Double-refrigerant pipe evaporator with radiator for electric refrigerator

A heat sink and evaporator technology, applied to evaporators/condensers, refrigerators, refrigeration components, etc., can solve the problems of reducing defrosting efficiency, difficult operation, and hindering the flow of cold air f1, so as to improve heat exchange efficiency, The effect of simplifying the manufacturing process and improving the defrosting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

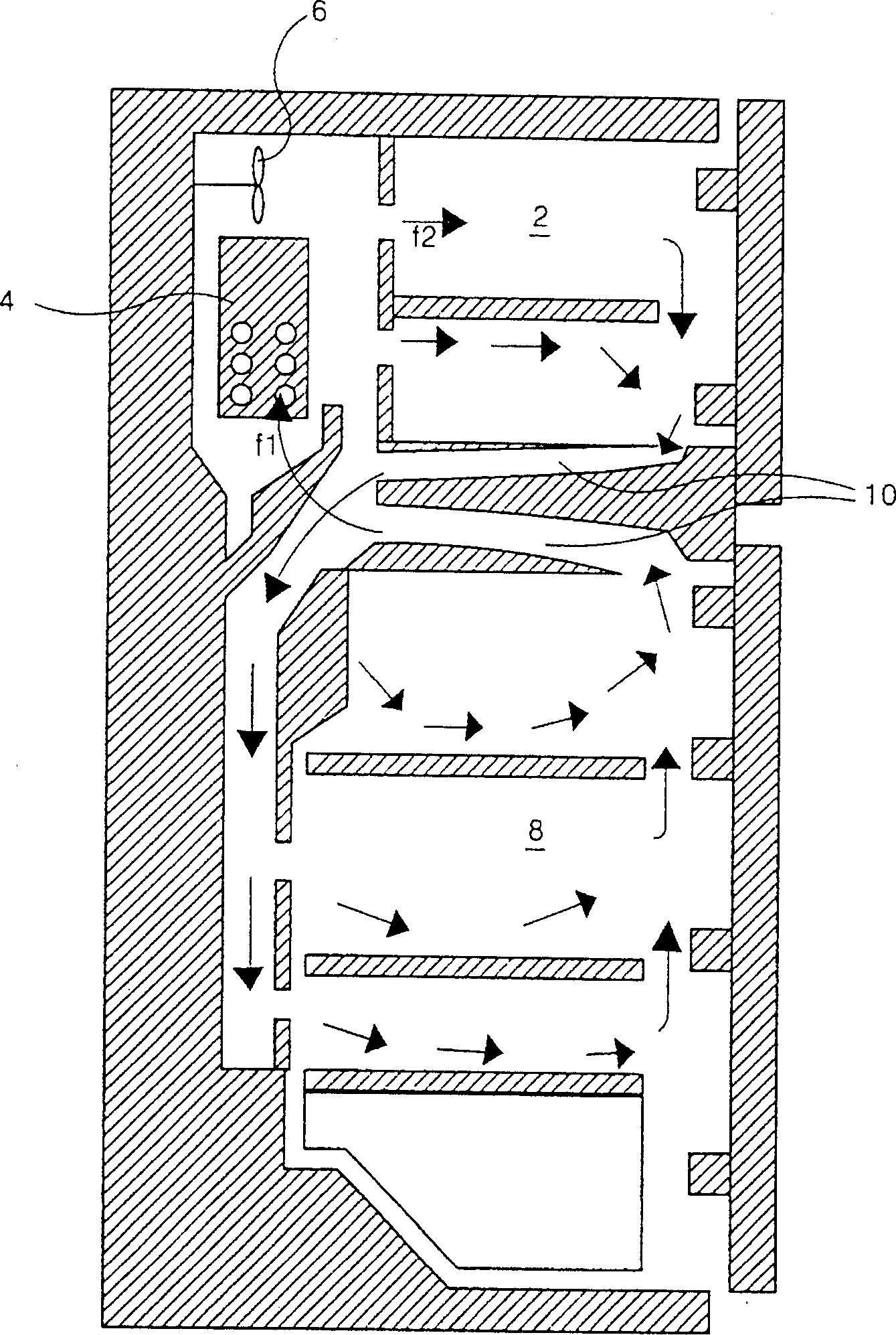

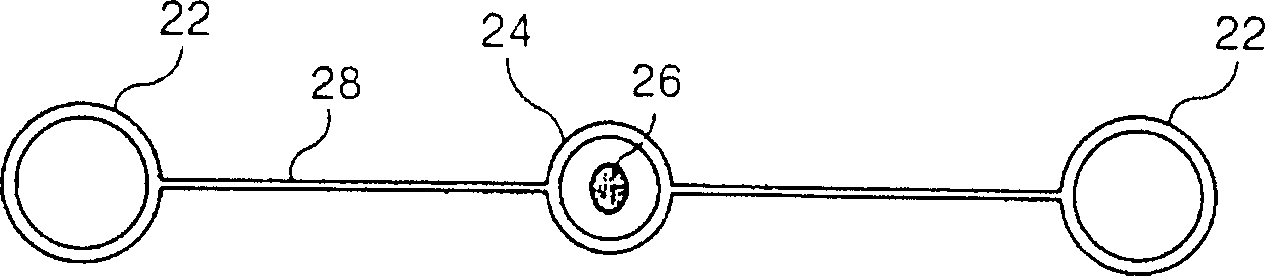

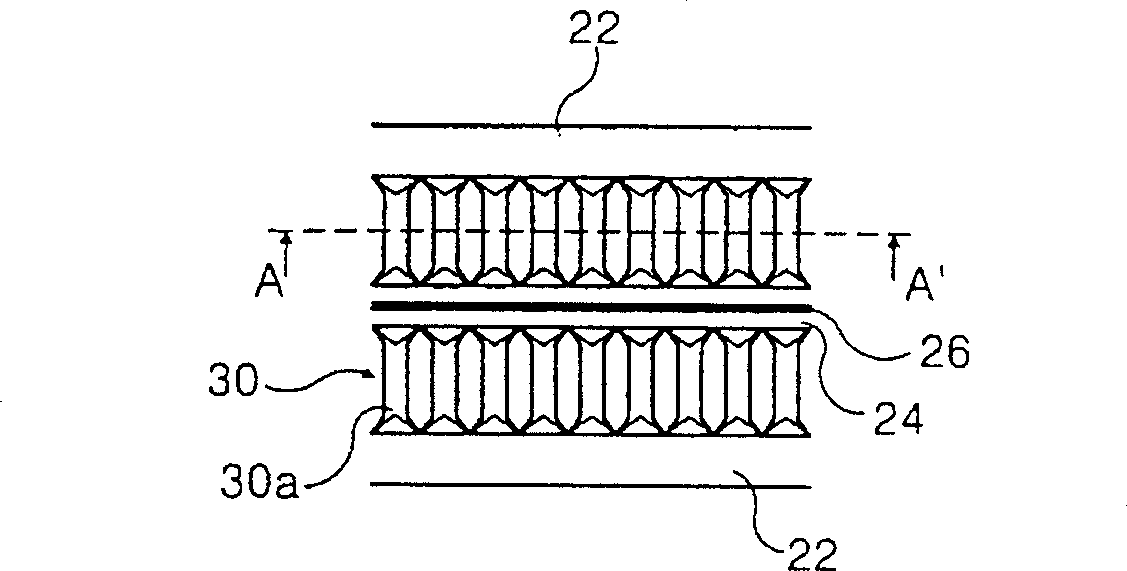

[0034] The evaporator with double refrigerant pipes and cooling fins for refrigerators includes a pair of refrigerant pipes 22 with refrigerant flowing inside, and a grid cooling fin 30 is arranged between the pair of refrigerant pipes 22 and is integrated. The pair of refrigerant pipes The tubes 22 and the louver fins 30 are bent into more than two sections. The louver fin surface 30a is provided parallel to the flow direction of the air flowing into the evaporator 4, and it is preferable to add a defrosting operation heater 64 at the lower end of the evaporator 4.

[0035] According to the present invention, between the grill fins 30 formed between the pair of refrigerant pipes 22, the space for cold air to flow is widened, thereby improving the heat exchange efficiency. Moreover, a defrosting heater 64 is additionally provided at the lower end of the evaporator 4 to improve the defrosting efficiency. And no defrosting pipe is provided between the pair of refrigerant pipes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com