Hinge assembly structure for microwave oven door

A technology of hinge assembly and microwave oven, which is applied in the directions of stove/stove door, household stove/stove, household heating, etc., can solve the problems of not being able to close the door, cannot use the microwave oven, etc., and achieves a simplified manufacturing process, simple structure, and anti-bending technology. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

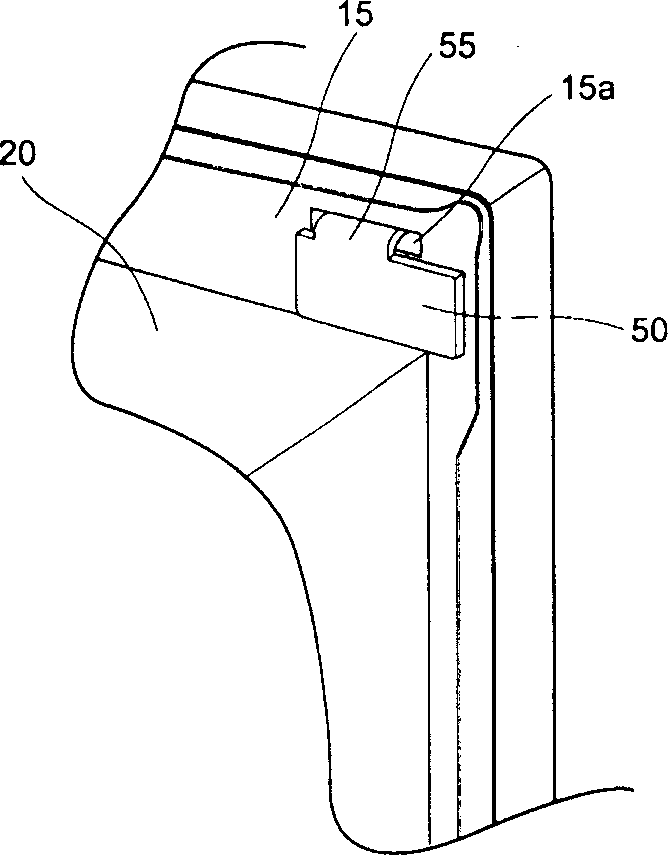

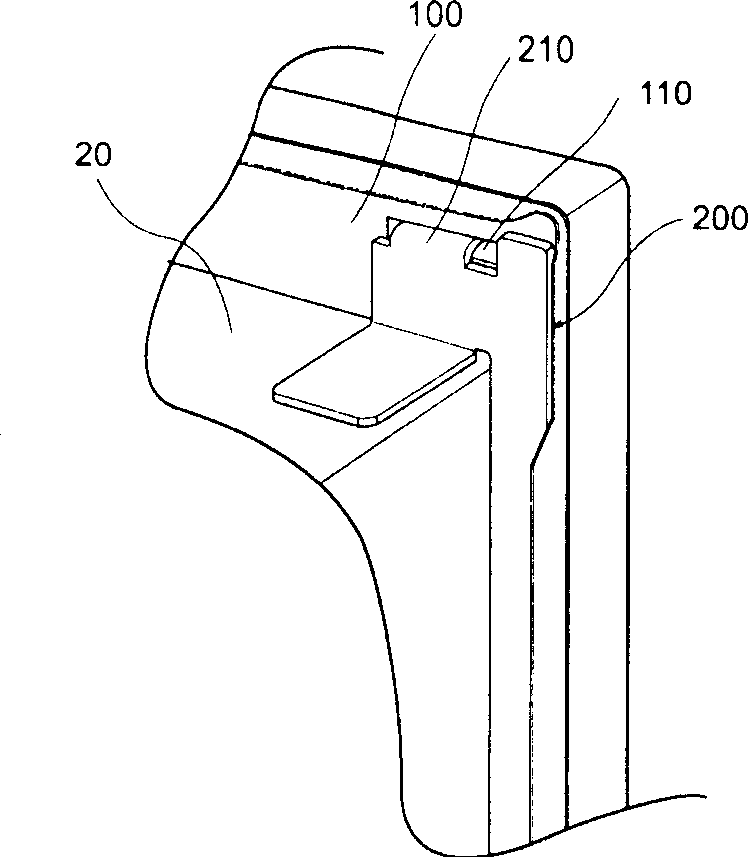

[0040] image 3 It is a partial oblique view of the upper back side of the front panel of the microwave oven equipped with the hinge assembly of the present invention, Figure 4 is a perspective view of the hinge assembly according to the present invention.

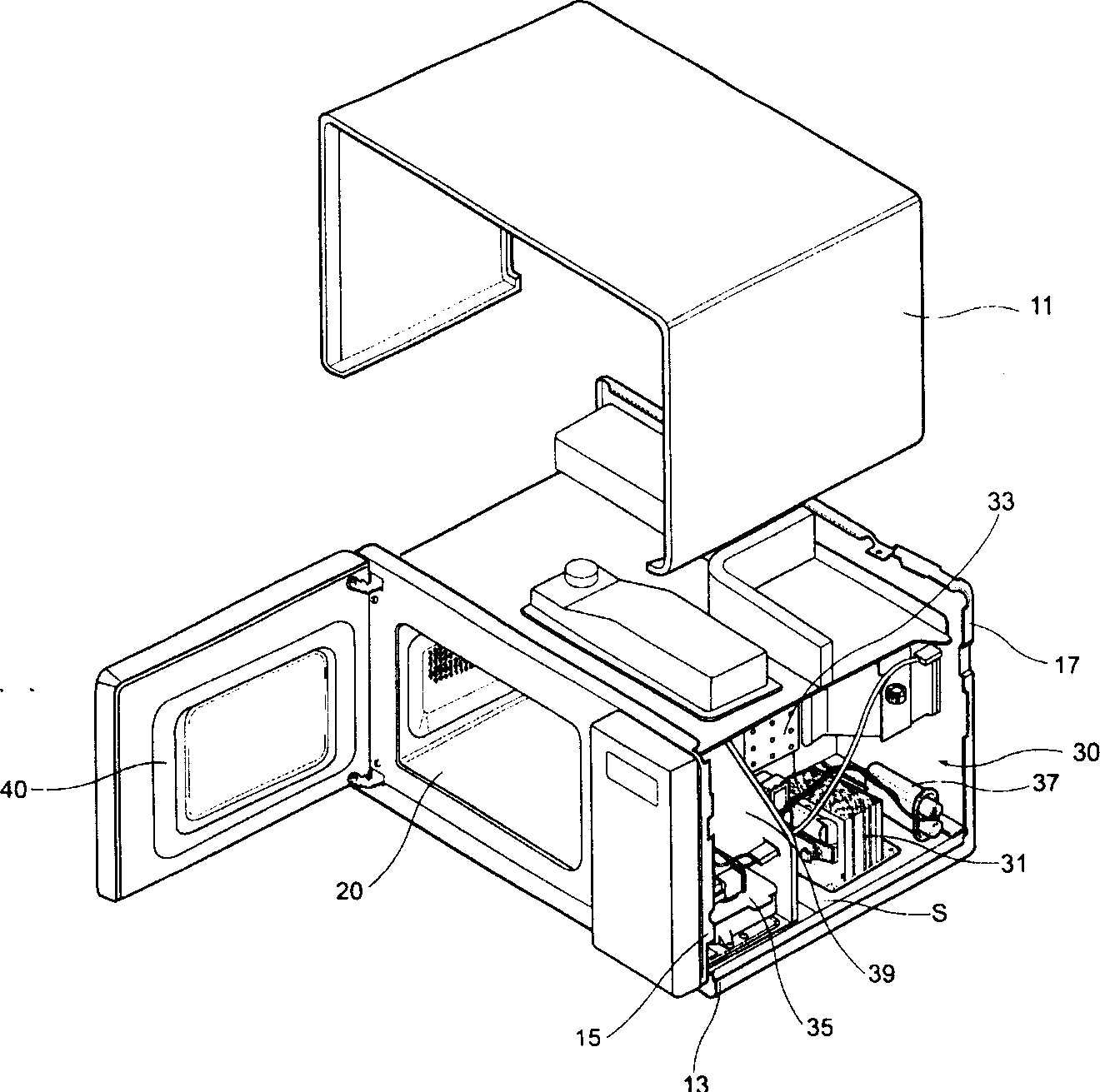

[0041] The microwave oven includes an outer casing forming an appearance, a cavity for placing food, and a storage room for controlling various electronic components for controlling the cavity. A door for selectively opening and closing the inner space of the oven cavity is provided in front of the oven cavity, and the door uses a hinge assembly on the back of the front panel to selectively open and close the oven cavity.

[0042] Such as image 3 as well as Figure 4 As shown, a hin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com