Electric heating mirror and its producing method

A manufacturing method and electric heating technology, which can be applied to transparent/reflective heating devices, conductive pattern formation, etc., can solve the problems of increased manufacturing cost, environmental pollution, easy residual hydrochloric acid and alkaline components, etc., and achieve simple manufacturing engineering and reduce manufacturing costs. effect of cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

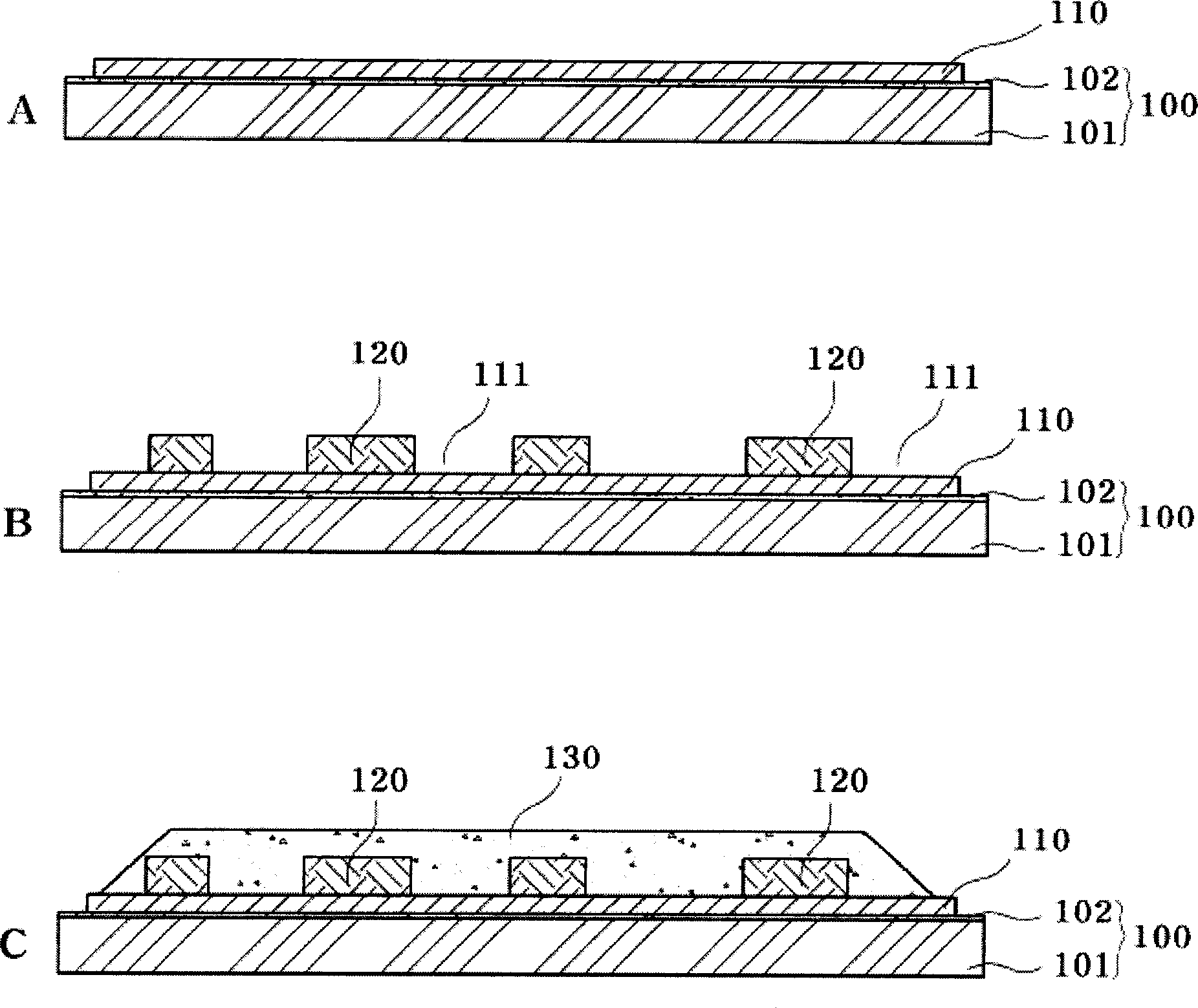

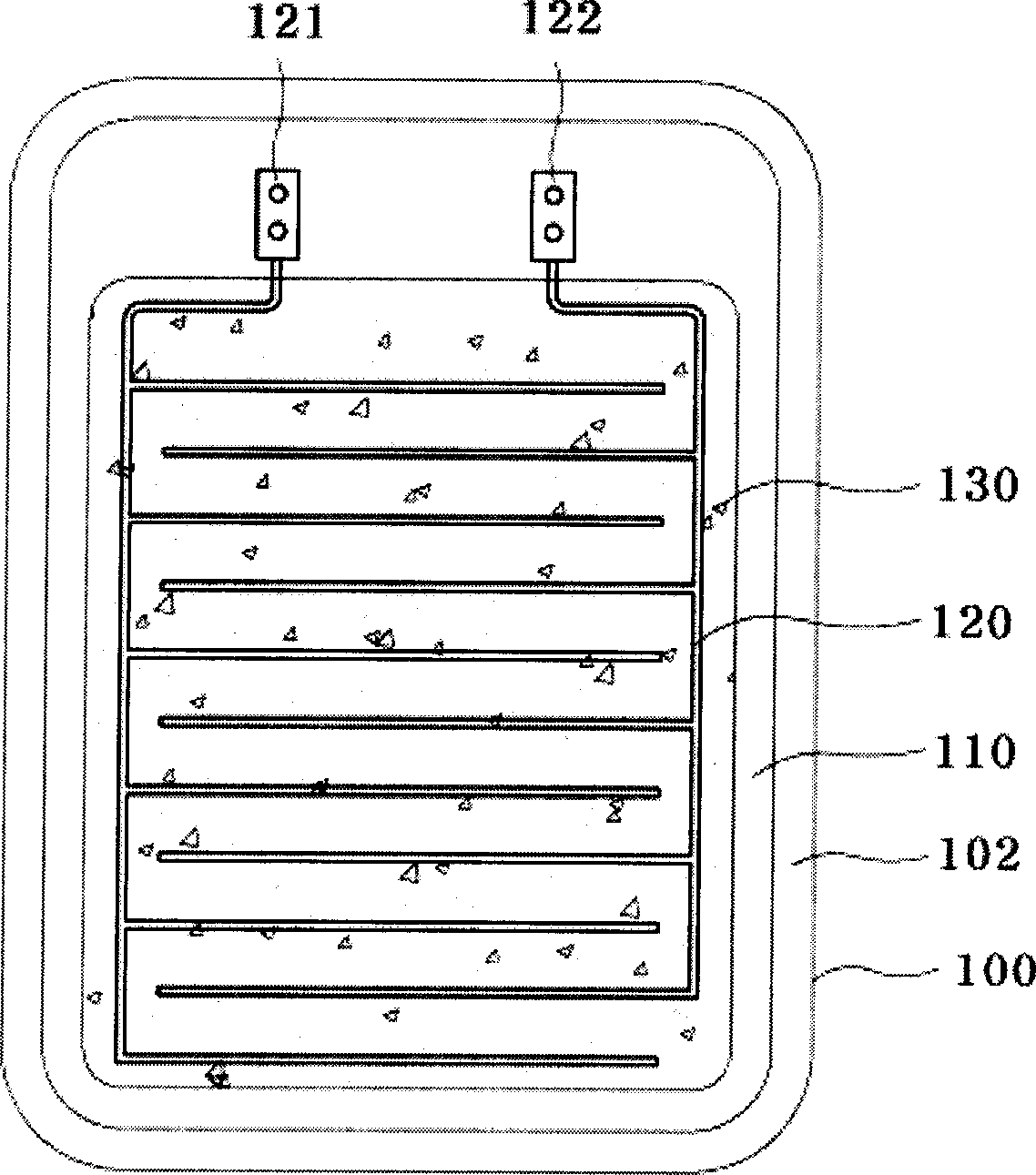

[0021] Example 1, figure 1 It is the engineering diagram of the manufacturing method of the PTC type electric heating mirror. An electric heating mirror (100) is formed by covering the metal surface (102) on the back of the glass (101).

[0022] Depend on figure 1 , figure 2 As shown, the glass plate (101) is prepared according to the specifications and sizes required by the electric heating mirror, and the covering surface (102) is formed with metals such as nickel, aluminum, chromium, etc. on the back of the glass plate (101), and epoxy resin is generally used on it. A series of insulating inks etc. form an insulating layer (110) (reference figure 1 A), after the insulating layer (110) is formed, use conductive inks such as carbon liquid, aluminum, copper, silver, gold ink, after the circuit line (120) of specific shape is directly printed on the insulating layer (110) and dried ( refer to figure 1 B), at this time, the above-mentioned circuit line (120) can be formed ...

Embodiment 2

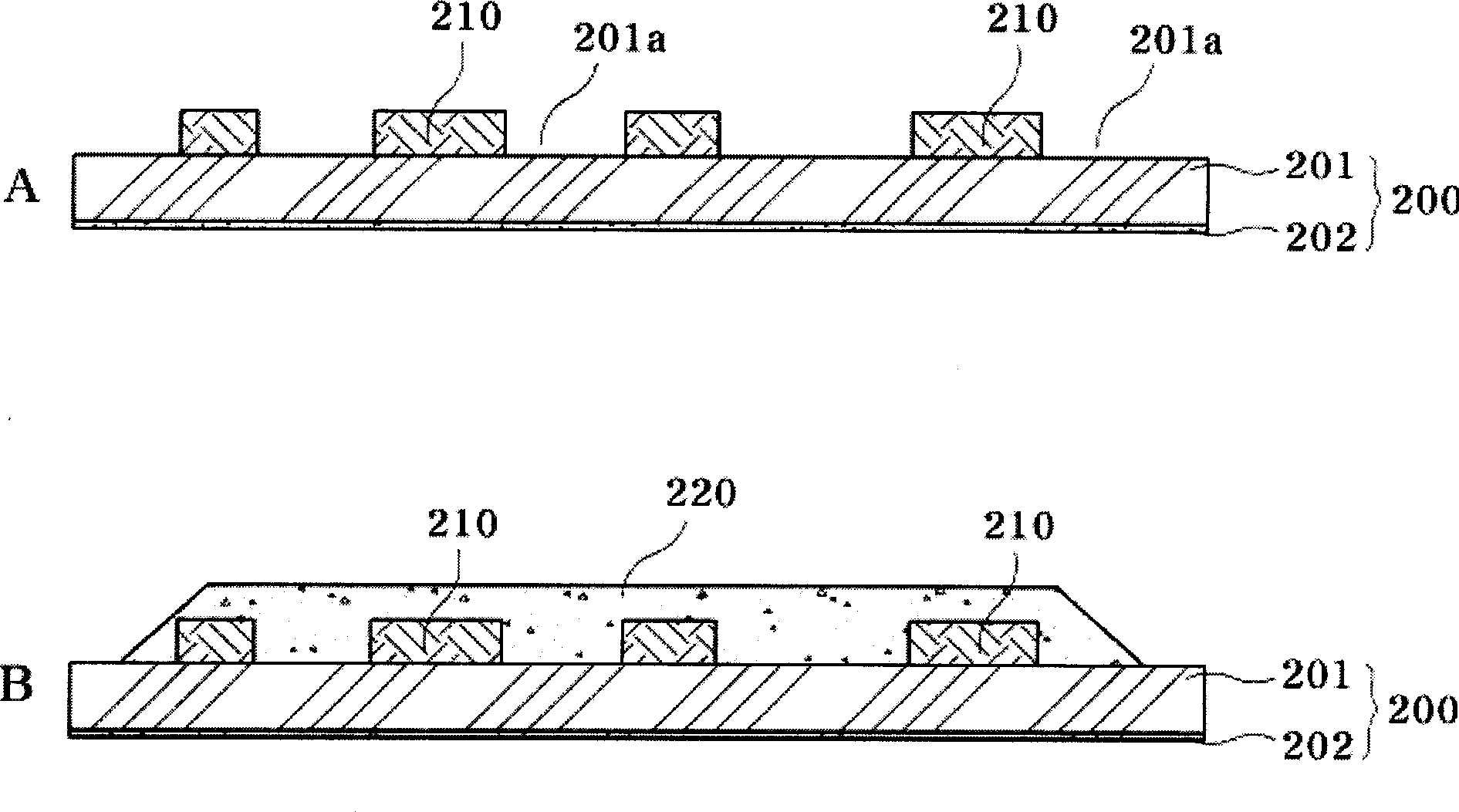

[0025] Example 2, image 3 It is an engineering drawing of the manufacturing method of the PTC type electric heating mirror. This method is applicable to the electrically heated mirror (200) formed on the glass (201) front surface with a metal covering surface (202).

[0026] Depend on image 3 , Figure 4 As shown, according to the required regulations, prepare a glass plate (201) with a specific size and shape, form a covering surface (202) with metal on the front of the glass (201), and use conductive inks such as carbon liquid, aluminum, copper, silver, and gold ink On the back side (201) of glass (201), directly print and dry by the circuit line (210) of specific shape (refer to image 3 A), at this moment glass plate (201) and Figure 5 The effect of the insulating layer (310) shown is the same, and the above-mentioned circuit line (210) can be formed in a variety of ways, forming the circuit line (210) on the back of the glass (201) and the surface ( 201a), after t...

Embodiment 3

[0029] Example 3, Figure 5 It is the engineering diagram of the manufacturing method of the NON-PTC type electric heating mirror. This method is suitable for the electric heating mirror (300) formed by covering the metal surface (302) on the back of the glass (301).

[0030] Depend on Figure 5 , Image 6 As shown, according to the required regulations, prepare a glass plate (301) according to a specific size and shape, and use nickel, aluminum, chromium and other metals to form a covering surface (302) on the back of the glass plate, and generally use epoxy resin series insulation on it. Ink etc. form the insulating layer (310) (reference Figure 5 A). After the insulating layer (310) is formed, use conductive inks such as carbon liquid, aluminum, copper, silver, and gold ink to directly print and dry according to the circuit line (320) of a specific shape on the insulating layer (310) (refer to Figure 5 B), at this time, the circuit line (320) can be formed in a varie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com