Patents

Literature

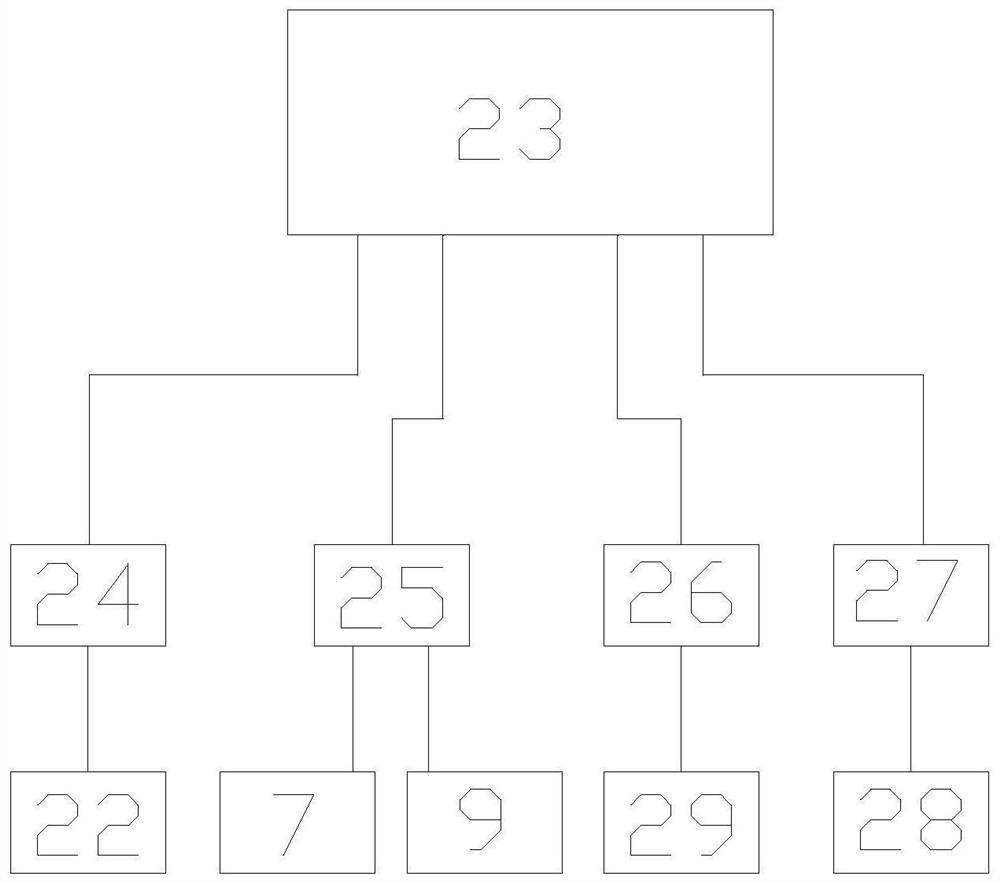

36results about How to "Increase supply speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

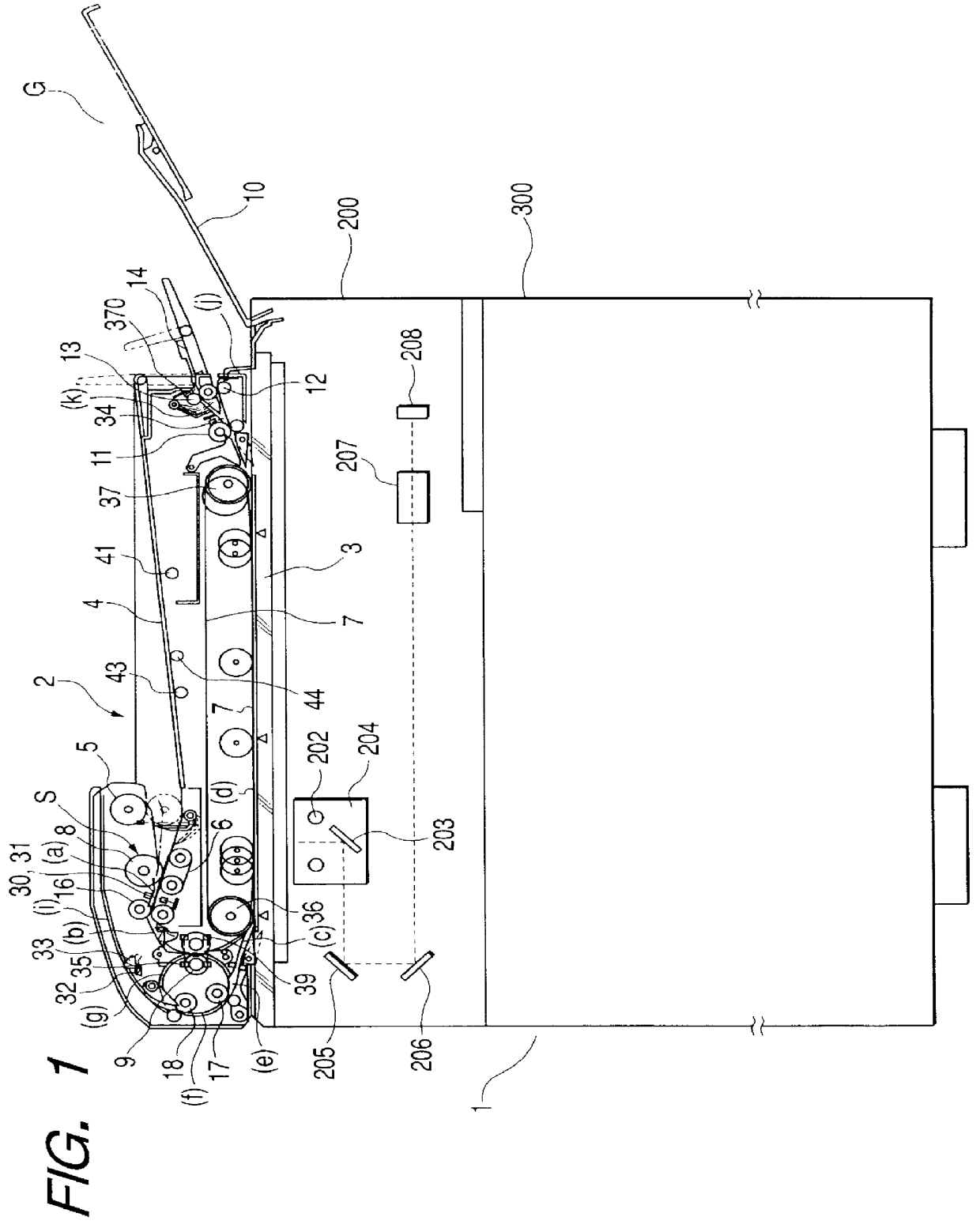

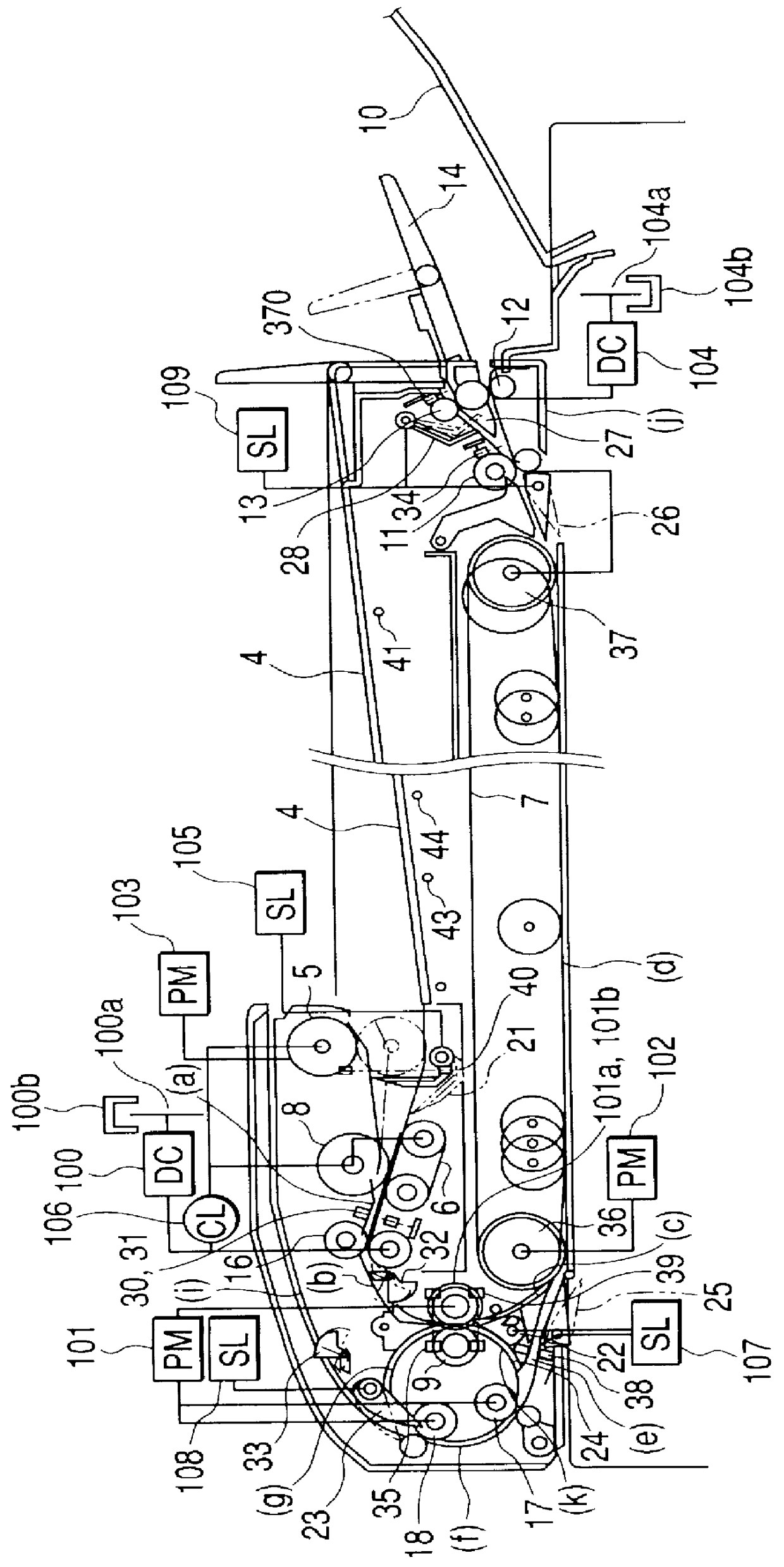

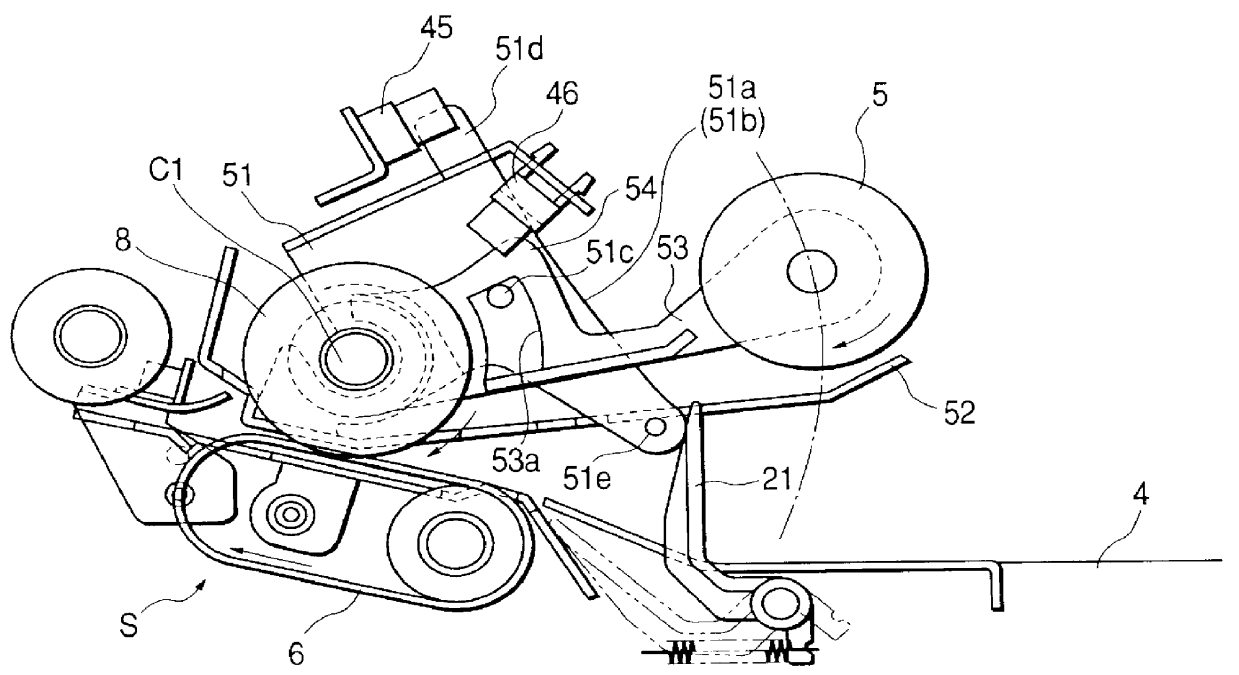

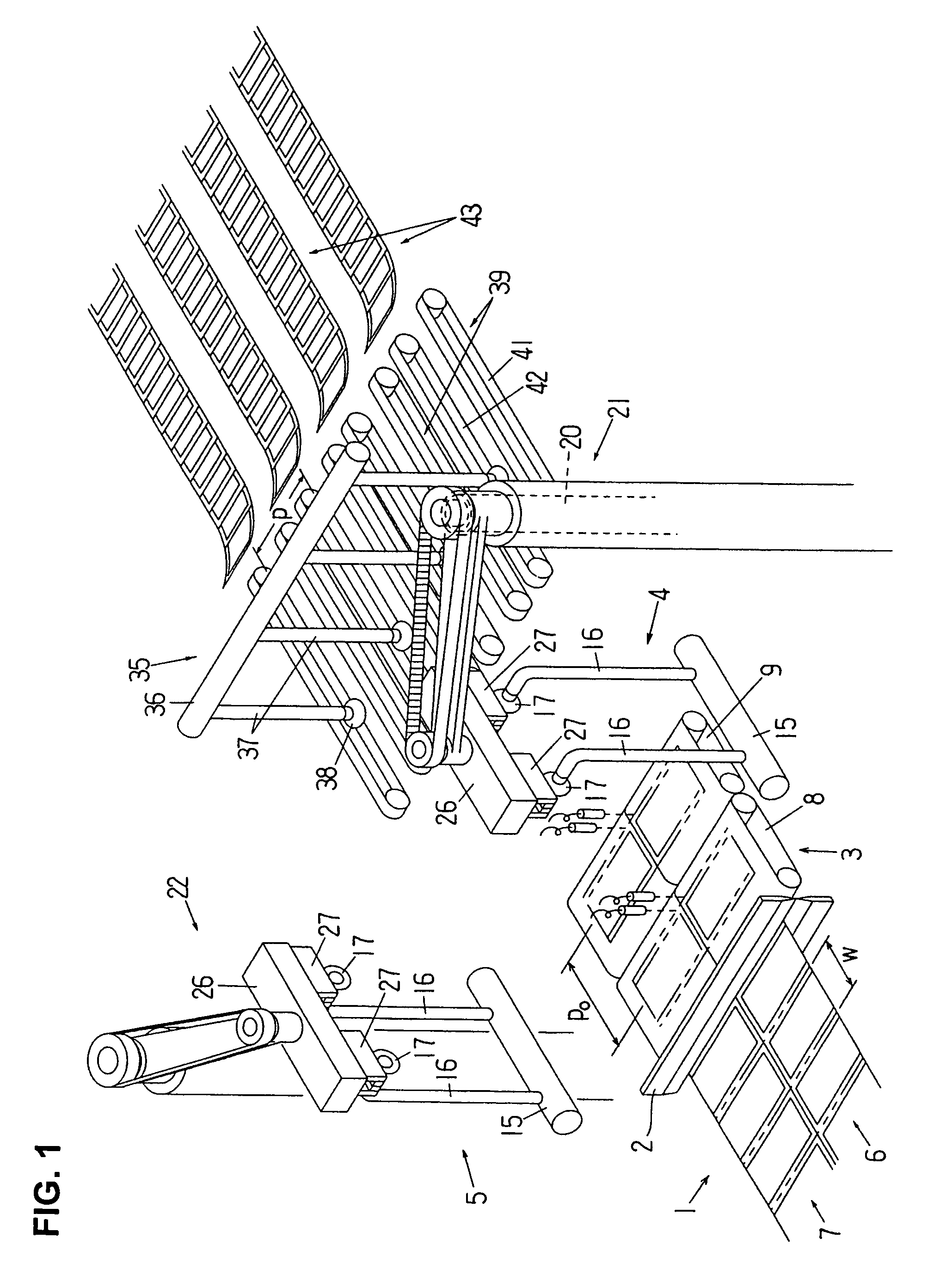

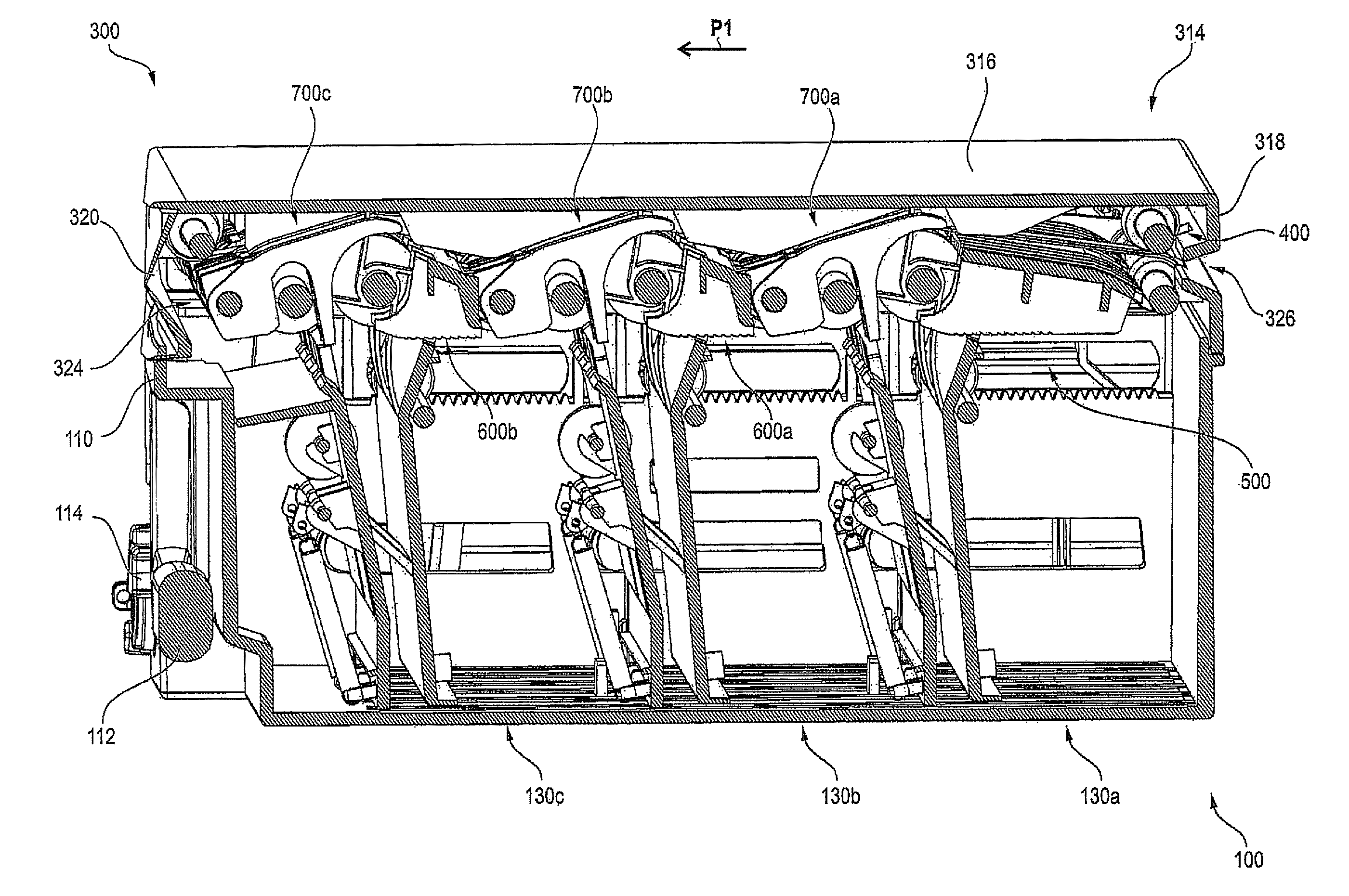

Image forming apparatus

InactiveUS6131898AStop in timeShorten stop timeFunction indicatorsArticle feedersImage formationEngineering

A stack sheet supplying apparatus has a sheet stacking unit, a supply roller for supplying a sheet by contacting with an uppermost sheet in a sheet stack resting on the sheet stacking unit, a lift / lower device for controlling lifting and lower of the supply roller, a drive for driving the lift / lower device, a detector for detecting the fact that the supply roller reaches a supply position after the supply roller is lowered, and a control for turning OFF the drive on the basis of a detected result of the detector.

Owner:CANON KK

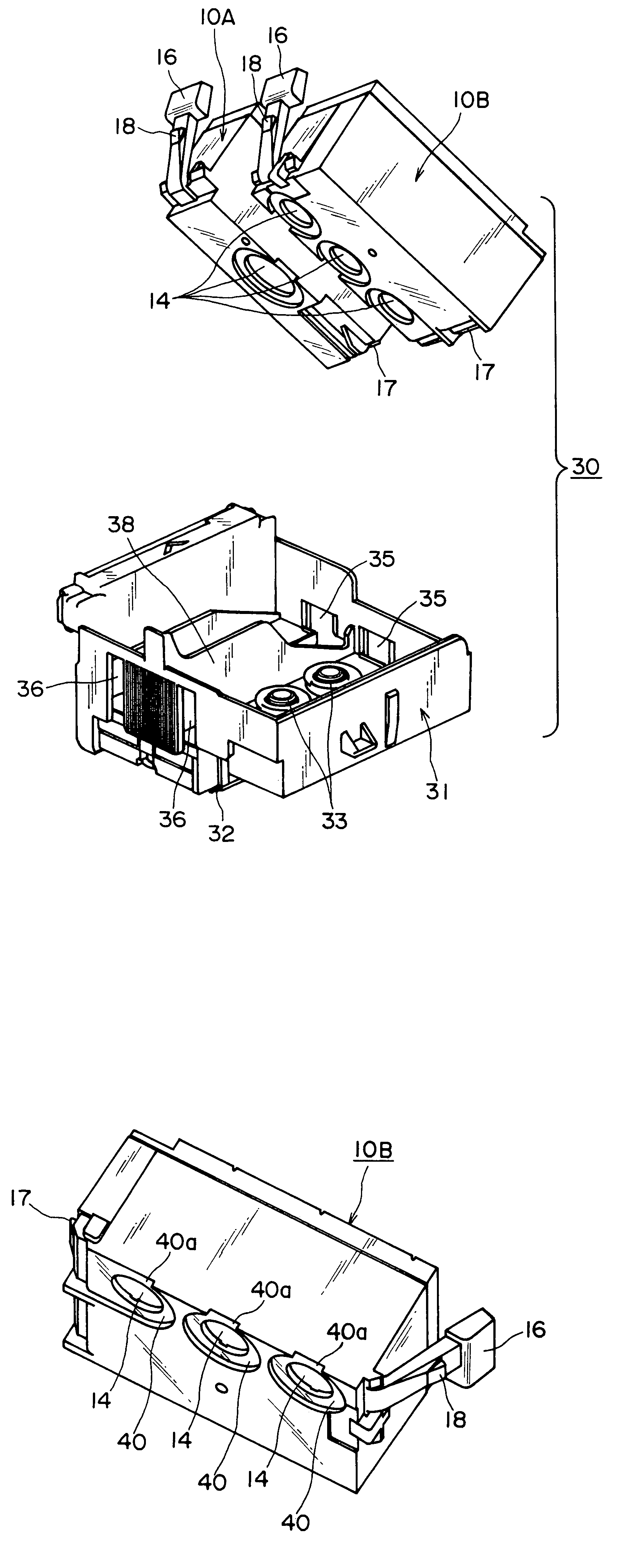

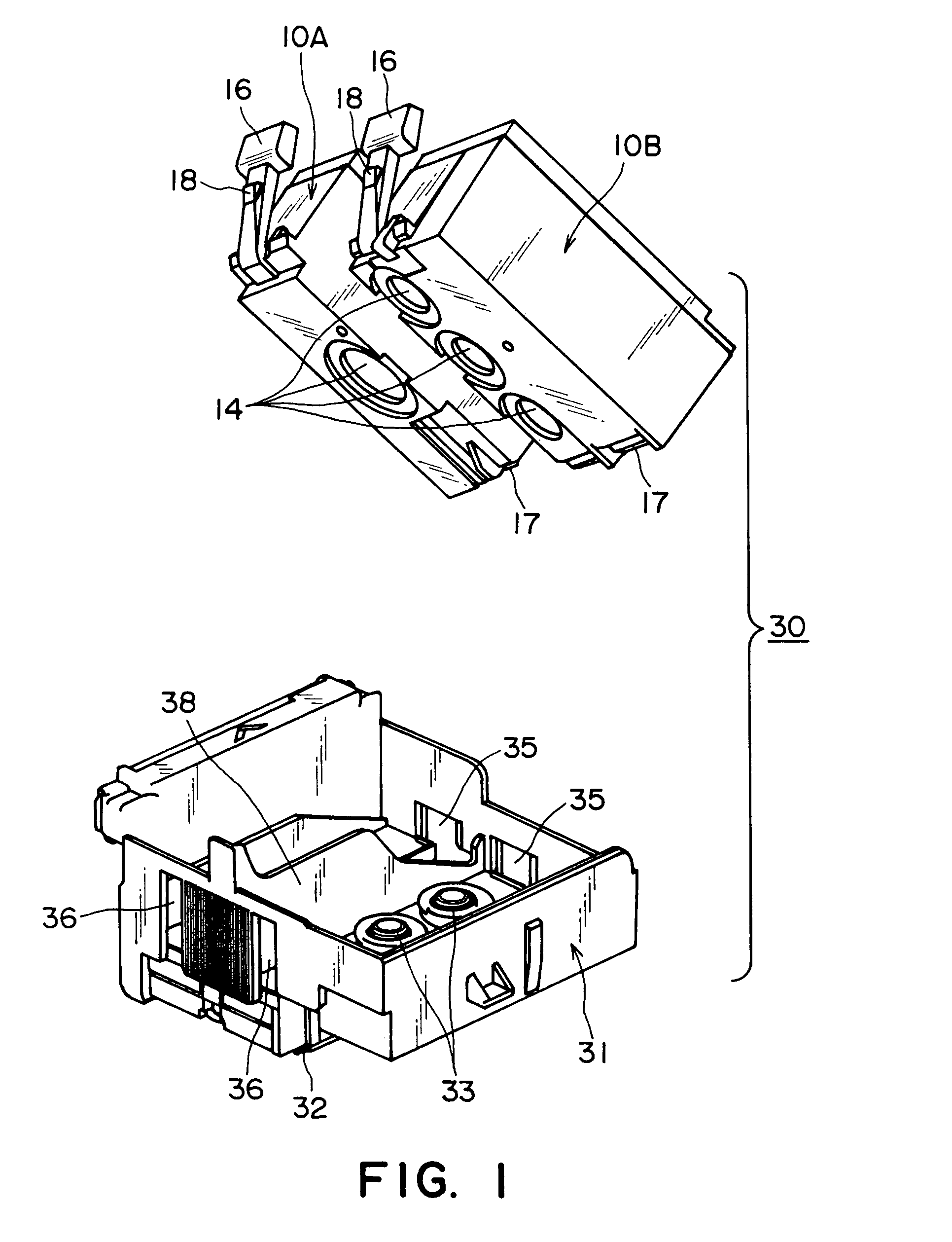

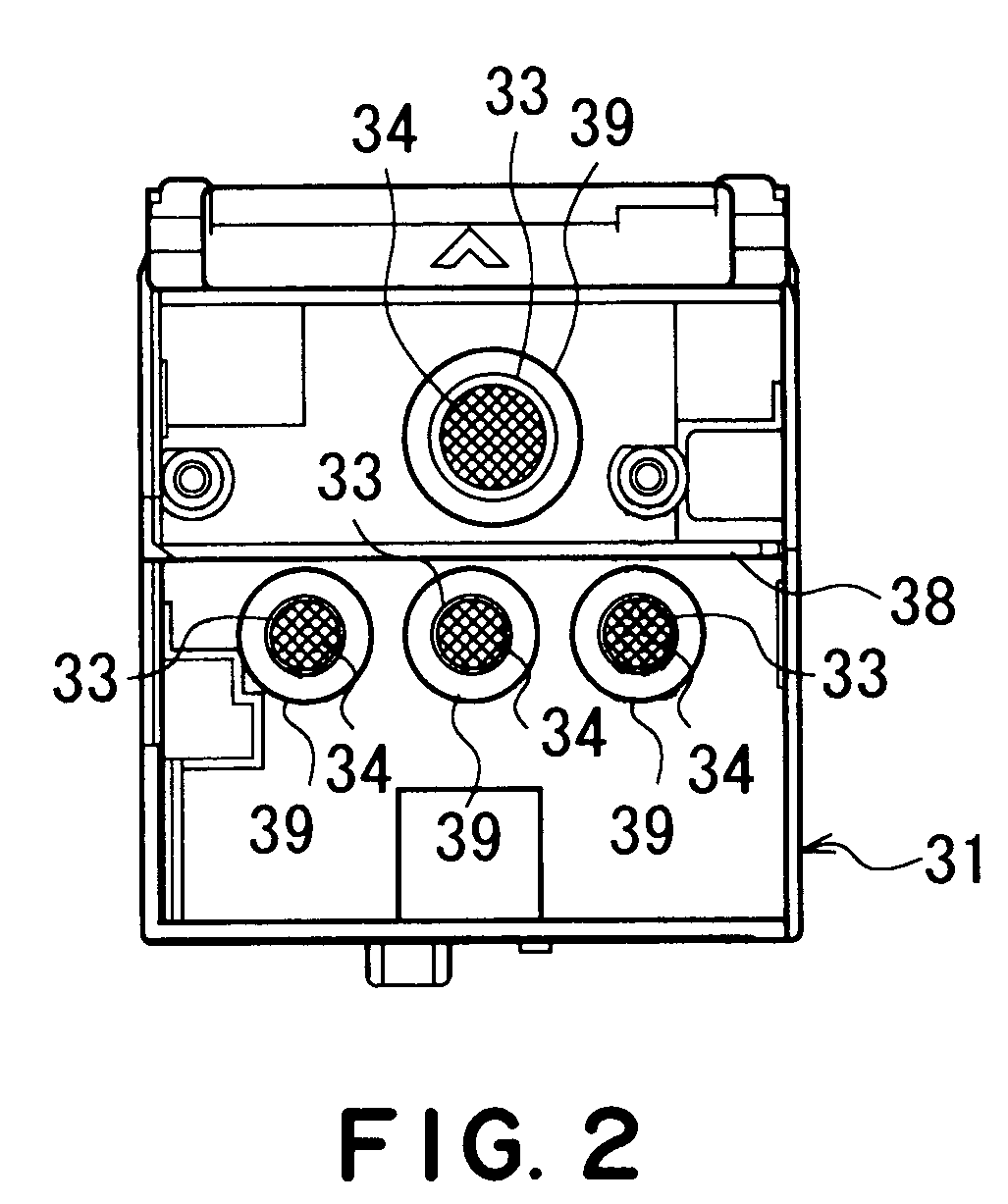

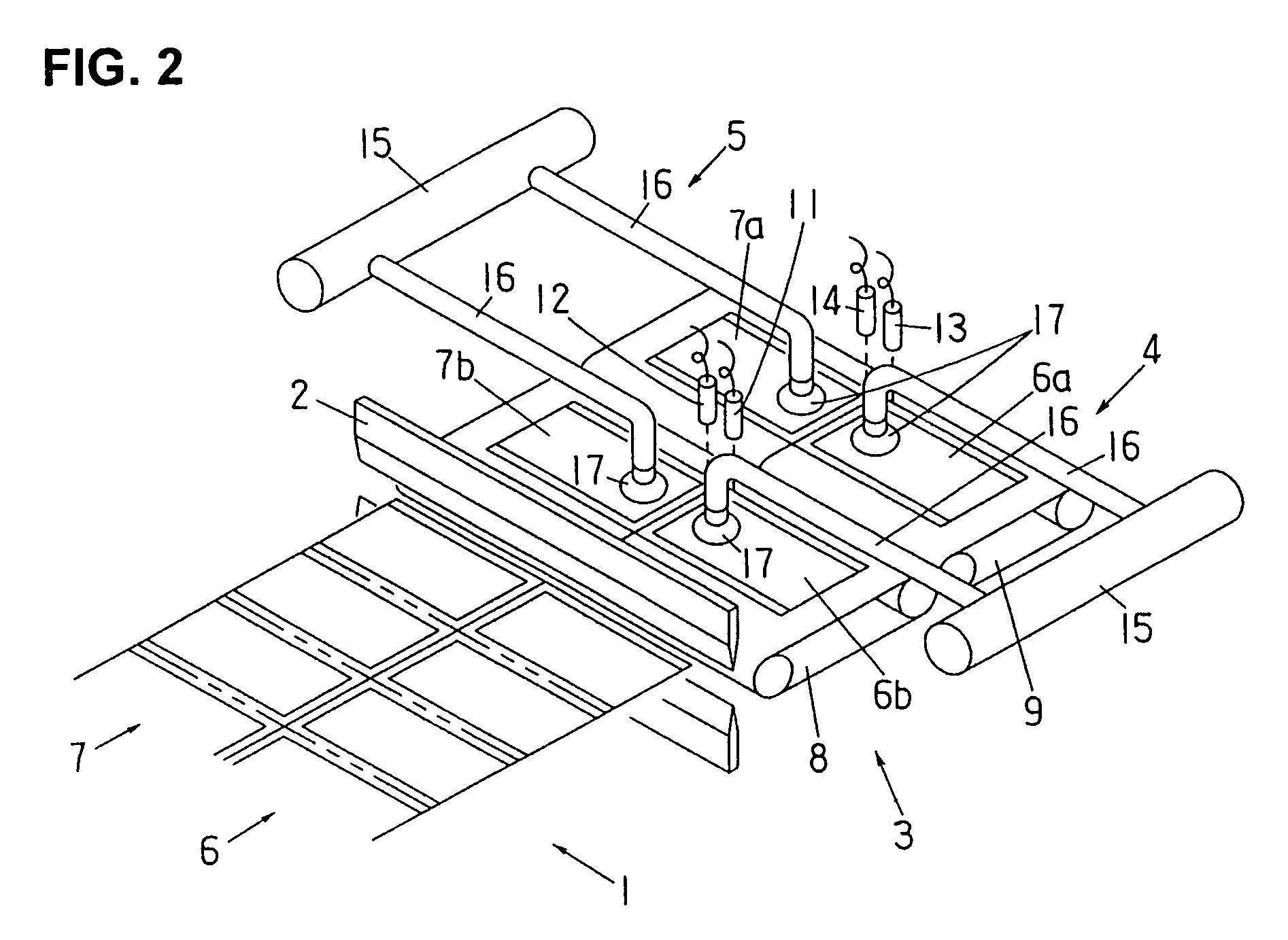

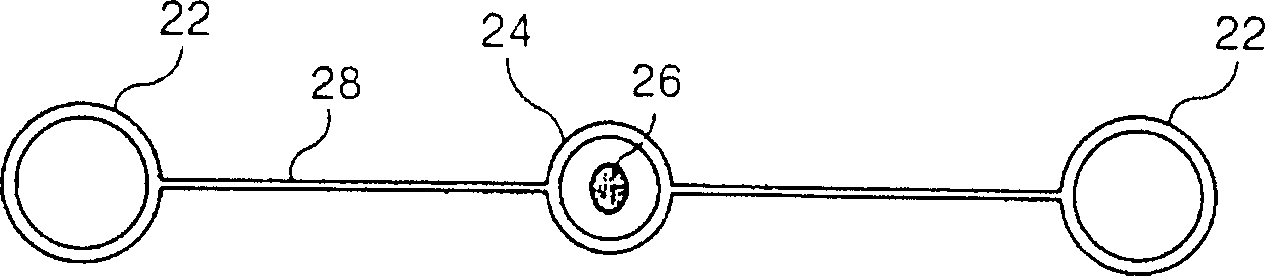

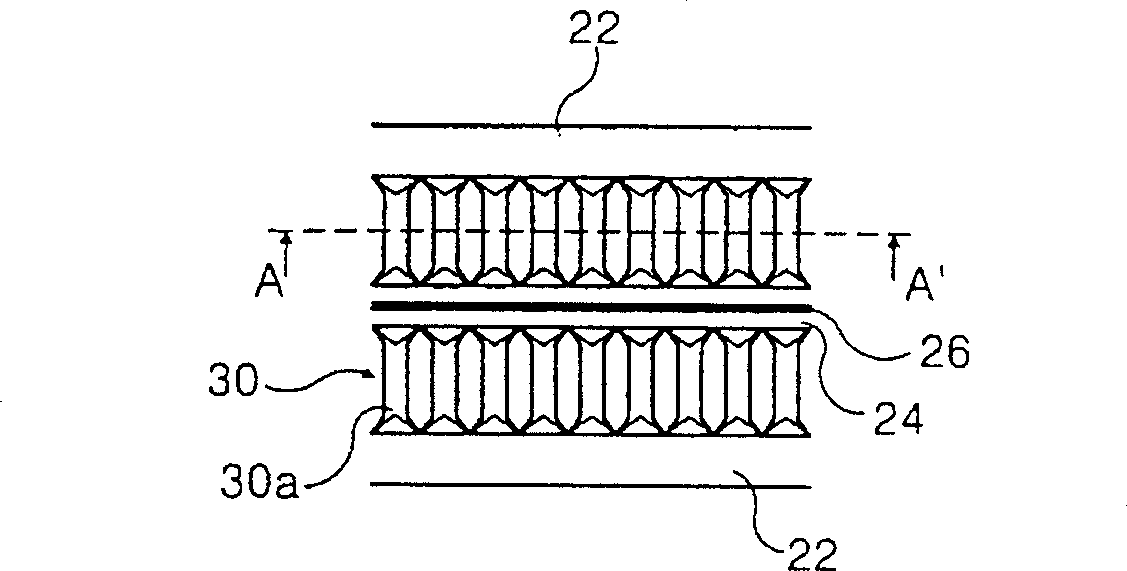

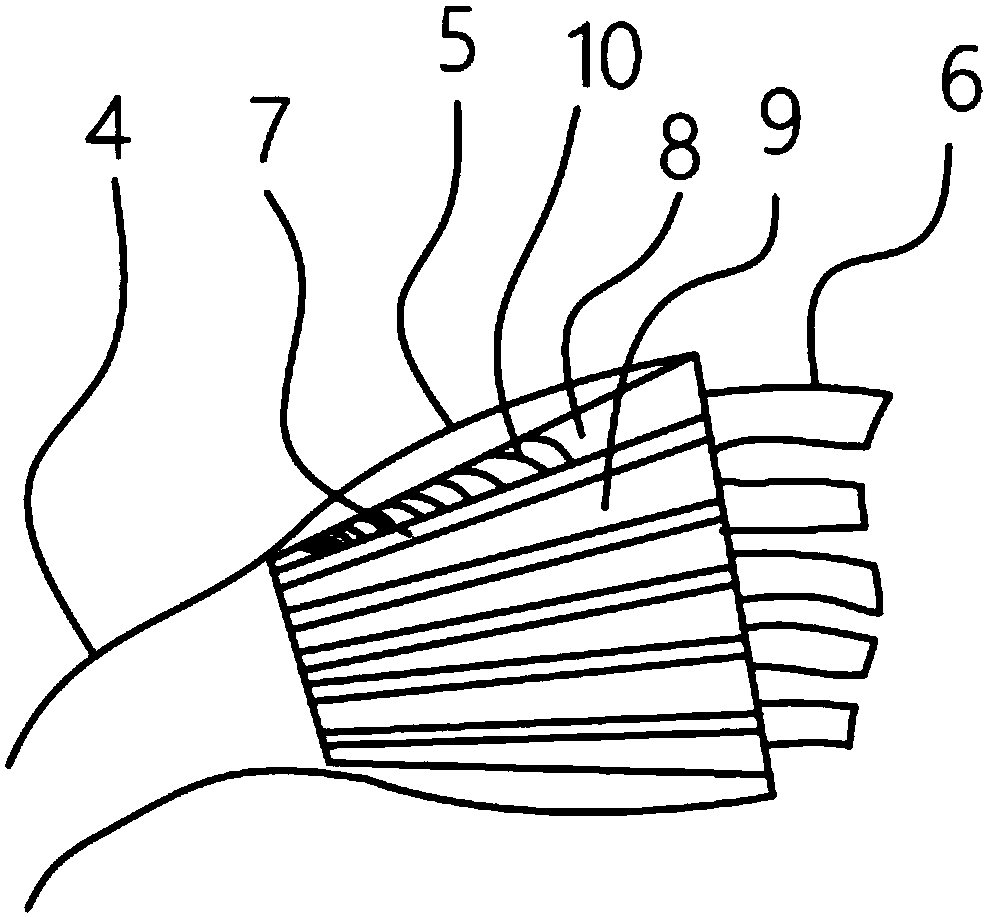

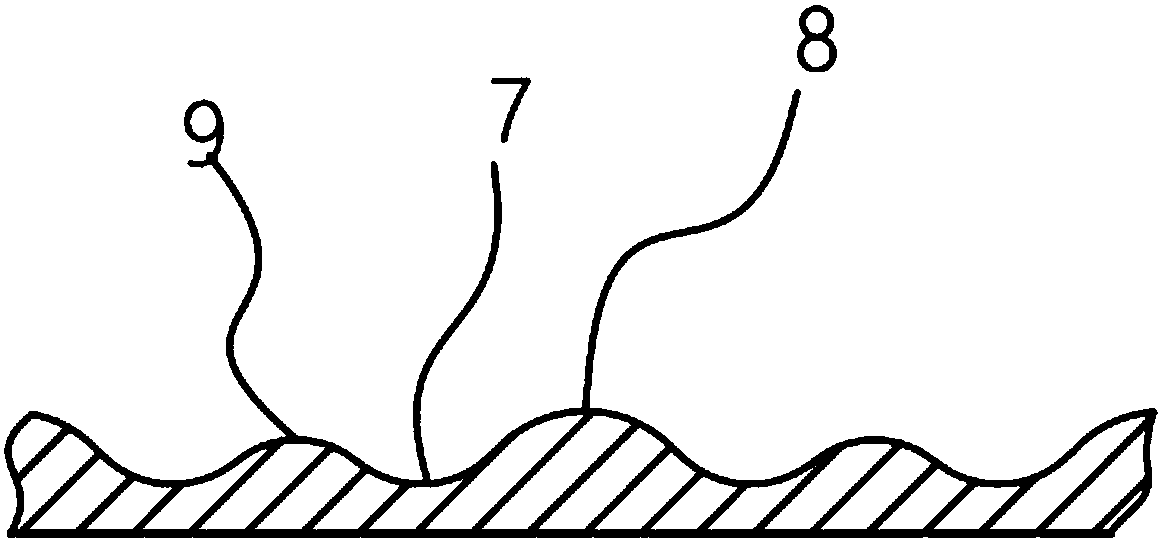

Ink container, recording head and recording device using same

InactiveUS7134747B2Stable ink supplyReduce remaining amountPrintingEngineeringMechanical engineering

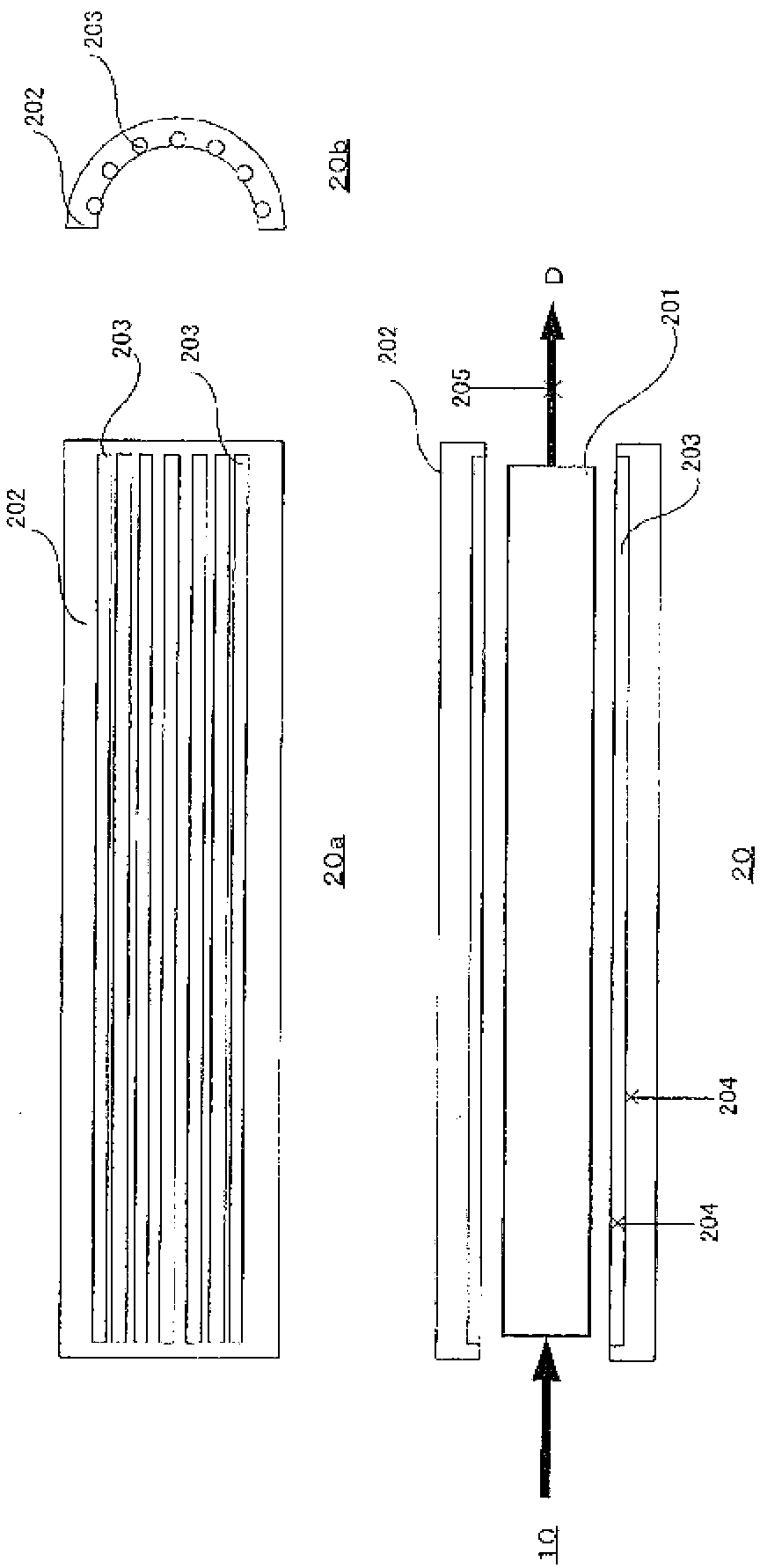

An ink container includes a casing having a substantially rectangular shape; a plurality of ink accommodating portions defined by partition in the casing; ink supply ports provided, in a bottom side of the casing, for the ink accommodating portions, respectively; wherein the ink container is detachably mountable to a holder provided with a recording head portion for ejecting ink accommodated in the ink accommodating portion, wherein the plurality of ink supply ports are disposed deviated toward one of long edge of the bottom side; and a plurality of dimple portions in which the supply ports are formed, respectively, and the dimples is cut away and opens adjacent to the one of edges.

Owner:CANON KK

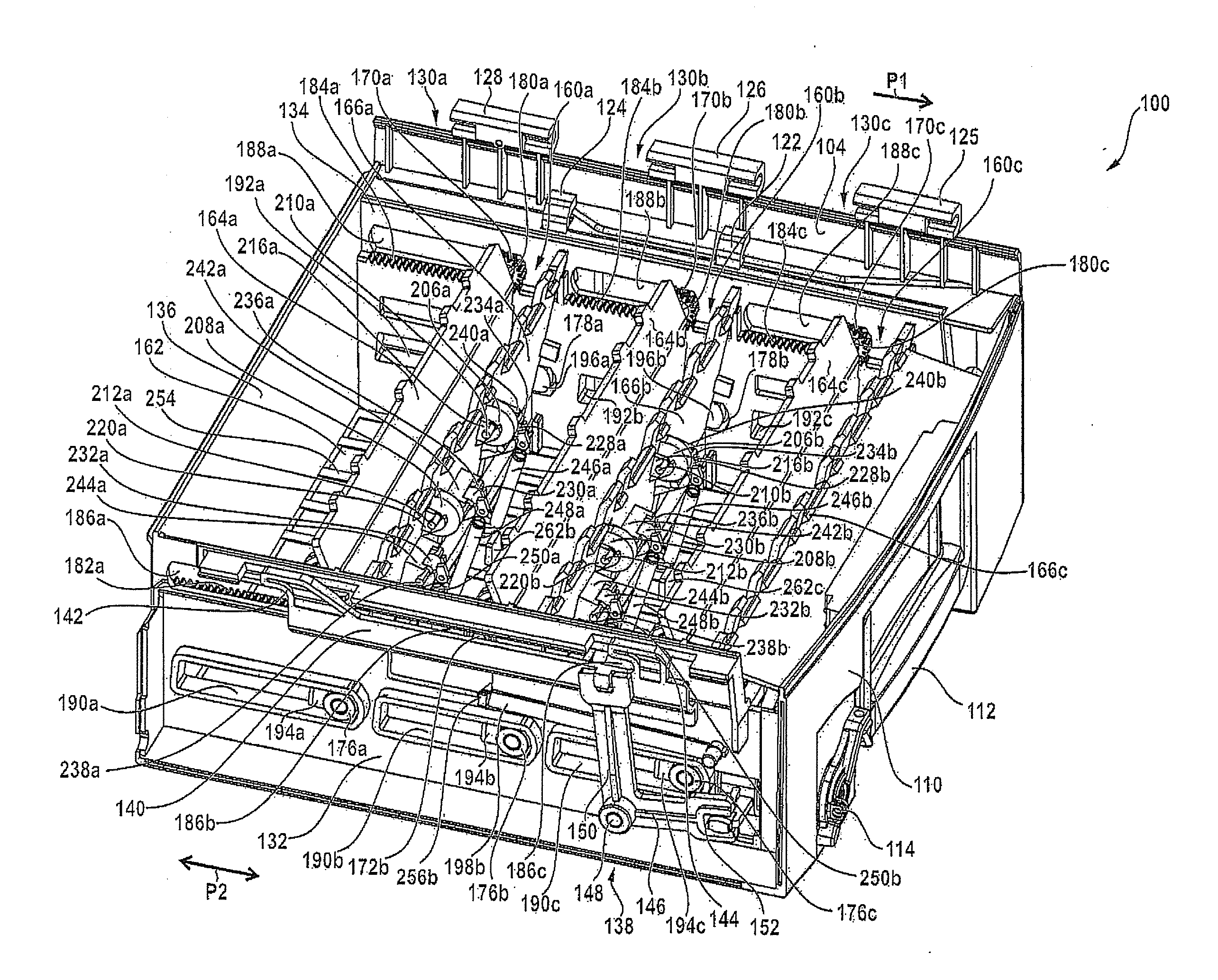

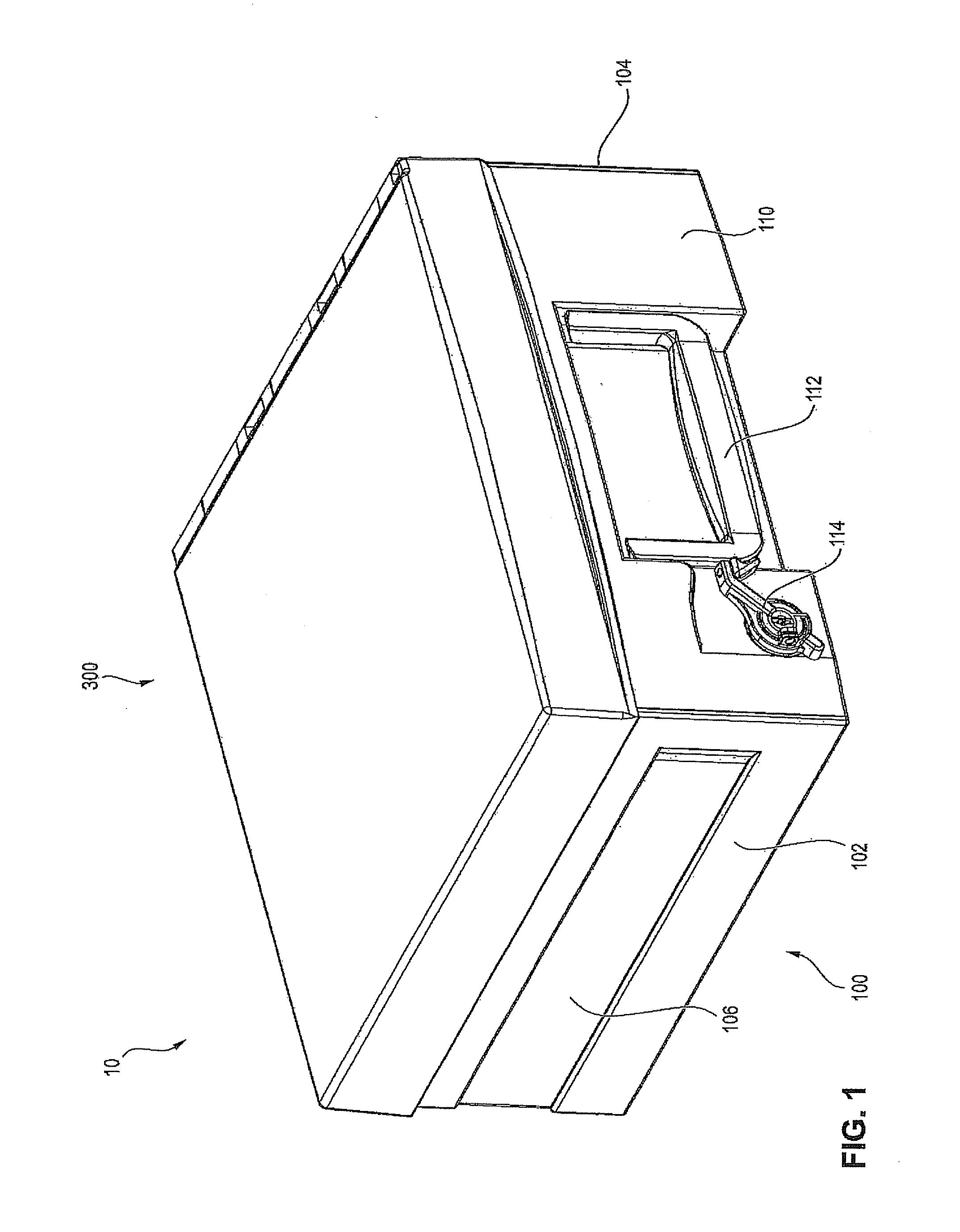

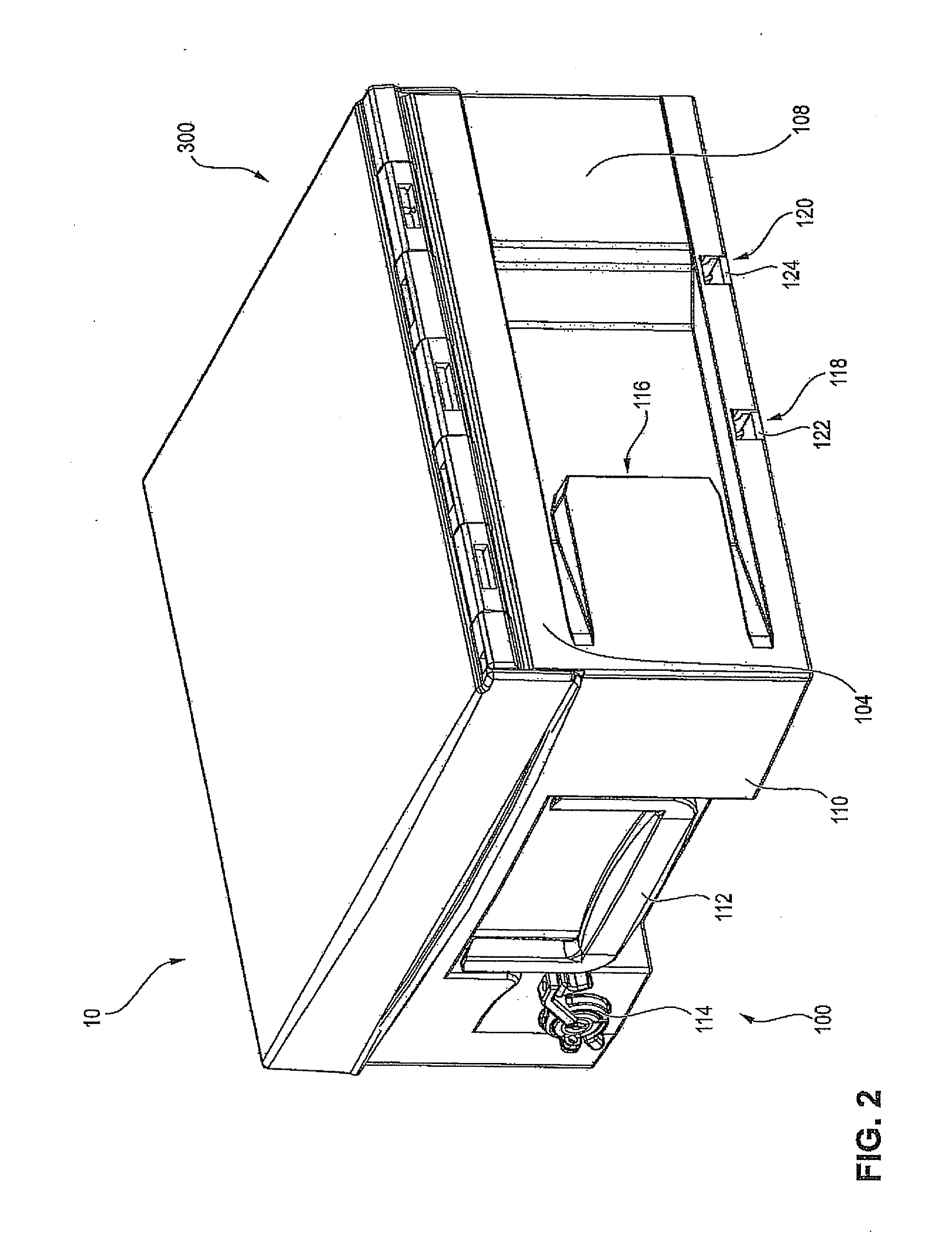

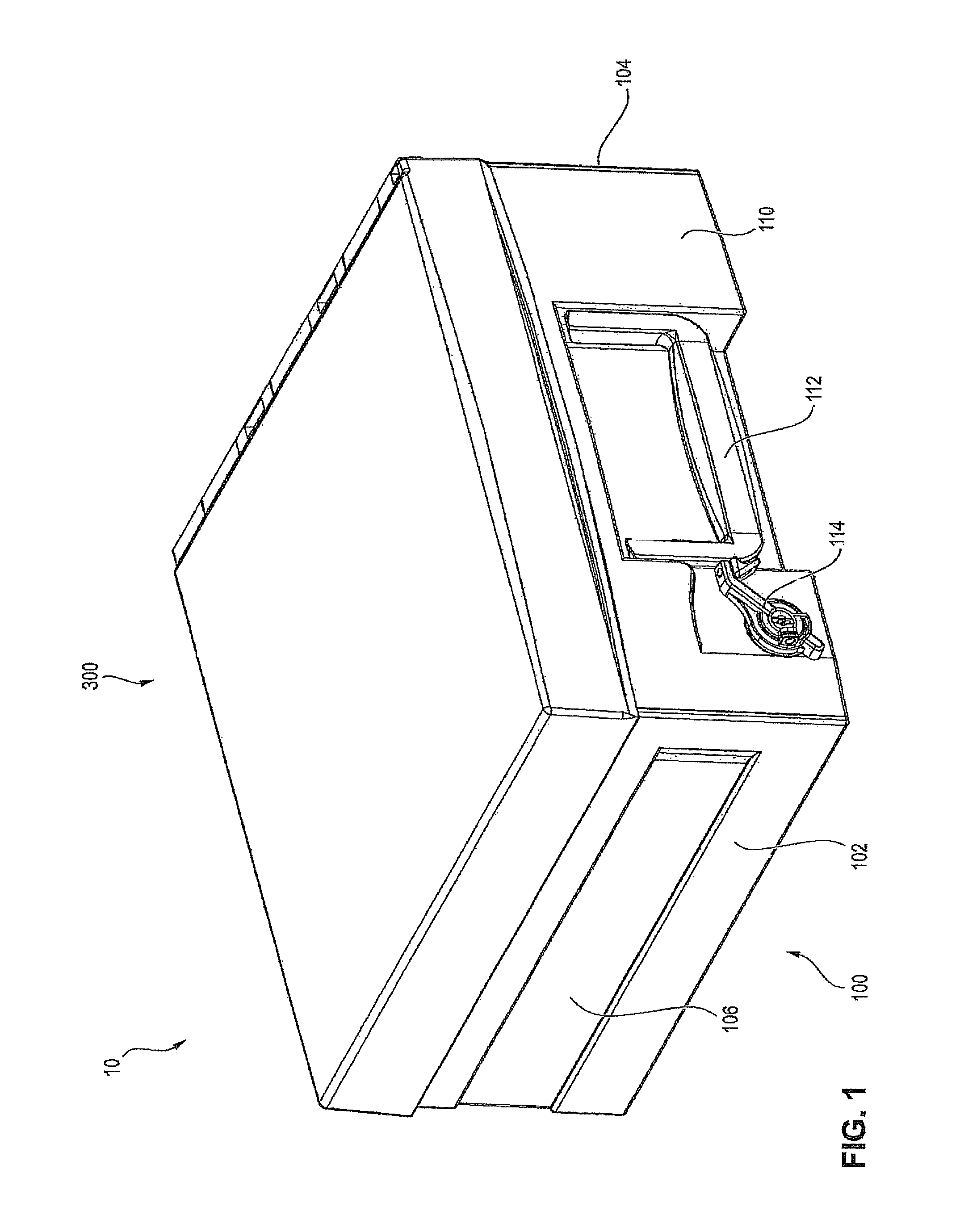

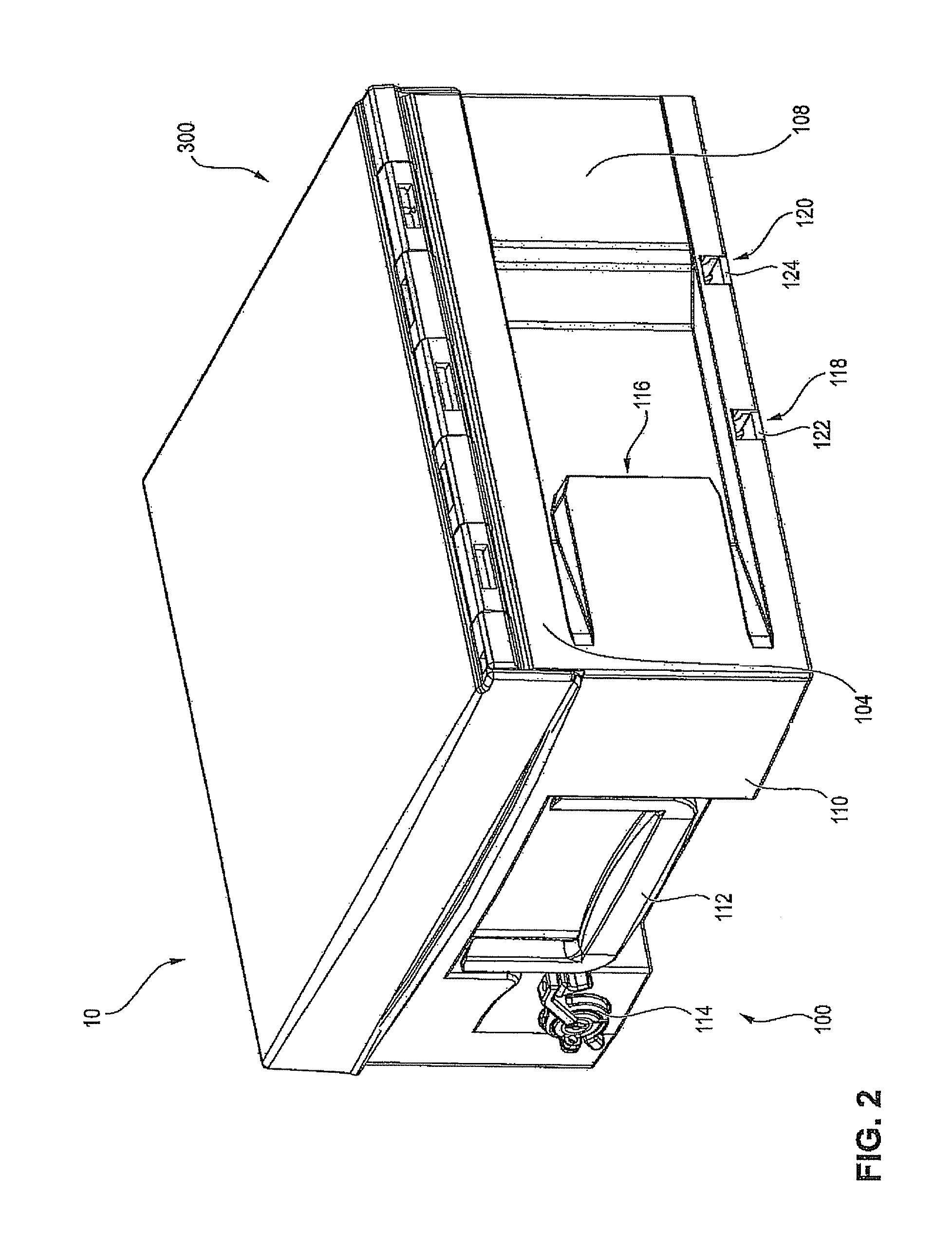

Voucher cassette

ActiveUS20120032391A1Increase speedCompact structureCoin/currency accepting devicesPile receiversVoucherEngineering

Owner:DIEBOLD NIXDORF SYST GMBH

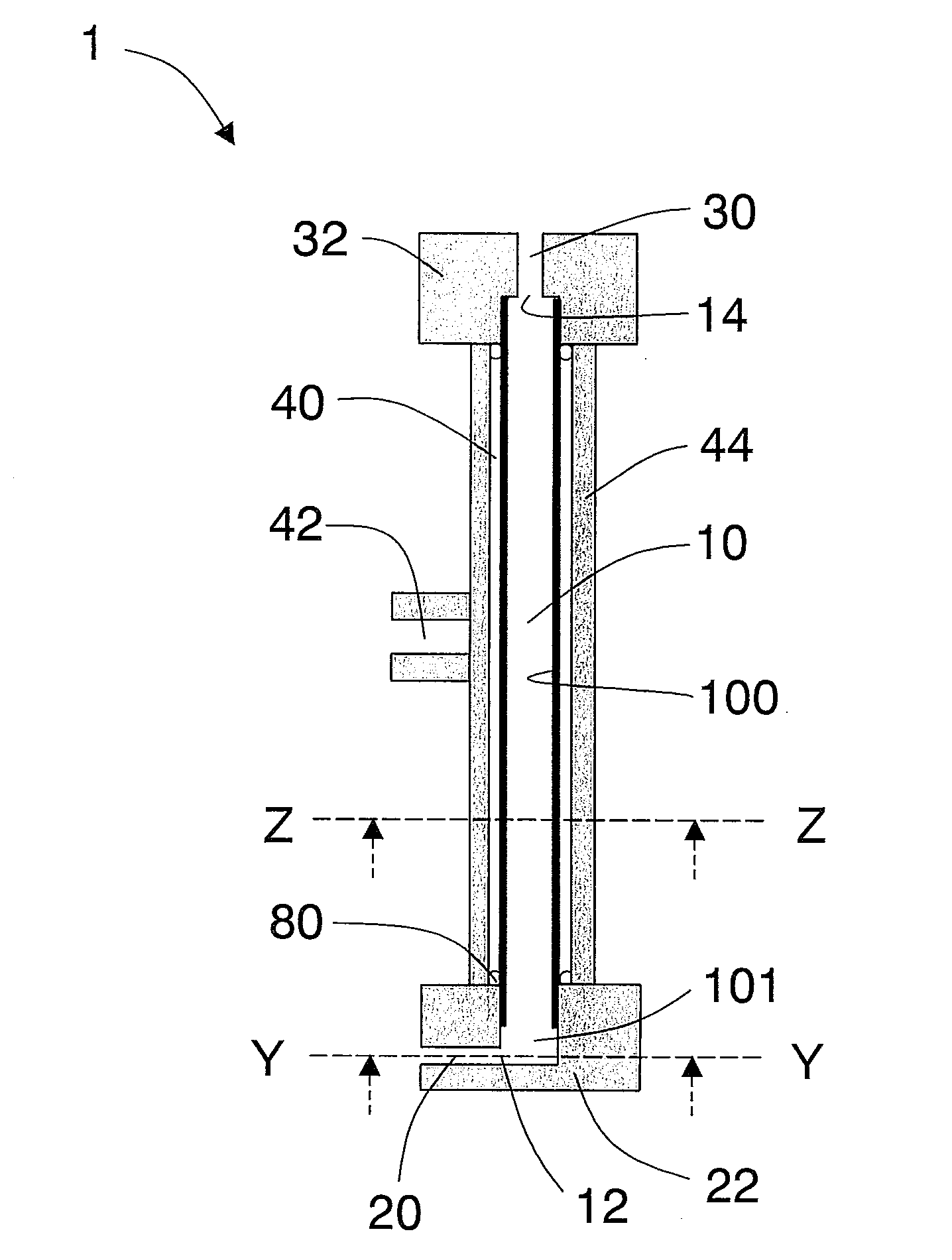

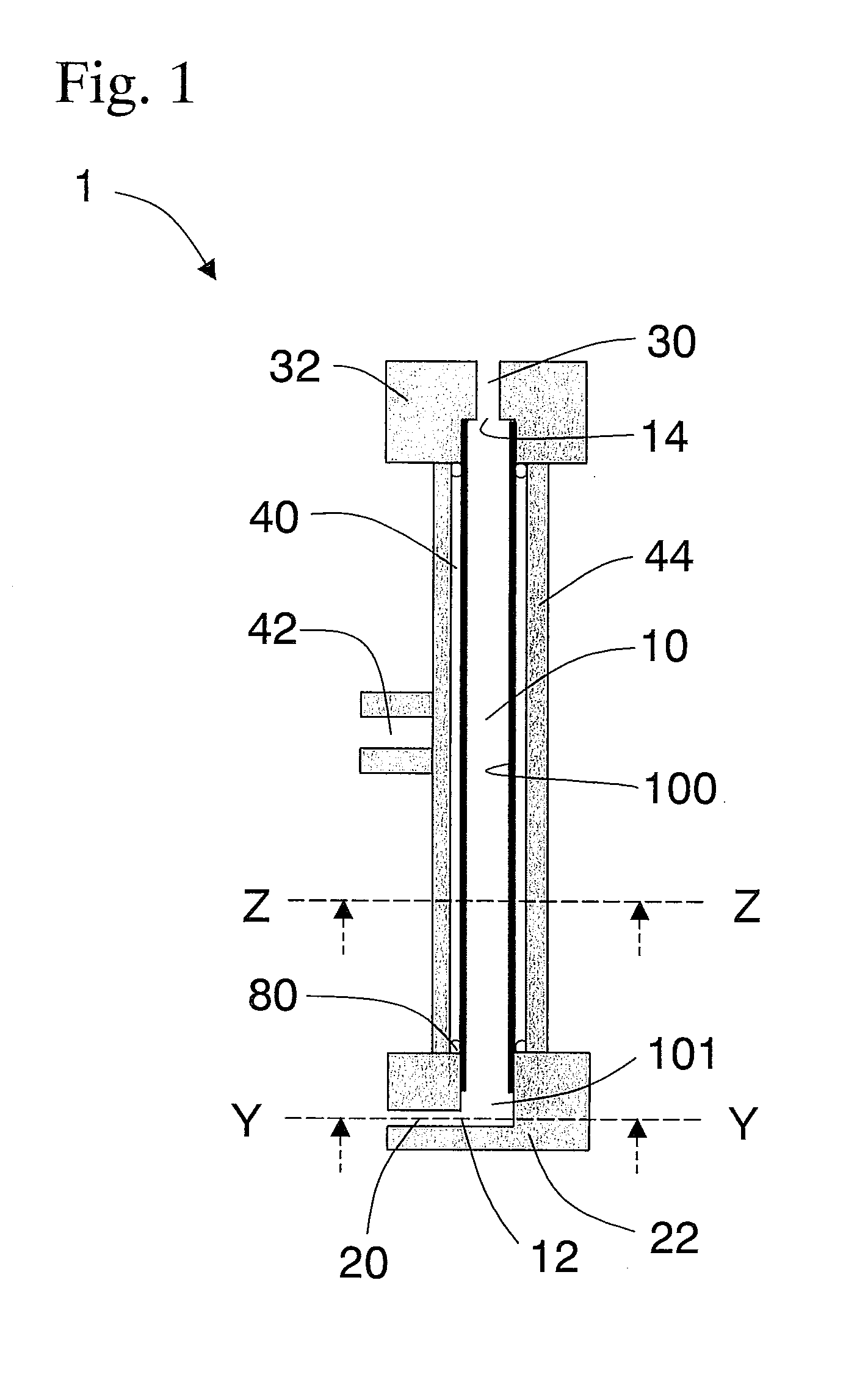

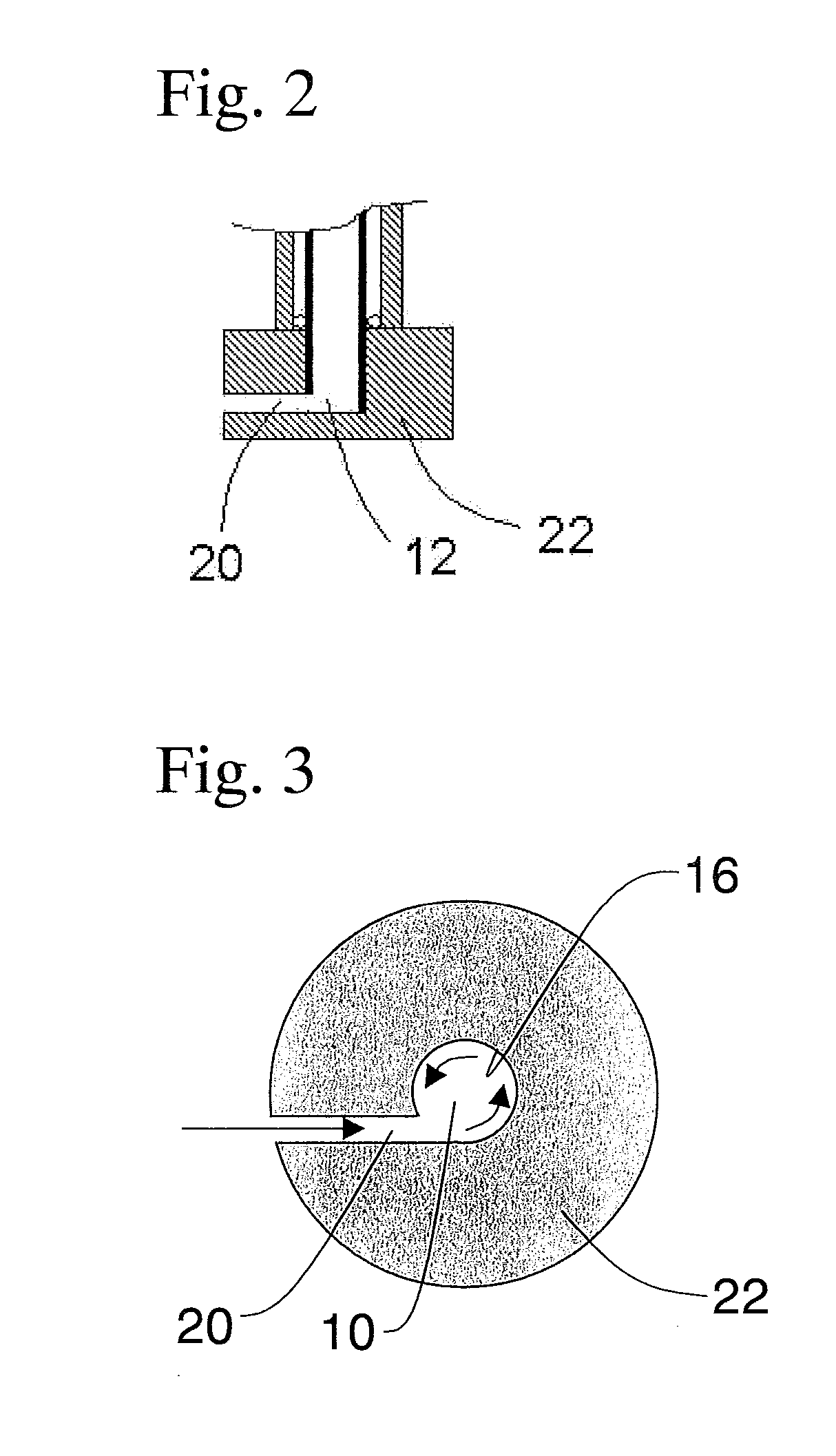

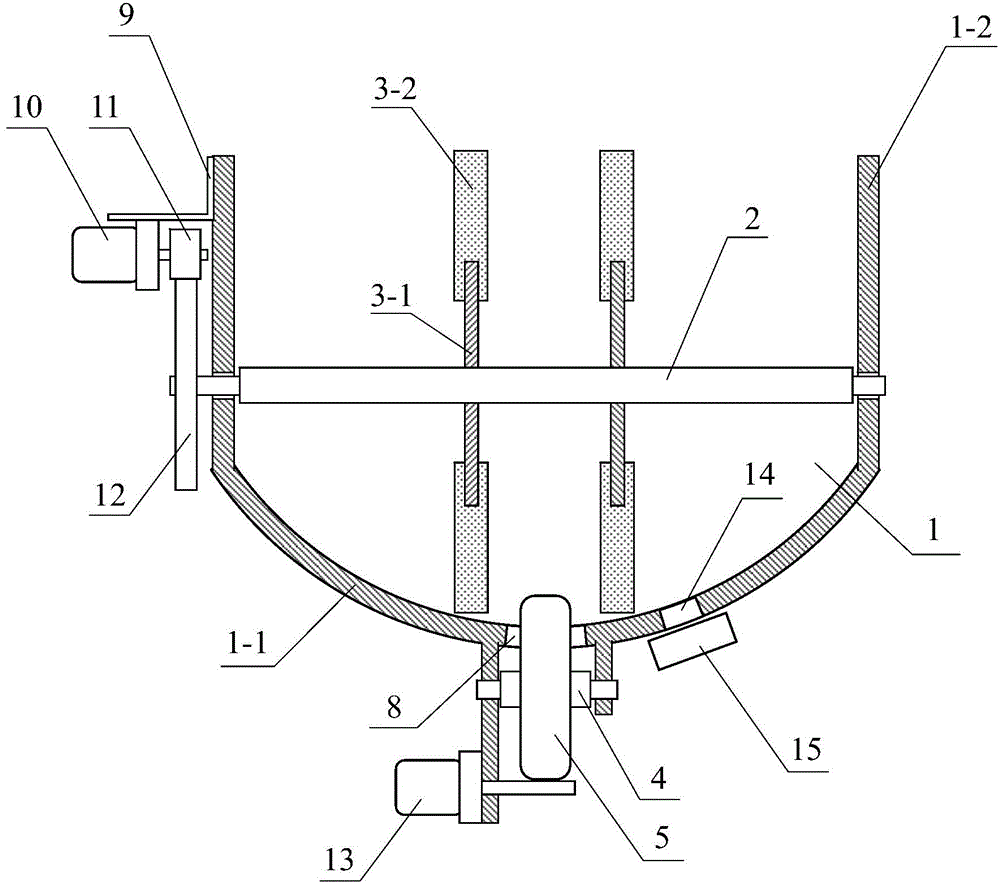

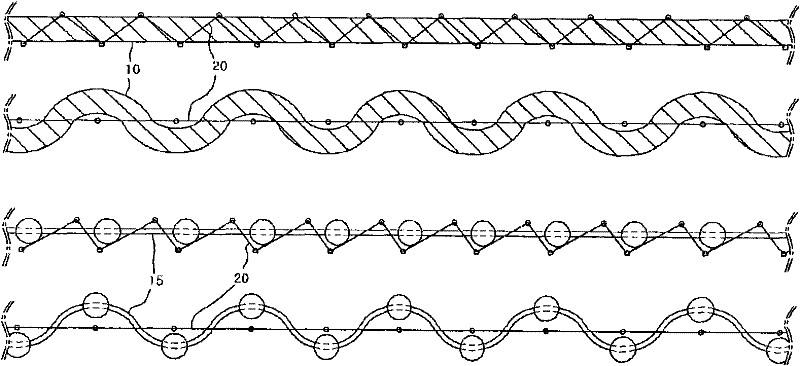

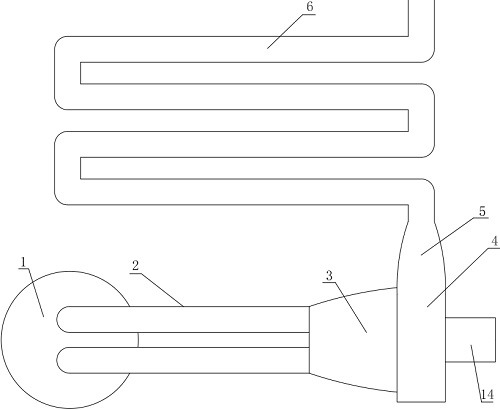

Method of producing composition having continuous phase and disperse phase dispersed finely in the continuous phase and apparatus for producing the compositon

InactiveUS20130137782A1Reduce polydispersityImprove production efficiencyBiocidePowder deliveryPorous membraneMaterials science

There is provided a method of producing a composition having a continuous phase and a disperse phase dispersed finely with low polydispersity in the continuous phase, with high production efficiency.The composition is produced by the production method including the steps of: (A) passing the swirling flow of the continuous phase liquid into a cylindrical body the circumferential surface of which is either in part or entirely formed by a porous membrane, (B1) supplying the disperse phase fluid to the swirling flow via the porous membrane to form the particles of the disperse phase on the porous membrane, and (B2) detaching the disperse phase particles formed on the porous membrane by the shear force of the swirling flow. The cylindrical body preferably has an inlet for the continuous phase liquid on the circumferential surface of the cylindrical body in the vicinity of one end of the cylindrical body and an inlet tube which extends from the inlet in the substantially vertical direction to the axis of the cylindrical body and the tangential direction to the cylindrical body. The step (A) is preferably carried out by use of the inlet tube to flow the continuous phase liquid in from the substantially vertical direction to the axis of the cylindrical body and the tangential direction to the inner wall surface of the cylindrical body.

Owner:KYUSHU UNIV

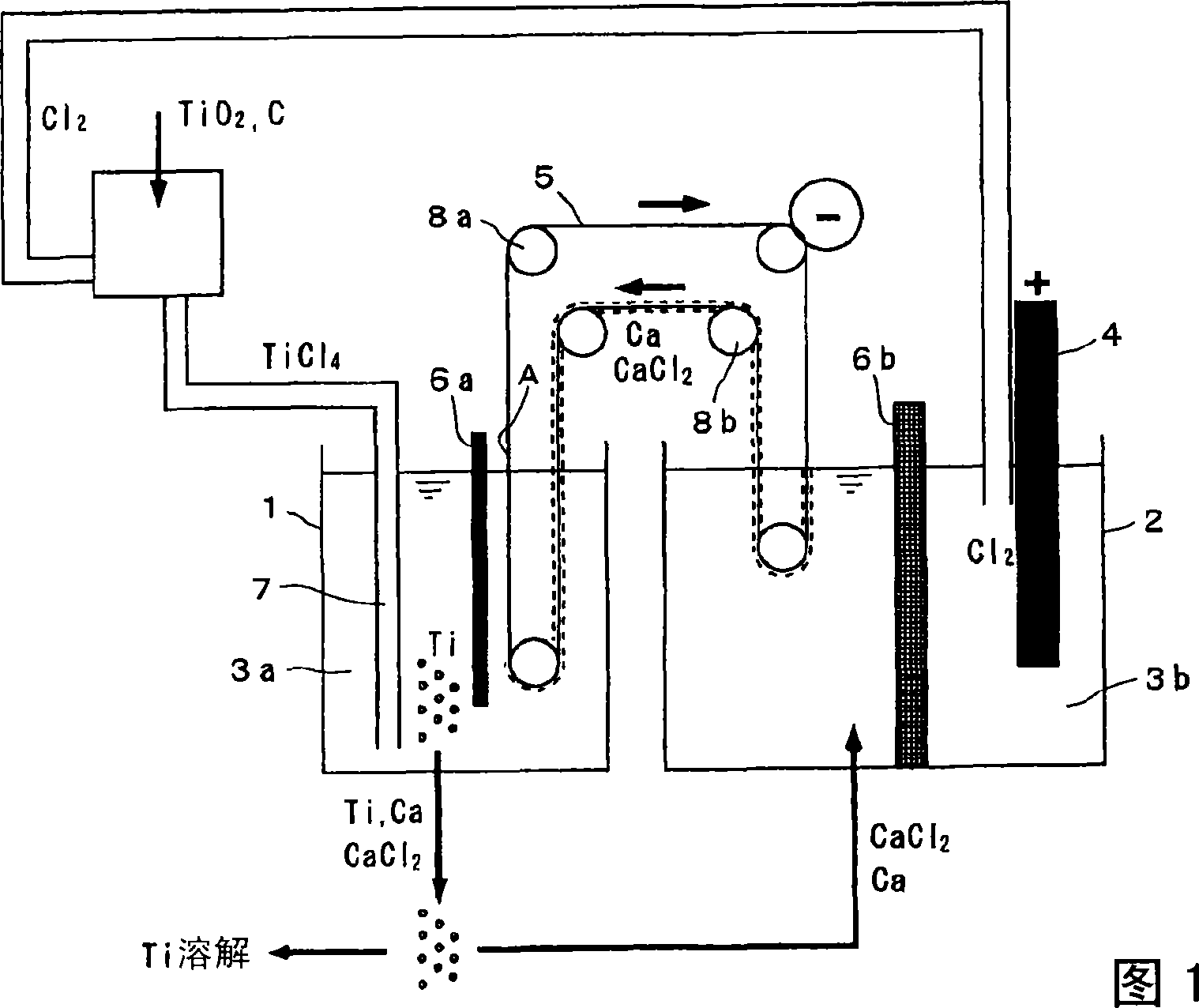

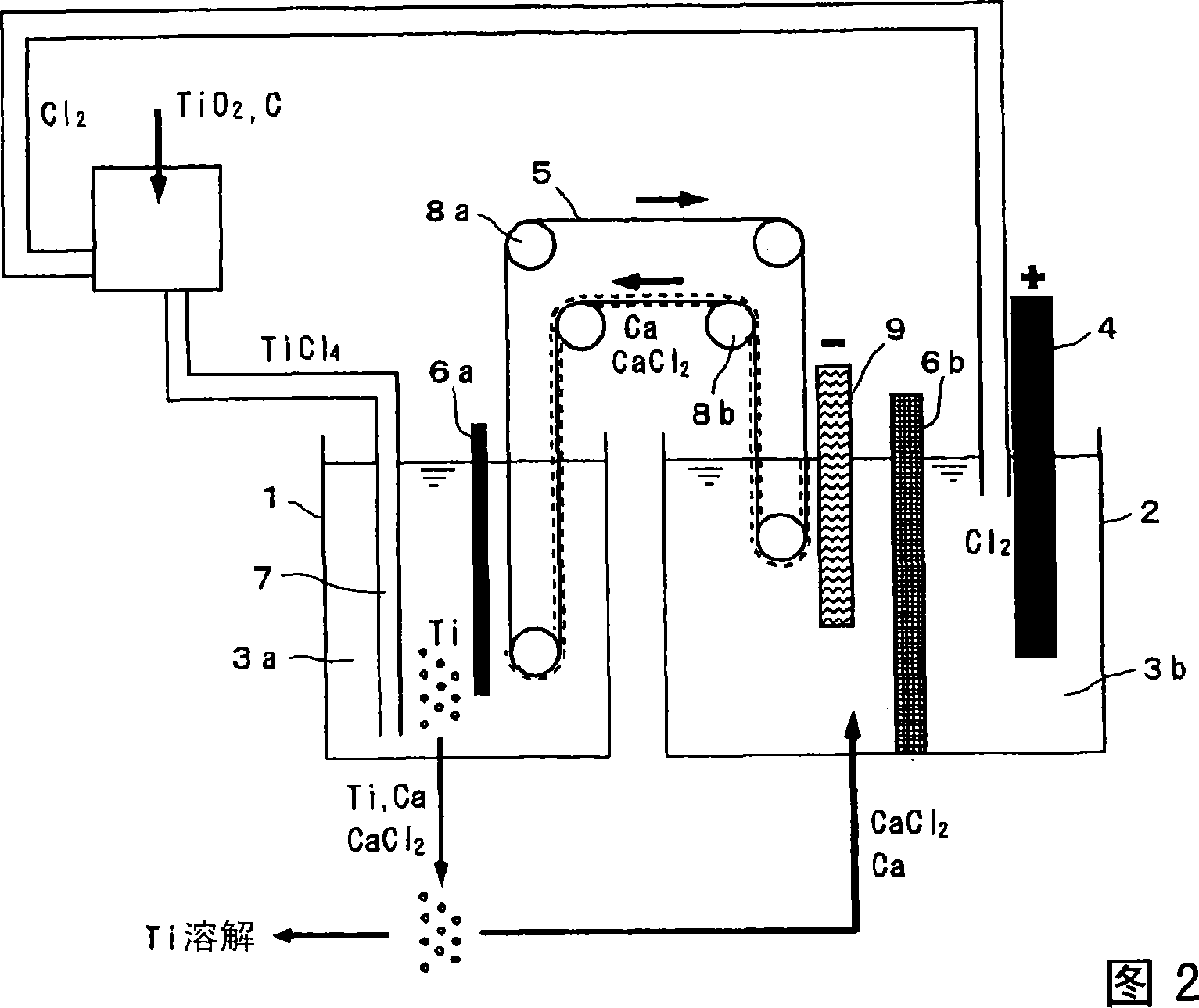

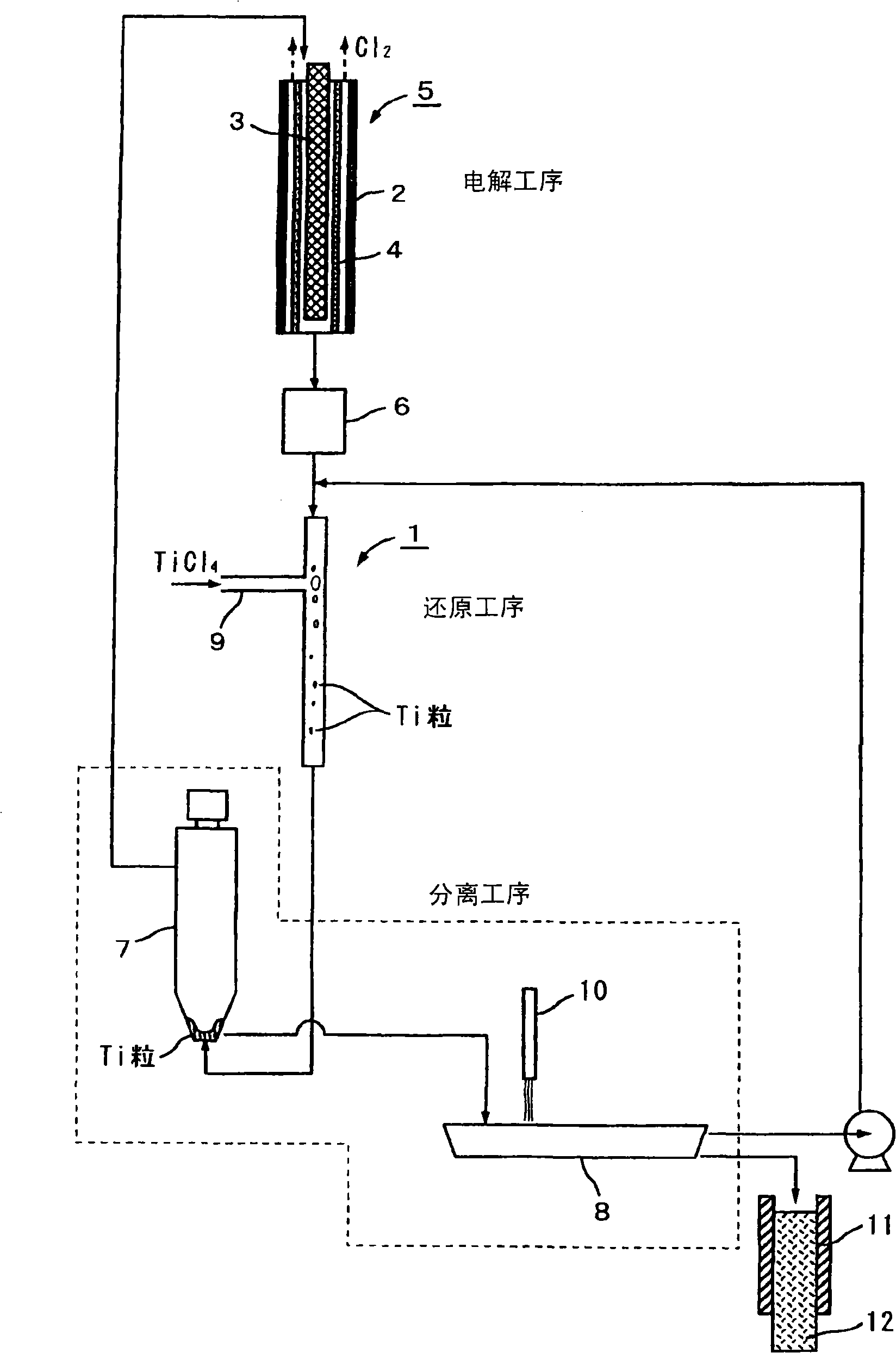

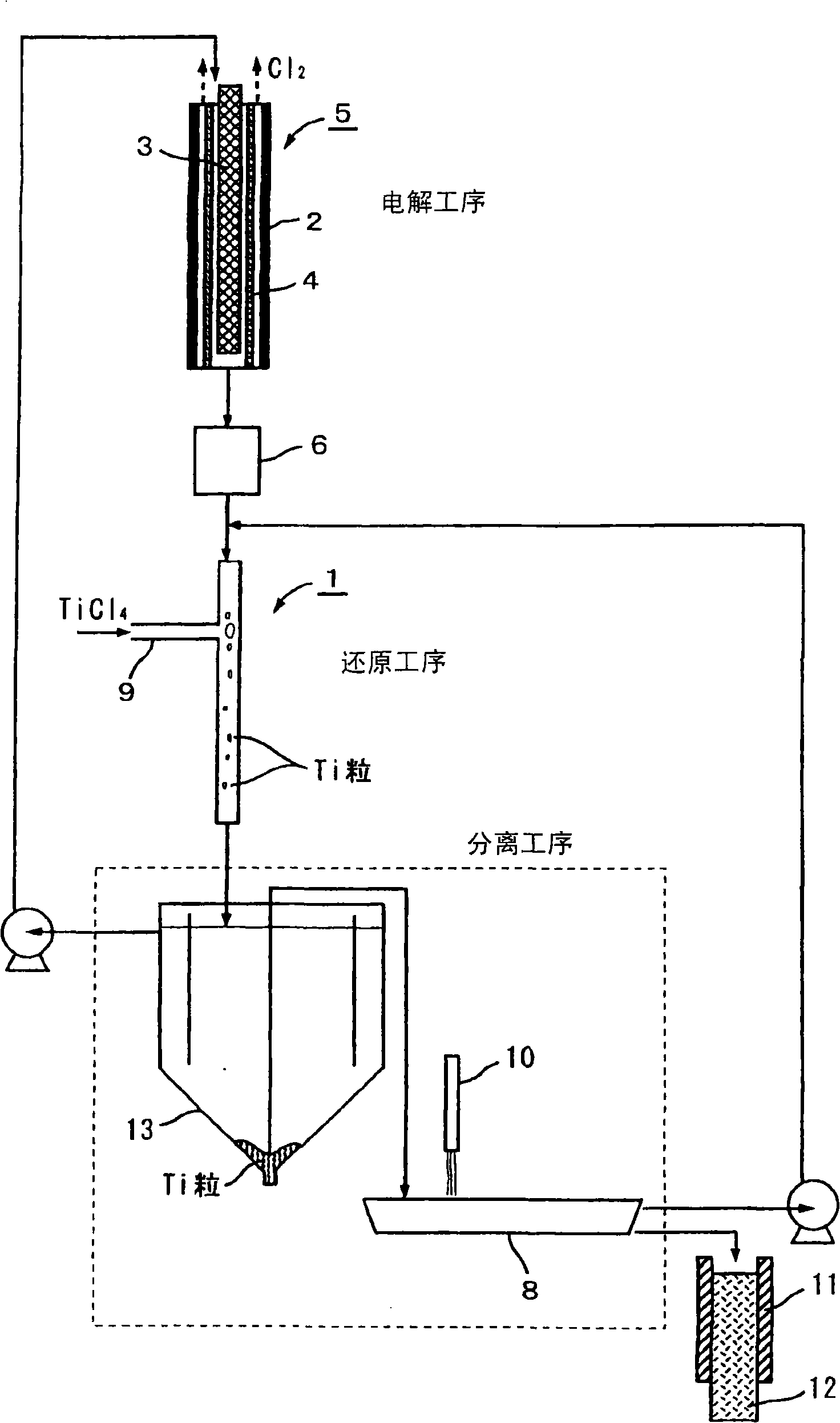

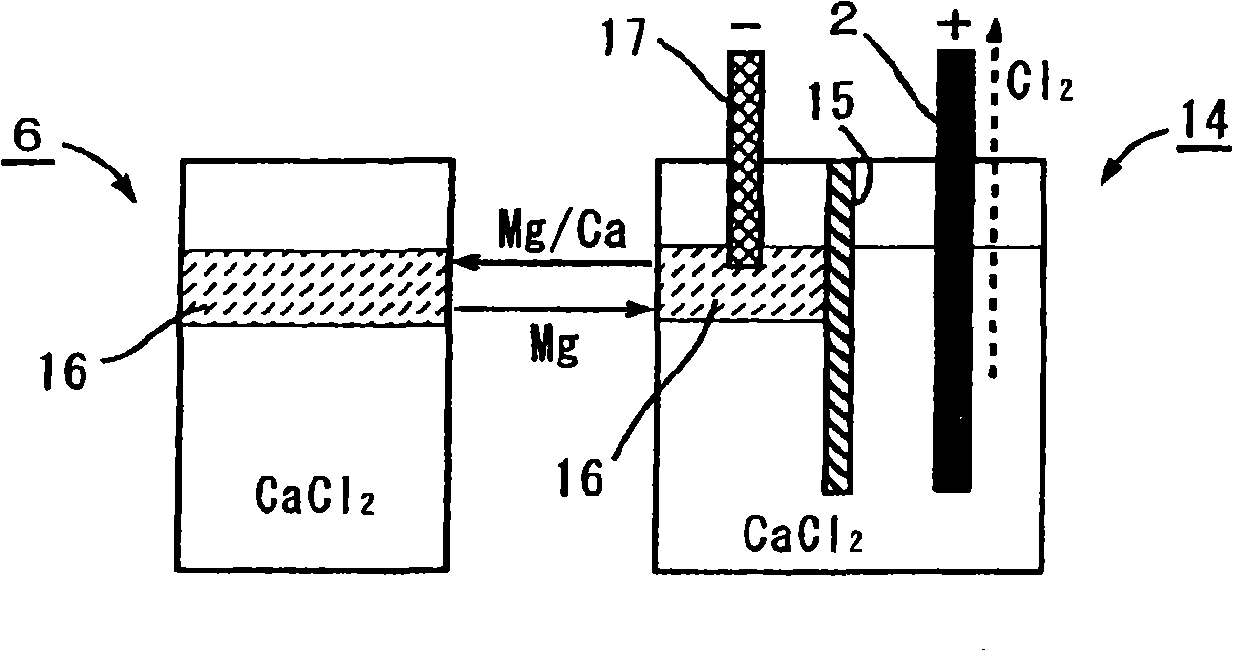

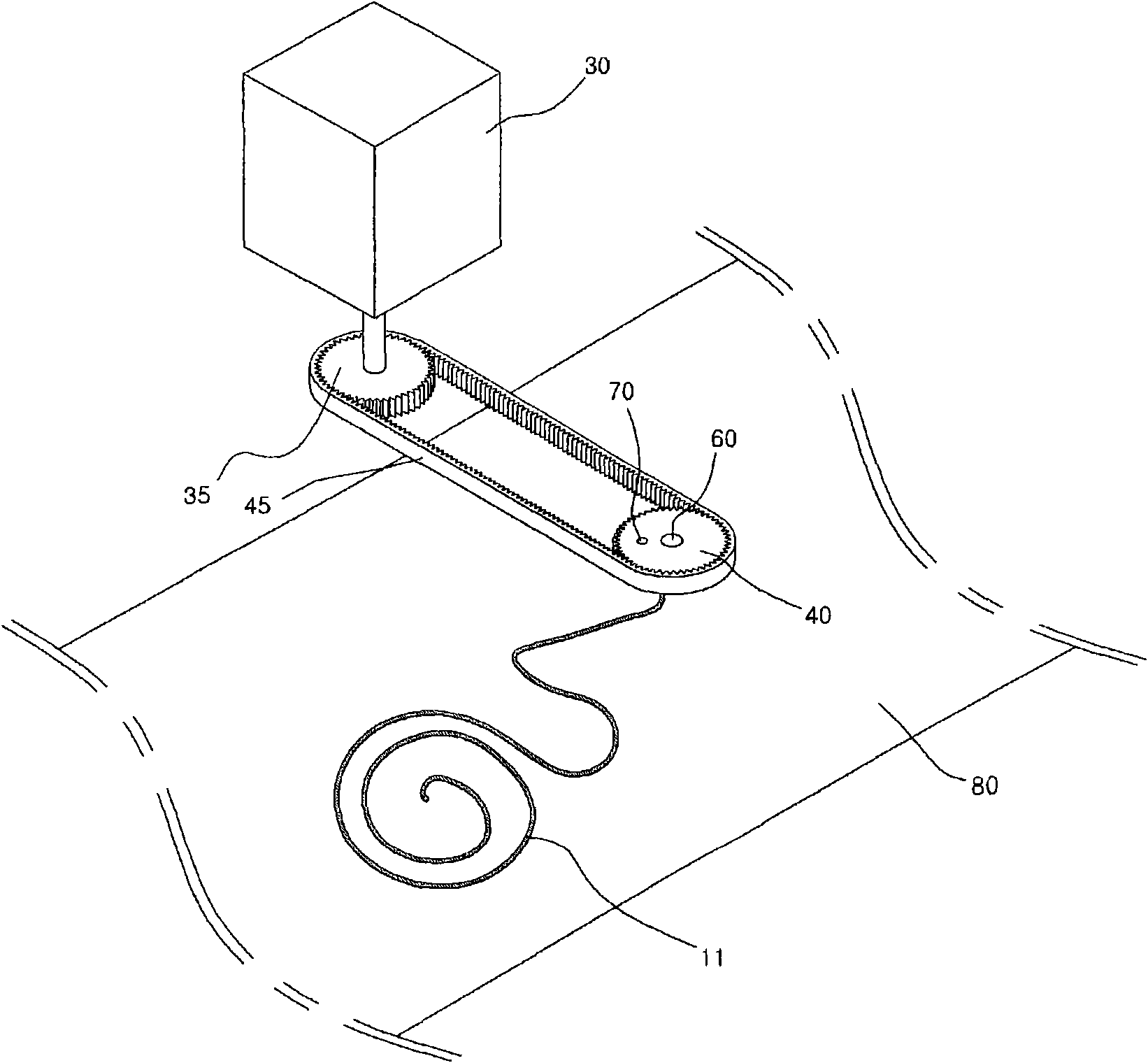

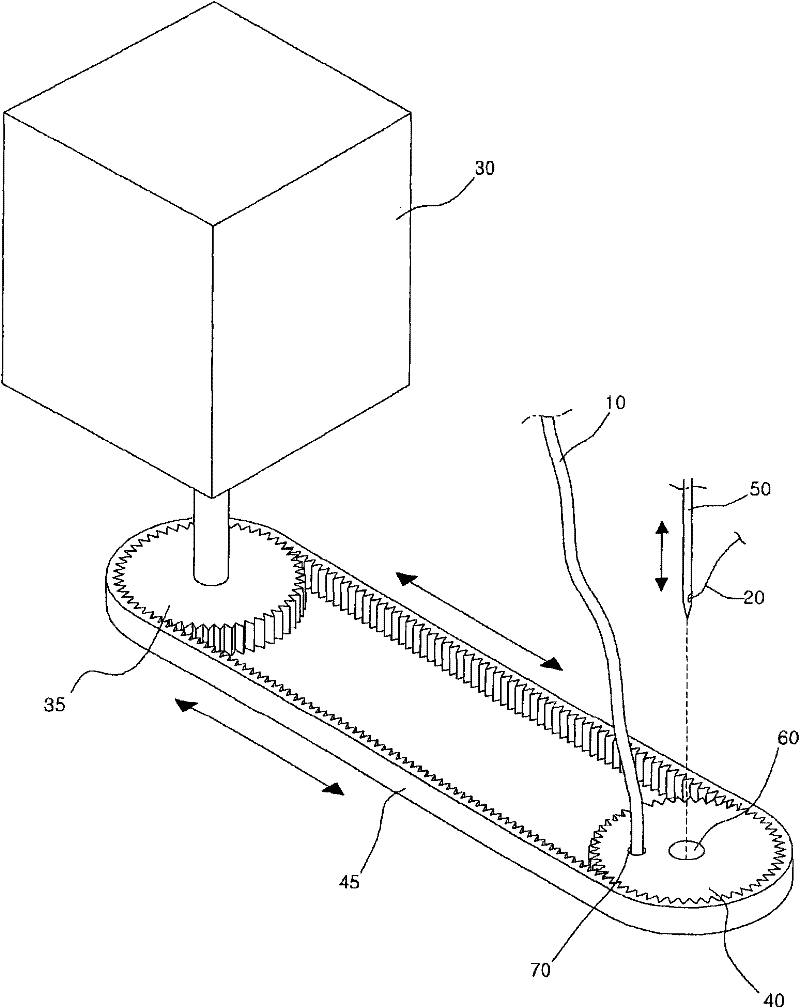

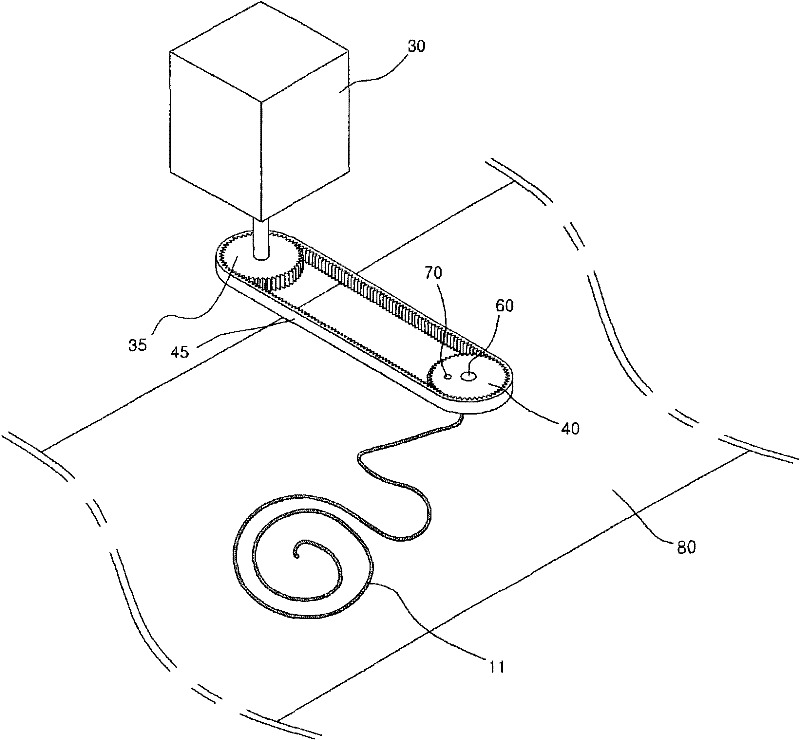

Process for producing ti through ca reduction and apparatus therefor

A process for producing Ti through Ca reduction, comprising providing an apparatus including a reaction vessel for retaining a molten salt containing CaCl2 and having Ca dissolved therein, an electrolytic vessel for retaining a molten salt containing CaCl2 and continuous means capable of moving while having parts thereof dipped in the molten salts of the reaction vessel and electrolytic vessel; conducting electrolysis of the molten salt of the electrolytic vessel to thereby form Ca on the negative electrode side, the formed Ca deposited on and attached to the continuous means; transporting the Ca to the reaction vessel; and feeding TiCl4 into the reaction vessel to thereby form Ti. This process is economically advantageous as the feeding rate of TiCl4 as a raw material can be increased, as continuous production can be effected, and as Ca consumed by reduction reaction of TiCl4 can be replenished by electrolysis of CaCl2. Thus, this process can be effectively utilized as means for efficient economically advantageous production of high-purity metallic Ti and can find wide applications.

Owner:OSAKA TITANIUM TECHNOLOGIES +1

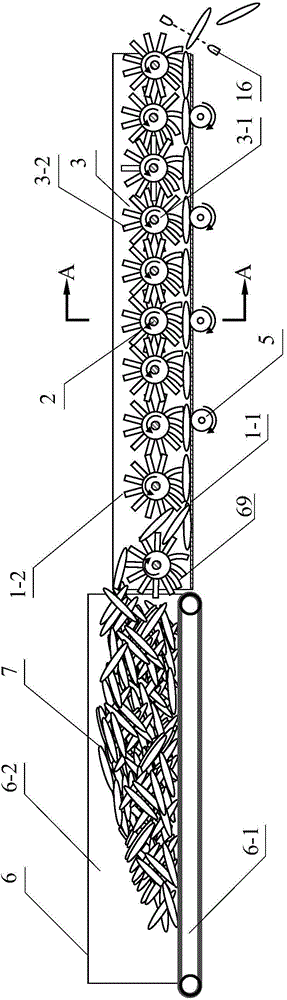

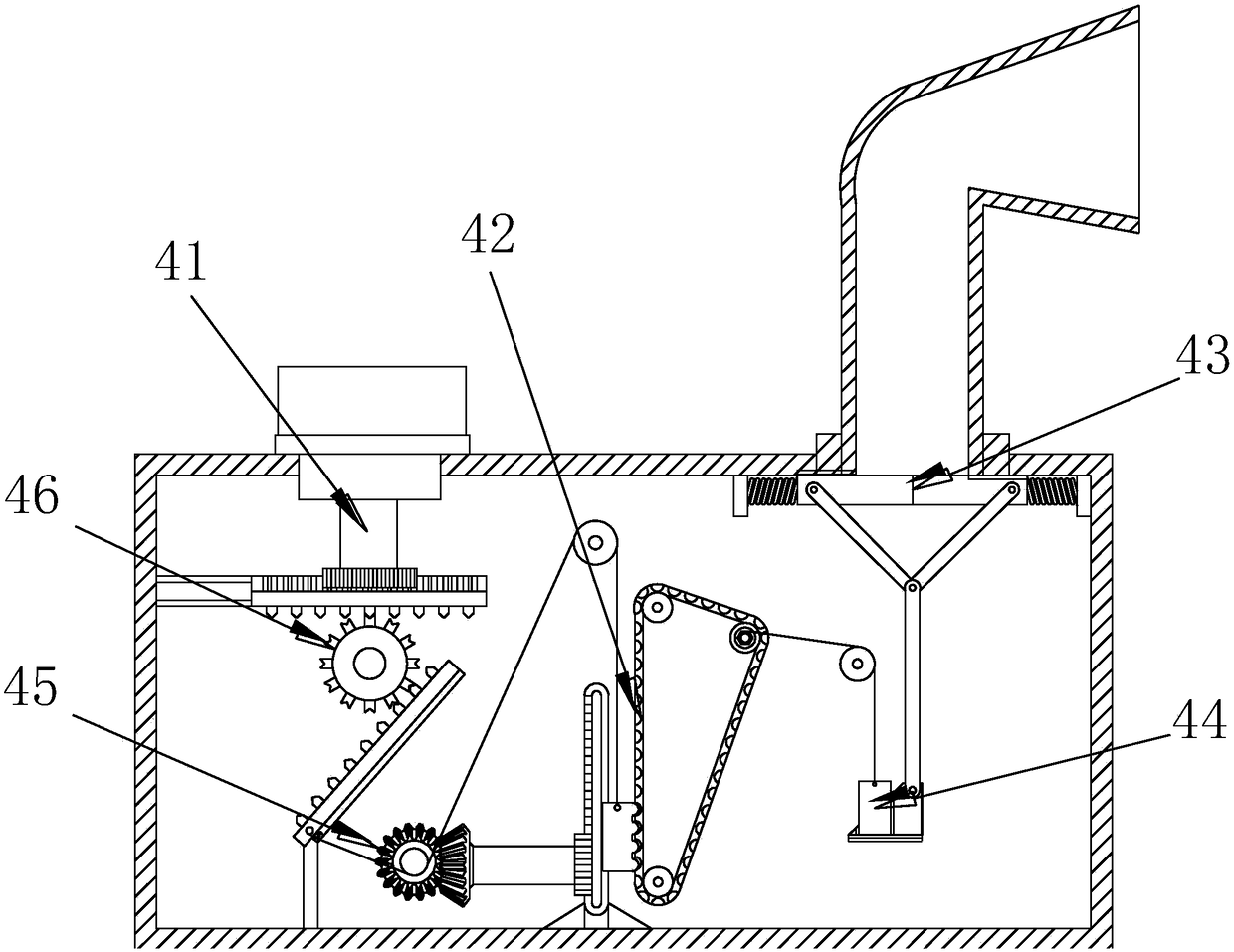

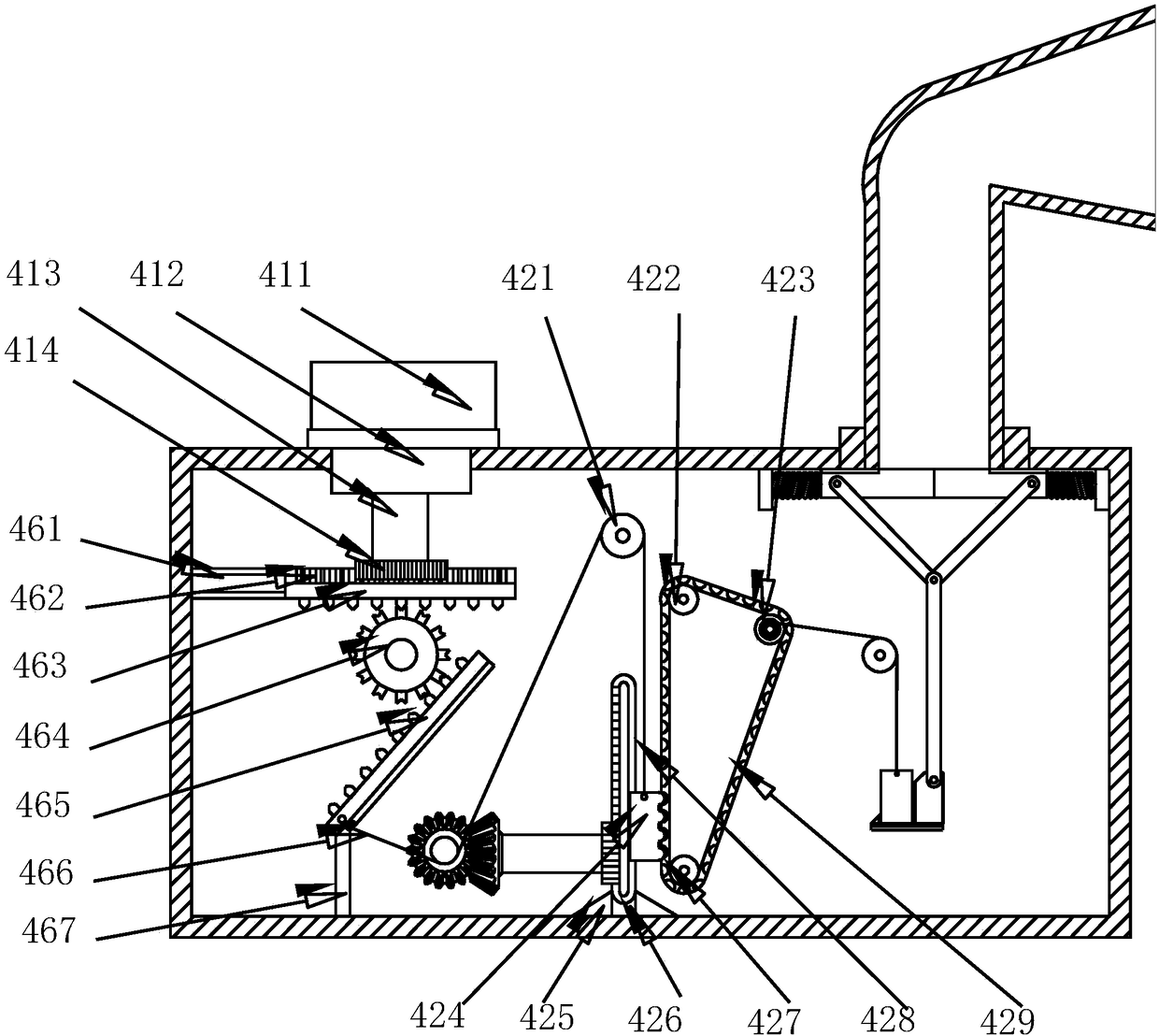

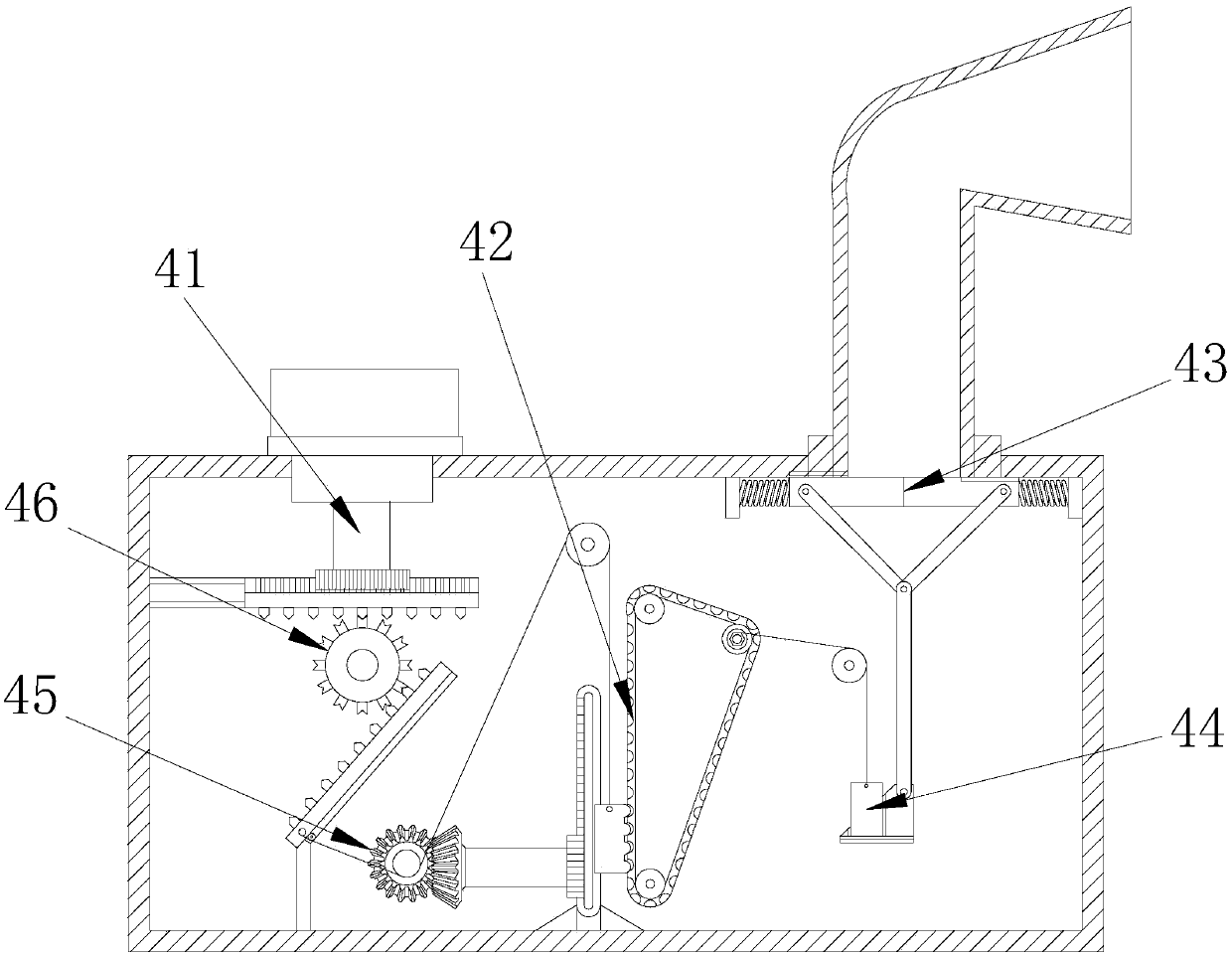

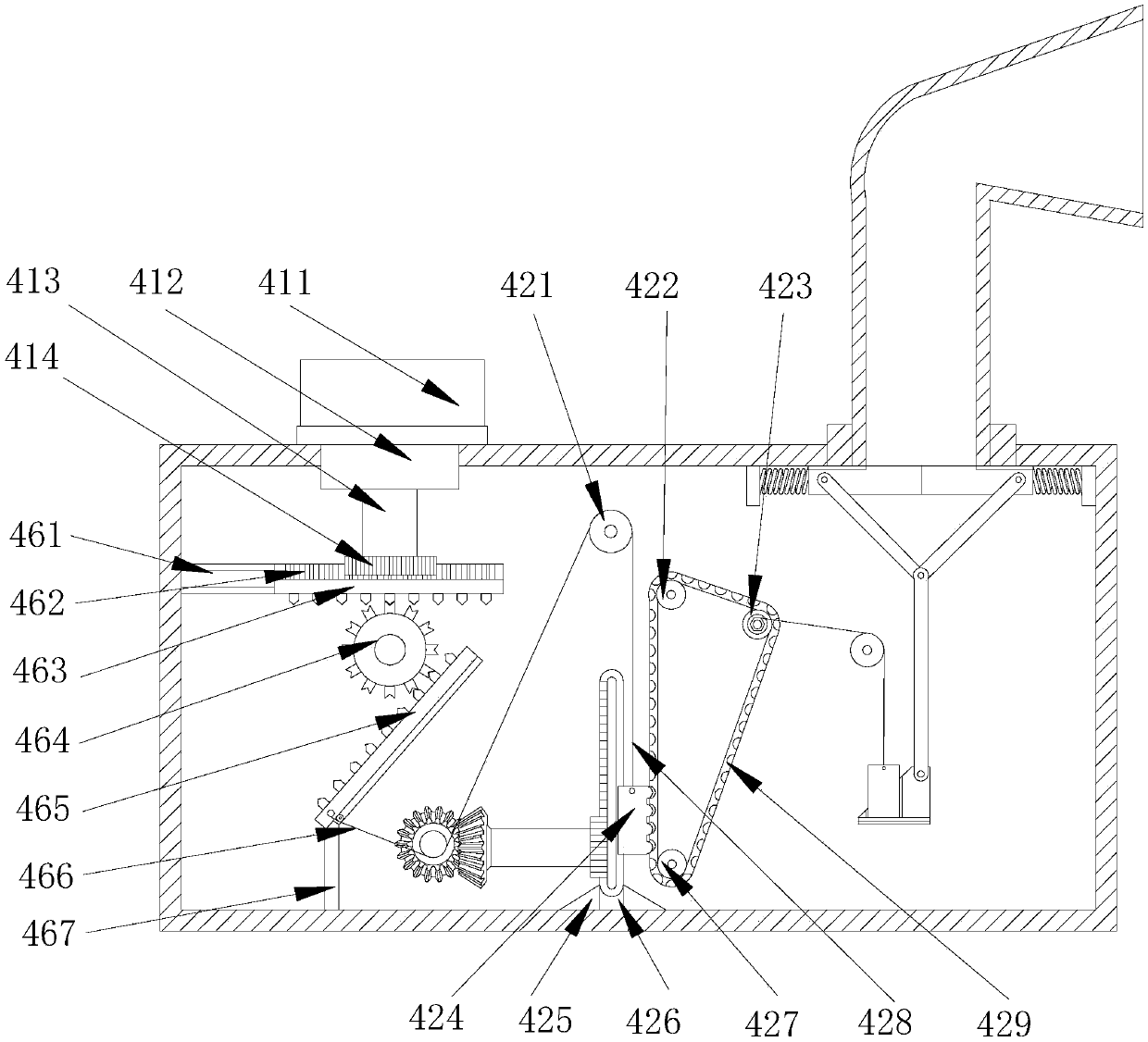

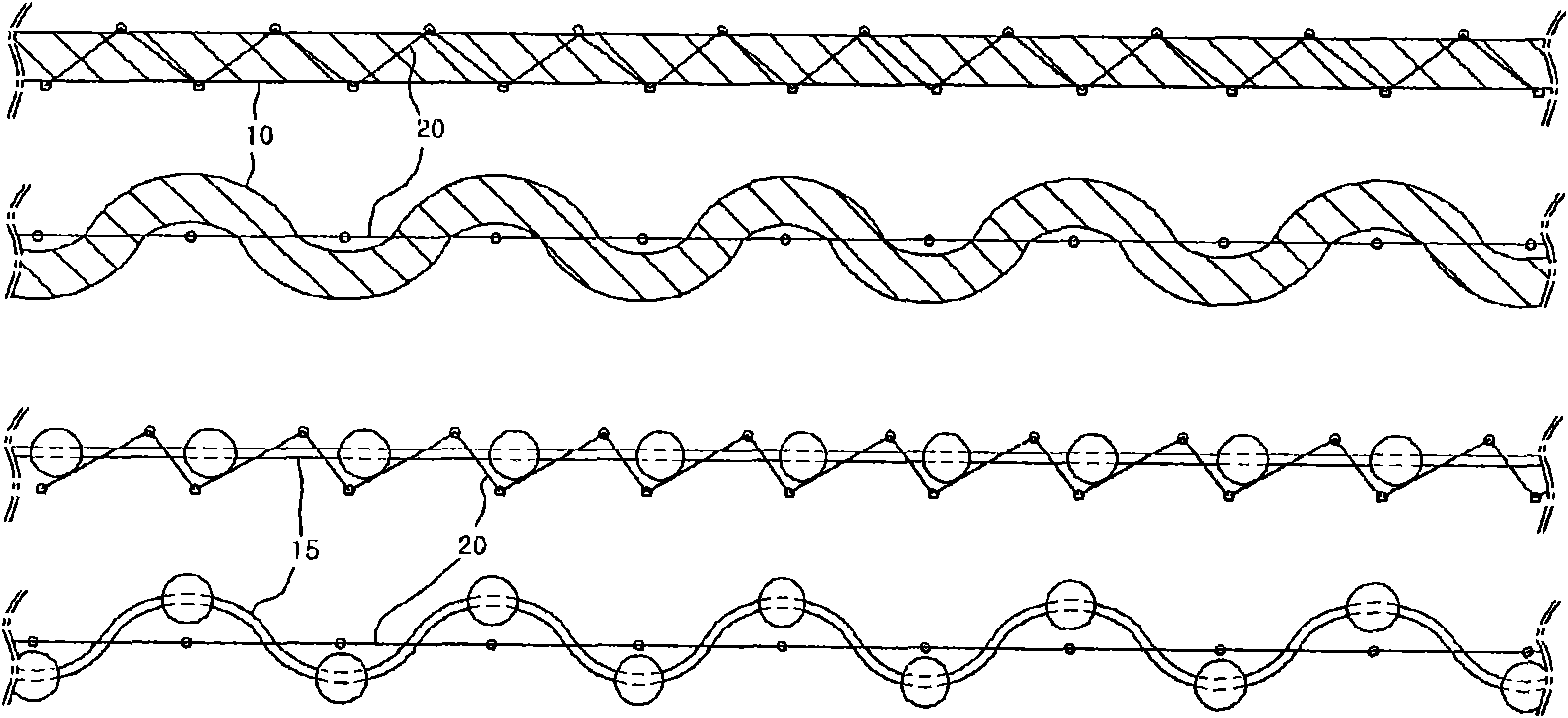

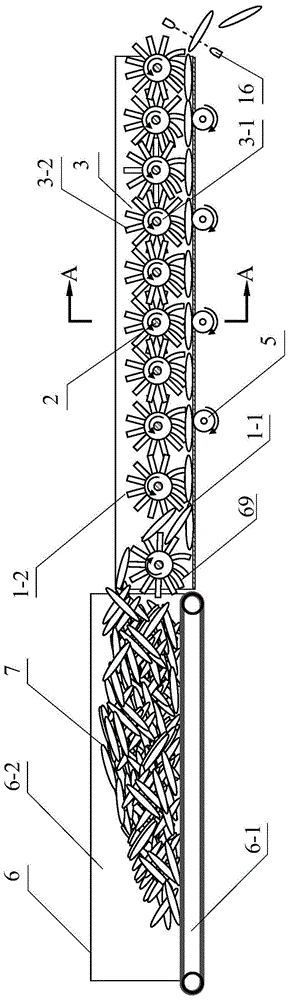

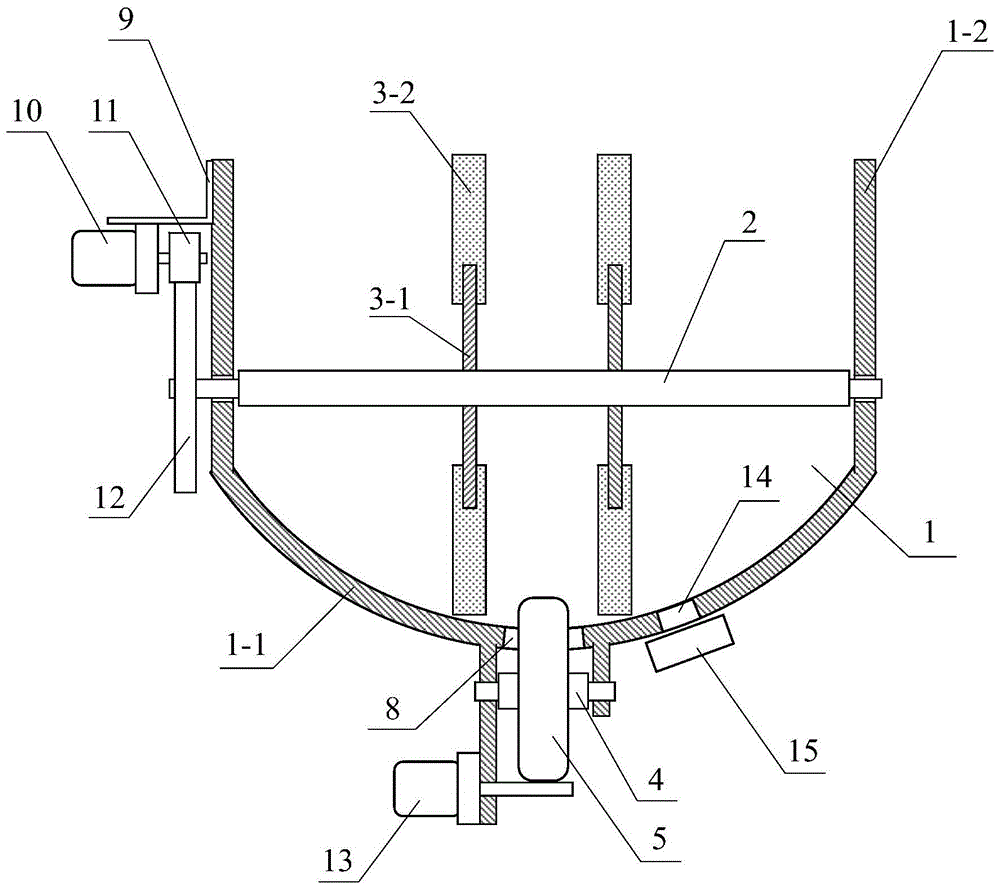

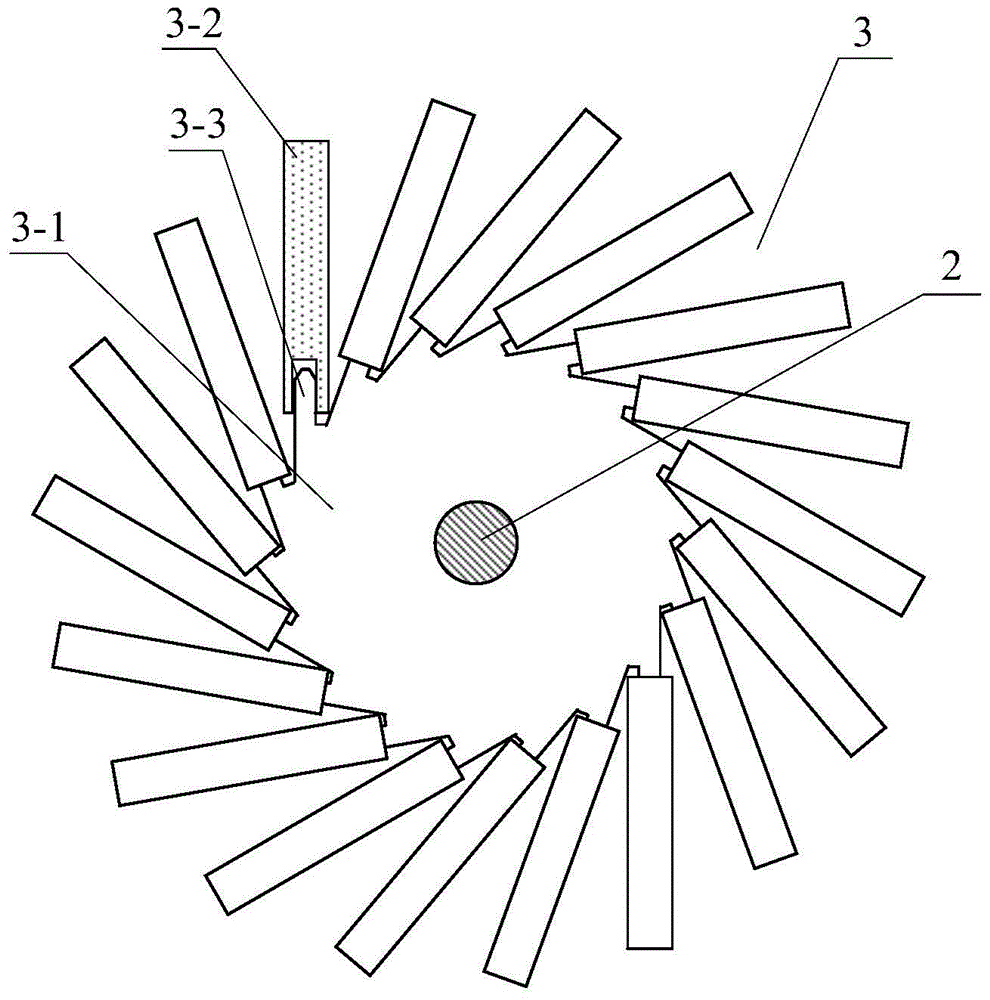

Counting device for bagged goods

ActiveCN104859900AImprove counting efficiencyGuaranteed uptimePackaging automatic controlCounting efficiencyEngineering

The invention discloses a counting device for bagged goods. The counting device is characterized by comprising an arrangement tank; one end of the arrangement tank is a bag inlet end, and the other end of the arrangement tank is a bag outlet end; multiple stages of bag stirring axles are arrayed on the arrangement tank in the length direction, each stage of bag stirring axle is provided with at least one bag stirring wheel located in the arrangement tank, each bag stirring axle is connected with a bag stirring wheel drive device in a transmission mode, and all the bag stirring wheels rotate in the same direction; an arrangement passageway for the bagged goods to conveniently pass through is formed by the gap between the bag stirring wheels and the tank bottom of the arrangement tank, a counting sensor is arranged at the bag outlet end of the arrangement tank, and a folded bag separation device which arranges and separates the bagged goods folded in the arrangement passageway is arranged on the arrangement tank. The counting device can count the bagged goods bag by bag, the folded bagged goods can be separated, the phenomenon that counting is not accurate when bags are folded is avoided, and the counting efficiency and accuracy are greatly improved compared with manual counting or weighing conversion.

Owner:张家港建辰机械科技有限公司

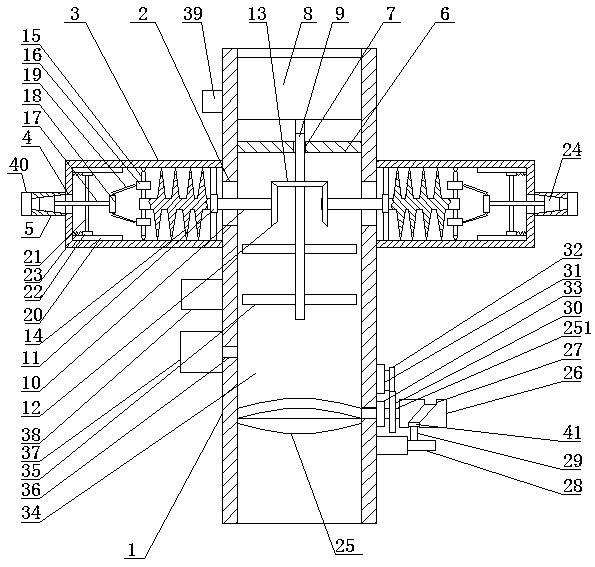

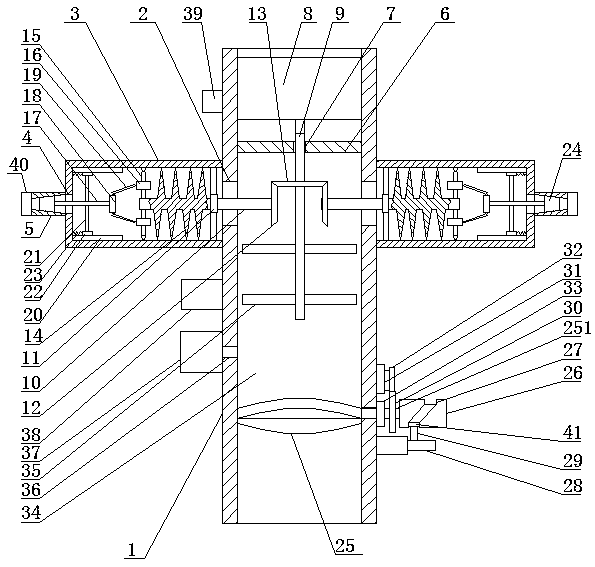

Efficient and energy-saving gas mixing device of internal combustion engine

InactiveCN110017223AEfficient speedIncrease air supply speedInternal combustion piston enginesFuel supply apparatusSpiral bladeExternal combustion engine

An efficient and energy-saving gas mixing device of an internal combustion engine comprises a vertical pipe. First through holes are symmetrically formed in the left side and the right side of the vertical pipe. Transverse pipes are arranged at the outer ends of the first through holes. One end of each transverse pipe is fixedly connected with the outer end of the corresponding first through hole.Second through holes are formed in the other ends of the transverse pipe. Connecting pipes are fixedly mounted at the outer ends of the second through holes and are coaxial with the transverse pipes.A round sealing plate is arranged on the upper sides of the inner ends of the first through holes. The efficient and energy-saving gas mixing device is simple in structure and ingenuous in concept; the mixing speed and supply speed of gas fuel can be increased; efficient acting of the internal combustion engine can be guaranteed; and under drive of spiral blades, the inlet efficiency of gas and air in a gas mixing cavity can be improved, and efficiency work of the internal combustion engine can be guaranteed. The efficient and energy-saving gas mixing device can be mounted and used without carrying out structure modification on a traditional internal combustion engine, is low in manufacturing cost and can be mounted on an automobile, a driver controls stretching and contracting of a hydraulic rod through an accelerator pedal to control the speed of the gas fuel entering the internal combustion engine, and therefore the rotating speed of the internal combustion engine is controlled.

Owner:LIAOCHENG UNIV

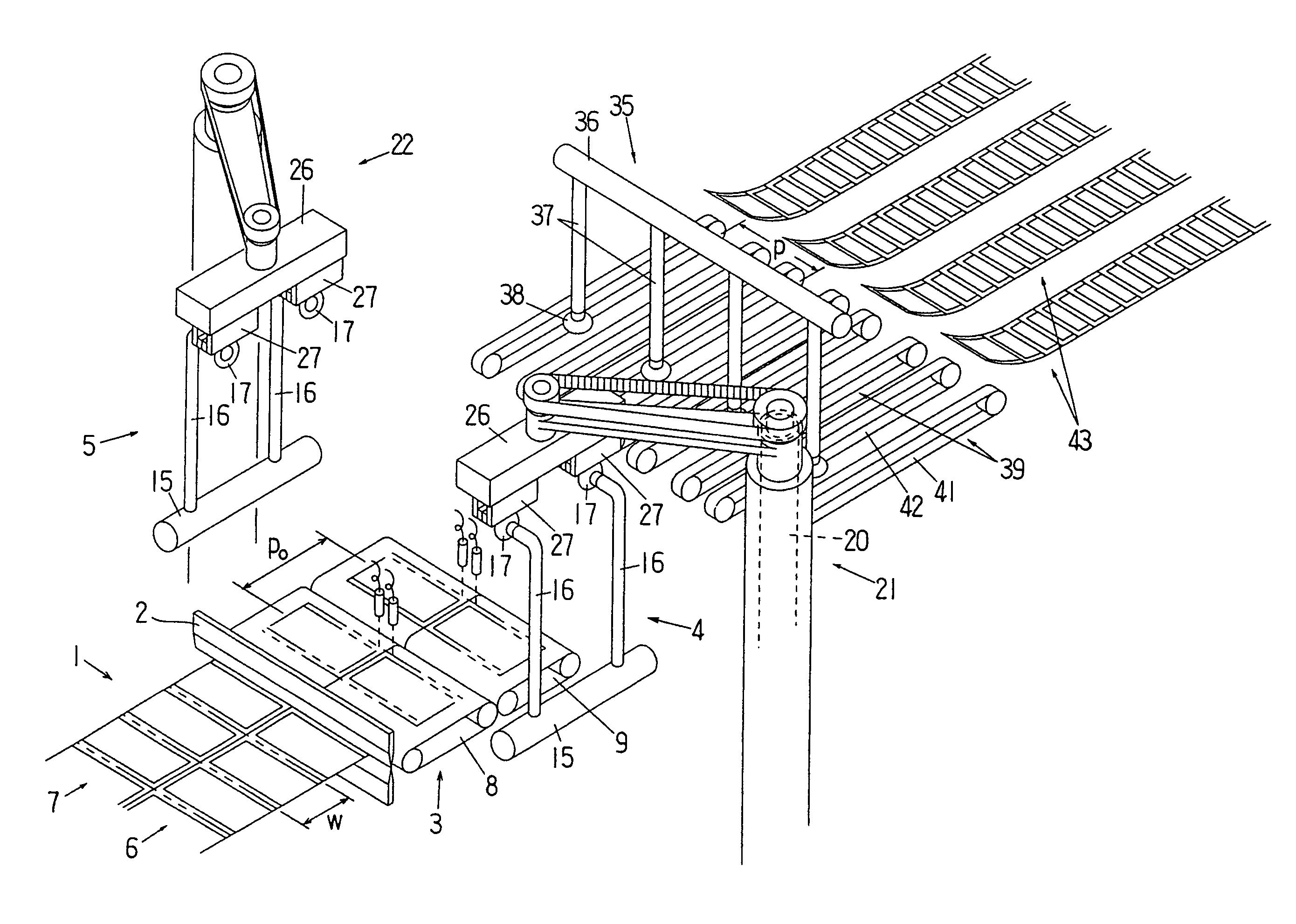

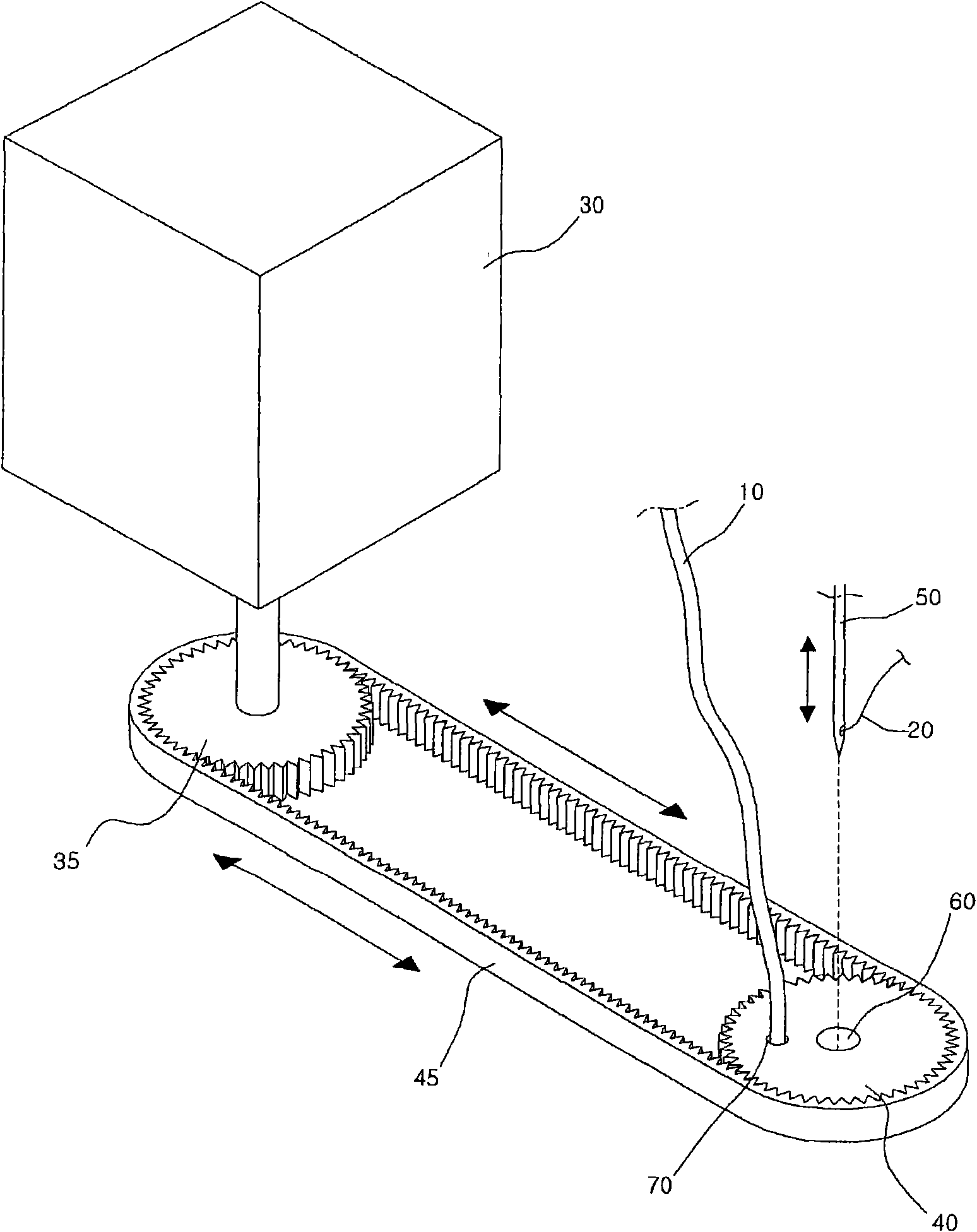

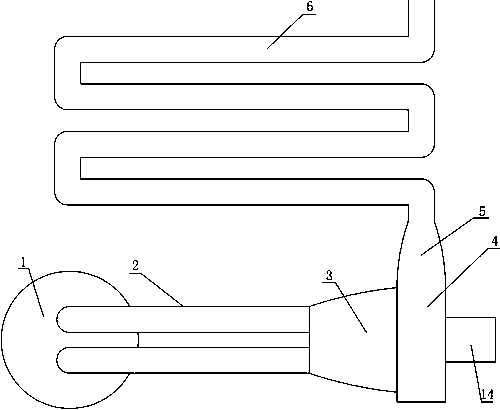

Method and apparatus for supplying bags to a packaging machine

ActiveUS8511458B2Improve efficiencySimple mechanismEnvelopes/bags making machineryBag making operationsEngineeringPackaging machine

A bag-making and packaging machine including first through third transportation devices provided between a positioning conveyor that positions bags fed out from a horizontal-type bag-making machine and a supply conveyor that supplies the bags to a conveyor magazine-type bag-supply apparatus of a packaging machine, wherein the first transportation device suctions and raises the bags from the positioning conveyor and changes them into a vertical attitude with the bag mouth portions facing downward, the second transportation device takes the bags held by the first transportation devices by gripping them with the gripping members, horizontally transports them to a prescribed position while rotating them, and then the third transportation device suctions and takes up the bags from the second transportation device, changes them to a horizontal attitude with the bag mouth portions facing in the bag feed direction and then places them on the supply conveyor.

Owner:TOYO JIDOKI CO LTD

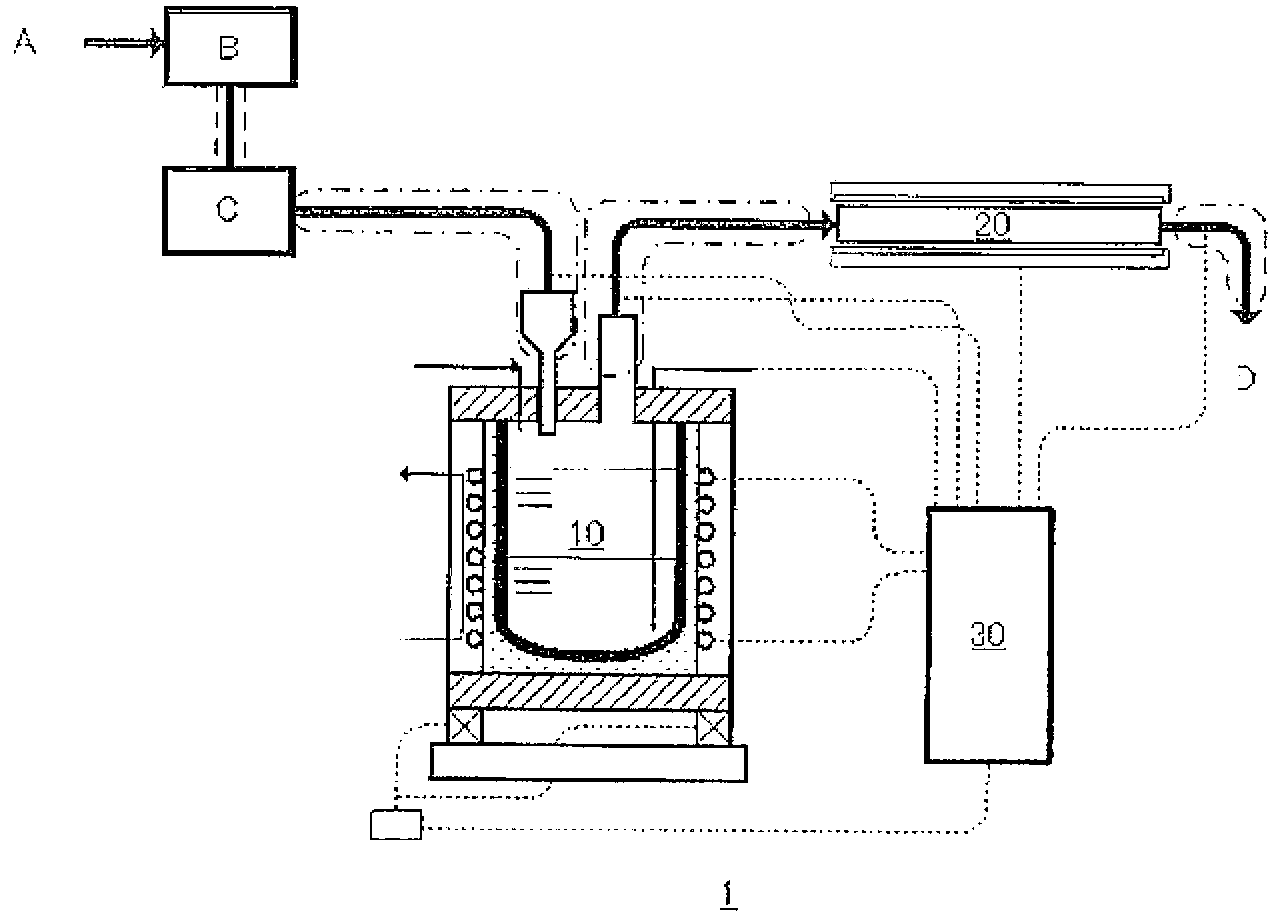

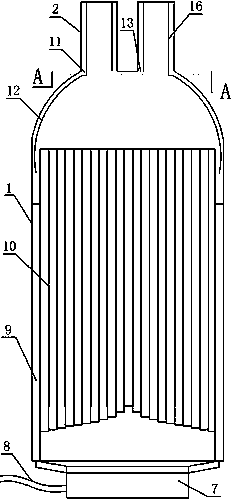

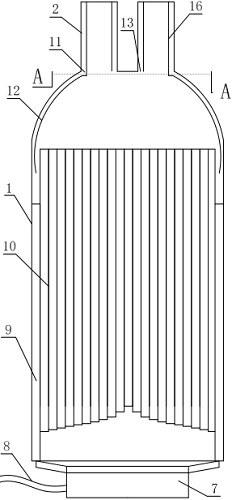

Method and device for supplying zinc gas

InactiveCN103282308AChangeEasy to controlCrucible furnacesSilicon compoundsElectrical resistance and conductanceBoiling point

The invention provides a method and device for supplying, at a controlled supply speed, zinc gas which is overheated to above the boiling point of zinc. The method for supplying zinc gas according to the present invention comprises: a step of introducing a zinc melt into a zinc gas evaporator; a step of inputting power corresponding to the supply speed of zinc gas and causing zinc to self-evaporate by high frequency induction heating to generate zinc gas from the zinc melt; a step of introducing the generated zinc gas into a gas heating device; and a step of heating the zinc gas by resistance heating to produce overheated zinc gas. The device for supplying zinc gas according to the present invention is used for the above method, and comprises a zinc gas evaporator, a gas heating device and a control device.

Owner:JNC CORP +2

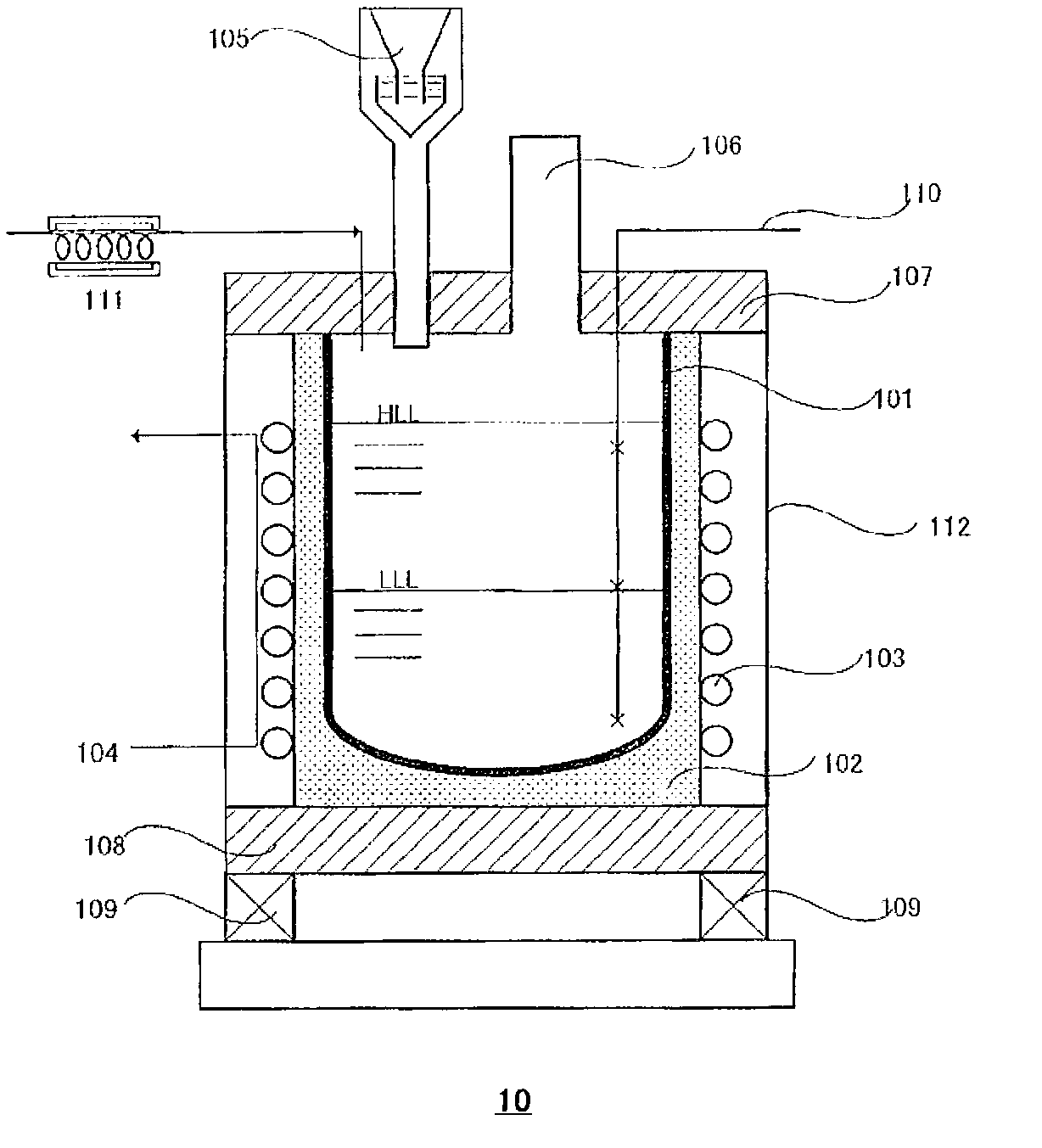

Process for producing Ti and apparatus therefor

A process for producing Ti, comprising the reduction step of providing a molten salt containing CaCl2 and having Ca dissolved therein and reacting TiCl4 with the Ca to thereby form Ti particles, the separation step of separating the Ti particles formed in the molten salt from the molten salt and the electrolysis step of electrolyzing the molten salt so as to increase the concentration of Ca, wherein the molten salt having the concentration of Ca increased in the electrolysis step is introduced in a regulation vessel to thereby render the Ca concentration of the molten salt constant and thereafter is used in the reduction of TiCl4 in the reduction step. In this process, not only can any fluctuation of Ca concentration of molten salt charged in a reduction vessel be suppressed but also a high concentration thereof can be maintained. Further, continuous processing of a large volume of molten salt becomes feasible. Therefore, the reduction reaction of TiCl4 can be efficiently performed, and as a process for realization of Ti production on an industrial scale, the process can be effectively utilized in the production of Ti by Ca reduction.

Owner:OSAKA TITANIUM TECHNOLOGIES

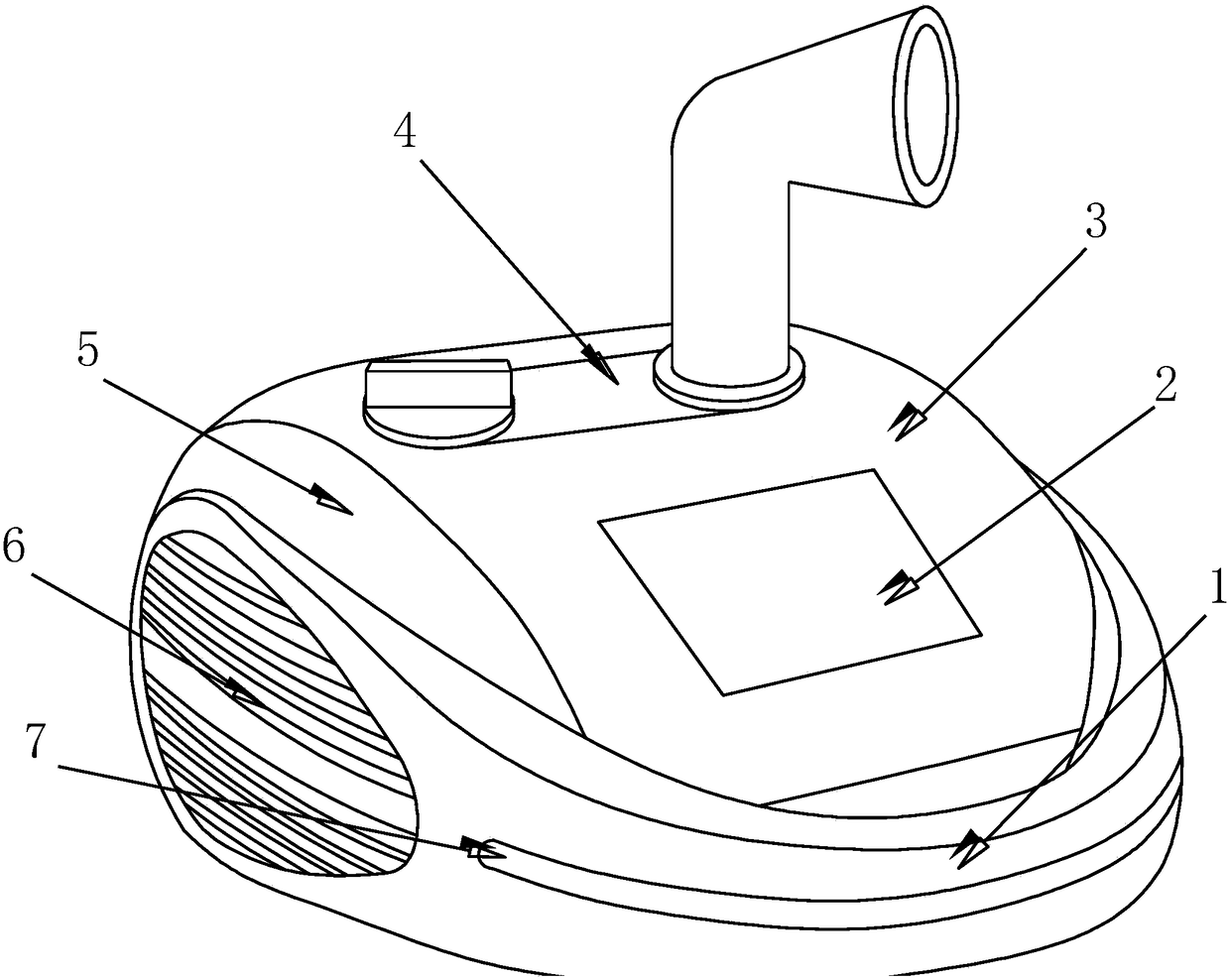

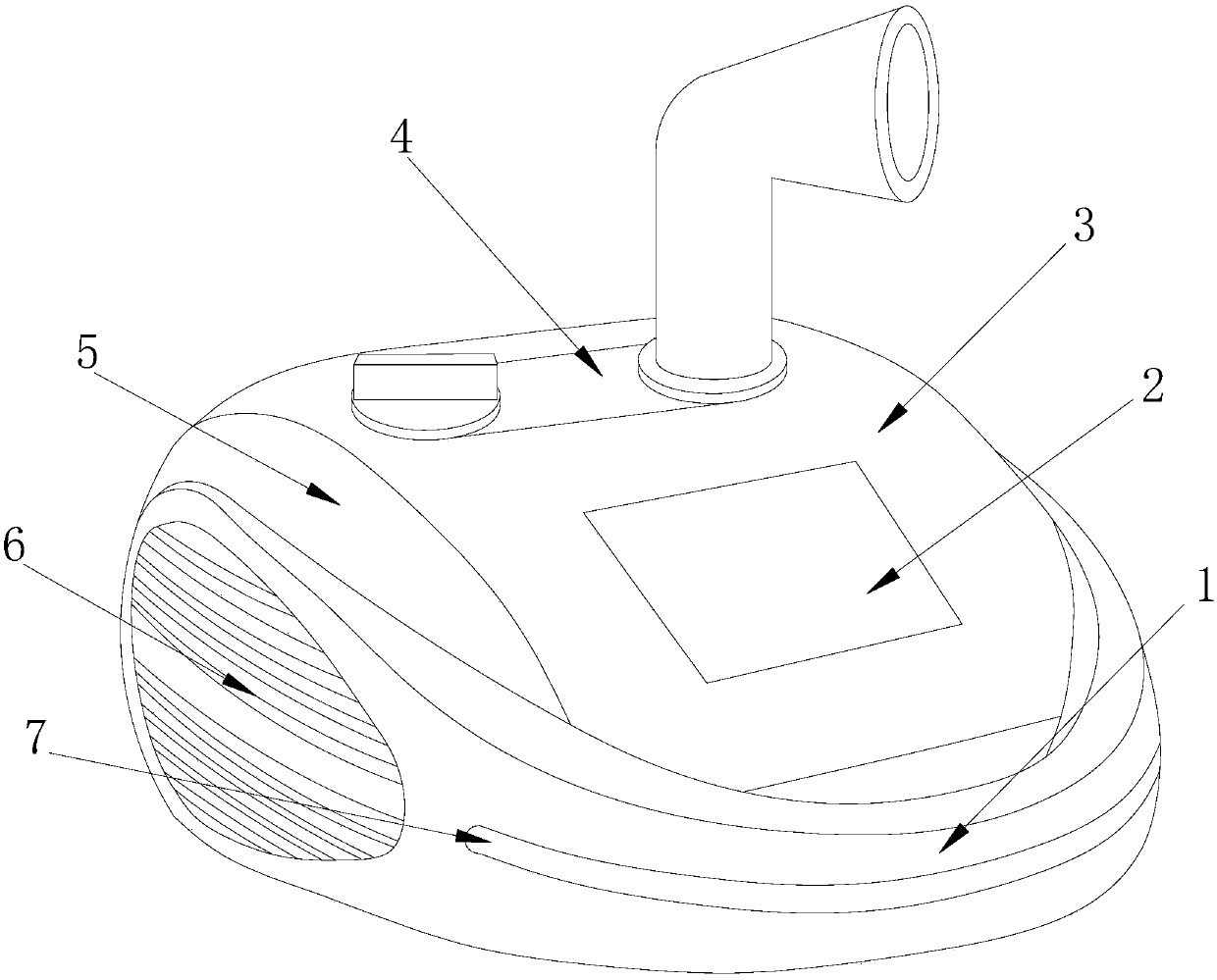

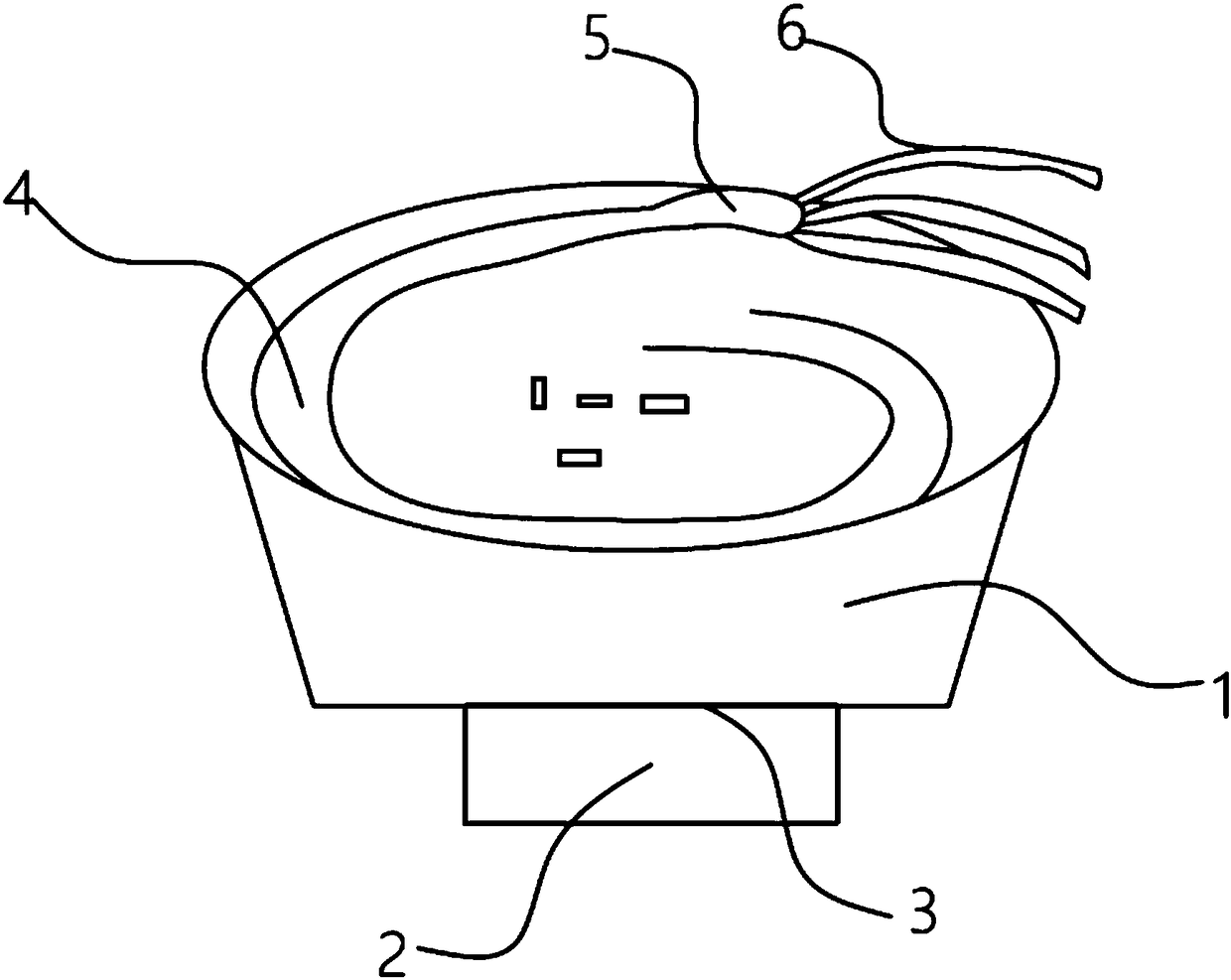

Dosing speed-adjustable respiratory department atomization doser

InactiveCN108421136AIncrease supply speedFully absorbedMedical devicesMedical atomisersTreatment effectRespiratory rate

The invention discloses a dosing speed-adjustable respiratory department atomization doser, structurally comprising an annular handle, an inward vision plate, an atomizer shell, an atomization dosingspeed-adjustable device, a side cover buckle, a cooling window and a channel 7, and characterized in that the inner surface of the annular handle is bonded with the outer surface of the side cover buckle, the cooling window forms an integrated structure with the annular handle, and is located at the left end of the annular handle, the channel 7 forms an integrated structure with the annular handle, the lower end of the inward vision plate is embedded and mounted at the upper end of of the atomizer shell, and the lower end of the atomization dosing speed-adjustable device is embedded and mounted at the upper end of the atomizer shell. When the dosing speed-adjustable respiratory department atomization doser is used, after a fixed amount of drug is put into an atomization treatment device, while the atomized drug is sucked for treatment, the atomization output rate of the atomizer can be adjusted according to different breath frequency of each person, so that the drug is absorbed more fully, and a better treatment effect is achieved.

Owner:谭健

Voucher cassette

ActiveUS8430396B2Increase speedCompact structureCoin/currency accepting devicesPile receiversEngineeringVoucher

Owner:DIEBOLD NIXDORF SYST GMBH

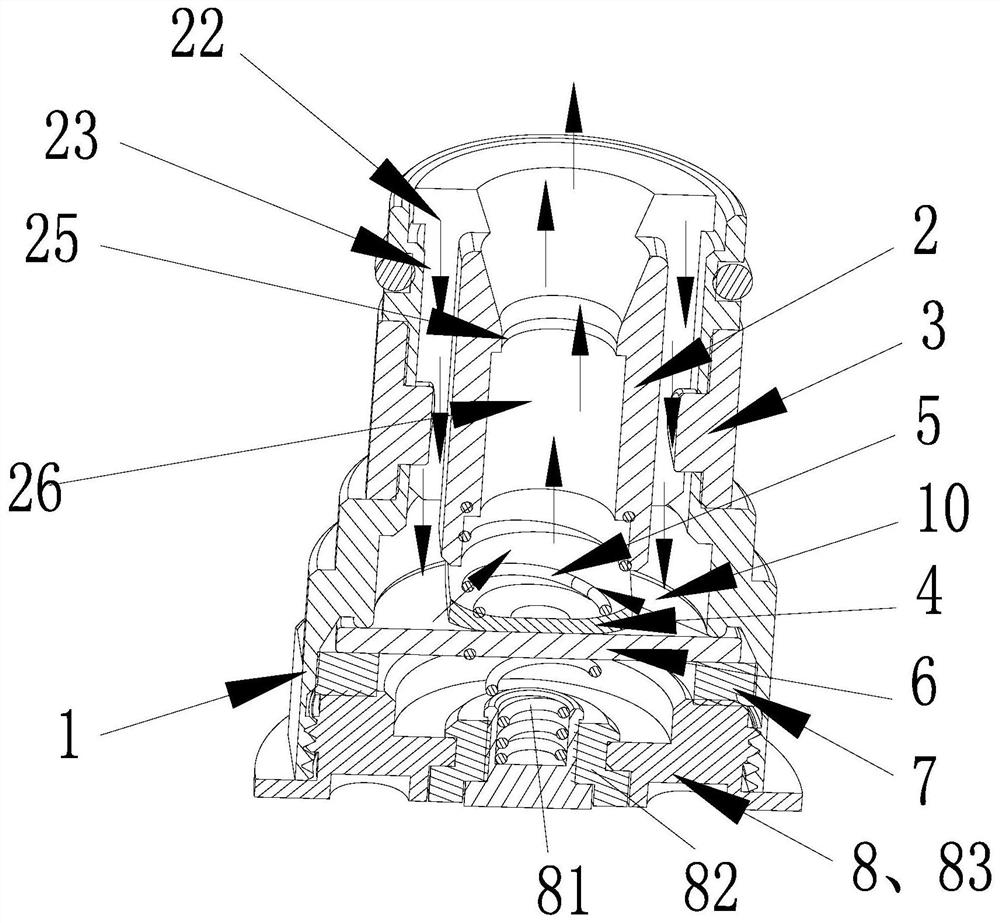

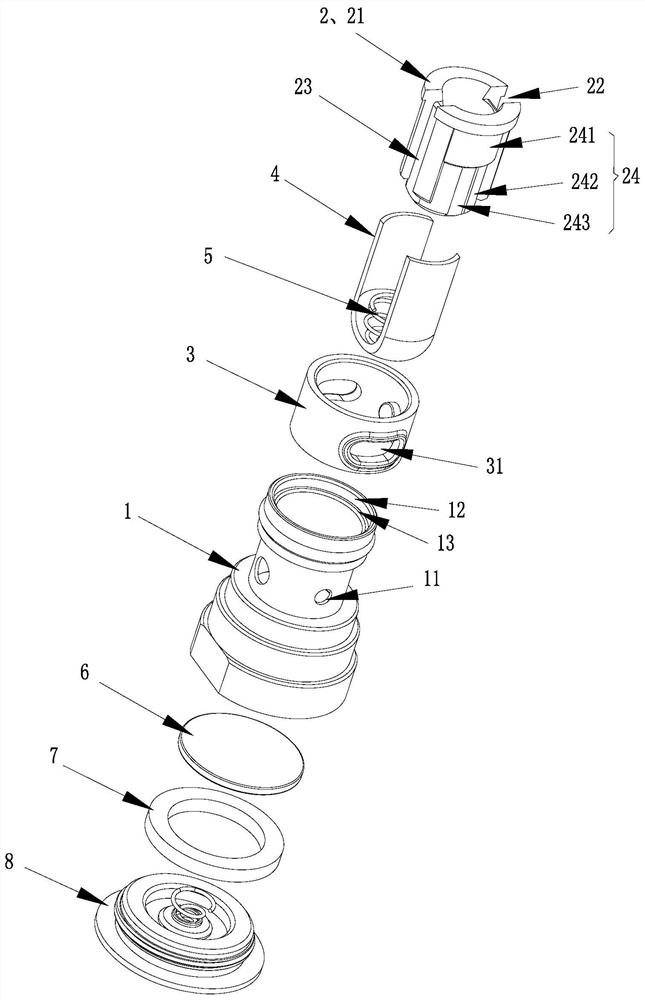

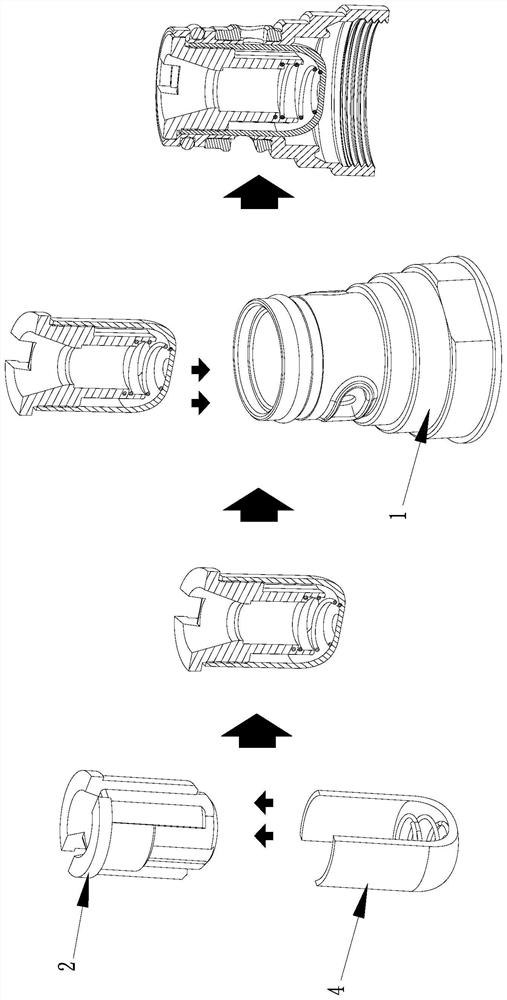

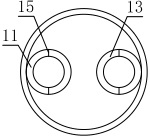

Electronic cigarette atomization core and atomizer

The invention discloses an electronic cigarette atomization core and an atomizer. The electronic cigarette atomization core comprises an outer atomizing sleeve (1) and an inner atomizing sleeve (2) which are sleeved with each other, a first oil passing opening (11) communicated with an oil outlet (A1) of an oil bin is formed in the side wall of the outer atomizing sleeve, U-shaped oil guide cotton(4) is clamped between the outer atomizing sleeve and the inner atomizing sleeve, the end of the oil guide cotton covers the first oil passing opening, an air supplementing groove (243) used for conveying air to the oil bin is formed in the position, corresponding to the first oil passing opening, of the outer wall of the inner atomizing sleeve, and the air supplementing groove is communicated with a first air inlet channel. A boss (25) used for sealing and clamping a breather pipe (9) is arranged in the middle of an inner cavity of the inner atomizing sleeve, and an air outlet cavity (26) isformed below the boss. According to the electronic cigarette atomization core and the atomizer, the tobacco tar supply speed is increased, the dry burning of an ultrasonic atomization piece can be effectively prevented, splashed tobacco tar is condensed in the air outlet cavity during ultrasonic atomization, and a user is not prone to the sucking of the tobacco tar.

Owner:CHINA TOBACCO HUNAN INDAL CORP

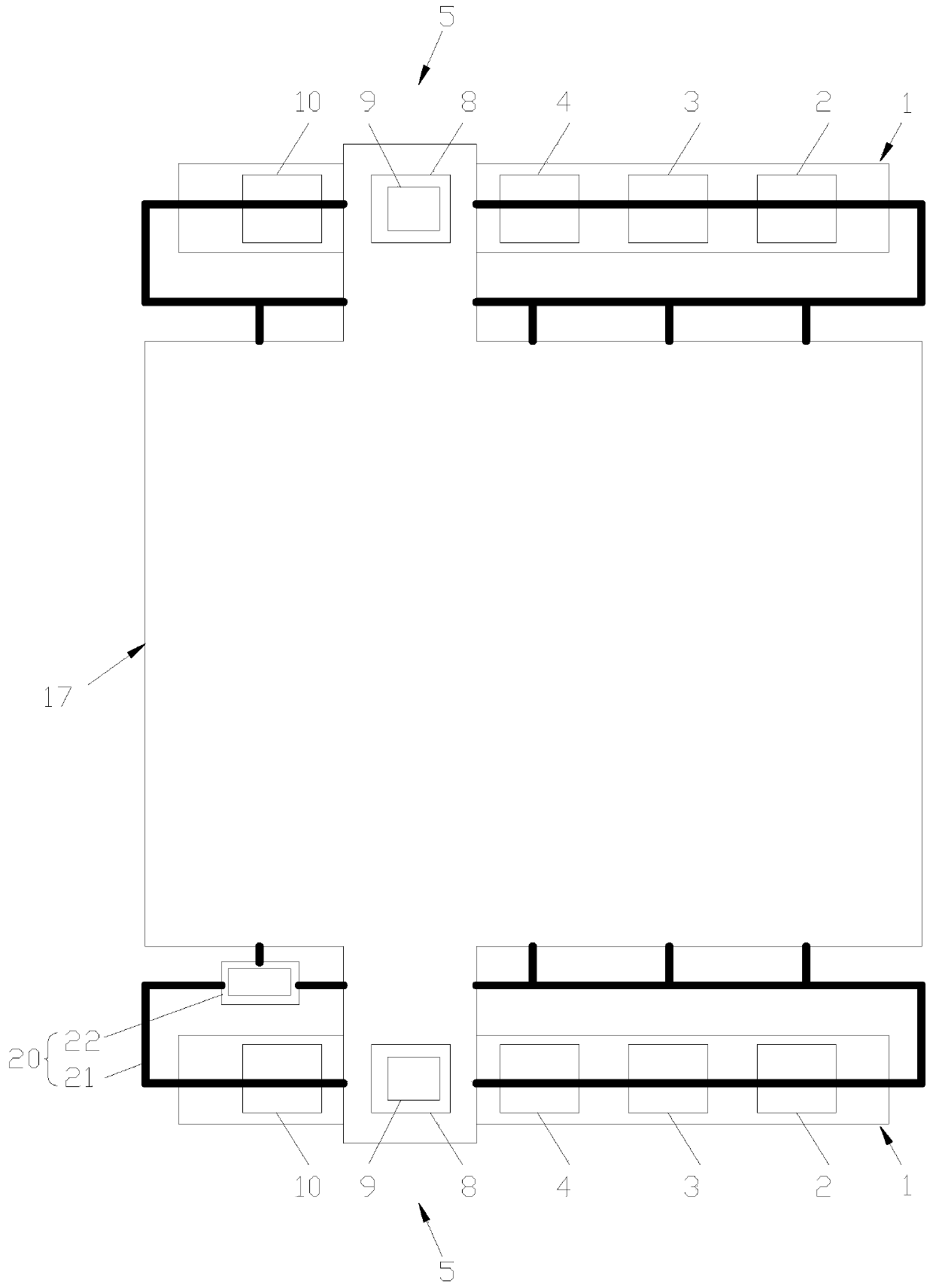

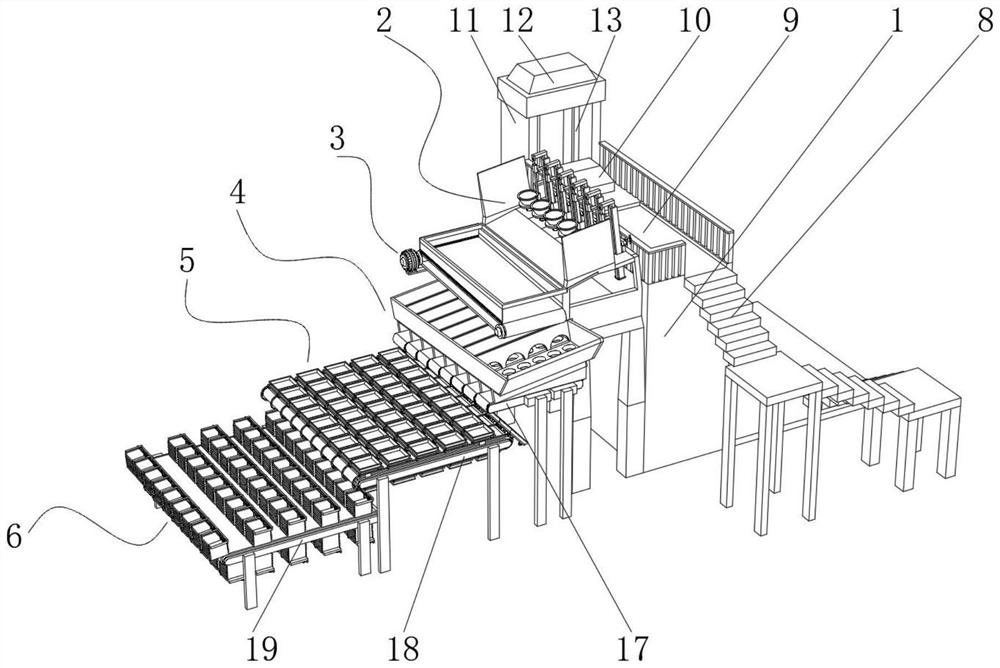

Pipe piece flexible production line

ActiveCN110509419AComplete supporting facilitiesSmall footprintCeramic shaping plantsProduction lineRebar

The invention relates to the technical field of prefabricated concrete lining piece pieces, in particular to a pipe piece flexible production line. The pipe piece flexible production line comprises production pouring lines, a steam curing area, static stopping areas, a die walking device and a reinforcement cage machining area. The static stopping areas and the production pouring lines are arranged on the two sides of the steam curing area from the near to the distant. The die walking device comprises rails and a carrying trolley, and the production pouring lines, the steam curing area and thestatic stopping areas communicate with one another through the rail. The carrying trolley is arranged on the rails, and the reinforcement cage machining area is overall arranged above the steam curing area and the static stopping areas on the two sides. By means of the pipe piece flexible production line, matched facilities are complete, the occupied area is smaller, the concentration degree of the production line is higher, and therefore the production technology is improved, and the production efficiency is improved.

Owner:苏州交通工程集团有限公司

Shock-absorbing material supply apparatus used for article packaging device

PendingUS20210347511A1Accurate supplySimple supplyConveyorsLarge containersMaterial supplyIndustrial engineering

The present invention relates to a shock-absorbing material supply apparatus used for a device-article packaging device for putting and packaging articles and a shock-absorbing material together in a packaging box. The present invention relates to the shock-absorbing material supply apparatus used for the article packaging device for filling the empty inner space of a packaging box B, into which articles are put, with the shock-absorbing material so as to package the articles, the apparatus comprising: a shock-absorbing material manufacturing device; a first hopper; a shock-absorbing material supply conveyor; a shock-absorbing material accommodation part; and a shock-absorbing material guide part.

Owner:CJ KOREA EXPRESS CORPORTAION

Atomization drug delivery device allowing drug-delivery speed to be adjusted and used for respiratory medicine department

PendingCN109621106AIncrease supply speedFully absorbedMedical devicesMedical atomisersNebulizerTherapeutic effect

The invention discloses an atomization drug delivery device allowing a drug-delivery speed to be adjusted and used for the respiratory medicine department. The atomization drug delivery device structurally comprises an annular handle, an inward vision plate, an atomizer shell, an atomization drug delivery speed adjustable device, a side cover buckle, a cooling window and a channel 7, and is characterized in that the inner surface of the annular handle and the outer surface of the side cover buckle adhere to each other, the cooling window and the annular handle are of an integrated structure, the cooling window is formed in the left end of the annular handle, the channel 7 and the annular handle are of an integrated structure, the lower end of the inward vision plate is embedded into the upper end of the atomizer shell, and the lower end of the atomization drug deliveryspeed adjustable device is embedded into the upper end of the atomizer shell. According to the design, when the atomization drug delivery device allowing the drug-delivery speed to be adjusted and used for the respiratory medicine department is used, quantified medicine is put into an atomization treatment device, then while atomization medicine is inhaled for treatment, the atomization output rate in the atomization device can be adjusted according to different breath frequencies of all persons, the medicine canbe absorbed more fully, and a batter treatment effect is realized.

Owner:董连鹏

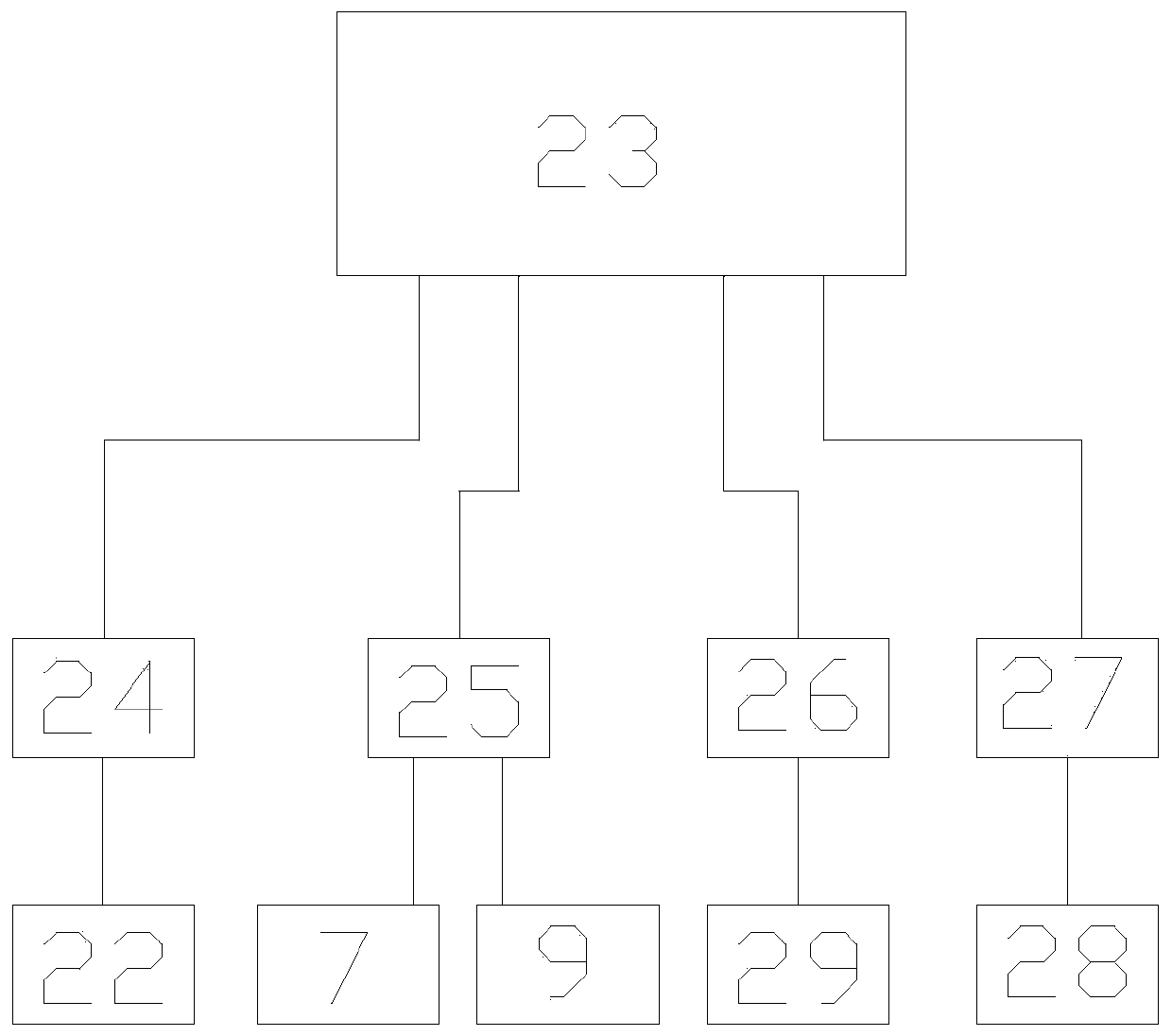

Cashmere yarn feeding controller of embroidery machine and method thereof

InactiveCN101597844APrevents the needle from breakingAvoid breakingProgramme-controlled sewing machinesAutomatic machinesElectric machineryYarn

The present invention relates to a cashmere yarn feeding controller of an embroidery machine and a method thereof, wherein the cashmere yarn feeding controller for the embroidery machine comprises the following components: a pattern part which can store the pattern information of cashmere yarn embroidery; a control unit which analyzes after loading selected pattern information from the pattern part and outputs a swinging control signal and an original point confirmation control signal of the feeding cashmere yarn; a motor which rotates according to a preset direction and angle through the swinging control signal of the control unit, and rotates according to a preset direction and a preset angle through the original point confirmation control signal; a calculating unit which adds and calculates the swinging control value of the motor from the original point value through the controlling of the control unit; and an input unit which can input the command signals comprising searching and selection of cashmere yarn embroidery pattern, the starting and stopping of the embroidery production, original point confirmation, etc.

Owner:SUSR PRECISION CO LTD

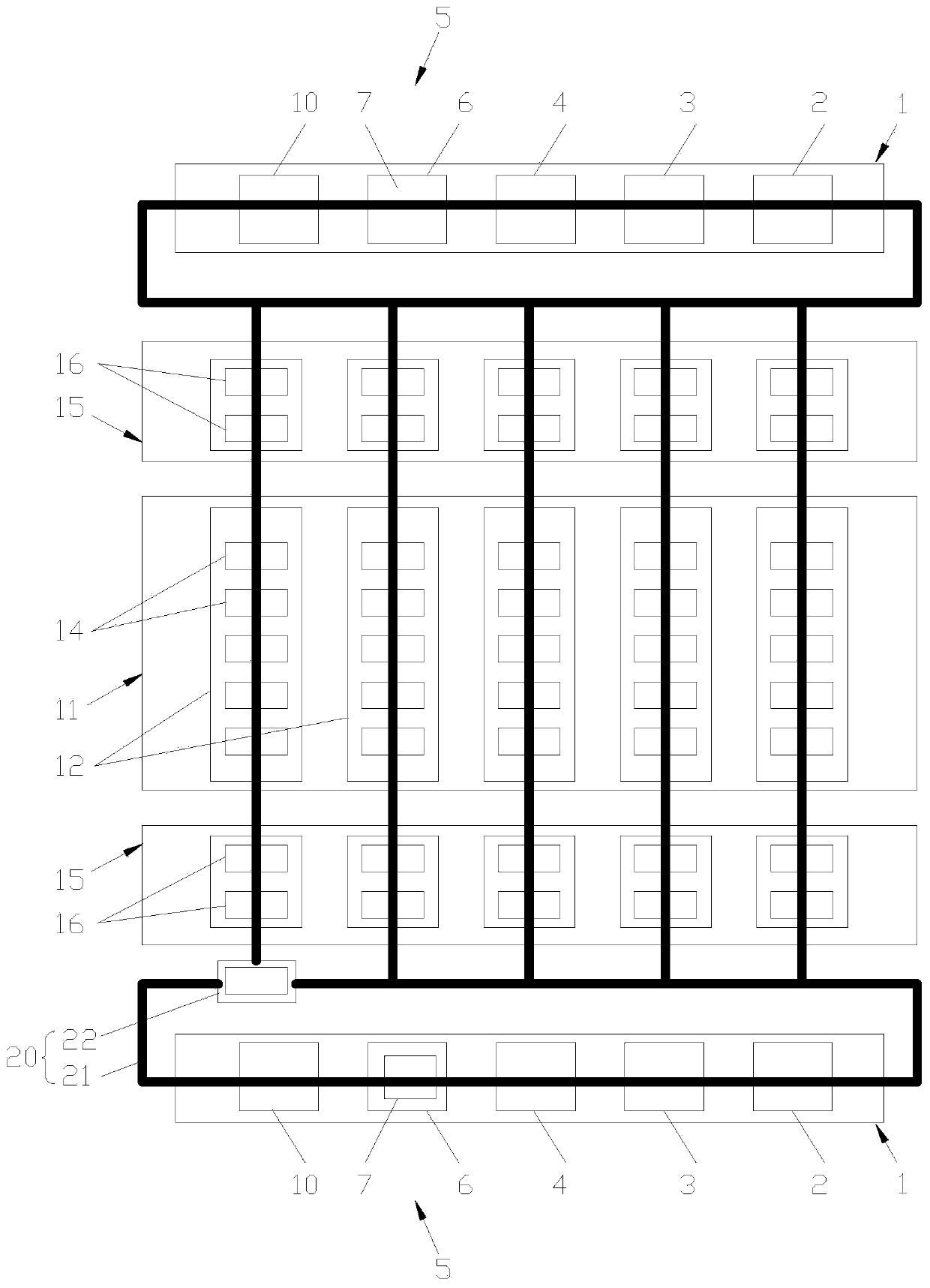

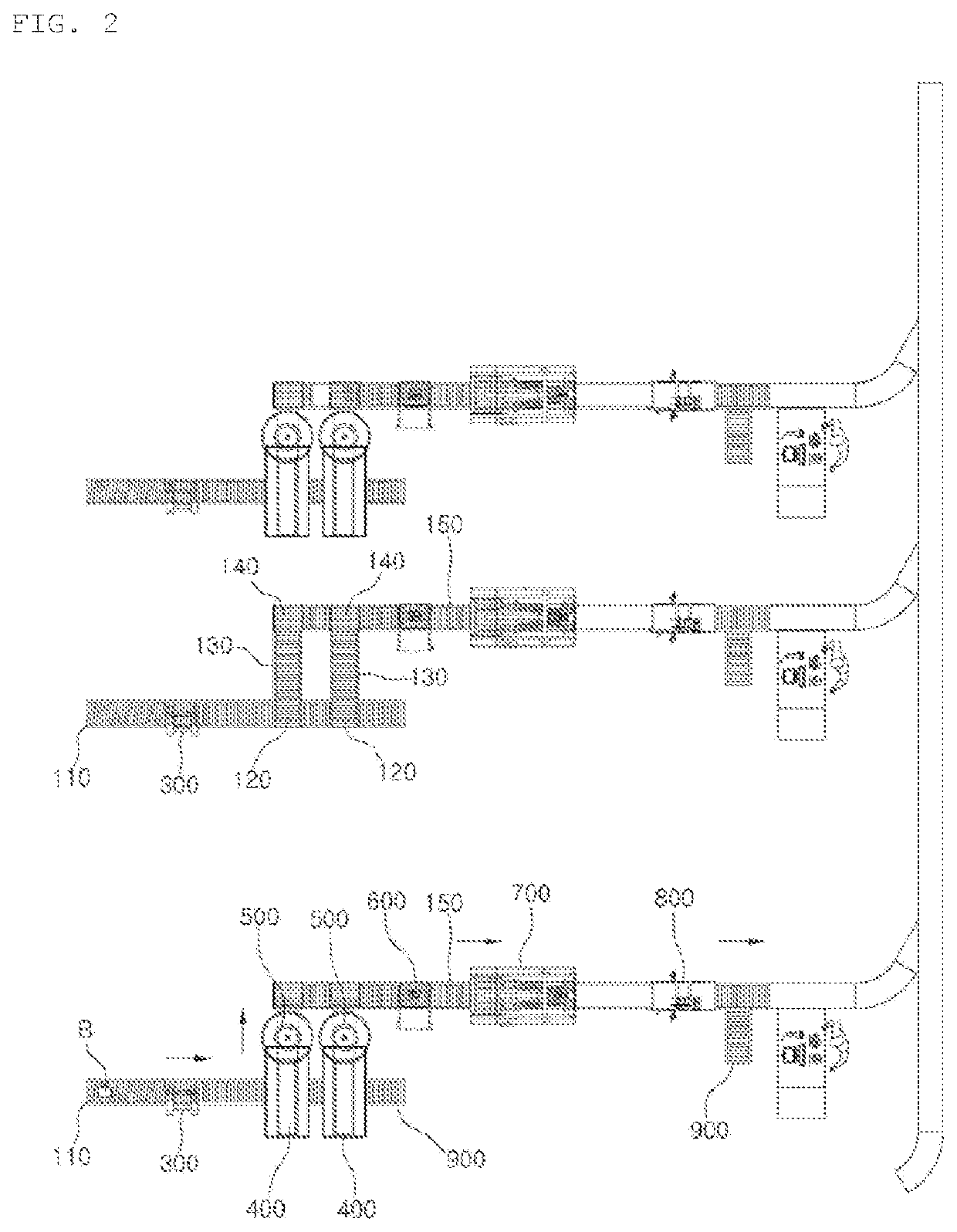

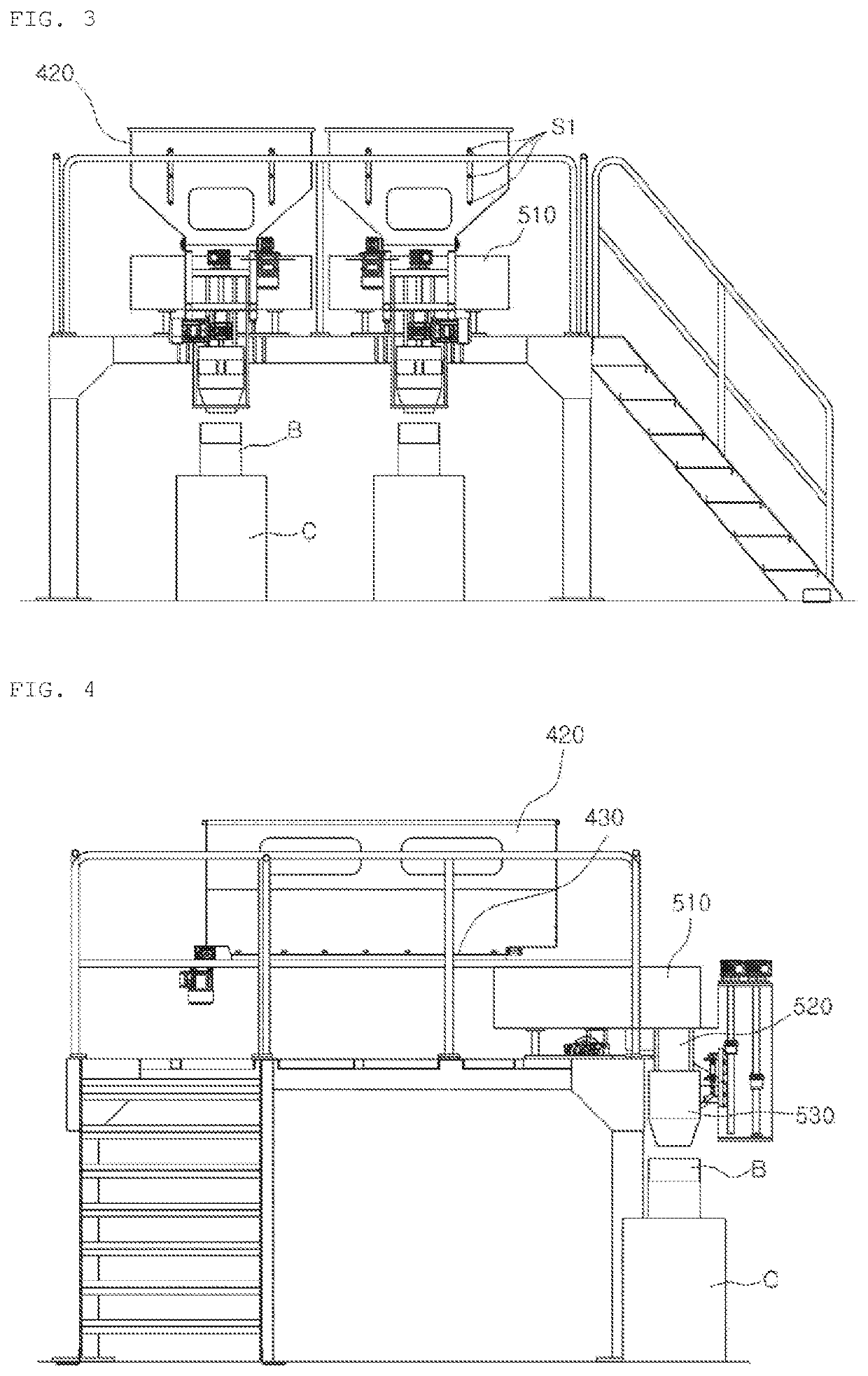

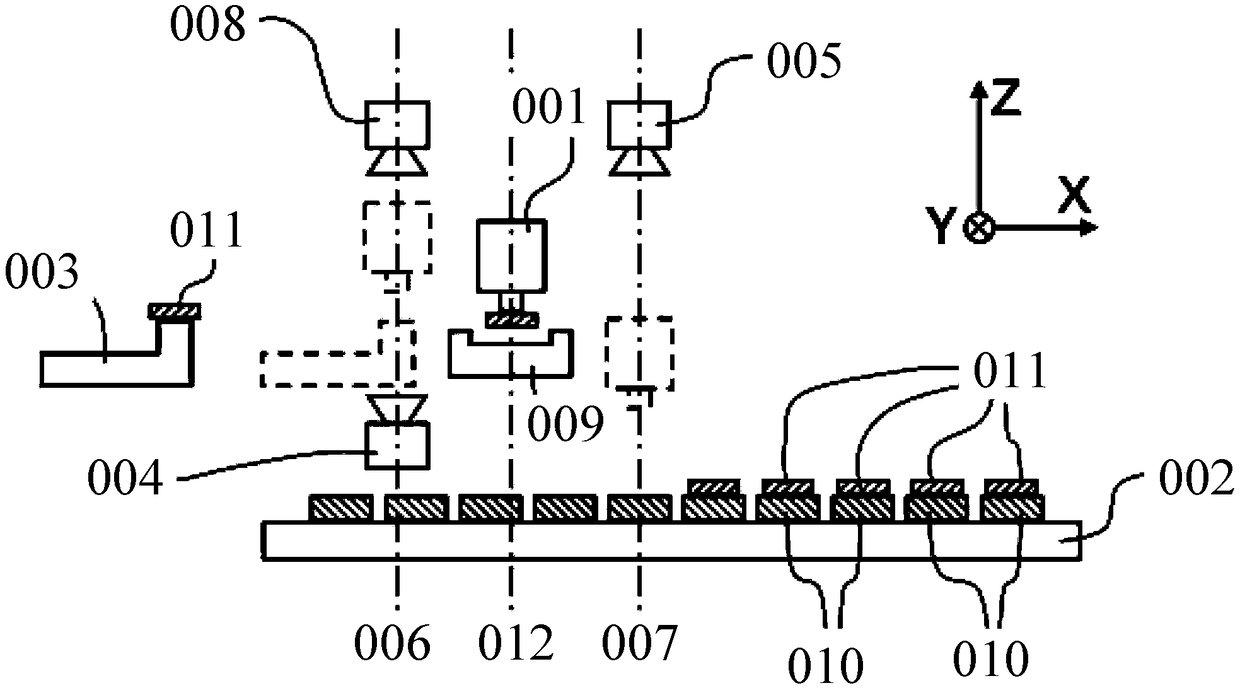

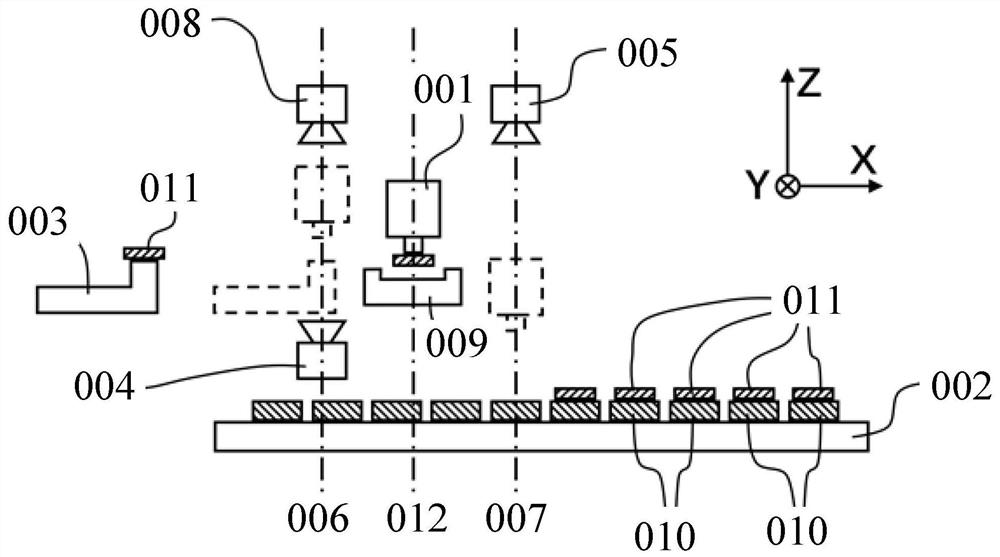

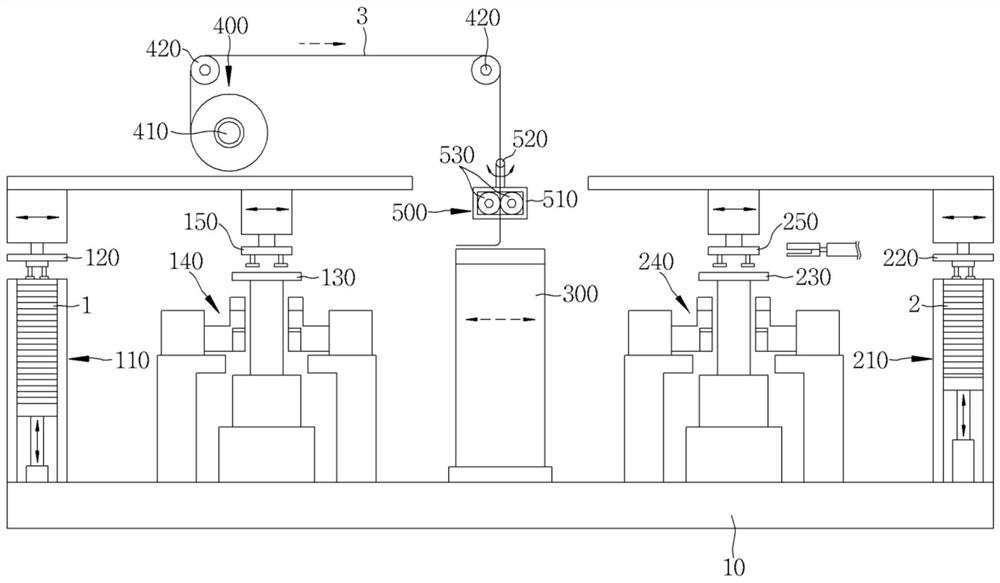

Workpiece surface-mounting device and method applying chip supply mechanism

ActiveCN108962795AAccelerateImprove overall efficiencySemiconductor/solid-state device manufacturingEngineeringElectrical and Electronics engineering

The invention provides a workpiece surface-mounting device and method applying a chip supply mechanism. The device comprises a substrate bearing mechanism, a chip supply mechanism, and a chip bondingmechanism; the substrate bearing mechanism fixes a substrate and drives the substrate to move on a first plane parallel to the surface of the substrate, the movement stroke of the substrate on the first plane being not smaller than the size of the substrate on the first plane; the chip supply mechanism acquires chips from the chip transfer position of the workpiece surface-mounting device, fixes the chips, and transfers the chips to the chip supply position; the chip bonding mechanism picks up the chips at the chip supply position, and mounts the chips on the predetermined surface-mounting positions of the substrate at a surface-mounting work area position; the chip supply mechanism includes a first transport mechanism, a first transport track, a second transport mechanism, and a second transport track, wherein the first transport track and the second transport track are located between the chip transfer position and the chip supply position, the first transport mechanism and the second transport mechanism reciprocate along the first transport track and the second transport track, and alternately acquires the chips from the chip transfer position and provides the chips at the chipsupply position.

Owner:唐人制造嘉善有限公司

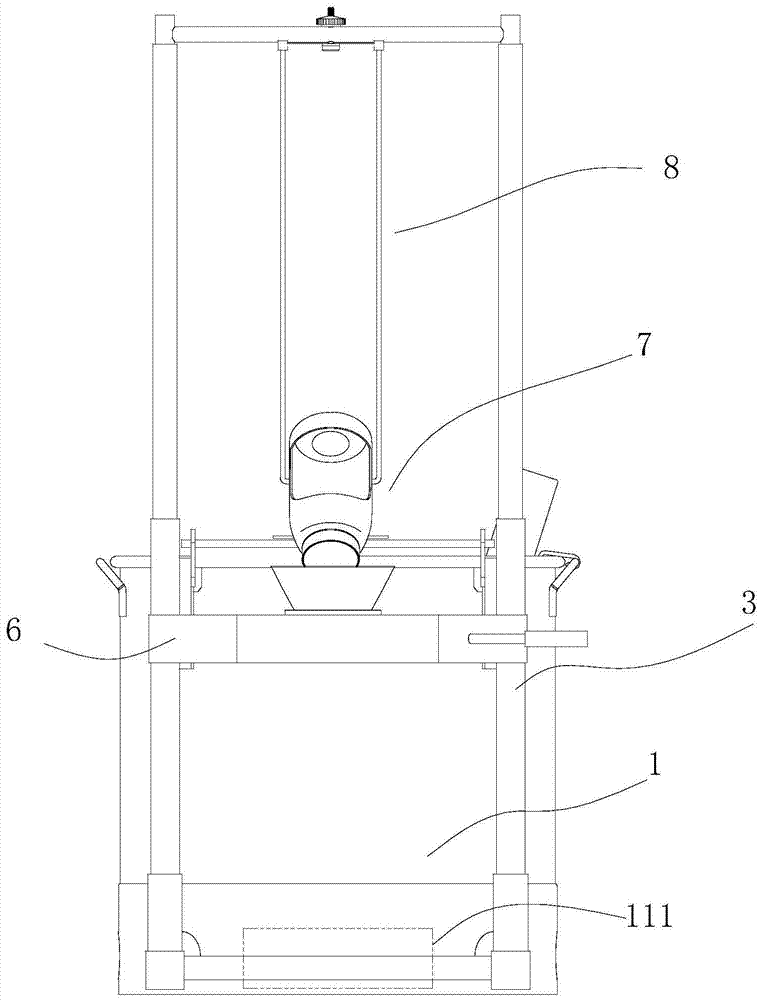

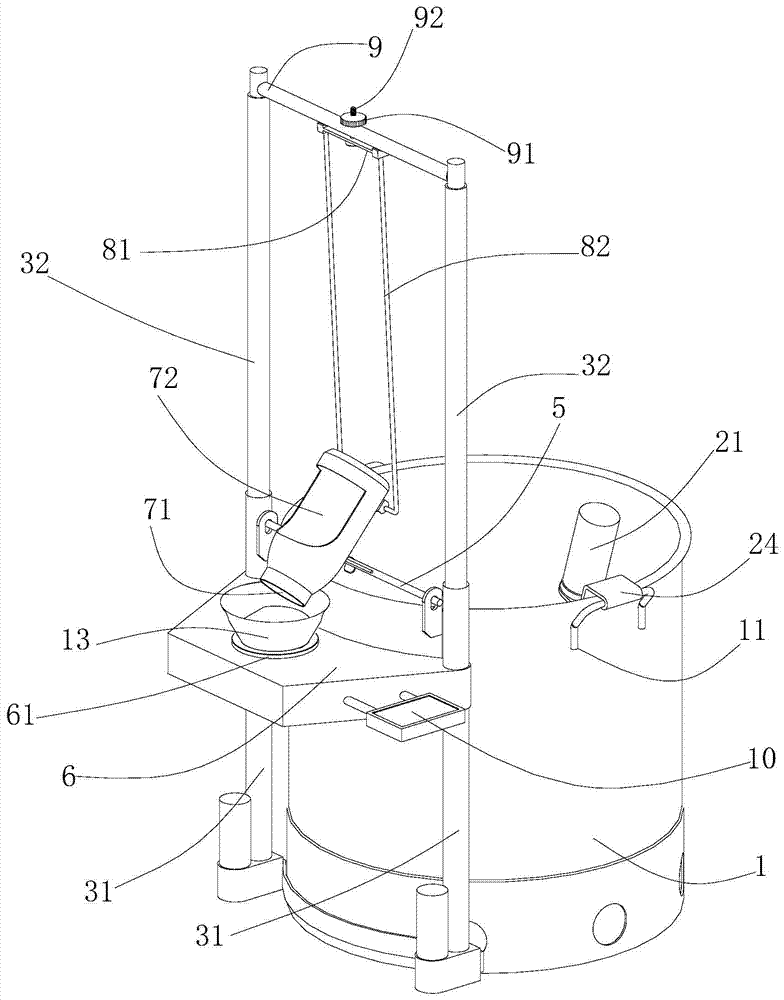

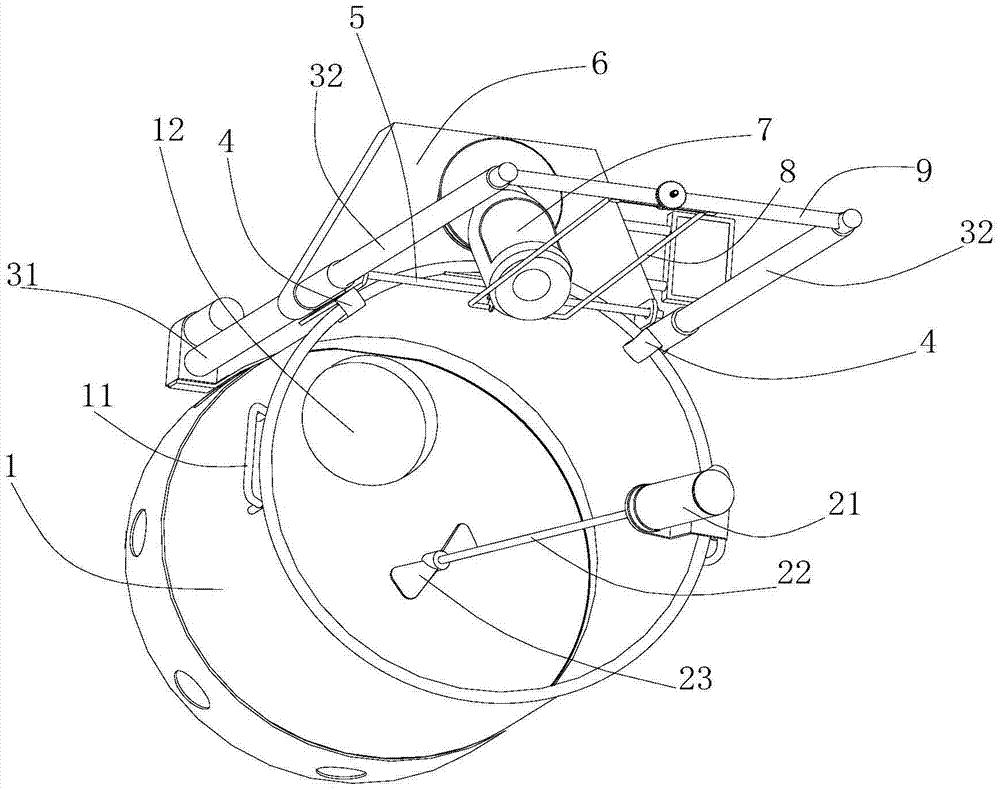

A device for automatically serving soup or liquid food

InactiveCN105125051BIncrease supply speedReduce laborCooking vesselsMechanical engineeringLiquid food

Owner:浙江机电职业技术学院

Sterilization and disinfection device for producing medical virus detection kit

InactiveCN112641966AEasy to installEasy to disassembleLavatory sanitoryDrying machines with progressive movementsUltraviolet lightsSurgery

The invention discloses a sterilization and disinfection device for producing a medical virus detection kit. The device comprises a steam generator, a conveying base is arranged at the top end of the steam generator, electric push rods are arranged between the two sides of the conveying base and a machine body of the steam generator, a heating box is arranged at the top end of the conveying base, and the top end of the heating box communicates with the interior of the conveying base. Ultraviolet lamps are arranged on two sides of the inside of the conveying base, a placing rack is arranged in the middle of the inside of the conveying base, and a plurality of trays are arranged on the placing rack. The problems that in the existing manner of ultraviolet disinfection for a virus detection kit body, the kit body cannot be effectively sterilized and disinfected , and the disinfection manner wastes manpower and material resources, and also results in low production efficiency of the virus detection kit are solved. By improving and optimizing the structure of sterilization and disinfection equipment, the sterilization and disinfection equipment can effectively sterilize and disinfect the virus detection kit body, and the problem that the virus detection kit body cannot be thoroughly sterilized and disinfected in a traditional sterilization and disinfection manner is solved.

Owner:刘倩倩

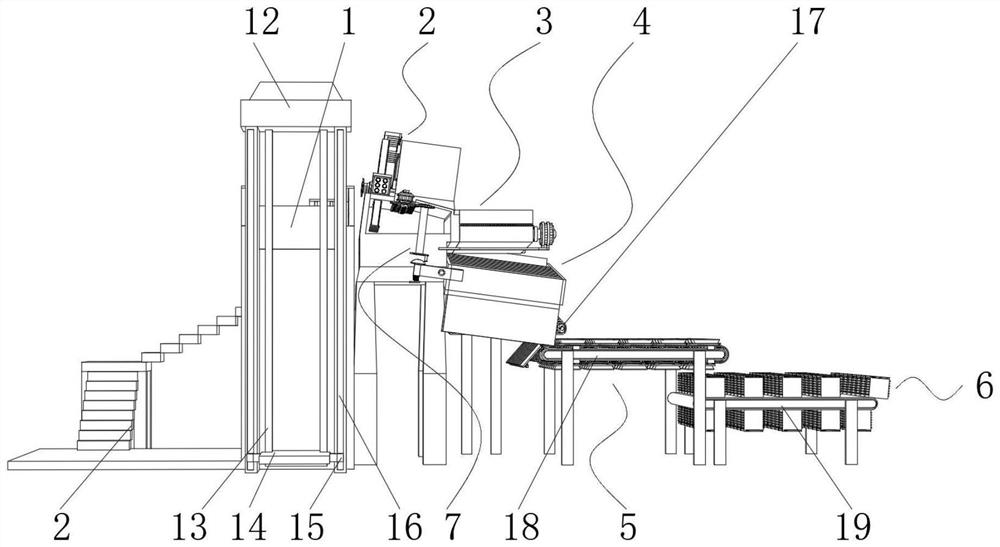

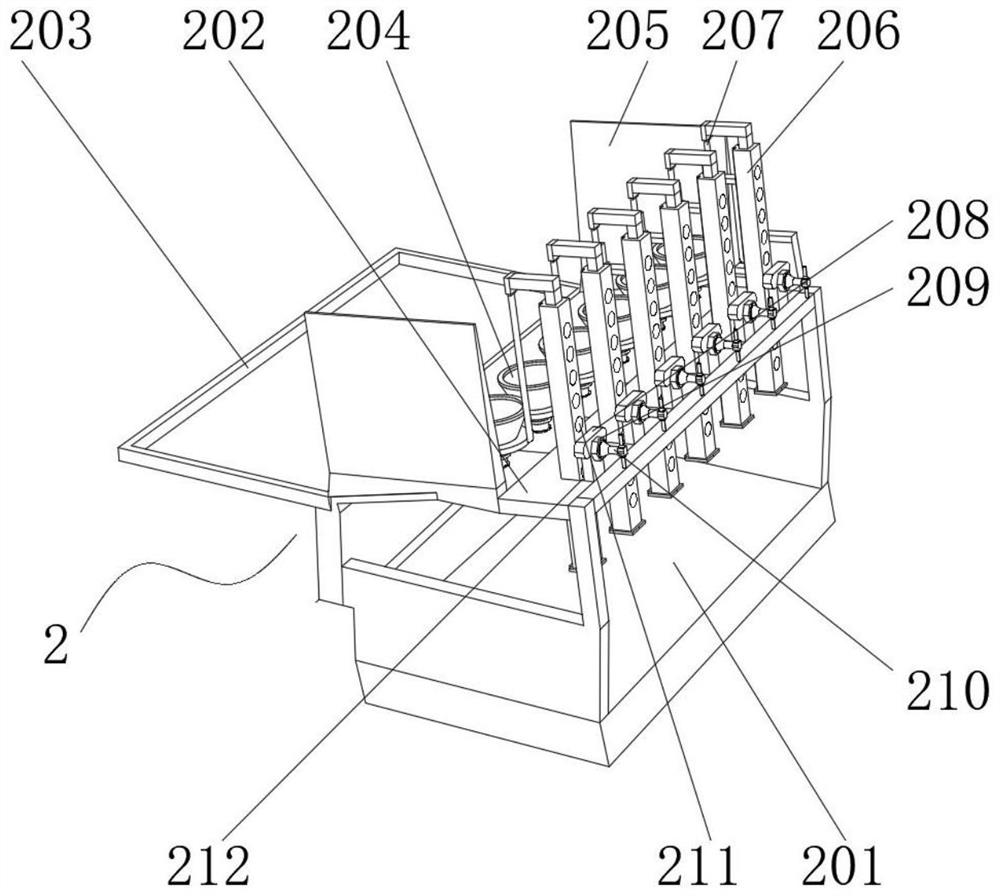

Automatic sorting and packaging all-in-one machine for mushroom type edible mushrooms

InactiveCN114313384AEasy to peel offImprove picking efficiencyCleaningCultivating equipmentsAgricultural engineeringStructural engineering

The invention discloses an automatic sorting and packaging all-in-one machine for mushroom edible mushrooms. The automatic sorting and packaging all-in-one machine comprises a machine body, walking stairs are installed on the side edge of the machine body, an operation platform is arranged on the machine body, a material table is arranged on one side of the operation platform, and a material lifting frame is arranged on the side, close to the material table, of the machine body; and the stripping mechanism is located on the side edge of the upper end of the machine body, the stripping mechanism is connected with the transmission cleaning mechanism, and a vibration mechanism is arranged at the connecting position of the stripping mechanism and the side edge of the transmission cleaning mechanism. According to the automatic sorting and packaging all-in-one machine for the mushroom type edible mushrooms, the stripping mechanism is integrally arranged to be of an inclined structure, material discharging can be rapidly and effectively completed in cooperation with gravitational force, mushrooms on mushroom sticks can be stripped conveniently, then the mushroom sticks can be fixed through mushroom stick fixing cups, the transmission gears rotate to drive the mushroom sticks to rotate, and therefore the mushroom sticks can be conveniently separated and packaged. Therefore, the stripping work between the mushroom roots and the mushroom sticks can be quickly completed when the mushroom roots are in contact with the stripping knife.

Owner:连云港银丰食用菌科技有限公司

A flexible production line for segments

ActiveCN110509419BComplete supporting facilitiesSmall footprintCeramic shaping plantsParking areaProcess engineering

Owner:苏州交通工程集团有限公司

A bag counting device

ActiveCN104859900BImprove counting efficiencyGuaranteed uptimePackaging automatic controlCounting efficiencyEngineering

The invention discloses a counting device for bagged goods. The counting device is characterized by comprising an arrangement tank; one end of the arrangement tank is a bag inlet end, and the other end of the arrangement tank is a bag outlet end; multiple stages of bag stirring axles are arrayed on the arrangement tank in the length direction, each stage of bag stirring axle is provided with at least one bag stirring wheel located in the arrangement tank, each bag stirring axle is connected with a bag stirring wheel drive device in a transmission mode, and all the bag stirring wheels rotate in the same direction; an arrangement passageway for the bagged goods to conveniently pass through is formed by the gap between the bag stirring wheels and the tank bottom of the arrangement tank, a counting sensor is arranged at the bag outlet end of the arrangement tank, and a folded bag separation device which arranges and separates the bagged goods folded in the arrangement passageway is arranged on the arrangement tank. The counting device can count the bagged goods bag by bag, the folded bagged goods can be separated, the phenomenon that counting is not accurate when bags are folded is avoided, and the counting efficiency and accuracy are greatly improved compared with manual counting or weighing conversion.

Owner:张家港建辰机械科技有限公司

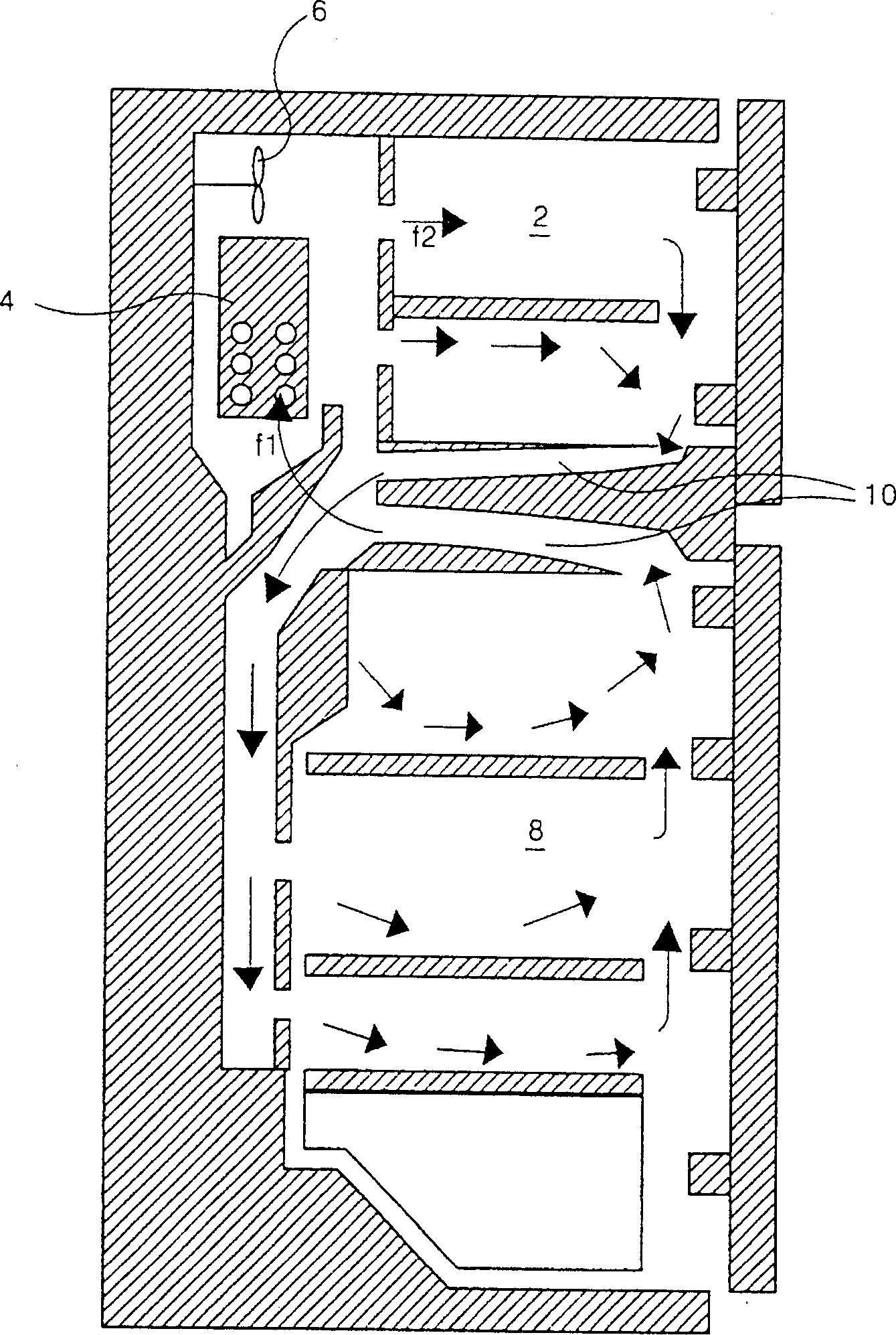

Heating furnace

ActiveCN108684533AImprove combustion efficiencyStorage temperatureAnimal housingProcess engineeringHeating furnace

The invention discloses a heating furnace. The heating furnace comprises a furnace body, heat supply pipes, an air blower, a motor and a heating pipe, wherein a gas furnace is arranged at the bottom of the furnace body, and a gas pipe is connected to one side of the gas furnace; the heat supply pipes are arranged at the top of the furnace body, and each heat supply pipe is of a single-layer structure or a double-layer structure; the heat supply pipes are connected with one side of the air blower through a heating cover, a pressurizing cover is arranged on the air blower, the heating pipe is connected with the pressurizing cover, and the motor is connected with the air blower.

Owner:冯忠

Double-refrigerant pipe evaporator with radiator for electric refrigerator

InactiveCN1435613AImprove heat exchange efficiencyBig spaceEvaporators/condensersRefrigerantHeat sink

An evaporator with dual cold medium pipe and grid radiator for refrigerator is characterized by that a grid radiator is between two cold medium pipes to form a whole and said radiator and pipes are bent by more than 2 segments. A defrost heater is under the evaporator. Its advantages are high cold volume and supplying speed, high heat exchanging efficiency, and high defrost effect.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Cashmere yarn feeding controller of embroidery machine and method thereof

InactiveCN101597844BAvoid breakingIncrease supply speedProgramme-controlled sewing machinesAutomatic machinesYarnControl signal

Owner:SUSR PRECISION CO LTD

Workpiece mounting device and method with chip supply mechanism

ActiveCN108962795BIncrease supply speedOptimize the overall efficiency of placementSemiconductor/solid-state device manufacturingEngineeringMechanical engineering

The invention provides a workpiece surface-mounting device and method applying a chip supply mechanism. The device comprises a substrate bearing mechanism, a chip supply mechanism, and a chip bondingmechanism; the substrate bearing mechanism fixes a substrate and drives the substrate to move on a first plane parallel to the surface of the substrate, the movement stroke of the substrate on the first plane being not smaller than the size of the substrate on the first plane; the chip supply mechanism acquires chips from the chip transfer position of the workpiece surface-mounting device, fixes the chips, and transfers the chips to the chip supply position; the chip bonding mechanism picks up the chips at the chip supply position, and mounts the chips on the predetermined surface-mounting positions of the substrate at a surface-mounting work area position; the chip supply mechanism includes a first transport mechanism, a first transport track, a second transport mechanism, and a second transport track, wherein the first transport track and the second transport track are located between the chip transfer position and the chip supply position, the first transport mechanism and the second transport mechanism reciprocate along the first transport track and the second transport track, and alternately acquires the chips from the chip transfer position and provides the chips at the chipsupply position.

Owner:唐人制造嘉善有限公司

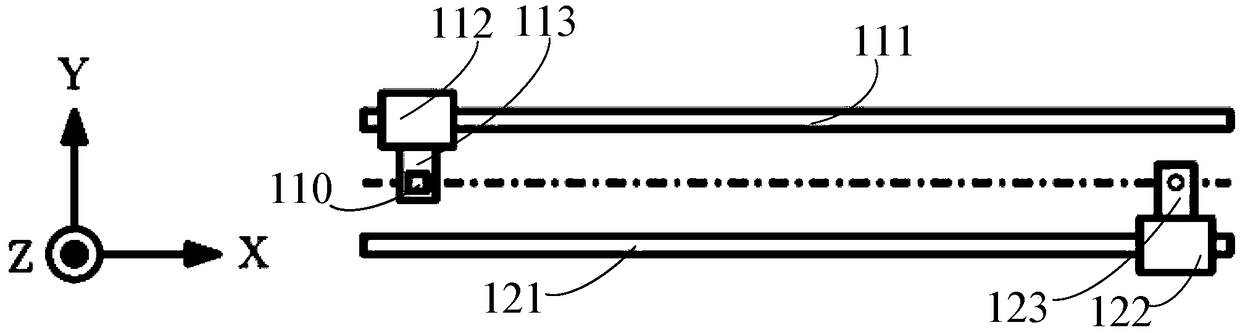

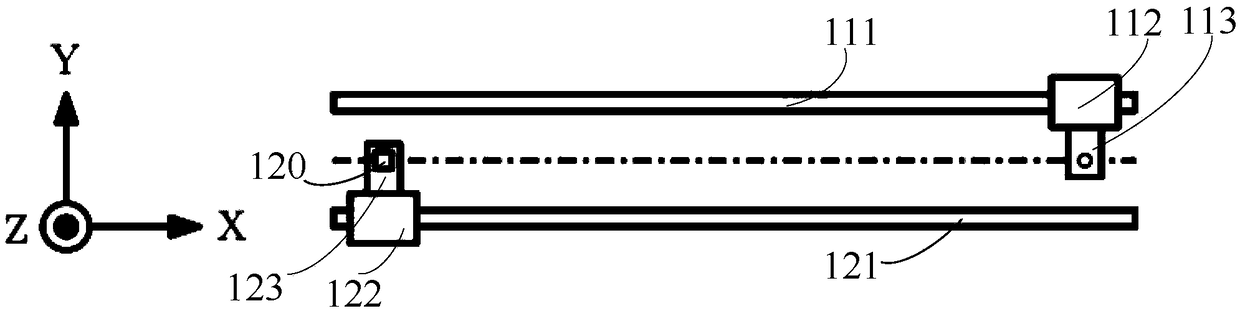

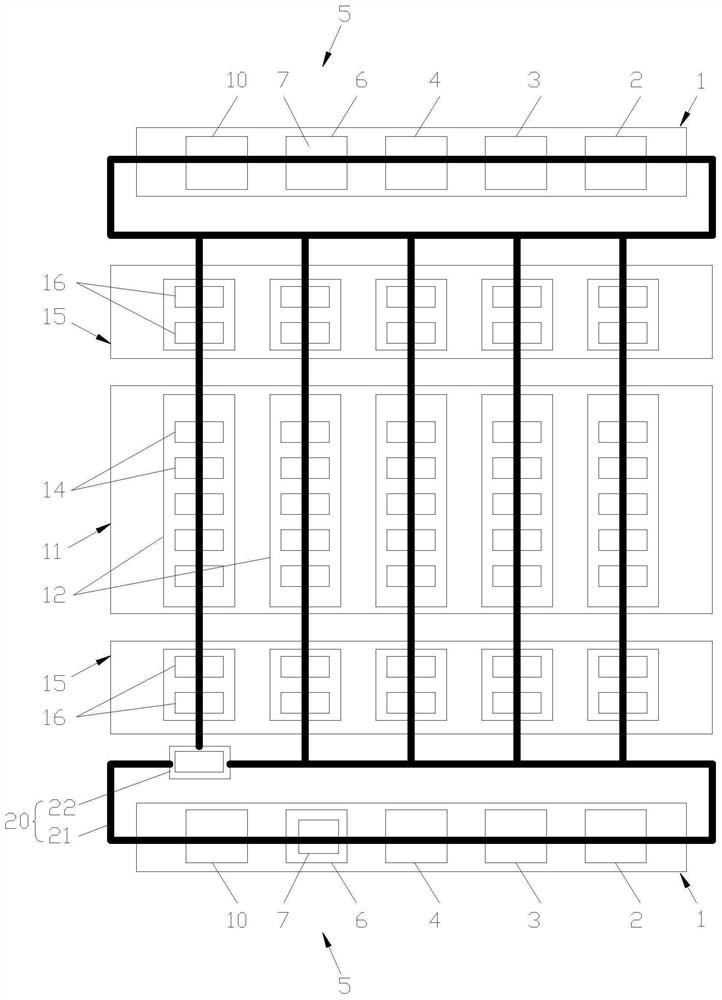

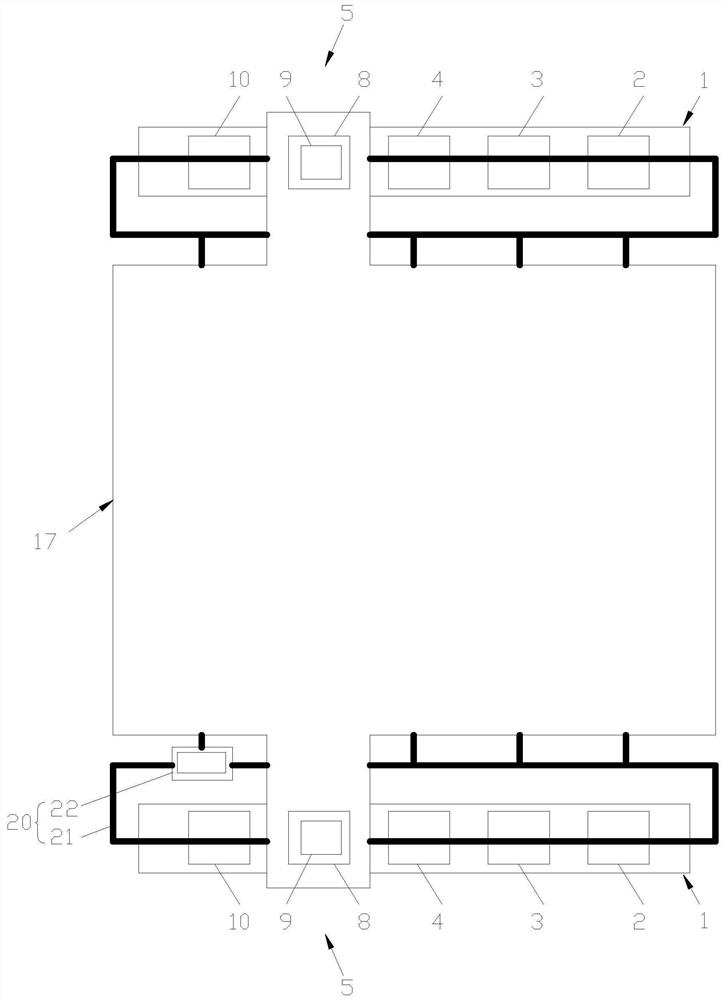

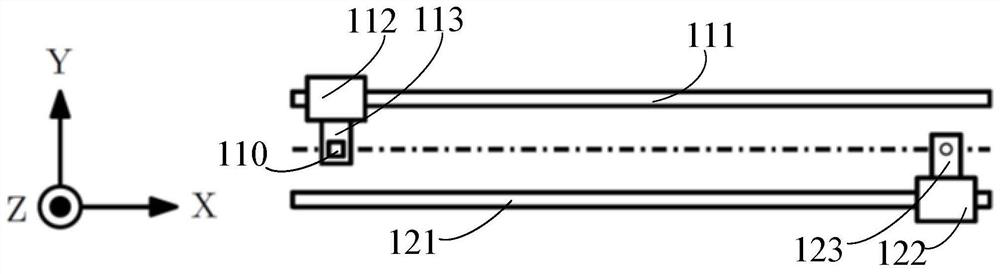

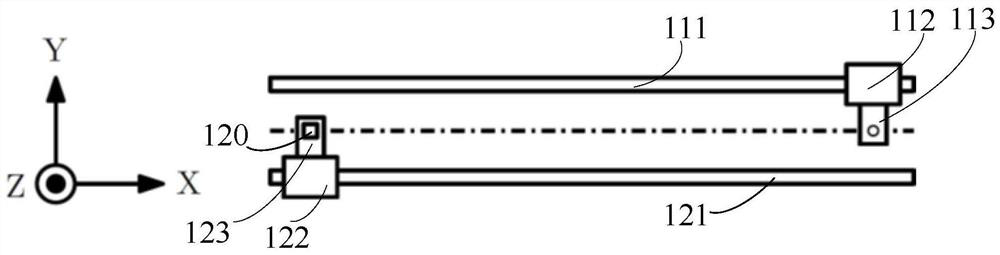

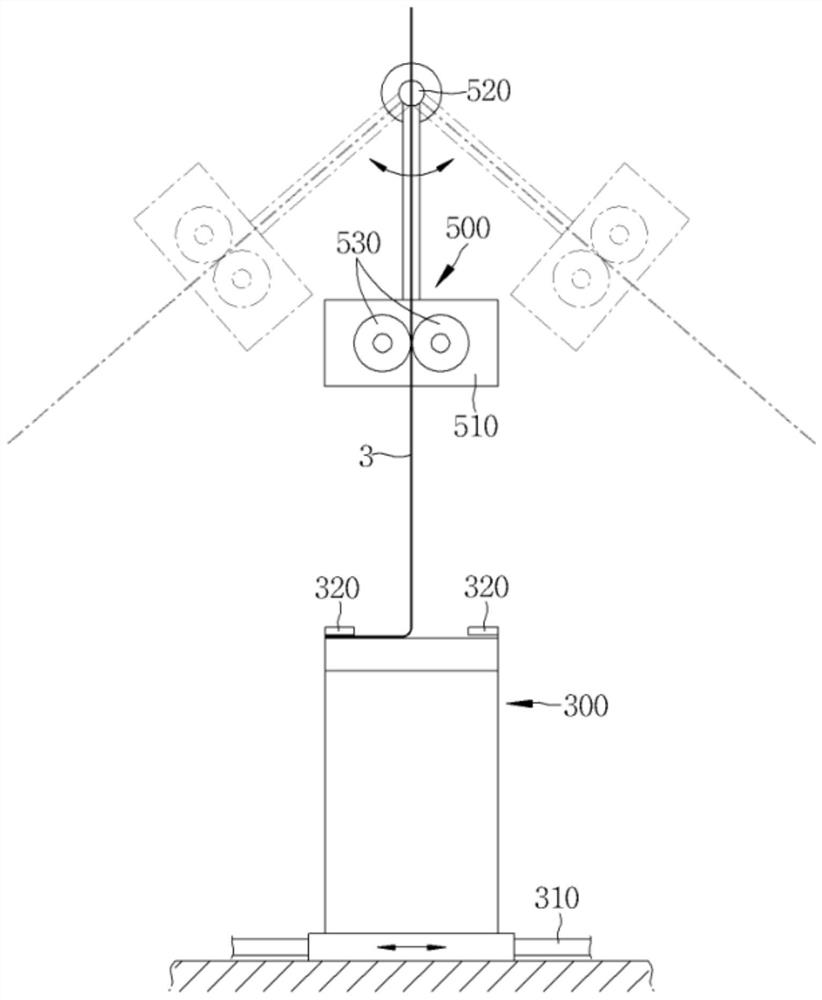

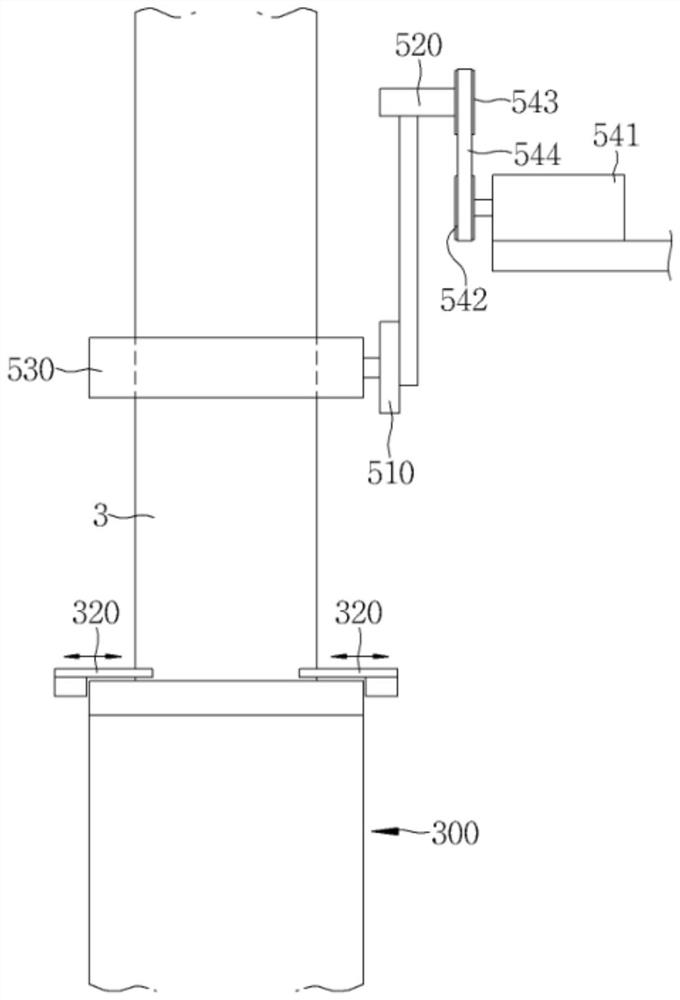

System and method for manufacturing cell stack of secondary battery

PendingCN112490479AIncrease supply speedRealize the effect of precision layeringAssembling battery machinesLarge-sized flat cells/batteriesStructural engineeringManufacturing cell

Disclosed are a system and method for manufacturing a cell stack of a secondary battery. Thus,a separation membrane can be supplied to a stacking table that reciprocates left and right, and electrodeplates (positive and negative plates) are alternately transferred on both sides of the stacking table, and the separation membrane is folded into a zigzag while a positive plate and a negative plate are stacked in the established order to make the battery cell stack. The system comprises a stacking table, which is installed to move horizontally back and forth with the help of a linear motion device, a separation membrane supply part, which supplies a separation membrane to the stacking table; a positive electrode supply part, which is arranged on one side of the stacking table; a negative electrode supply part, which is arranged on the other side of the stacking table, supplies and stacks negative plates to the separation membrane on the stacking table; and a separation membrane guide unitwhich is arranged on the upper side of the stacking table and guides and supports the separation membrane supplied through the separation membrane supply part.

Owner:DATECH

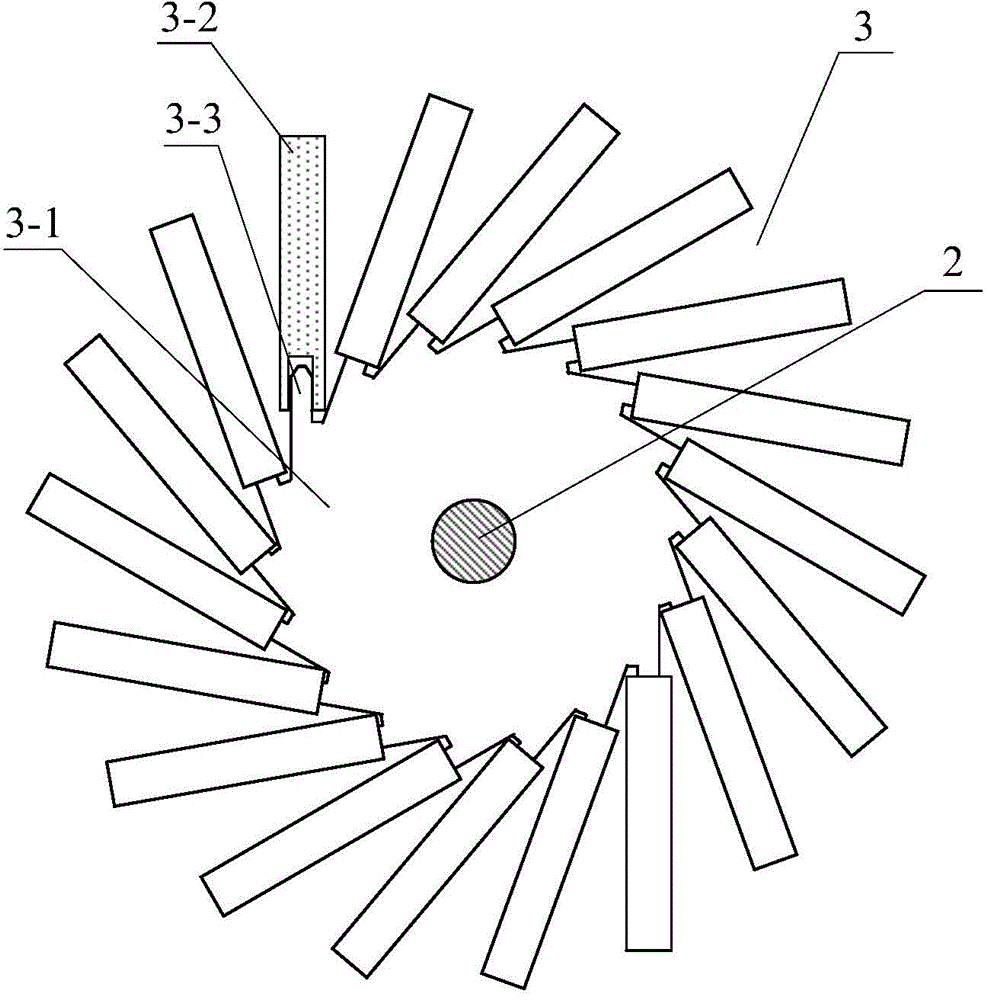

An automatic vibrating feeding tray for metal short tubes

ActiveCN106081564BIncrease the feeding speedIncrease supply speedConveyorsConveyor partsMechanical engineeringMetal

Owner:PINGHU PINYAO MACHINERY AUTOMATION CO LTD

a heating furnace

ActiveCN108684533BImprove combustion efficiencyStorage temperatureAnimal housingThermodynamicsElectric machinery

The invention discloses a heating furnace, which comprises a furnace body, a heat supply pipe, a blower, a motor and a heating pipe; There are several heat supply pipes, the heat supply pipe is a single-layer or double-layer structure, the heat supply pipe is connected to one side of the blower through the heating cover, the blower is provided with a pressurized cover, the heating pipe is connected to the pressurized cover, and the motor is connected to the blower .

Owner:冯忠

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com