Reaction kettle with automatic cleaning function for coating processing

An automatic cleaning and reaction kettle technology, which is applied to mixers with rotating containers, dissolvers, mixers, etc., can solve the problems of wasting finished products, high cleaning difficulty, and not easy to clean, so as to reduce the setting of mechanical parts, Reduce the difficulty of cleaning and improve the effect of paint collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

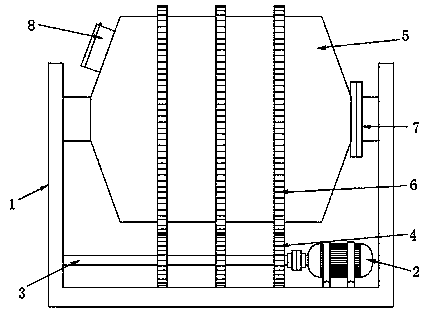

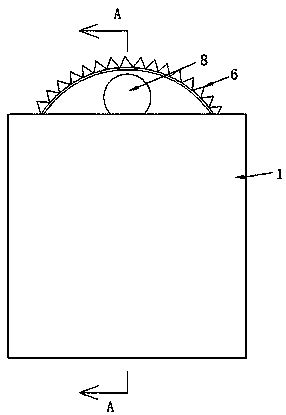

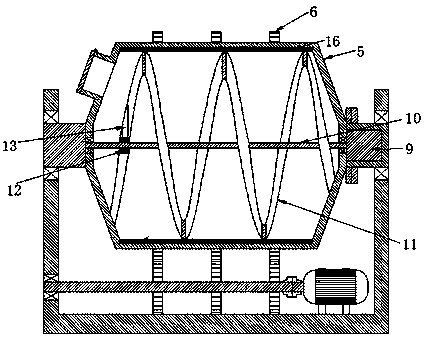

[0025] Such as Figure 1-Figure 5 As shown, this specific embodiment adopts the following technical scheme: it includes a base 1, a rotary drive motor 2, a rotating shaft 3, a driving gear 4, a reactor body 5, a gear ring 6, a flange 7, a feed port 8, a translation drive Motor 9, screw rod 10, elastic metal ring piece 11, screw nut 12, connecting rod 13, strong magnetic ring 16; the bottom plate of the base 1 is fixed with a rotating drive motor 2 (forward and reverse motor, the specific model is not limited) , selected according to actual production needs), the output shaft of the rotating drive motor 2 is connected to the rotating shaft 3 by a coupling, and the other end of the rotating shaft 3 is screwed into one of the side plates of the base 1 by a bearing; the rotating shaft 3 is connected to three Drive gear 4, each drive gear 4 is meshed with a gear ring 6, and the three gear rings 6 are set and welded on the outer ring wall of the reactor body 5, and the two ends of t...

specific Embodiment approach 2

[0035] see Image 6 The difference between this embodiment and Embodiment 1 is that: the inner ring surface of the elastic metal ring piece 11 is integrally formed with a cutting edge 15, and the rest of the structural connections are the same as Embodiment 1. This embodiment Method When stirring, the elastic metal ring piece 11 is stretched to the maximum by using the translational drive motor 9. During the stirring process, the setting of the cutting edge 15 provides shear stress for the paint in the rotating process and improves the mixing efficiency.

specific Embodiment approach 3

[0037] see Figure 7 The difference between this specific embodiment and specific embodiment 1 is that: the inner wall of the reactor body 5 is integrally formed with ribs 5-1, and the elastic metal ring piece 11 is integrally formed with several ribs 11 -1, the rib 11-1 is clamped on the rib 5-1; the rest of the structural connection relationship is the same as that of the specific embodiment 1, and the rib 5-1 in this specific embodiment can be rotated in the process of stirring The paint provides resistance, increases turbulence, and improves mixing uniformity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com