Tire comprising fabric strip

A fabric and strip technology, applied in special tires, tire parts, reinforcement layers of pneumatic tires, etc., can solve the problems of weight reduction and cost saving effect, so as to improve fuel efficiency, reduce rotational resistance, and simplify manufacturing engineering. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example

[0050] (Manufacturing example: Manufacture of fabric strips)

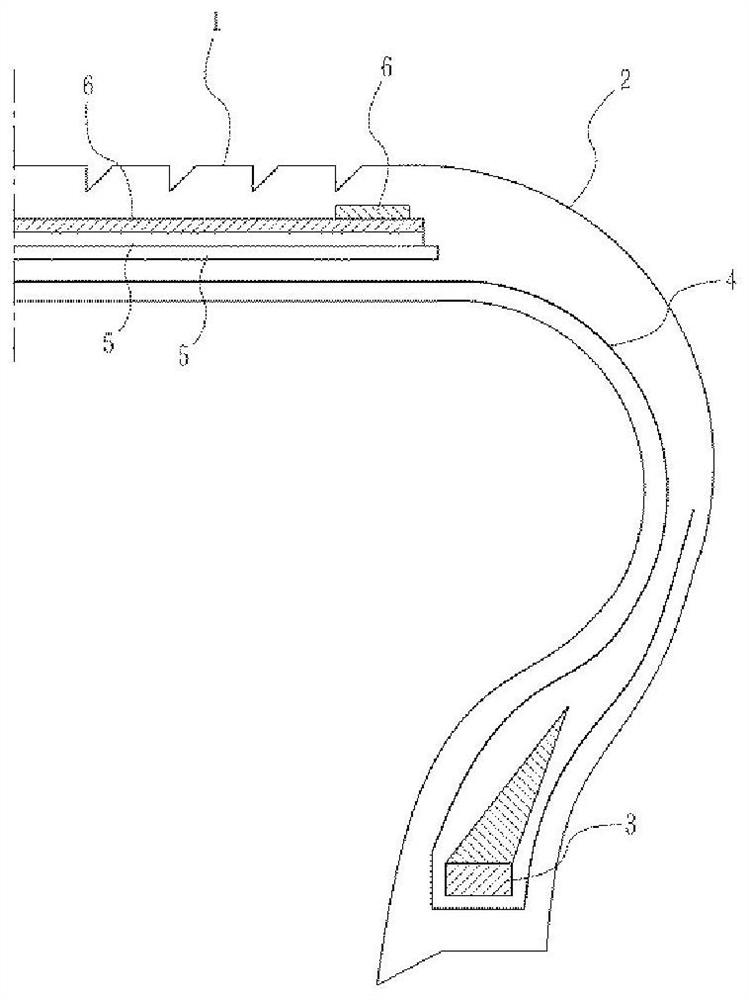

[0051] A comparative test of the existing reinforcing tape structure and the fabric tape of the present invention was carried out using 205 / 55R16 size passenger car tires. The reinforcement tape structure is manufactured by tire rolling, cutting, forming and vulcanization processes, while the fabric strip is formed by tire forming (see Figure 4 ) and the vulcanization process, wherein the manufacturing is carried out according to the general method except that the rolling and cutting processes are omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com