Electronic dust-collecting filter of air purifier

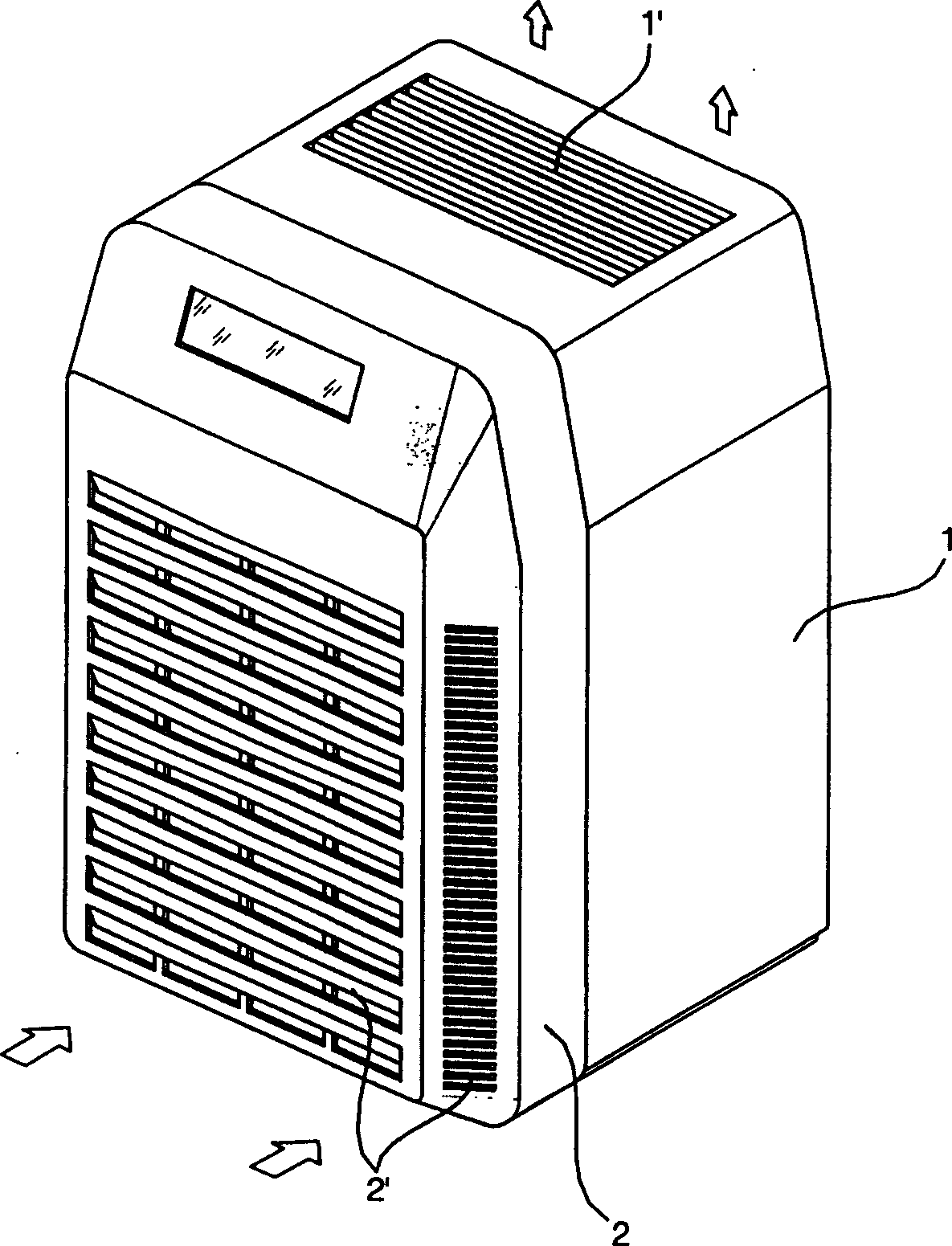

An air purifier, electronic technology, applied in the direction of chemical instruments and methods, heating methods, air conditioning systems, etc., can solve the problems of long production process, lower adsorption efficiency, complex structure of collection devices, etc., and achieve simplification of manufacturing engineering and improvement The effect of air freshening efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

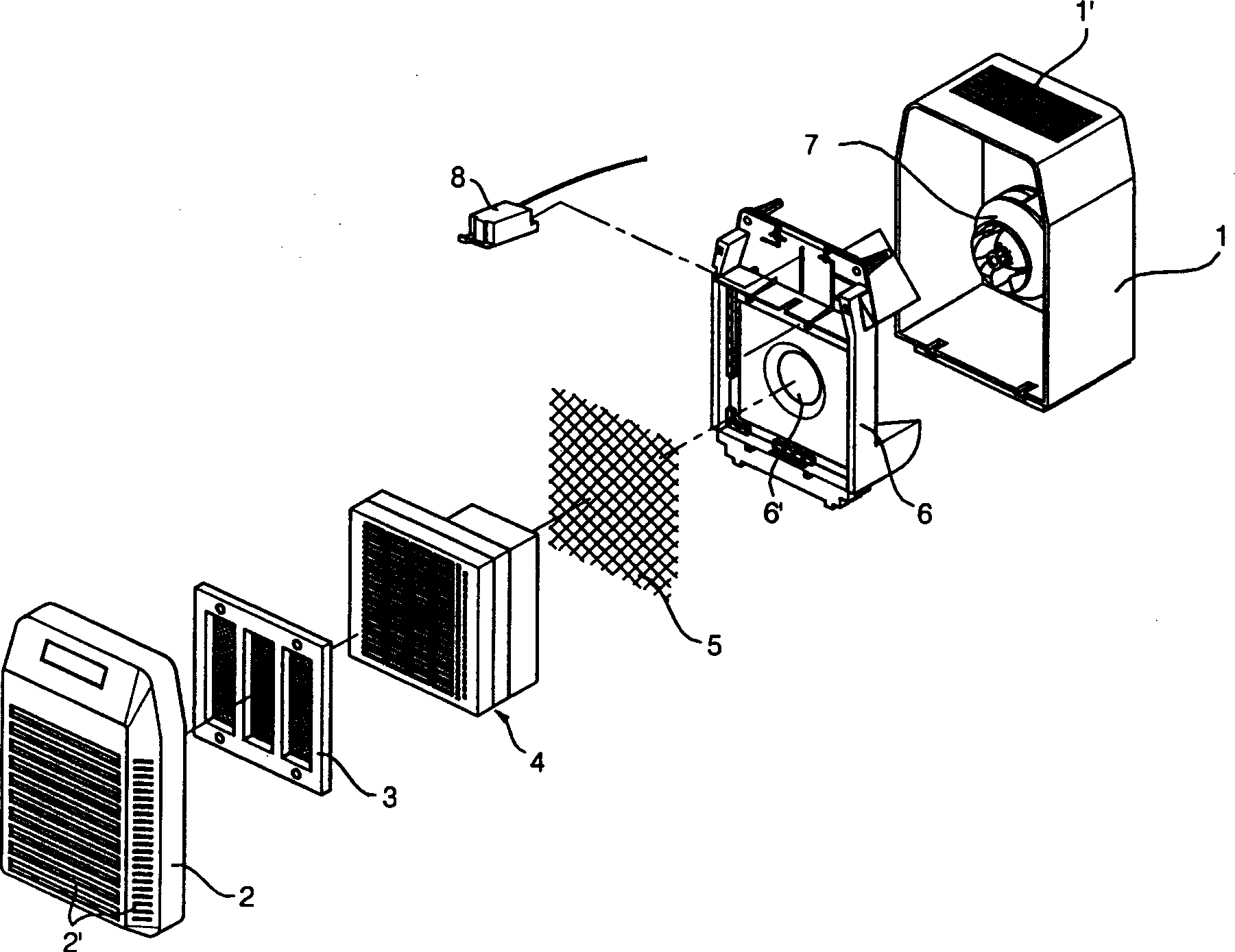

[0034] Embodiments of the present invention will be described below with reference to the accompanying drawings.

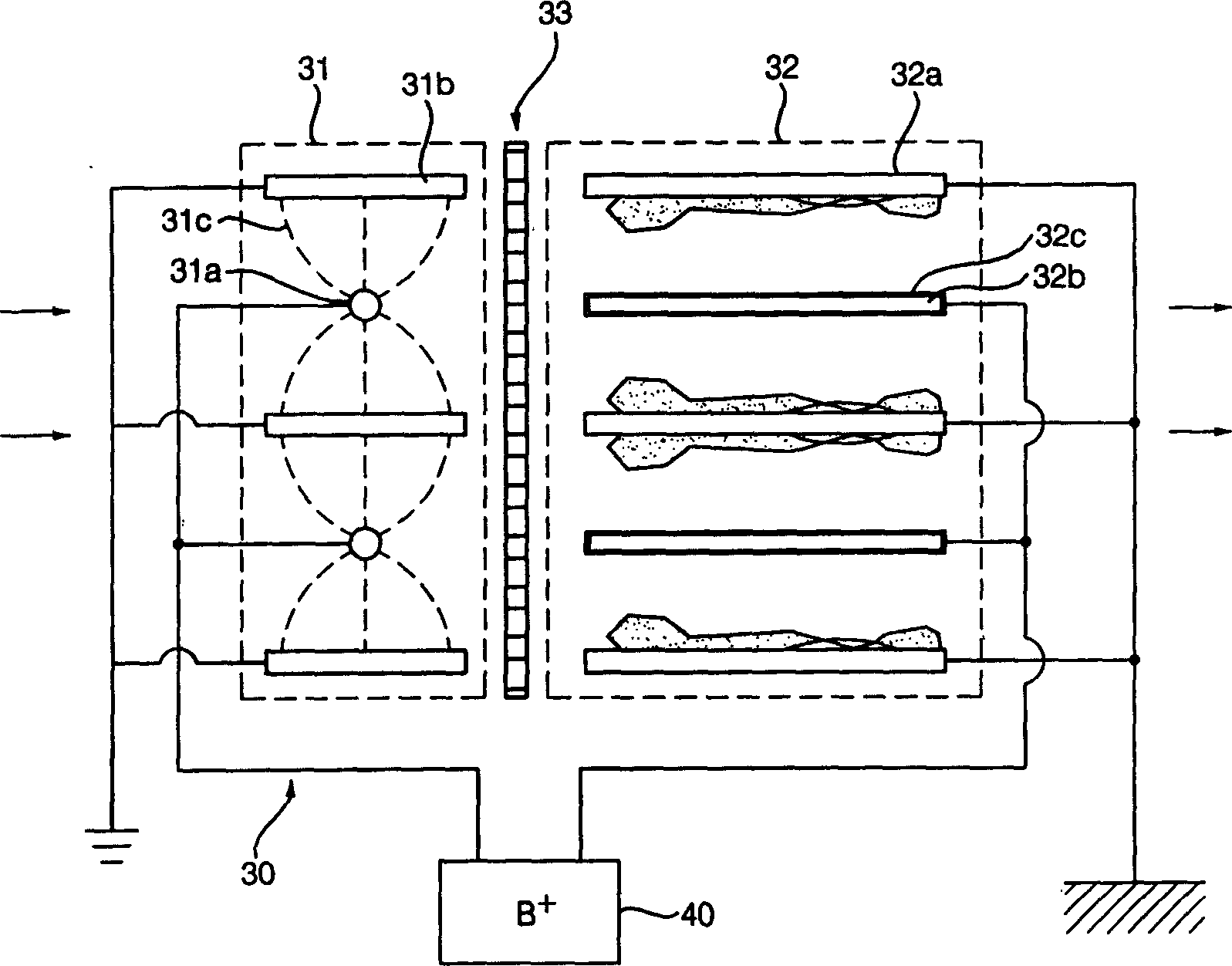

[0035] like Figure 4As shown, the electronic dust collection filter of the air cleaner of the present invention generally includes an ionization component 51, a collection device 52, a metal mesh 53 and a casing. The above-mentioned ionization component 51 utilizes high voltage to charge the fine dust contained in the air when it passes through the ionization component; the above-mentioned collection device 52 is arranged behind the above-mentioned ionization component 51, connected to the ground wire or applied with a high voltage of -3.5kV, The charged dust is adsorbed; the metal mesh 53 is arranged between the ionization component 51 and the collection device 52, and connected to the ground wire; the casing supports the ionization component 51, the collection device 52 and the metal mesh 53 respectively.

[0036] The ionization member 51 is composed of a line...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com