Steel slag pervious concrete

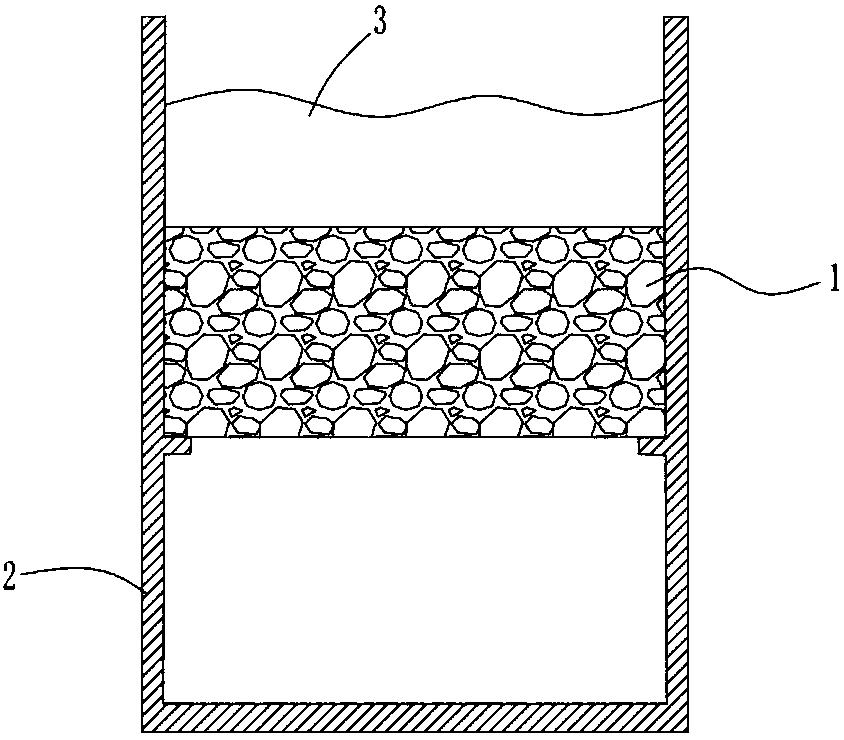

A permeable concrete and steel slag technology, applied in the field of steel slag permeable concrete, can solve the problems of weakening the function of the reservoir, achieve the effect of increasing the rate, reducing the amount of residual water, and improving the collection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

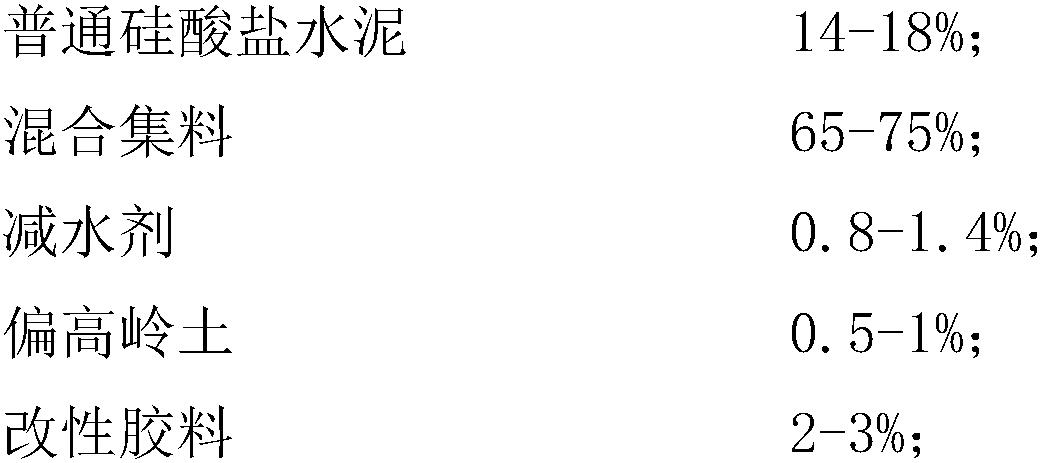

[0033] A steel slag permeable concrete with a total weight of 1 ton, including:

[0034] Ordinary Portland cement (strength grade 42.5, the same below) 140kg;

[0035] Mixed aggregate 650kg (steel slag (Deton Mining, the same below) 333kg, gravel (Deton Mining, the same below) 317kg);

[0036] Polycarboxylate water reducer (Minghuang Technology MH-JS-102, the same below) 8kg;

[0037] Metakaolin (Rongtai Chemical, the same below) 5kg;

[0038] Modified rubber 20kg (silicone modified polyacrylate (Jianmeng Chemical KR-9706, the same below) 9.2kg and styrene-butadiene rubber emulsion (Haiyun Building Materials T2535L, the same below) 10.8kg);

[0039] Calcium carbonate powder (Shenghaiyuan new material HY-8016, the same below) 2kg;

[0040] 175kg of water.

[0041] Performance test: The steel slag permeable concrete in Example 1 is made into concrete bricks, and the following performance indicators are obtained according to the GB28635-2012 test method:

[0042]

[0043]...

Embodiment 2

[0050] Replace 9.2 kg of silicone-modified polyacrylate in Example 1 with 9.2 kg of organic fluorine-modified polyacrylate (Rieter resin LD-1084), and the rest are the same as in Example 1.

Embodiment 3

[0052] A steel slag permeable concrete with a total weight of 1 ton, including:

[0053] Ordinary Portland cement (strength grade 42.5) 140kg;

[0054] Mixed aggregate 650kg (steel slag (Deton Mining) 333kg, gravel (Deton Mining) 317kg);

[0055] Polycarboxylate water reducer (Minghuang Technology MH-JS-102) 8kg;

[0056] Metakaolin (Rongtai Chemical) 5kg;

[0057] Modified rubber 20kg (silicone modified polyacrylate (Jianmeng Chemical KR-9706) 9.2kg and styrene-butadiene rubber emulsion (Haiyun Building Materials T2535L) 10.8kg);

[0058] Calcium carbonate powder (Shenghaiyuan new material HY-8016) 2kg;

[0059] Straw powder 3kg;

[0060] 172kg of water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com