Manufacturing method of strengthed glass for touch panel

A technology of tempered glass and manufacturing method, applied in glass manufacturing equipment, glass tempering, glass production and other directions, can solve the problems of reduced operation rate and production efficiency, lengthened construction period, waste of materials, etc., to improve production efficiency and product quality, The effect of improving production efficiency and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

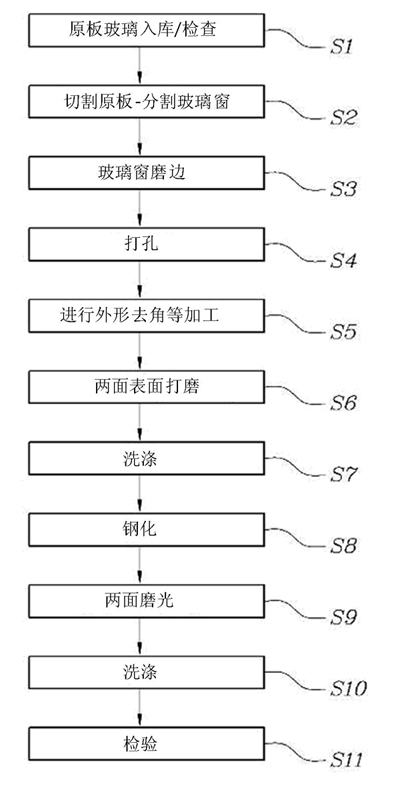

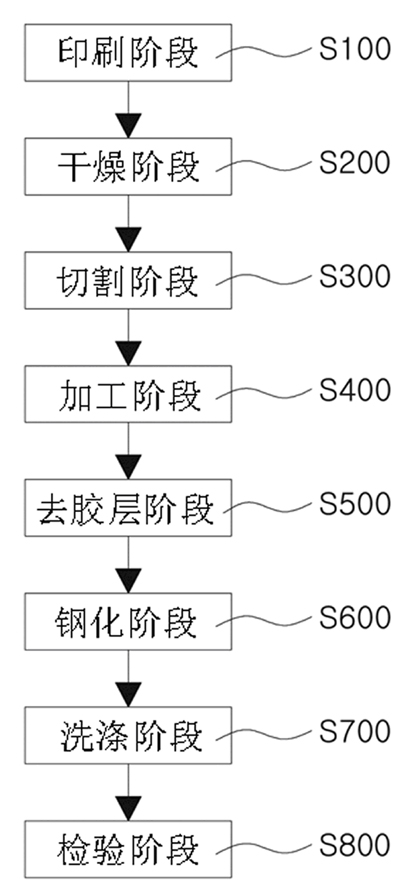

[0016] Fig. 2 is a flow chart of the manufacturing method of the tempered glass used in the touch screen according to the present invention. As shown in Fig. 2, the manufacturing method engineering of tempered glass for touch screen of the present invention includes printing stage (step S100), drying stage (step S200), cutting stage (step S300), processing stage (step S400), debonding layer stage (step S500 ), tempering stage (step S600 ), washing stage (step S700 ) and inspection stage (step S800 ).

[0017] The printing stage (step S100 ) is the stage of painting both sides of the original plate glass in the warehouse with peelable ink; the peelable ink contains epoxy resin, pigment, additive and solvent.

[0018...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com