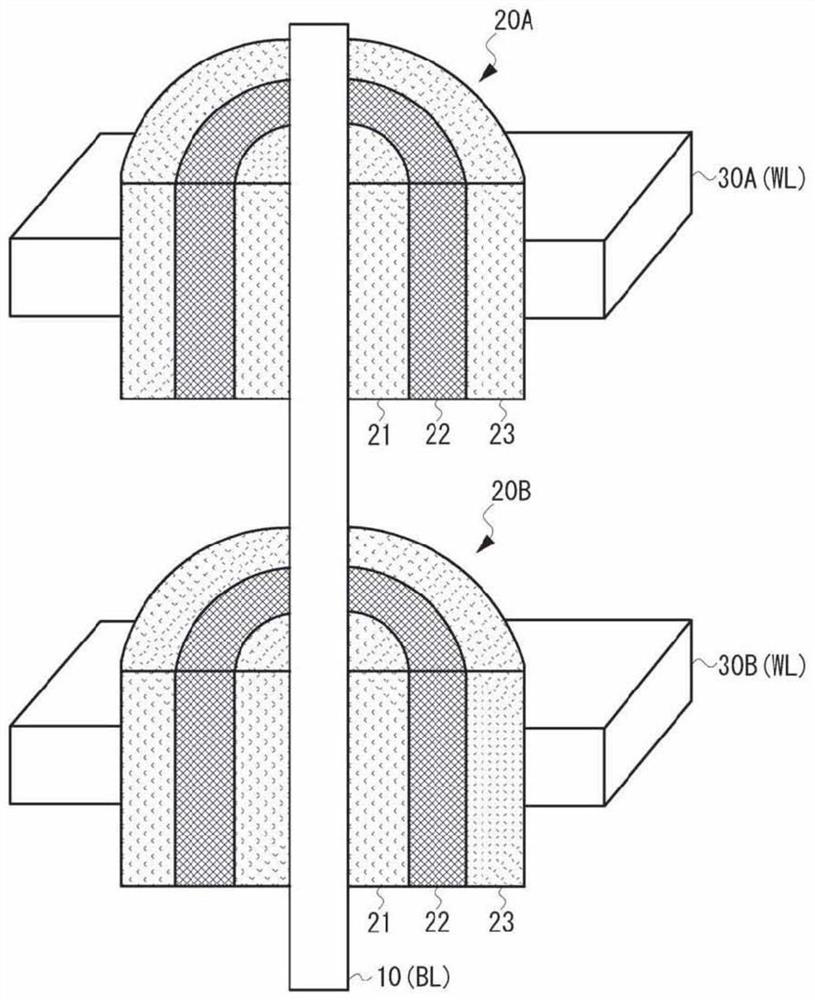

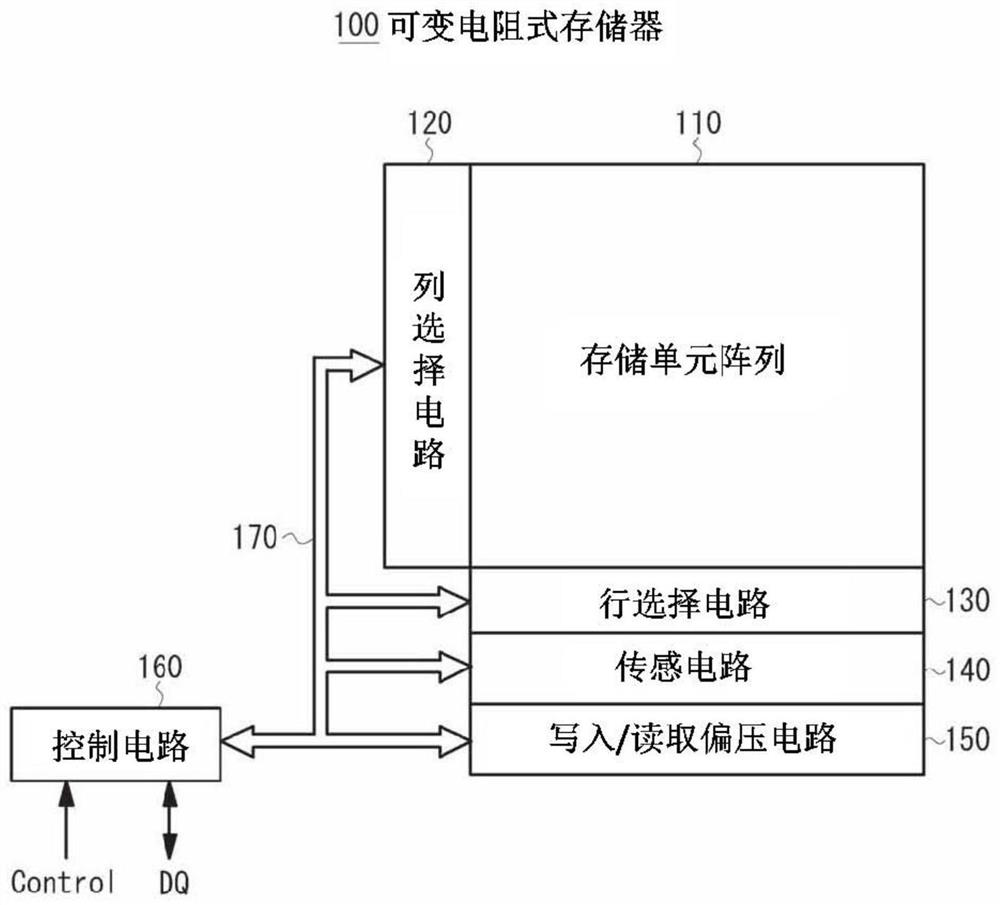

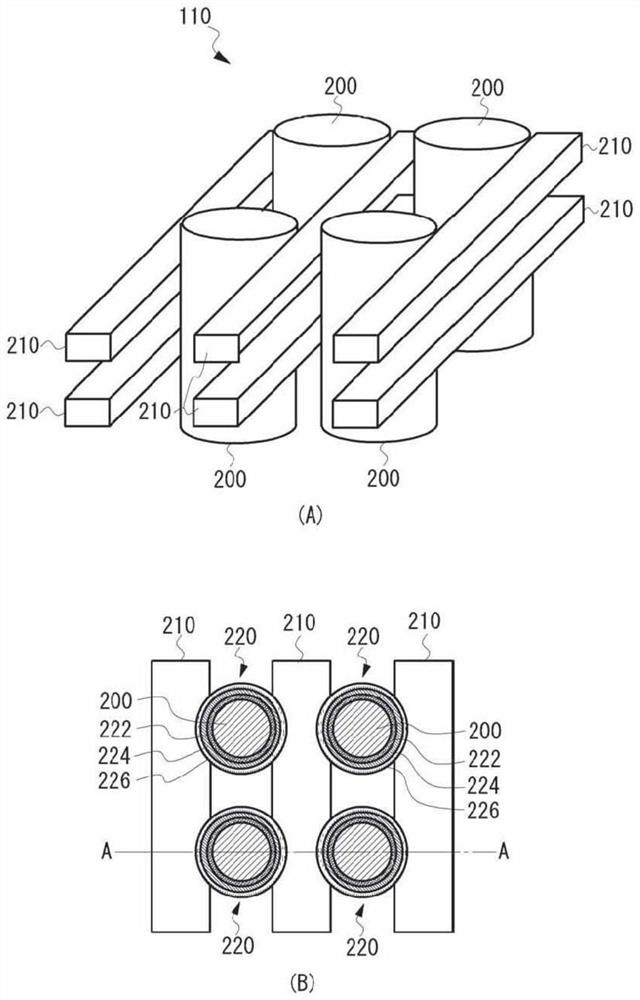

Resistive random-access memory device and manufacturing method thereof

ActiveCN113078183AThree-dimensional structure is simpleSimplify Manufacturing EngineeringSolid-state devicesDigital storageBit lineMemory cell

The invention provides a resistive random-access memory device and a manufacturing method thereof. The resistive random-access memory includes a plurality of pillars, a plurality of bit lines, and a memory cell. The pillars extend vertically along the main surface of the substrate. The bit lines extend in a horizontal direction. The memory cell is formed at the intersection of the pillars and the bit lines. The memory cell includes a gate insulating film, a semiconductor film, and a resistive element. The gate insulating film is formed on the circumference of the pillar. The semiconductor film is formed on the circumference of gate insulating film and provides a channel area. The resistive element is formed on the circumference of the semiconductor film. A first electrode area on the circumference of the resistive element and a second electrode area facing the first electrode area are electrically connected to a pair of adjacent bit lines.

Owner:WINBOND ELECTRONICS CORP

LCD panel, its manufacture method and LCD device using the same

ActiveCN100507688CImprove featuresTo achieve the effect of wide viewing angleStatic indicating devicesNon-linear opticsActive matrixVertical alignment

Owner:AU OPTRONICS CORP

Electronic dust-collecting filter of air purifier

InactiveCN100503049CImprove freshness efficiencySimplify Manufacturing EngineeringCombination devicesLighting and heating apparatusElectricityFresh air

The electronic dust collection filter in the prior art has the following problems: due to the complex structure of the collecting device, the manufacturing process is long, and the charged dust is only adsorbed on the collecting electrodes, which reduces the adsorption efficiency. The present invention provides an electronic dust collection filter for an air purifier, which is characterized in that it includes: an ionization component, a collecting device and a metal mesh; Charged; the above-mentioned collection device is formed of conductive foam to maximize the adsorption area of dust, and it is arranged behind the above-mentioned ionization part and connected to the ground wire to absorb charged dust; the above-mentioned metal mesh is set on the above-mentioned ionization part and the collection device between and connected to ground. Through the above-mentioned structure, the electronic dust-collecting filter of the air purifier can bring the following effects: because no electrodes are arranged in the collecting device, the manufacturing process is simplified, and the dust can be collected through the front of the collecting device, improving Air freshening efficiency.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com