Beating sleeve for cantilever screen

A cantilever and sleeve technology, applied in the direction of filter screen, solid separation, grille, etc., can solve the problems of not being able to achieve the anti-clogging effect, achieve the effect of highlighting the substantive characteristics, making significant progress, and improving the anti-clogging effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to clearly illustrate the technical characteristics of the two schemes, the two schemes are described below through a specific implementation mode and in conjunction with the accompanying drawings.

[0013] The first technical solution:

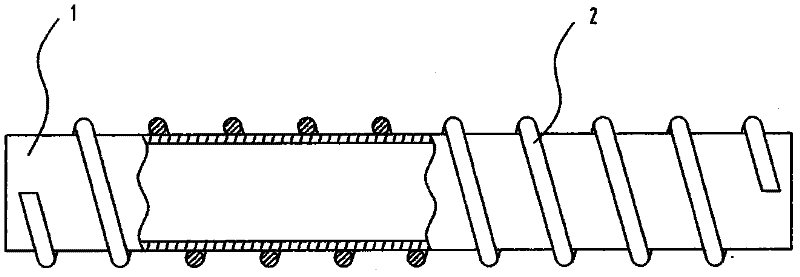

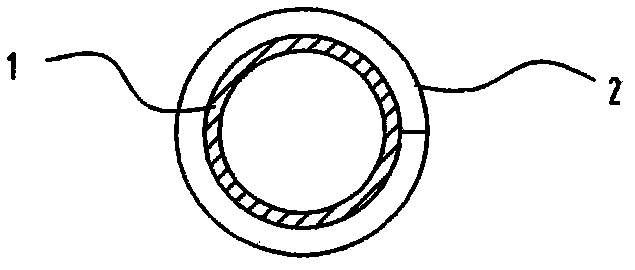

[0014] by attaching figure 1 with 2 It can be seen that the impact sleeve for the cantilever screen of this program has a cylindrical barrel-shaped impact sleeve body 1. In this program, there is a spiral protrusion on the outer surface of the impact sleeve body 1, and the height of the spiral protrusion is 3-10mm, the pitch is 10-30mm. It is also possible to have a fixed helical spring 2 on the outer surface of the striking sleeve 1, the diameter of the helical spring 2 is 3-10 mm, preferably 6 mm, and the pitch is 10-30 mm. What this concrete examination mode adopts is to have fixed helical spring 2 on the outer surface of percussion cover body 1, and described helical spring 2 diameter is 6 millimeters, and pitch is 18 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com