LCD panel, its manufacture method and LCD device using the same

A liquid crystal display panel, panel technology, applied in static indicators, nonlinear optics, instruments, etc., can solve the problems of complex driving voltage waveform and driving circuit, low yield, etc., to improve the viewing angle characteristics, simplify manufacturing engineering, The effect of increasing the elastic space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

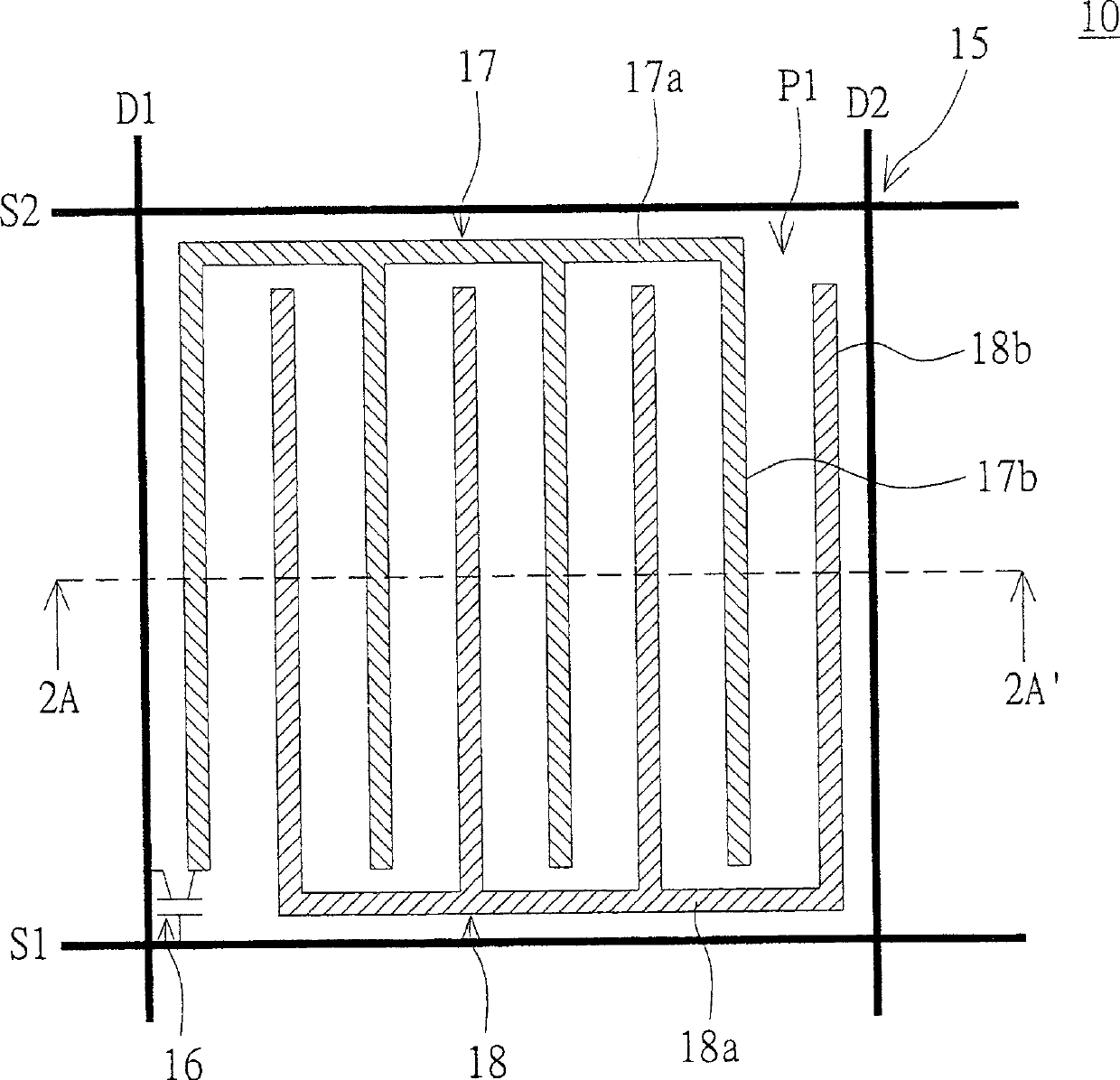

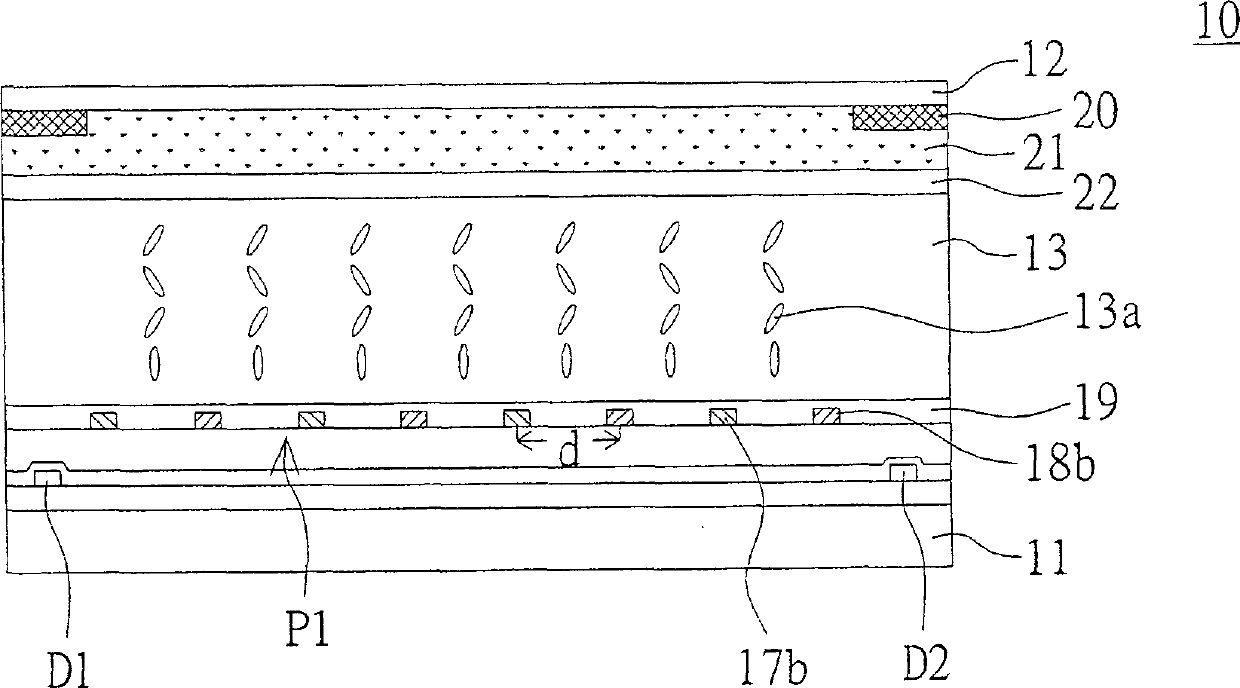

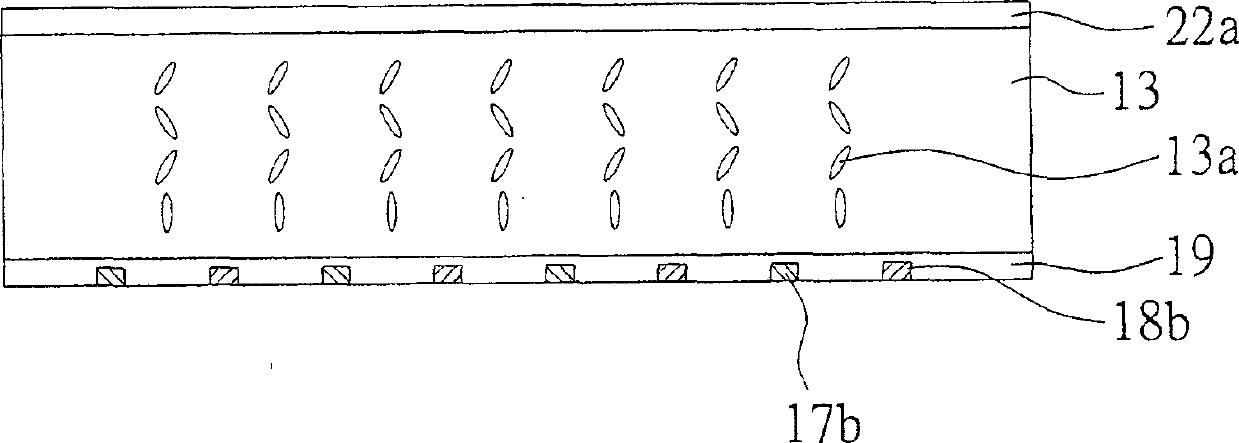

[0055] Please also refer to Figures 1 to 2A , figure 1 A schematic top view showing the circuit structure of the liquid crystal display panel according to the first embodiment of the present invention, Figure 2A Draw along figure 1 A schematic diagram of a partial cross-sectional structure of the liquid crystal display panel viewed from the section line 2A-2A'. exist Figures 1 to 2A The liquid crystal display panel 10 includes an active matrix 15 , a first electrode 17 , a second electrode 18 , a first vertical alignment film 19 , a second vertical alignment film 22 and a smectic liquid crystal layer 13 . The active matrix 15 has one or more switch elements and one or more pixels, and is disposed on the first substrate 11 . Each pixel is defined by the interval between two adjacent scan lines (or gate lines) and two adjacent data lines (or source lines) disposed on the first substrate 11 . In this embodiment, the active matrix 15 is illustrated by taking the pixel P1 a...

Embodiment 2

[0078] Please also refer to 8A to 8B , which shows a schematic diagram of a partial cross-sectional structure of the liquid crystal display panel according to the second embodiment of the present invention. The difference between the liquid crystal display panels 10 a to 10 b of the present embodiment and the liquid crystal display panel 10 of the first embodiment is that there is only a vertical alignment film. As for other identical constituent elements, the reference numerals will continue to be used, and will not be repeated.

[0079] like Figure 8AAs shown, the liquid crystal display panel 10a has only the first vertical alignment film 19 with strong anchoring energy, but does not have the second vertical alignment film 22, so that the anchoring energy provided by the second substrate 12 relative to the smectic liquid crystal layer 13 is almost Zero, not even. Therefore, the layer of liquid crystal molecules 13a of the smectic liquid crystal layer 13 adjacent to the ...

Embodiment 3

[0086] Please refer to Figure 10 , which shows a schematic diagram of a partial cross-sectional structure of the liquid crystal display panel according to the third embodiment of the present invention. The difference between the liquid crystal display panel 40 of the present embodiment and the liquid crystal display panel 10 of the first embodiment lies in the position of the color filter 41 . The rest of the same constituent elements continue to use the labels, and will not be repeated.

[0087] like Figure 10 As shown, the color filter 41 is disposed between the first substrate 11 and the first vertical alignment film 19 . In this embodiment, the color filter 41 covers the first electrode 17 and the second electrode 18 , here Figure 10 Only the color filter 41 is shown covering the first electrode portion 17 b of the first electrode 17 and the second electrode portion 18 b of the second electrode 18 . The first vertical alignment film 19 covers the color filter 41 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com