Patents

Literature

124results about How to "Reduce polydispersity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

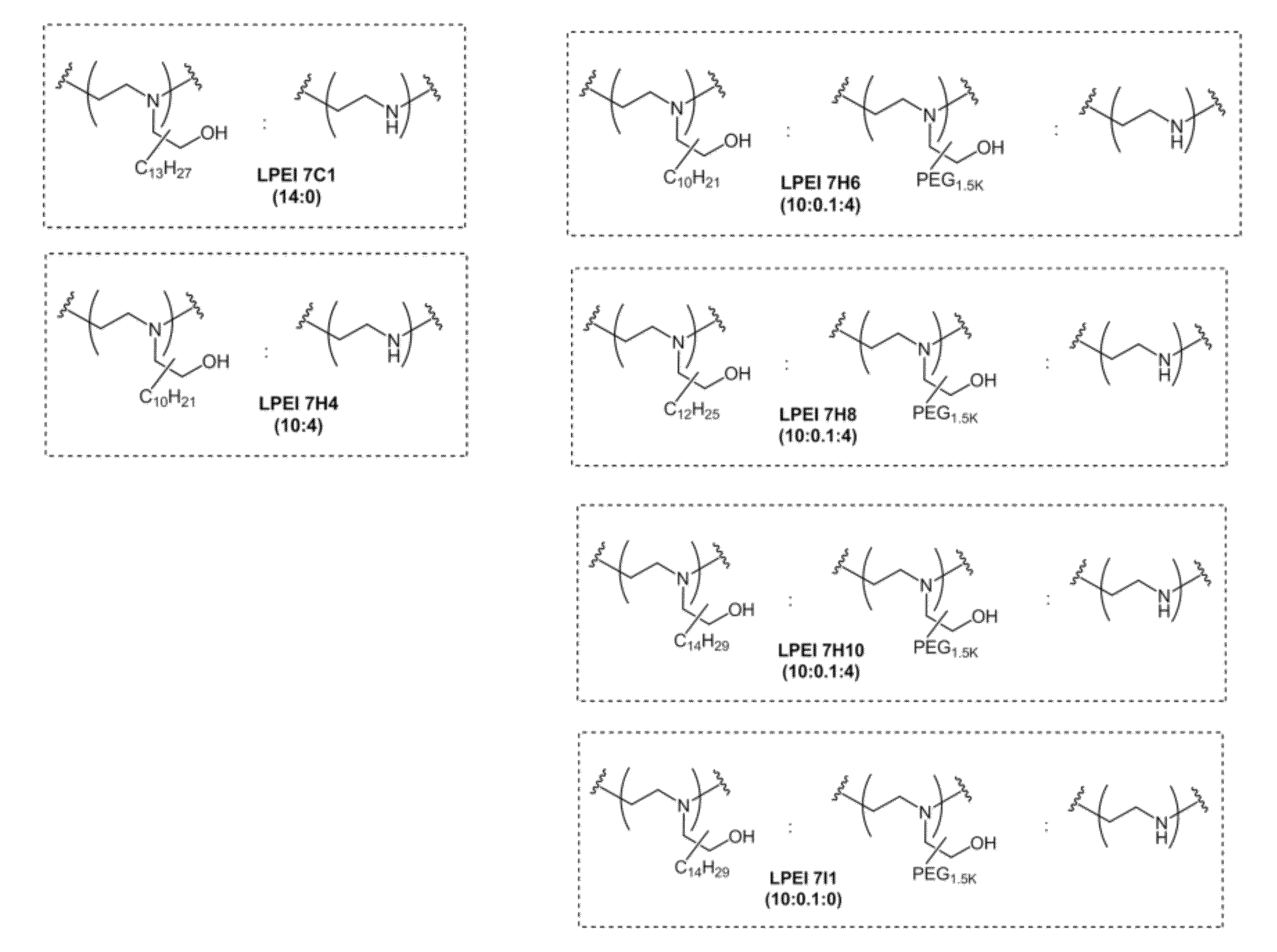

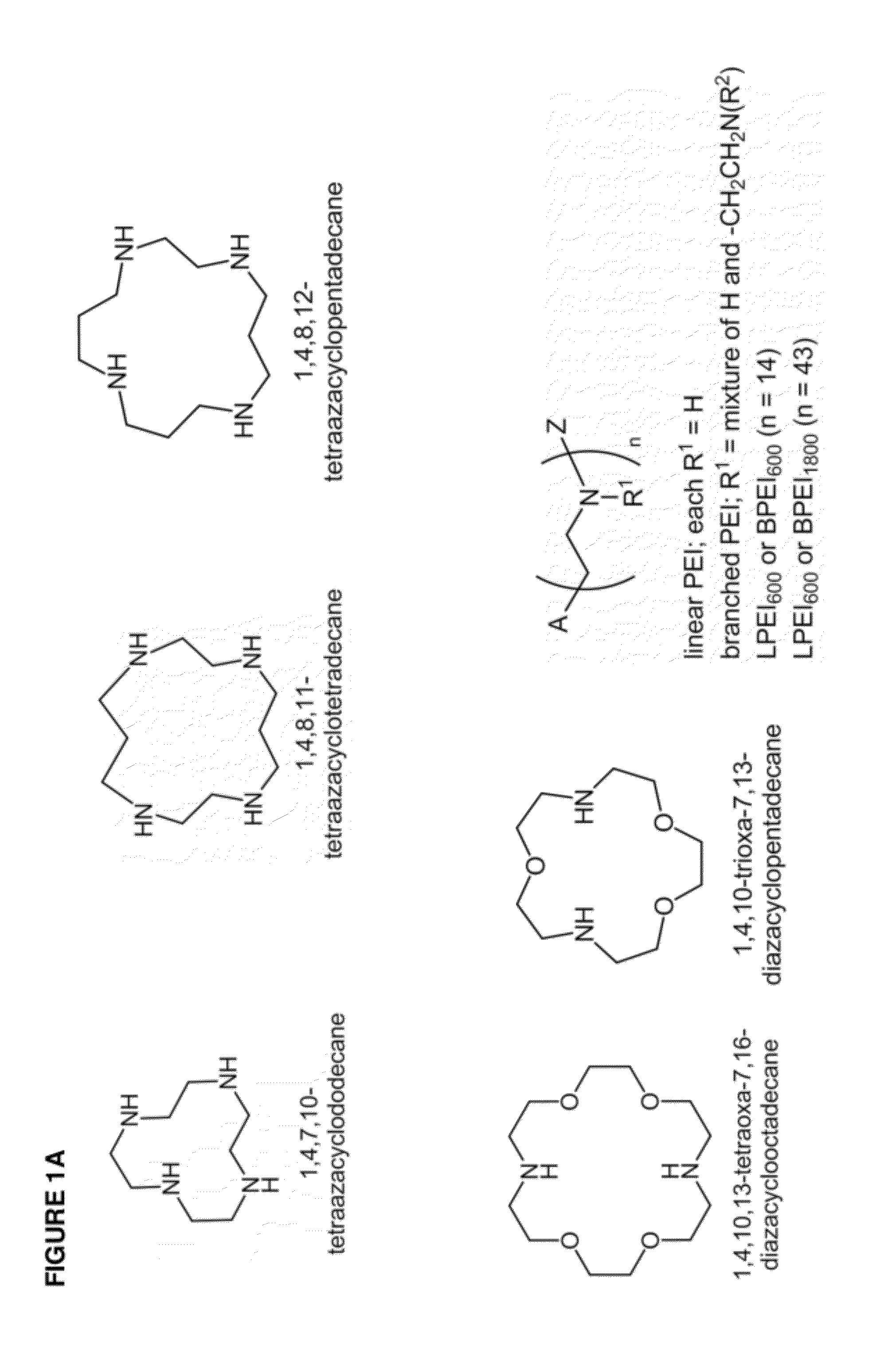

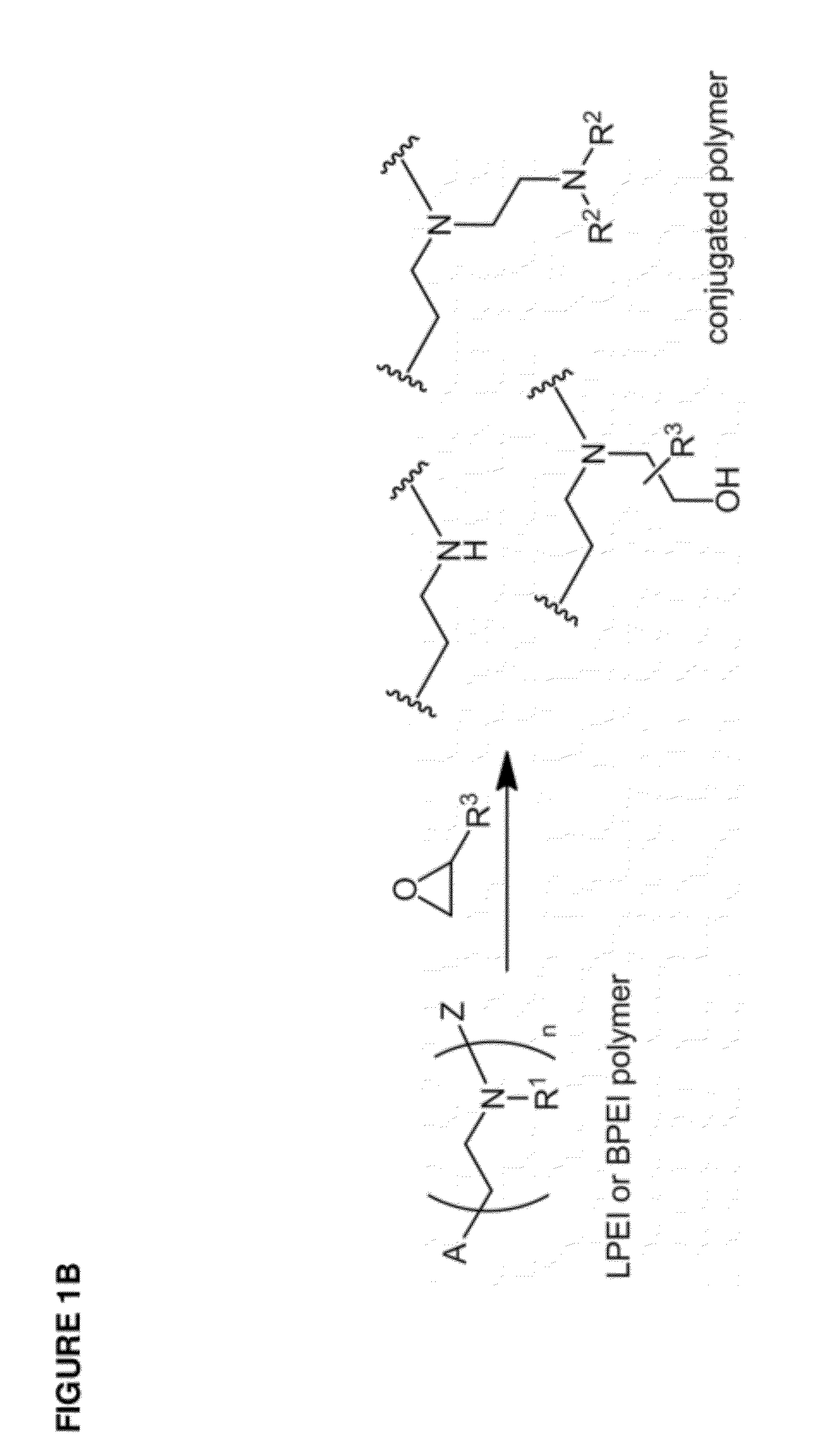

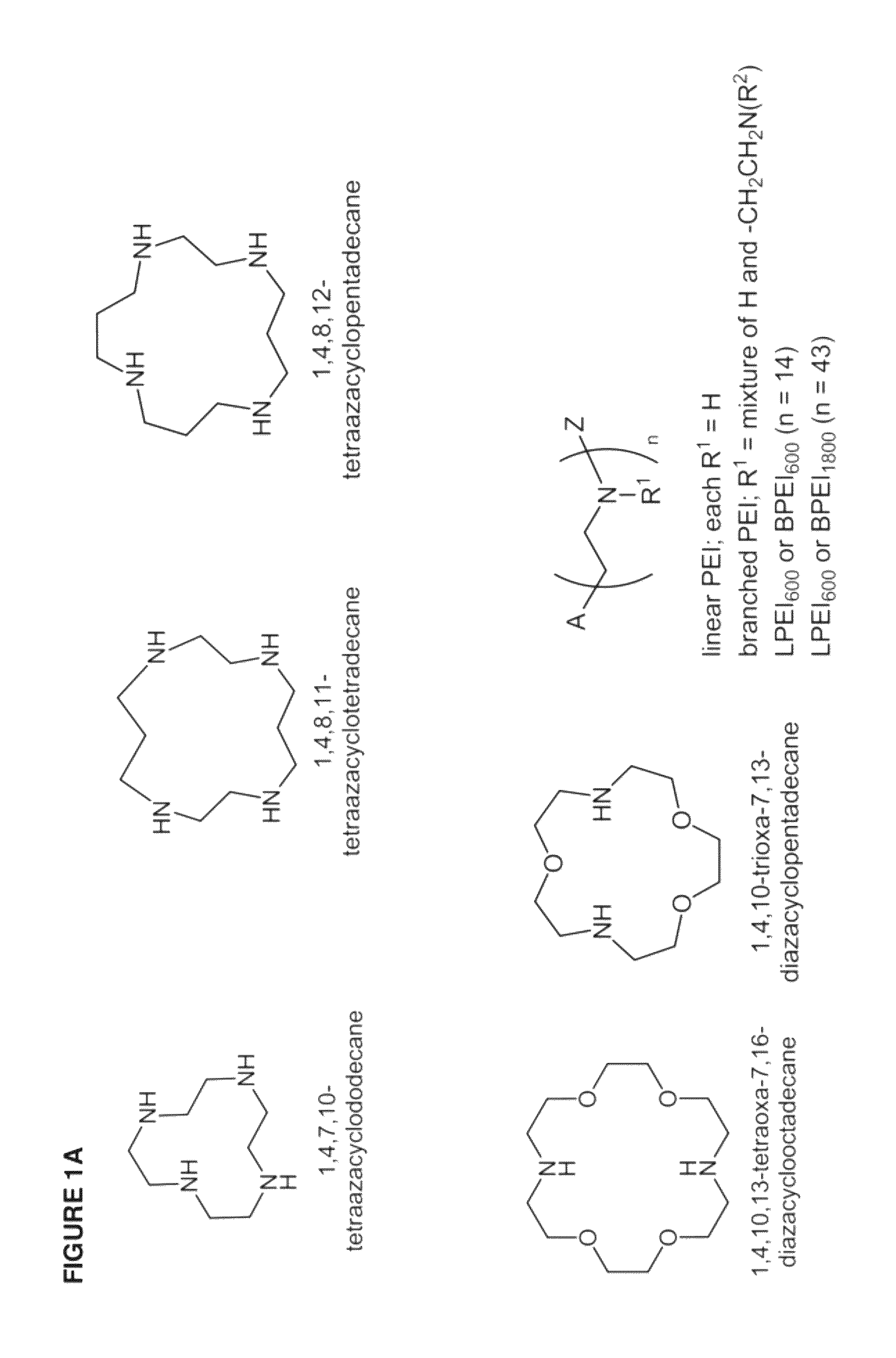

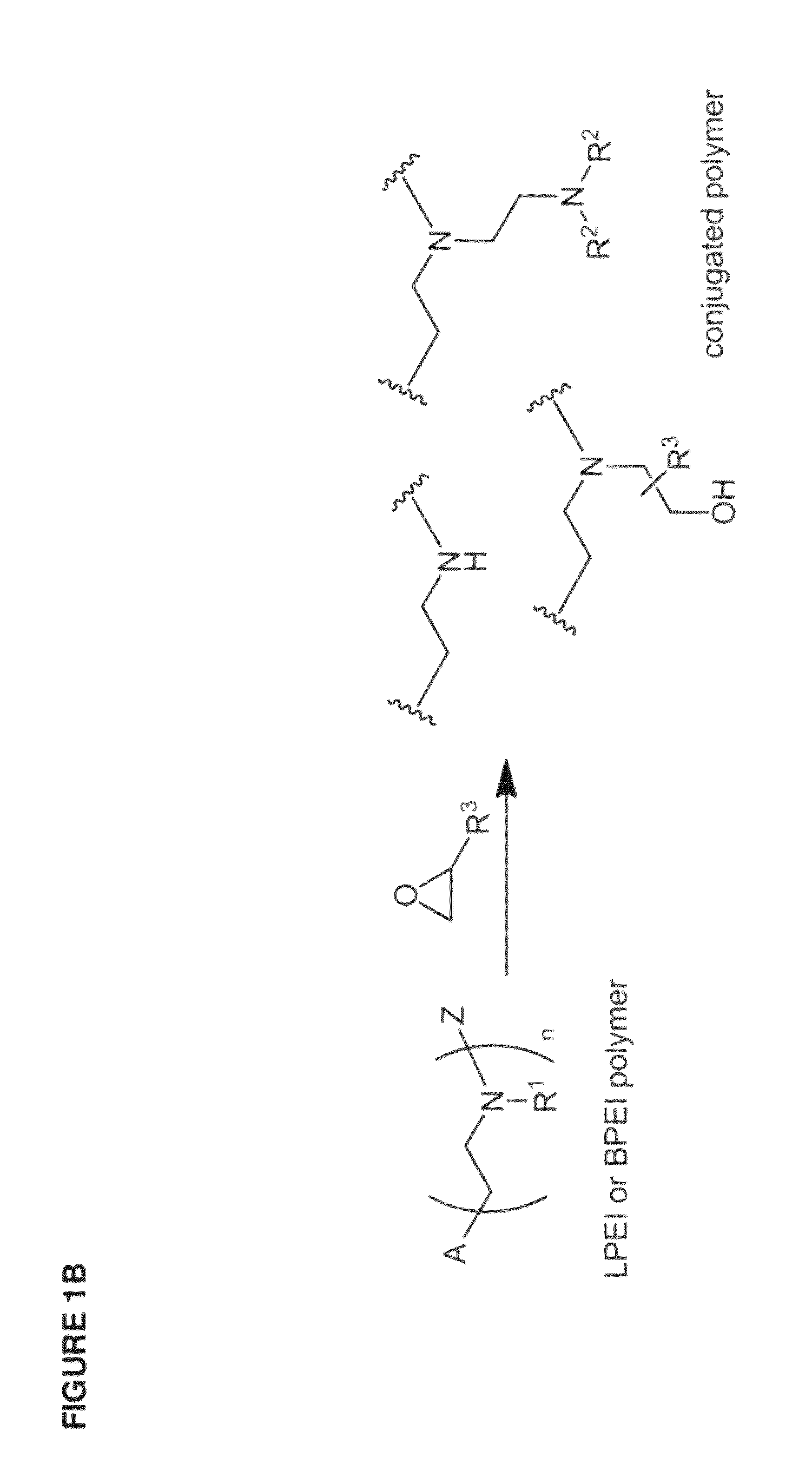

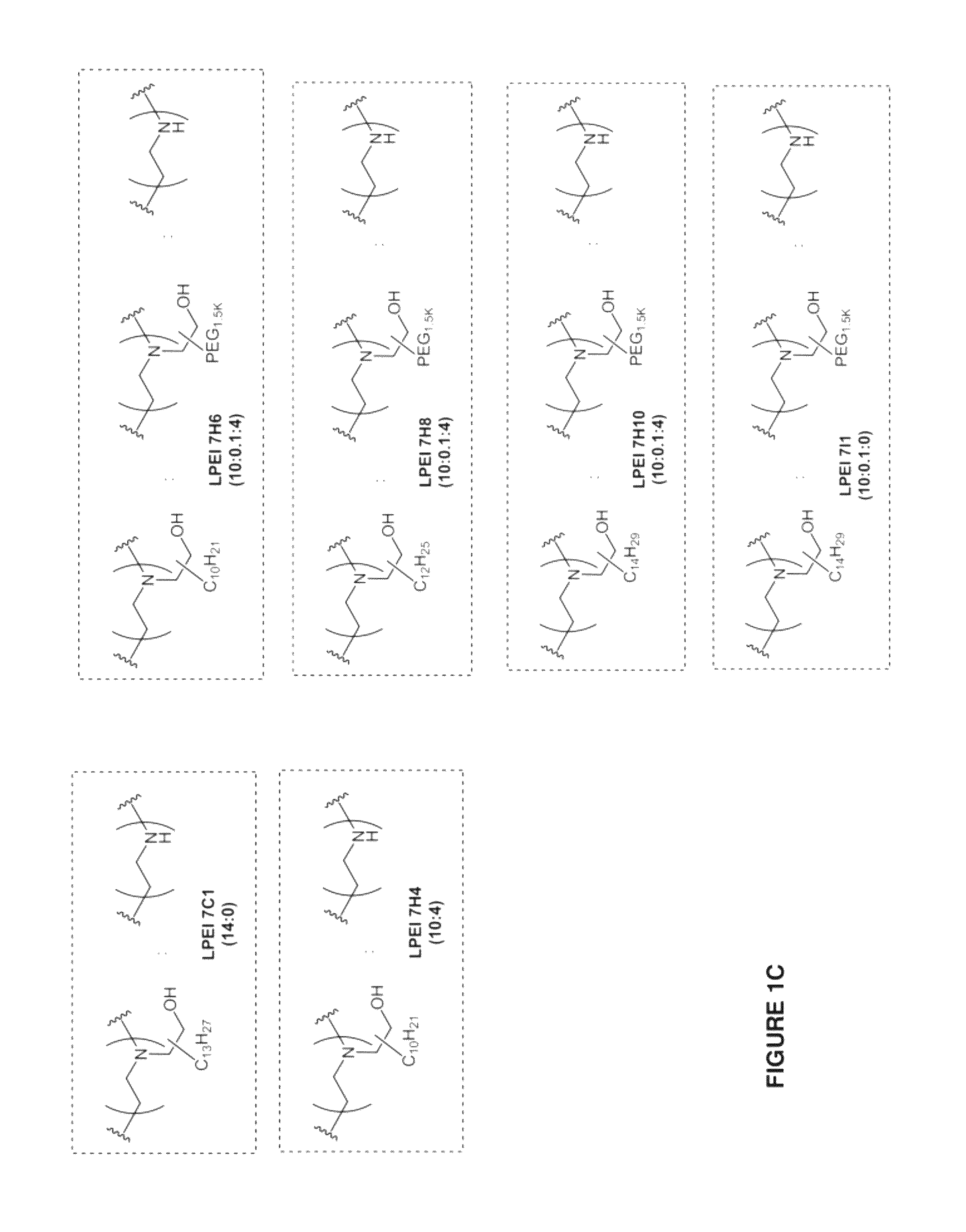

Conjugated lipomers and uses thereof

ActiveUS20120251560A1Reduce polydispersityHigh transfection efficiencyBiocideCosmetic preparationsAza CompoundsPolymer

Owner:MASSACHUSETTS INST OF TECH

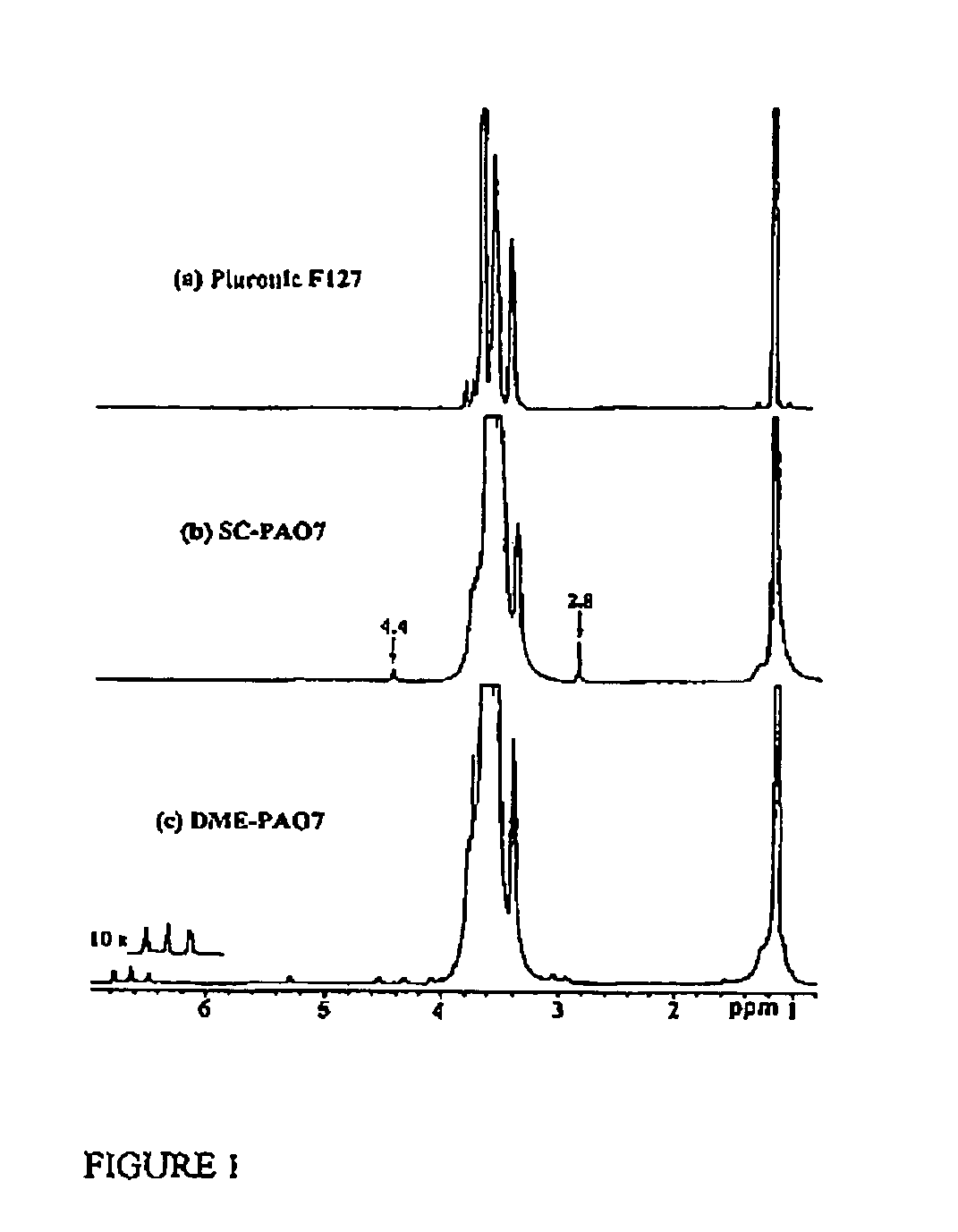

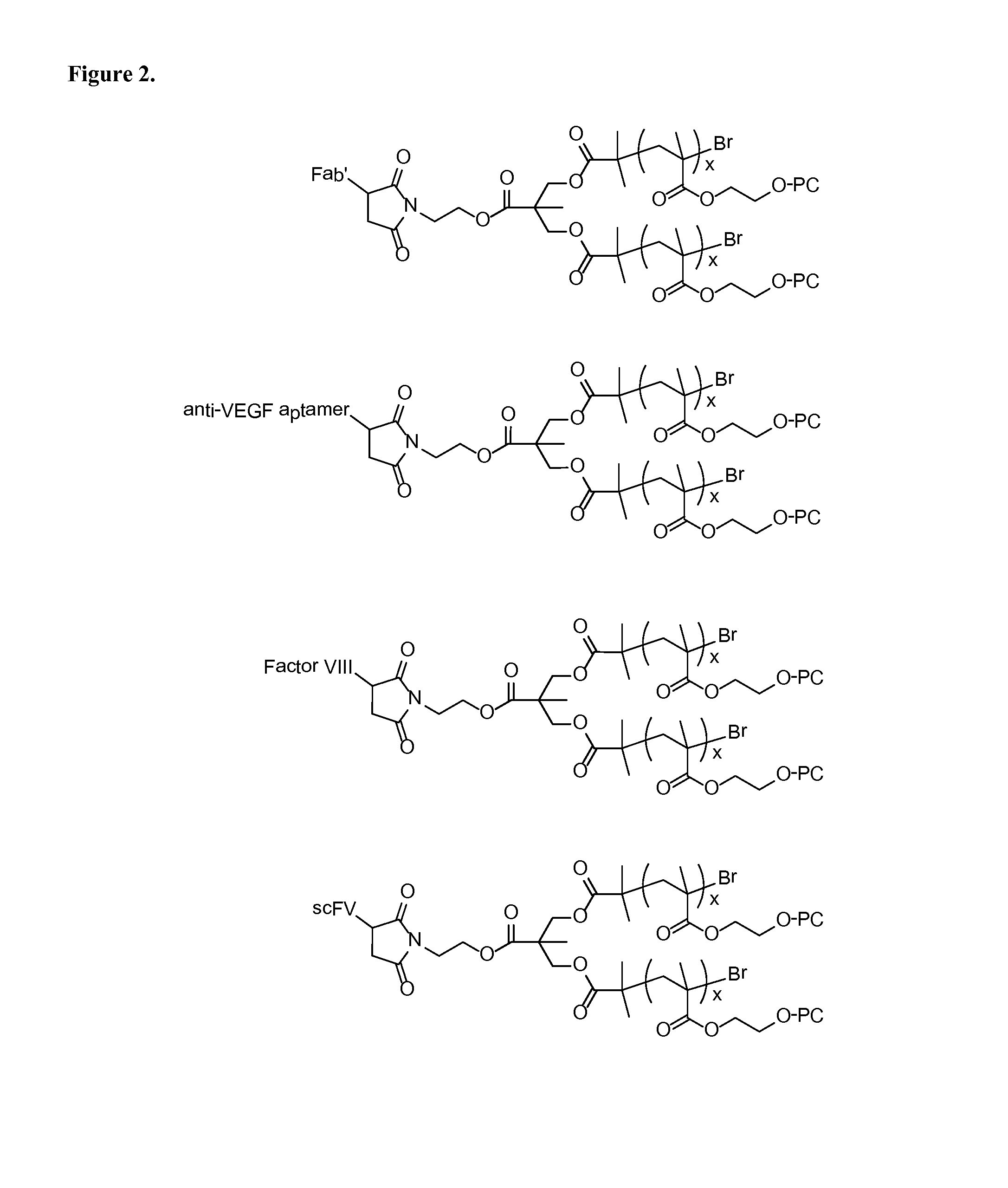

Polymeric compositions and related methods of use

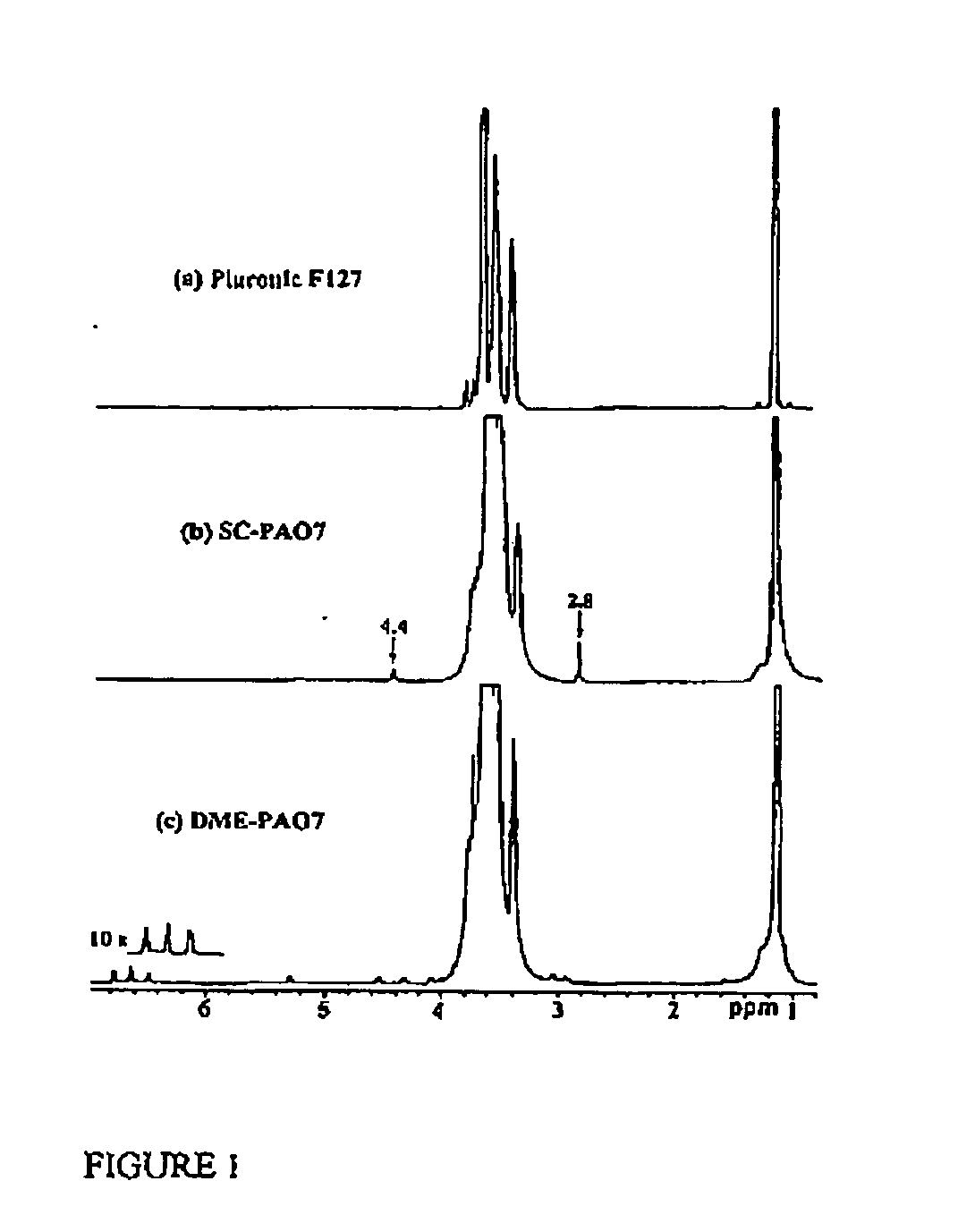

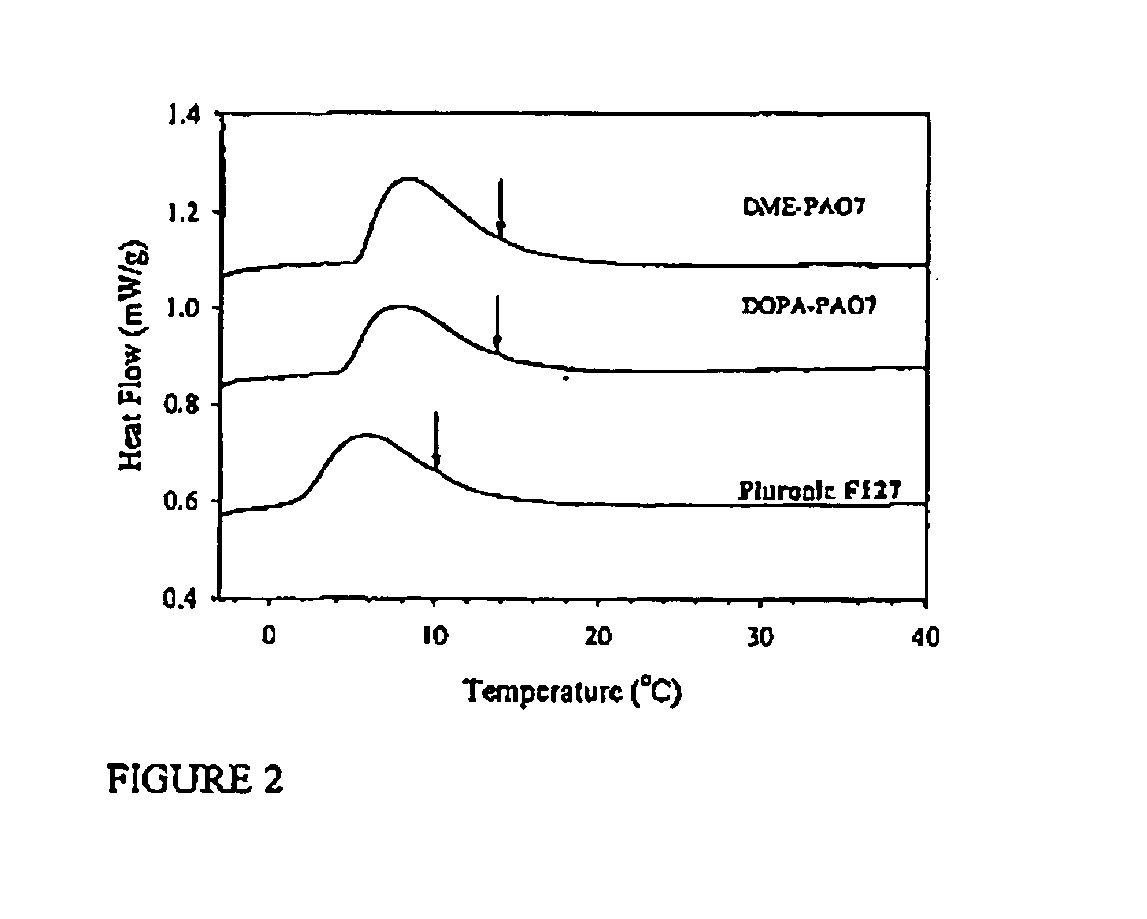

InactiveUS20060009550A1Desire effectReduce polydispersityMaterial nanotechnologyPeptide/protein ingredientsSurface initiatedPolymer

Methods for surface-initiated atom transfer radical polymerization, which can utilize a catecholic alkyl halide initiator.

Owner:NORTHWESTERN UNIV

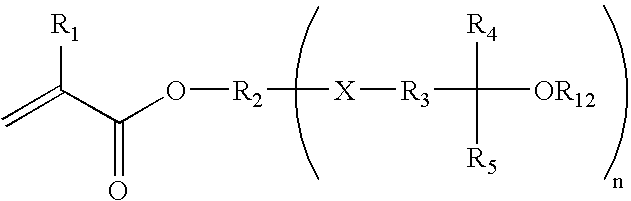

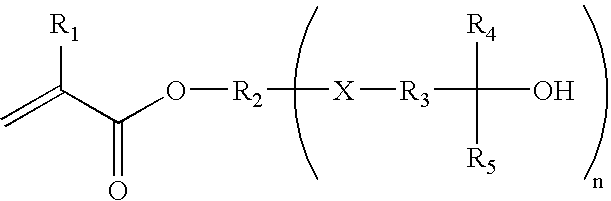

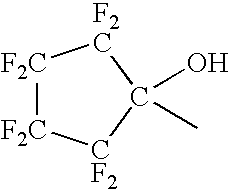

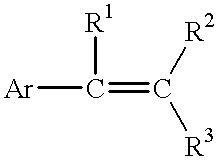

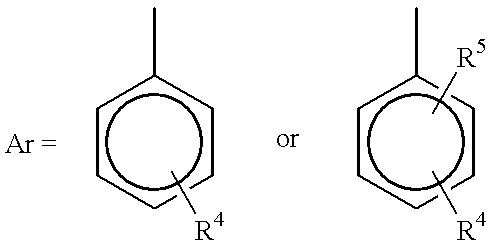

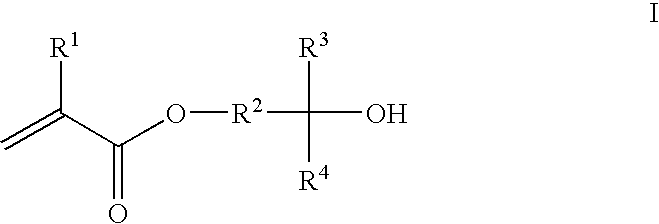

Fluorinated photoresist materials with improved etch resistant properties

InactiveUS20060105269A1Amenable to free-radical copolymerizationReduce polydispersityRadiation applicationsPhotomechanical apparatusPhotoresistCarbonate

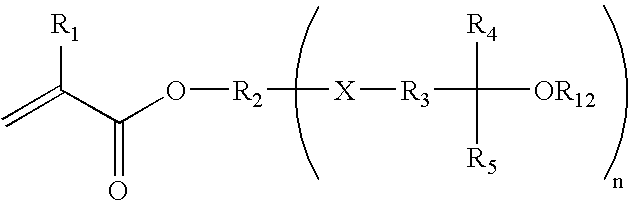

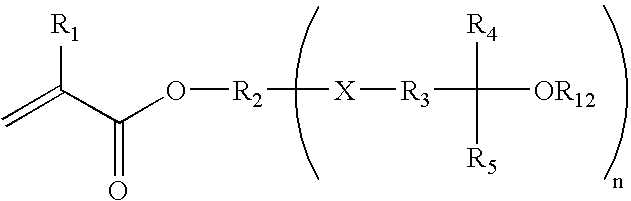

A photoresist composition including a polymer is disclosed, wherein the polymer includes at least one monomer having the formula: where R1 represents hydrogen (H), a linear, branched or cyclo alkyl group of 1 to 20 carbons, a semi- or perfluorinated linear, branched or cyclo alkyl group of 1 to 20 carbons or CN; R2 represents an alicyclic group of 5 or more carbon atoms; X represents a methylene, ether, ester, amide or carbonate linkage; R3 represents a linear or branched alkylene group or semi- or perfluorinated linear or branched alkylene group with 1 or more carbon atoms; R4 represents hydrogen (H), methyl (CH3), trifluoromethyl (CF3), difluoromethyl (CHF2), fluoromethyl (CH2F), or a semi- or perflourinated aliphatic group; R5 represents trifluoromethyl (CF3), difluoromethyl (CHF2), fluoromethyl (CH2F), or a semi- or perfluorinated substituted or unsubstituted aliphatic group; n represents an integer of 1 or more; and OR12 represents OH or at least one acid labile group selected from a tertiary alkyl carbonate, a tertiary alkyl ester, a tertiary alkyl ether, an acetal and a ketal. A method of patterning a substrate is also disclosed, wherein the method includes: applying the photoresist composition mentioned above to the substrate to form a film; patternwise exposing the film to an imaging radiation source; and developing areas of the film to form a patterned substrate.

Owner:GLOBALFOUNDRIES INC

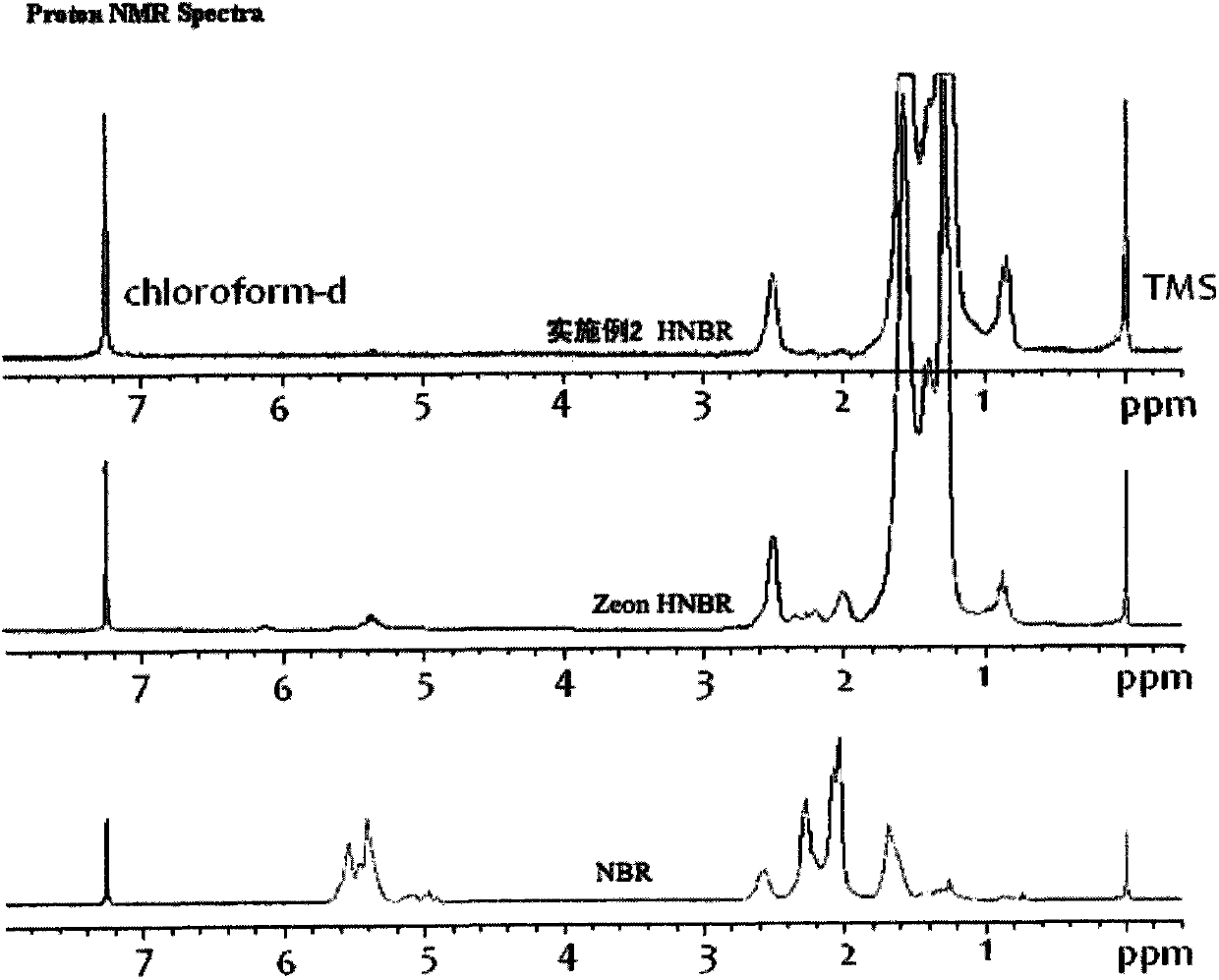

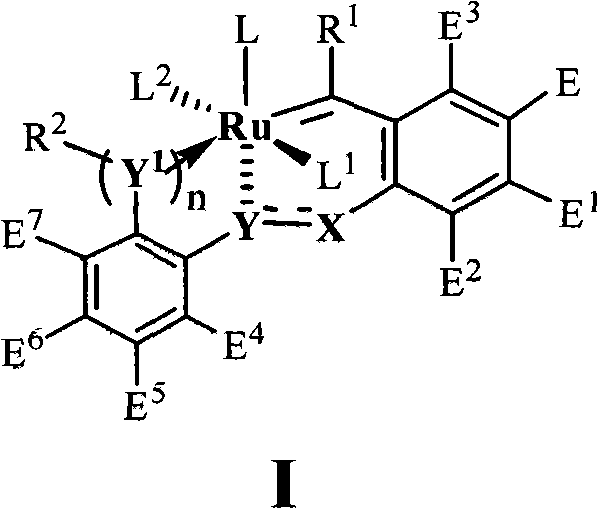

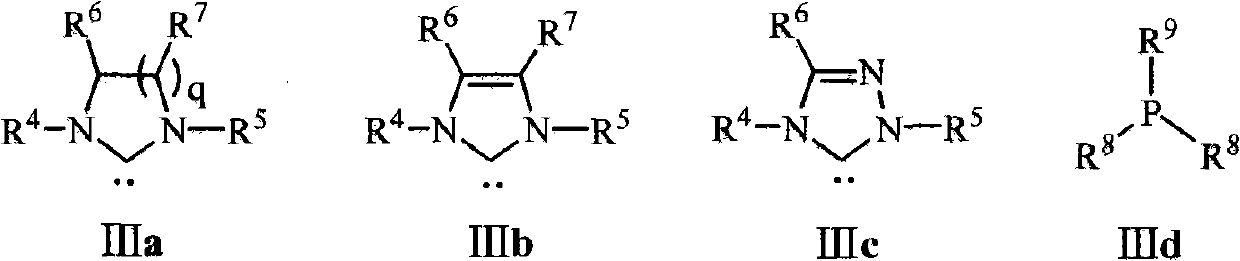

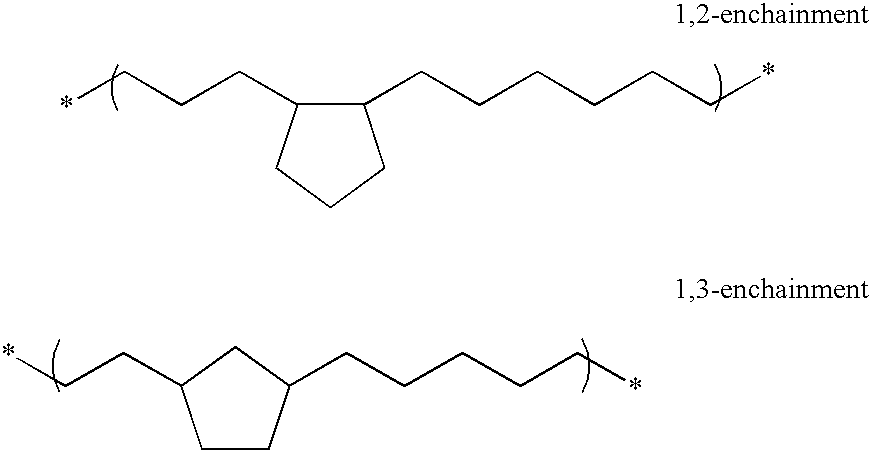

Preparation method of hydrogenated nitrile rubber and degradation and hydrogenation method of butadiene type rubber

The invention discloses a preparation method of hydrogenated butadiene special rubber, which comprises the following steps: subjecting butadiene rubber to a degradation reaction and a hydrogenation reaction under an action of a Zhan Catalyst as showed in the general formula I to obtain hydrogenated butadiene special rubber. The invention also provides a degradation reaction of the butadiene rubber, which is also under the action of a Zhan Catalyst as showed in the general formula I. The preparation method provided by the invention overcomes the shortcomings that the existing various types of catalysts can not be applicable to the preparation of low Mooney viscosity and high Mooney viscosity hydrogenated butadiene special rubber at the same time, so as to provide a preparation method of high-performance hydrogenated butadiene special rubber with a wide controllable Mooney viscosity range of 5-130. The catalyst used in the invention is the catalyst for both rubber degradation and hydrogenation reduction, so as to avoid a process requiring addition of the catalysts with different catalytic activities in two times respectively in the prior art. The method is simple, and easy to operate.

Owner:ZANNAN SCITECH

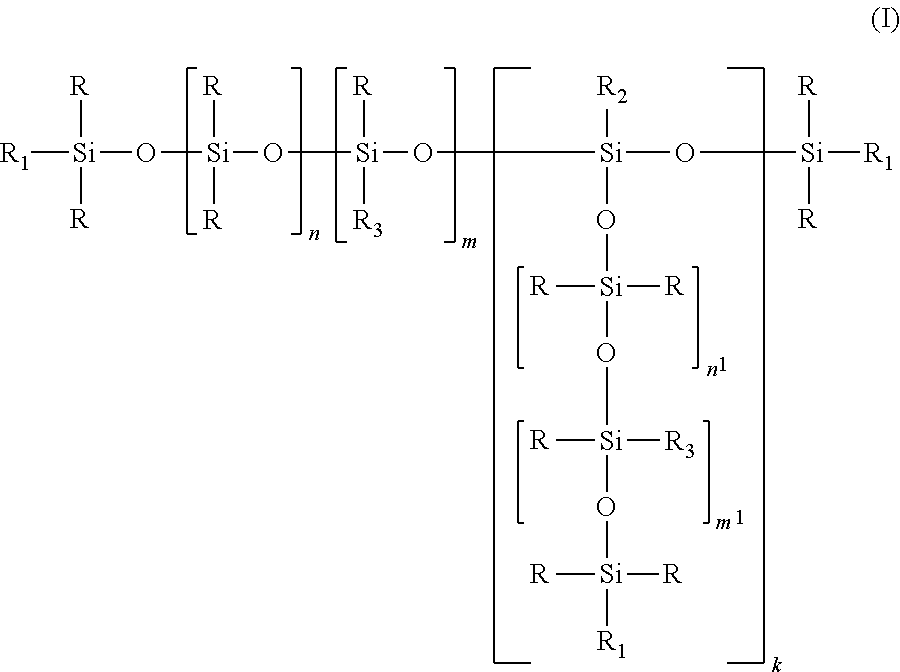

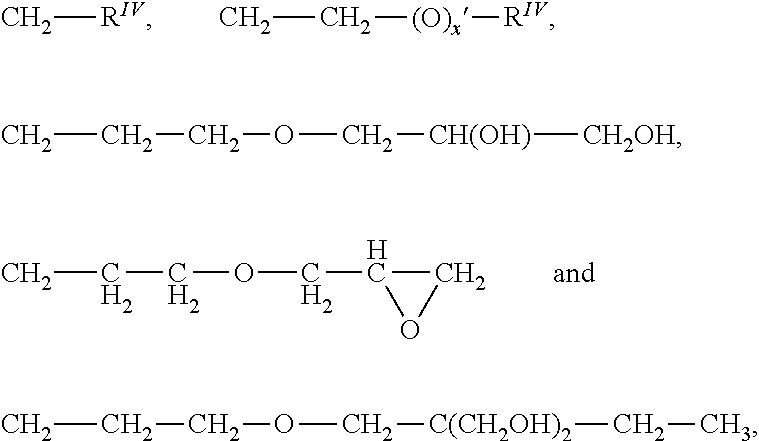

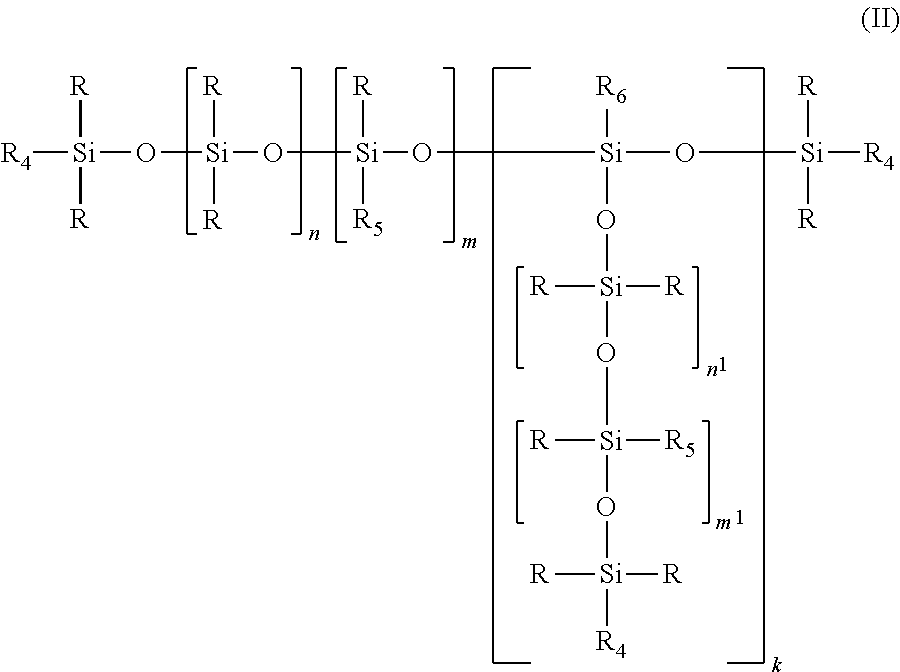

Silicone-polyether block copolymers with high molecular weight polyether residues and their use as stabilizers for production of polyurethane foams

InactiveUS20120190760A1Improve foam stabilityGood cell finenessAntifouling/underwater paintsPaints with biocidesCopolymerStabilizing Agents

Silicone-polyether block copolymer comprising a polyorganosiloxane which includes at least one polyether residue having a molecular weight of not less than 5000 g / mol, and wherein a weight average molecular weight of all polyether residues attached to the polyorganosiloxane by a chemical bond is above 3000 g / mol, its production and use and also compositions and polymeric articles obtained therewith.

Owner:EVONIK DEGUSSA GMBH

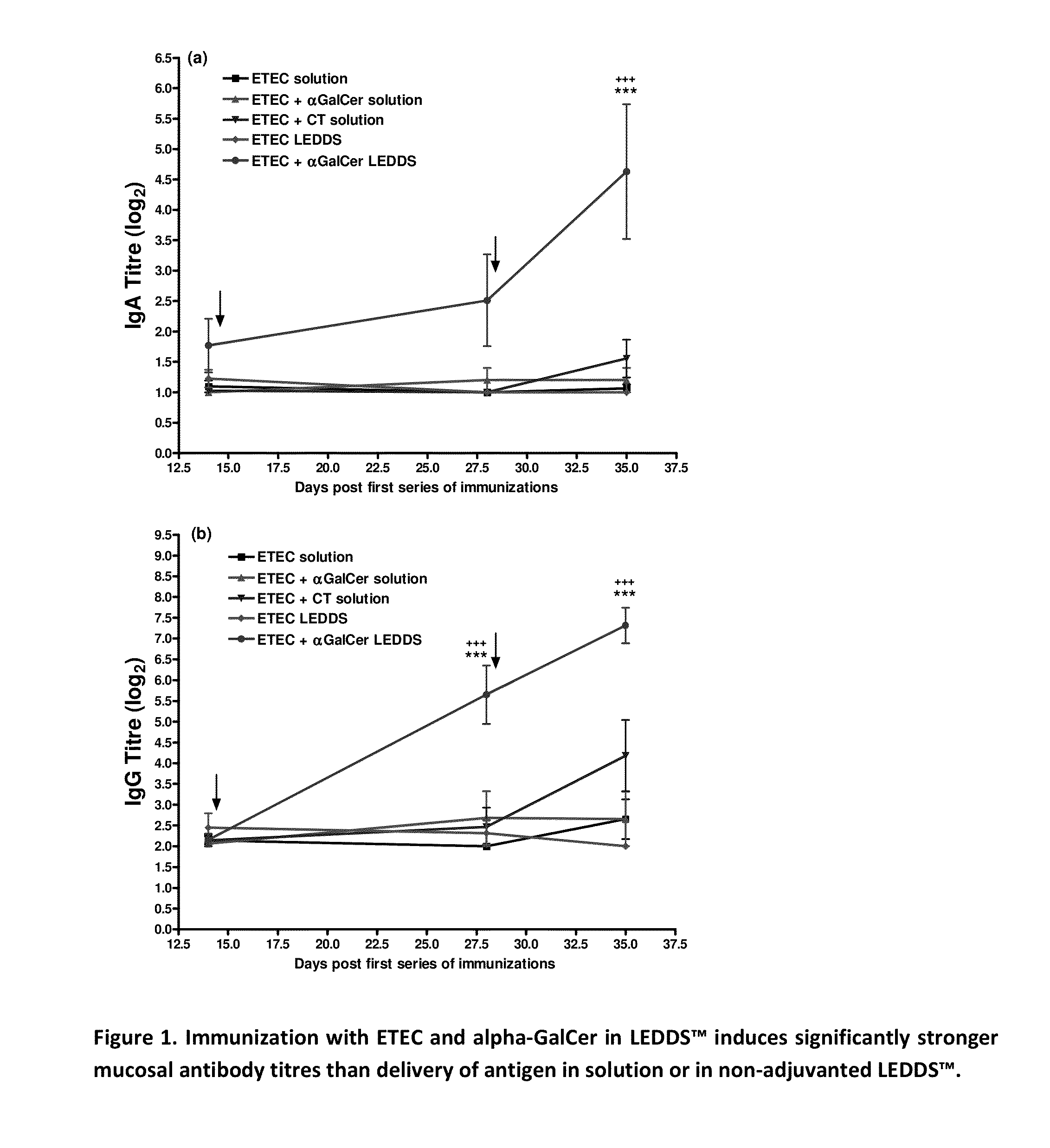

Formulations

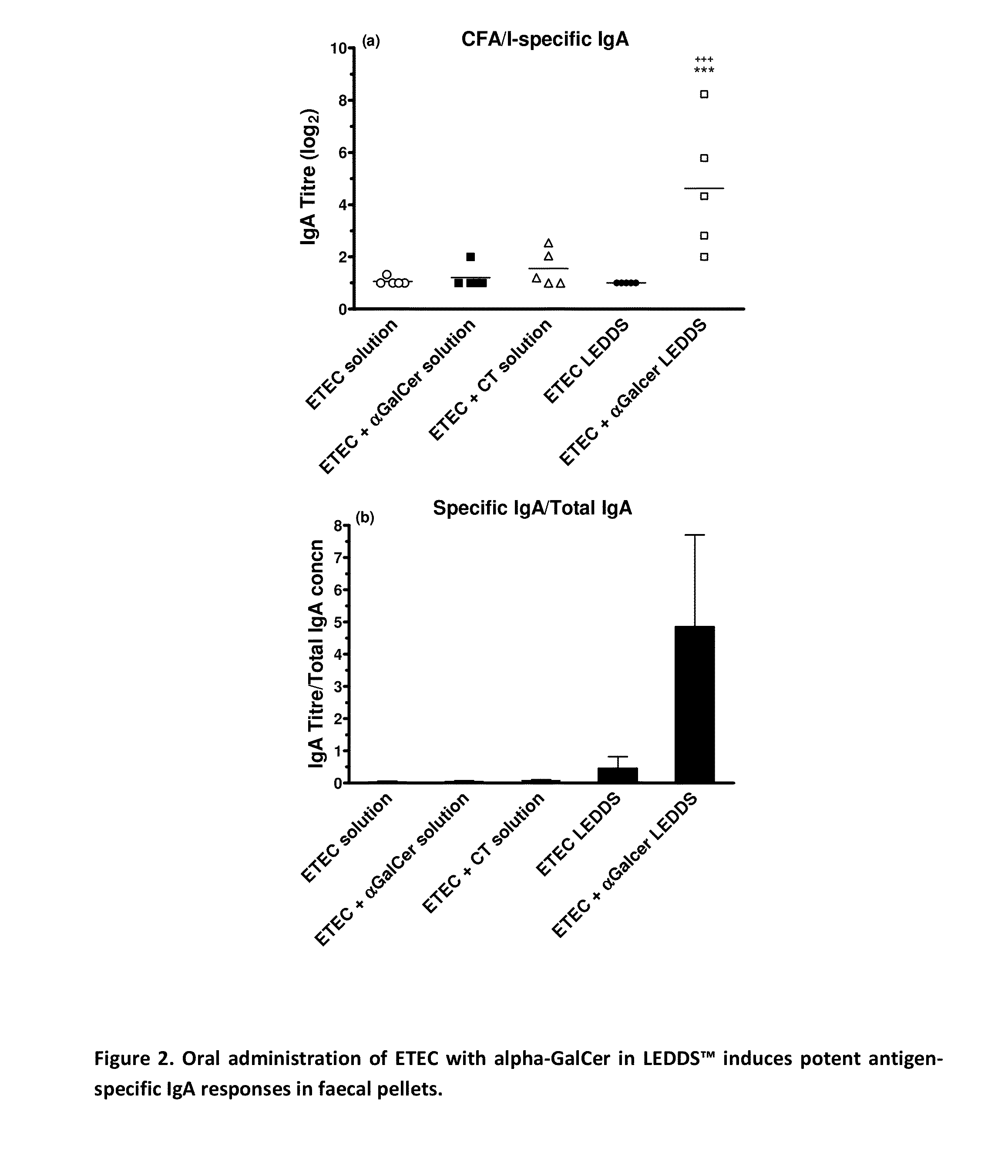

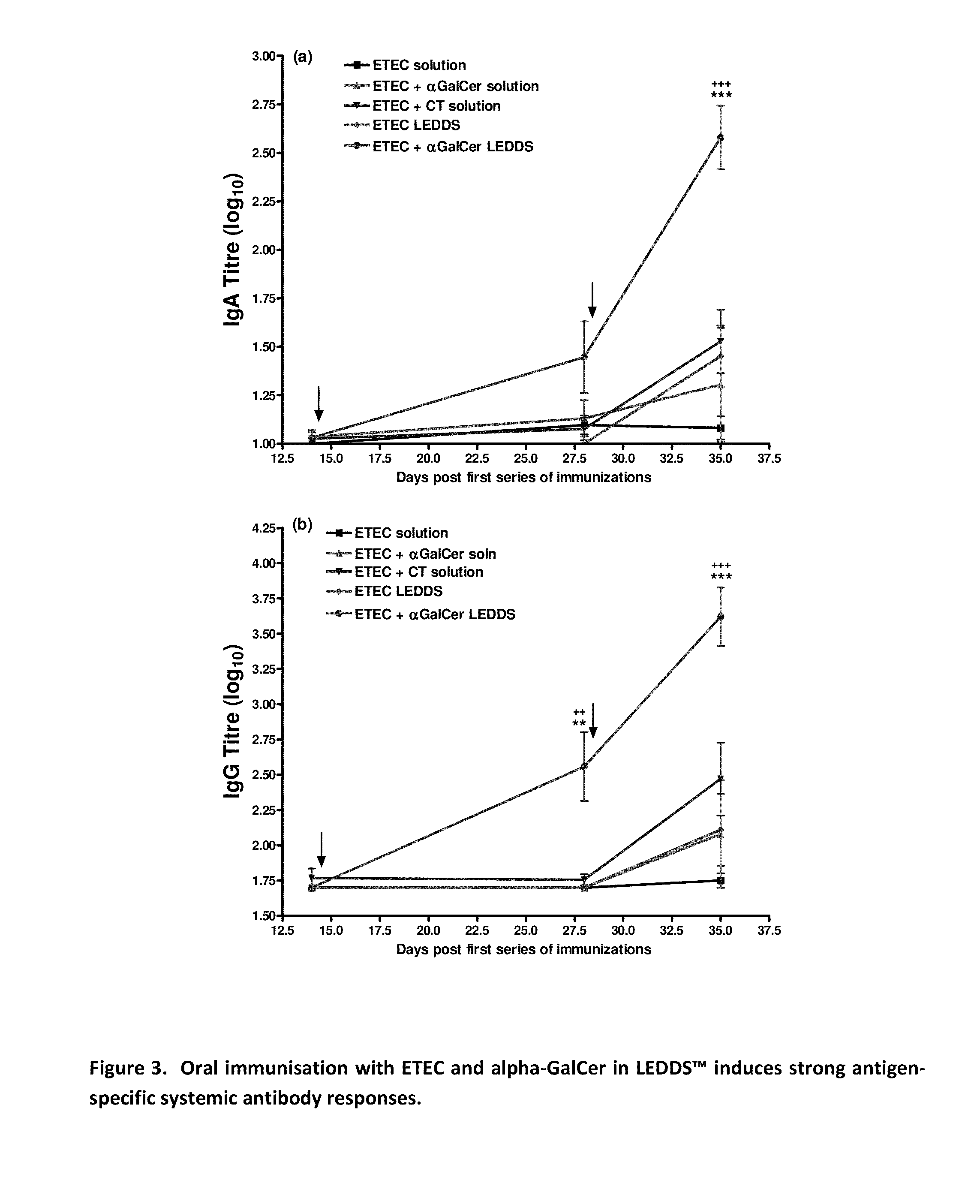

InactiveUS20140017313A1Large specific surface areaIncrease contactPowder deliveryBacterial antigen ingredientsBiotechnologyMicroorganism

This invention relates to compositions for delivering one or more active ingredients, and more particularly to compositions, e.g. beads, comprising a matrix material which matrix material comprises a microorganism. In particular, the invention relates to compositions comprising a microorganism selected from live, killed, attenuated and inactivated microorganisms. The matrix material may also comprise a surfactant and may further comprise an adjuvant. The invention further relates to the manufacture and use of such compositions, and to other subject matter.

Owner:SUBLIMITY THERAPEUTICS LTD

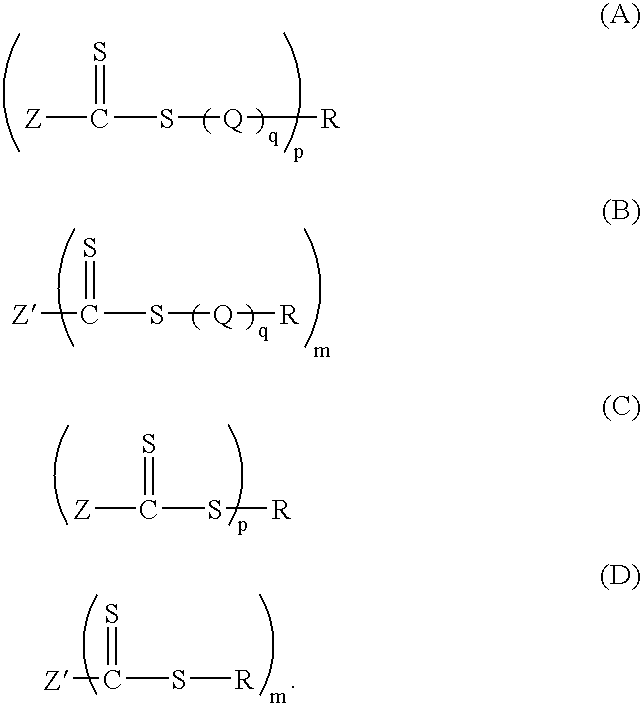

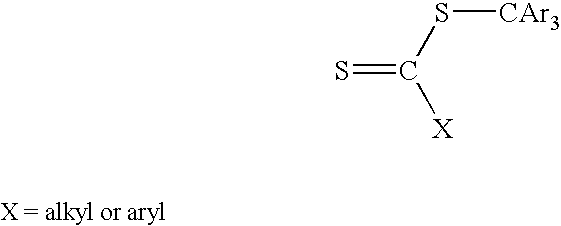

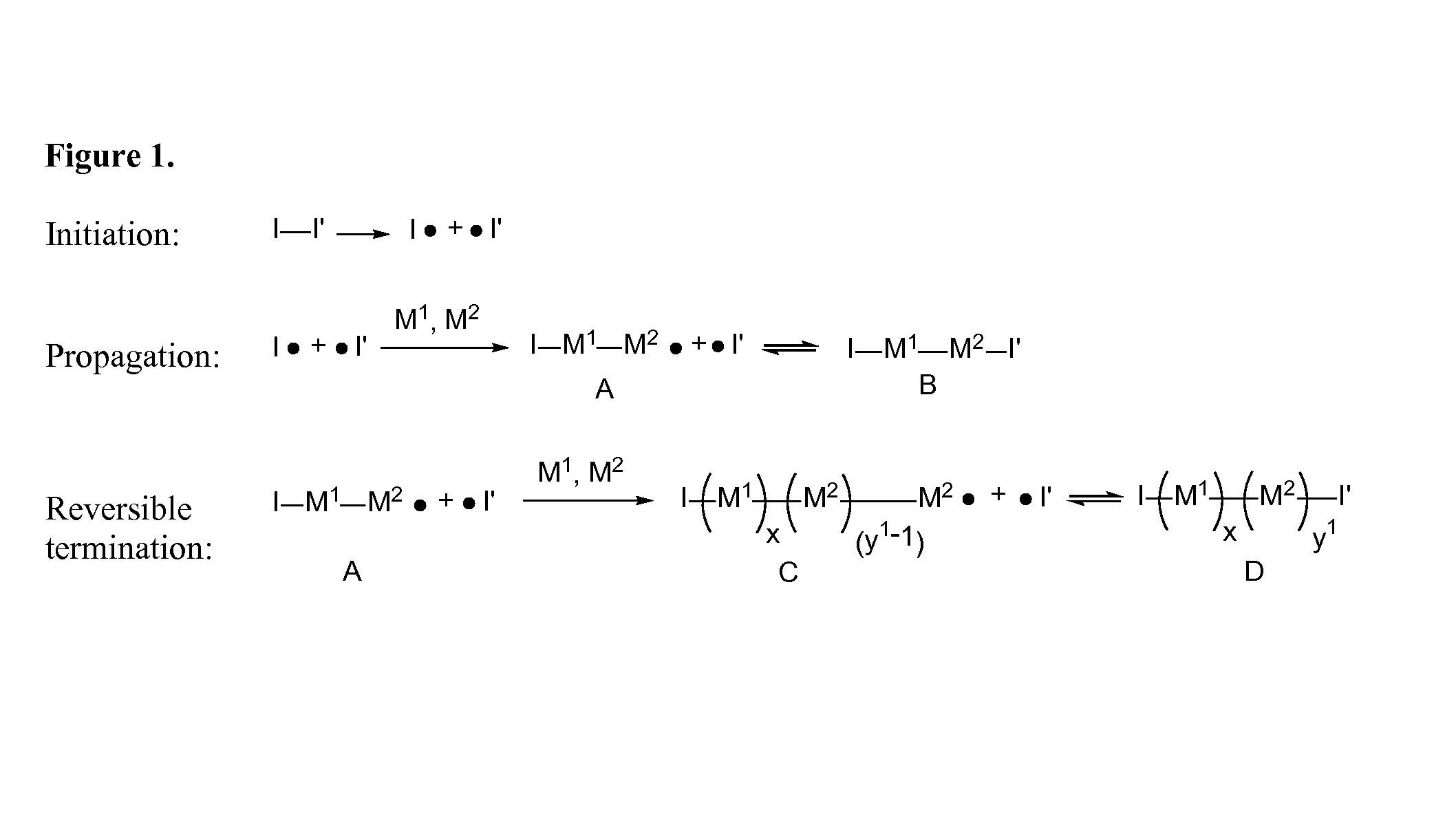

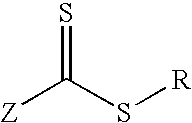

Polymerization with living characteristics

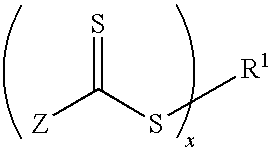

InactiveUS7250479B2Reduce polydispersityIncreased polydispersityGroup 5/15 element organic compoundsMaleic anhydrideChain transfer

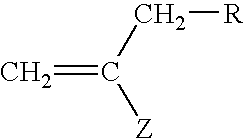

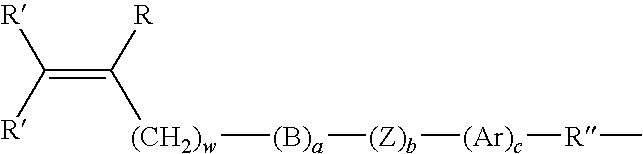

This invention concerns a free radical polymerization process, selected chain transfer agents employed in the process and polymers made thereby, in which the process comprises preparing polymer of general Formula (A) and Formula (B) comprising contacting: (i) a monomer selected from the group consisting of vinyl monomers (of structure CH2═CUV), maleic anhydride, N-alkylmaleimide, N-arylmaleimide, dialkyl fumarate and cyclopolymerizable monomers; (ii) a thiocarbonylthio compound selected from Formula (C) and Formula (D) having a chain transfer constant greater than about 0.1; and (iii) free radicals produced from a free radical source; the polymer of Formula (A) being made by contacting (i), (ii) C and (iii) and that of Formula (B) by contacting (i), (ii) D, and (iii); and (iv) controlling the polydispersity of the polymer being formed by varying the ratio of the number of molecules of (ii) to the number of molecules of (iii); wherein Q, R, U, V, Z, Z′, m, p and q are as defined in the text

Owner:COMMONWEALTH SCI & IND RES ORG

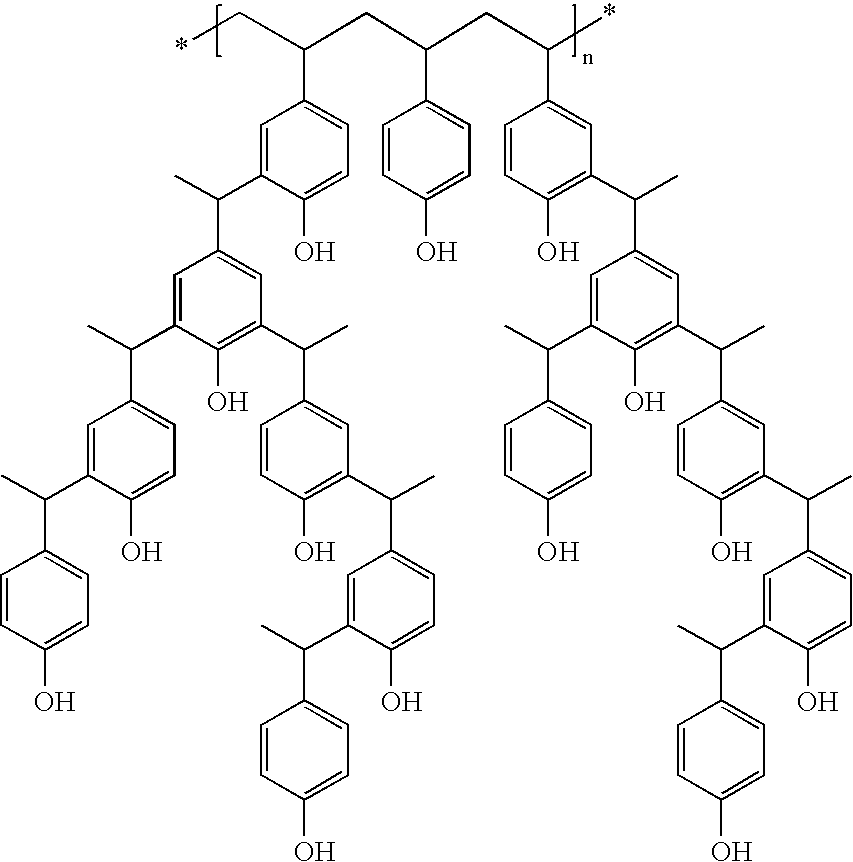

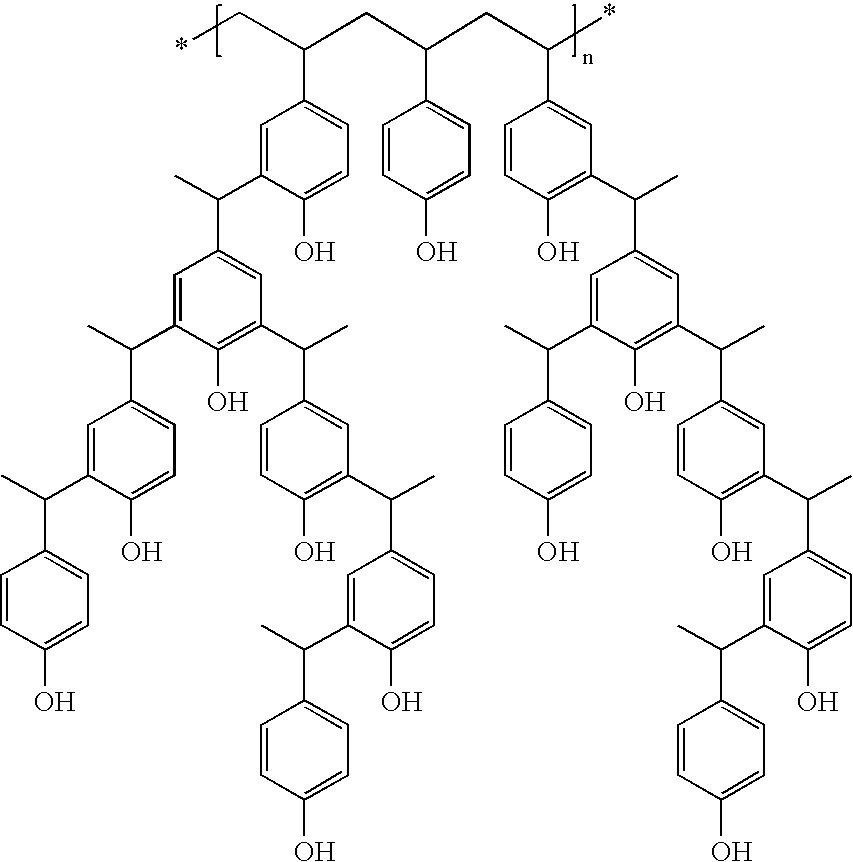

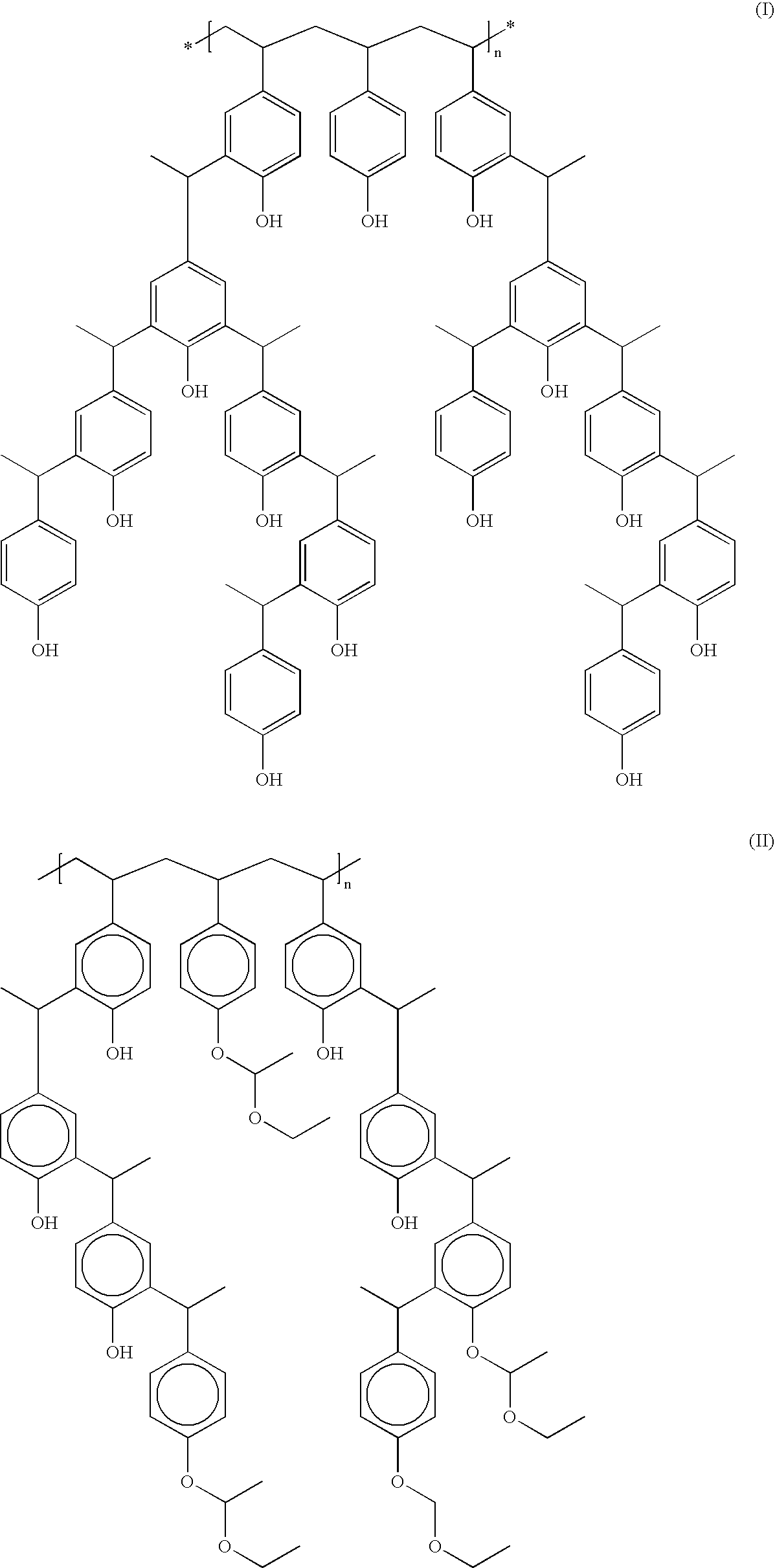

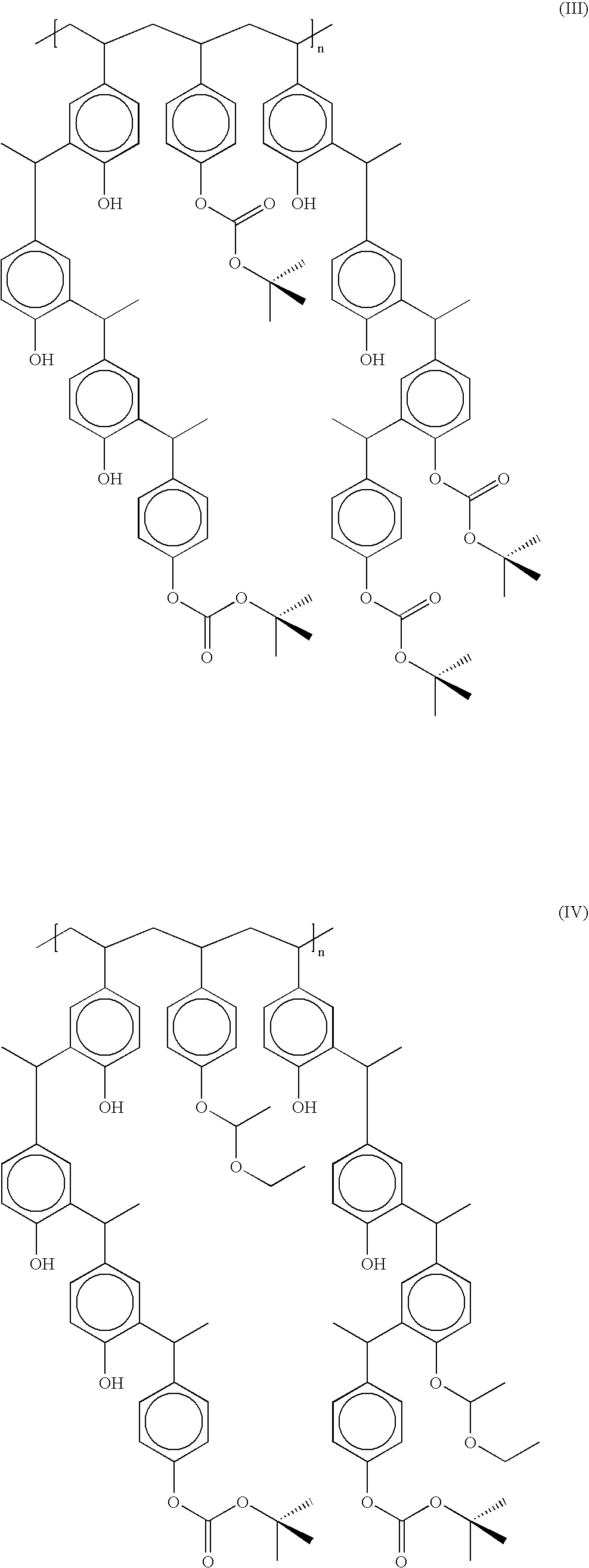

Derivatized polyhydroxystyrenes with a novolak type structure and processes for preparing the same

ActiveUS20050250042A1Reduce polydispersityPhotomechanical apparatusPhotosensitive material auxillary/base layersEpoxyDisplacement reactions

A process for preparing derivatized poly(4-hydroxystryrene) having a novolak type structure which comprises the steps of (i) supplying a solution of methanol containing 4-hydroxyphenylmethylcarbinol, (ii) subjecting said solution to an acid catalyzed displacement reaction for a sufficient period of time and under suitable conditions of temperature and pressure to convert substantially all of said carbinol to 4-hydroxyphenylmethylcarbinol methyl ether in solution, (iii) polymerizing said ether containing solution in the presence of a suitable acid catalyst for a sufficient period of time and under suitable conditions of temperature and pressure to form a novolak type polymer. New compositions of matter which comprise the derivatized poly(4-hydroxystyrene) prepared in the above manner and which have application in the electronic chemicals market such as in a photoresist composition, and in other areas such as in varnishes, printing inks, epoxy resins, copying paper, tackifiers for rubber, crude oil separators, and the like.

Owner:DUPONT ELECTRONICS POLYMERS

Polymeric compositions and related methods of use

InactiveUS7858679B2Reduce polydispersityBiocideMaterial nanotechnologySurface initiatedPhotochemistry

Methods for surface-initiated atom transfer radical polymerization, which can utilize a catecholic alkyl halide initiator.

Owner:NORTHWESTERN UNIV

Biomedical devices

ActiveUS20100317816A1Clear processReduce polydispersityOptical partsOptical elementsHydrophilic monomerPolymer science

Biomedical devices such as contact lenses formed from a comprising a polymerization product of a mixture comprising an ethylenically unsaturated-containing non-amphiphilic macromonomer comprising hydrophilic units or hydrophobic units derived from a living radical polymerization of one or more ethylenically unsaturated hydrophilic monomers or one or more ethylenically unsaturated hydrophobic monomers are disclosed.

Owner:BAUSCH & LOMB INC

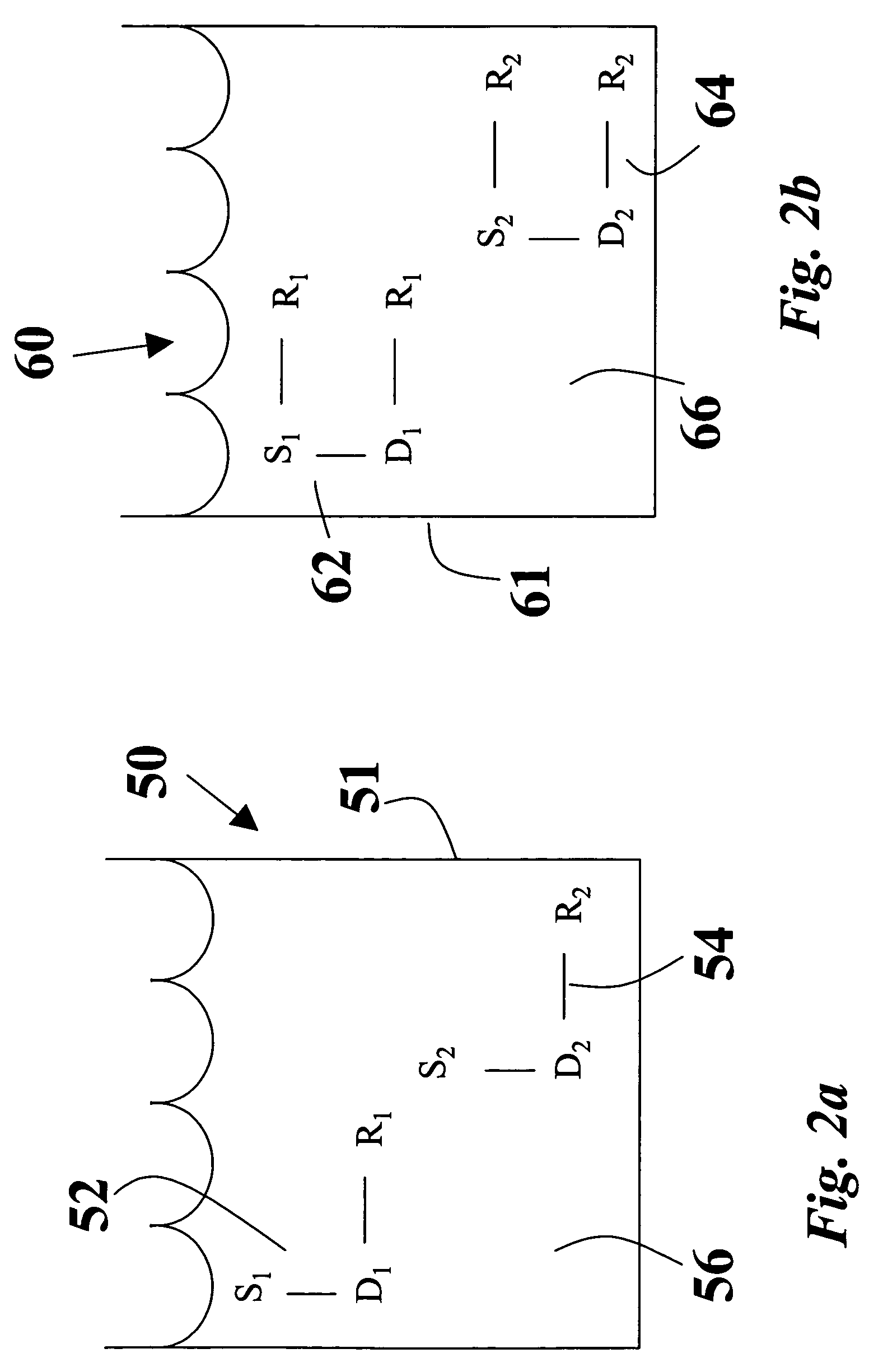

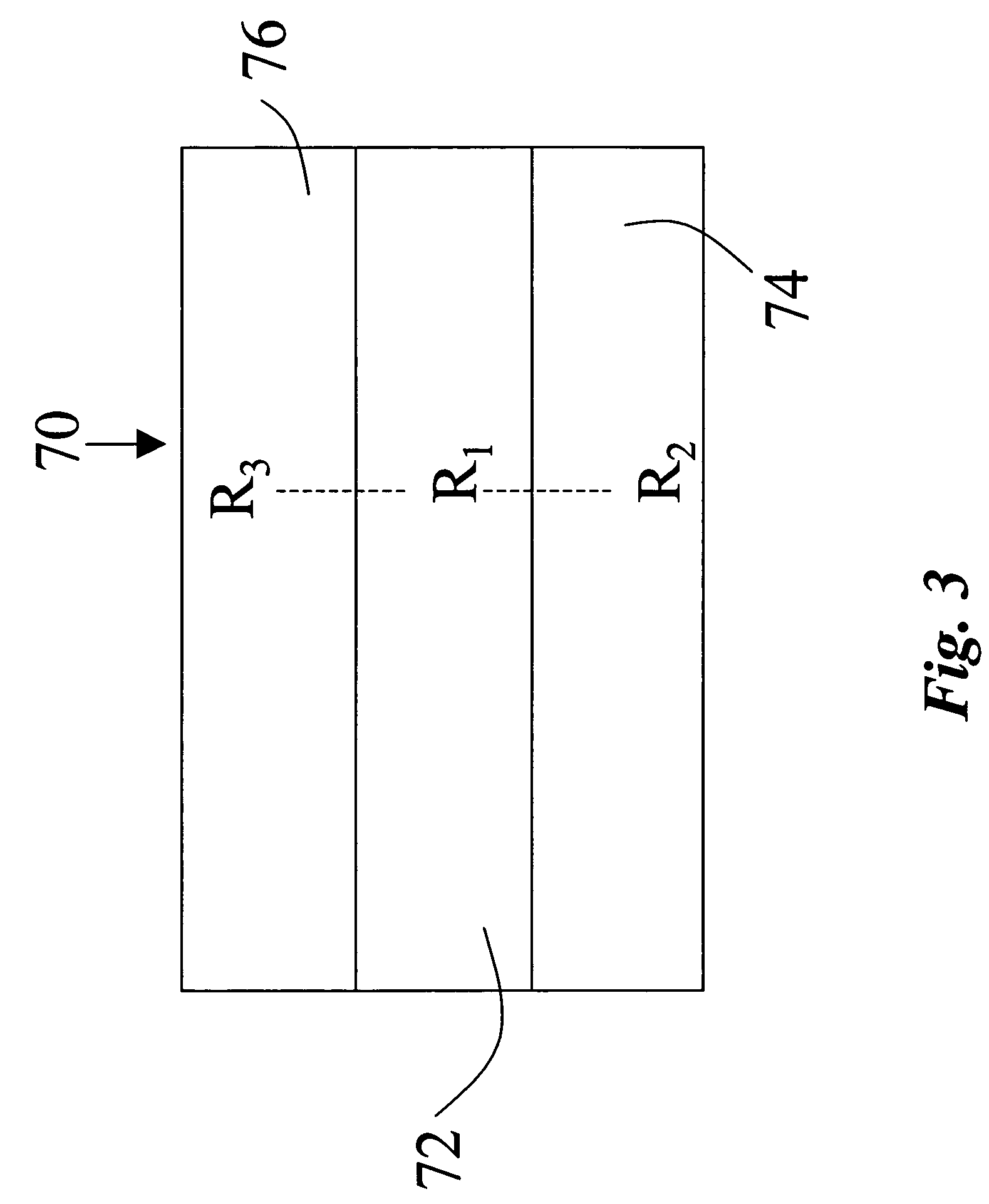

Organosol including amphipathic copolymeric binder having crystalline material, and use of the organosol to make dry tones for electrographic applications

InactiveUS7005225B2Reduce polydispersityExceptional uniformityDevelopersElectrographic processes using charge patternCrystalline materialsCopolymer

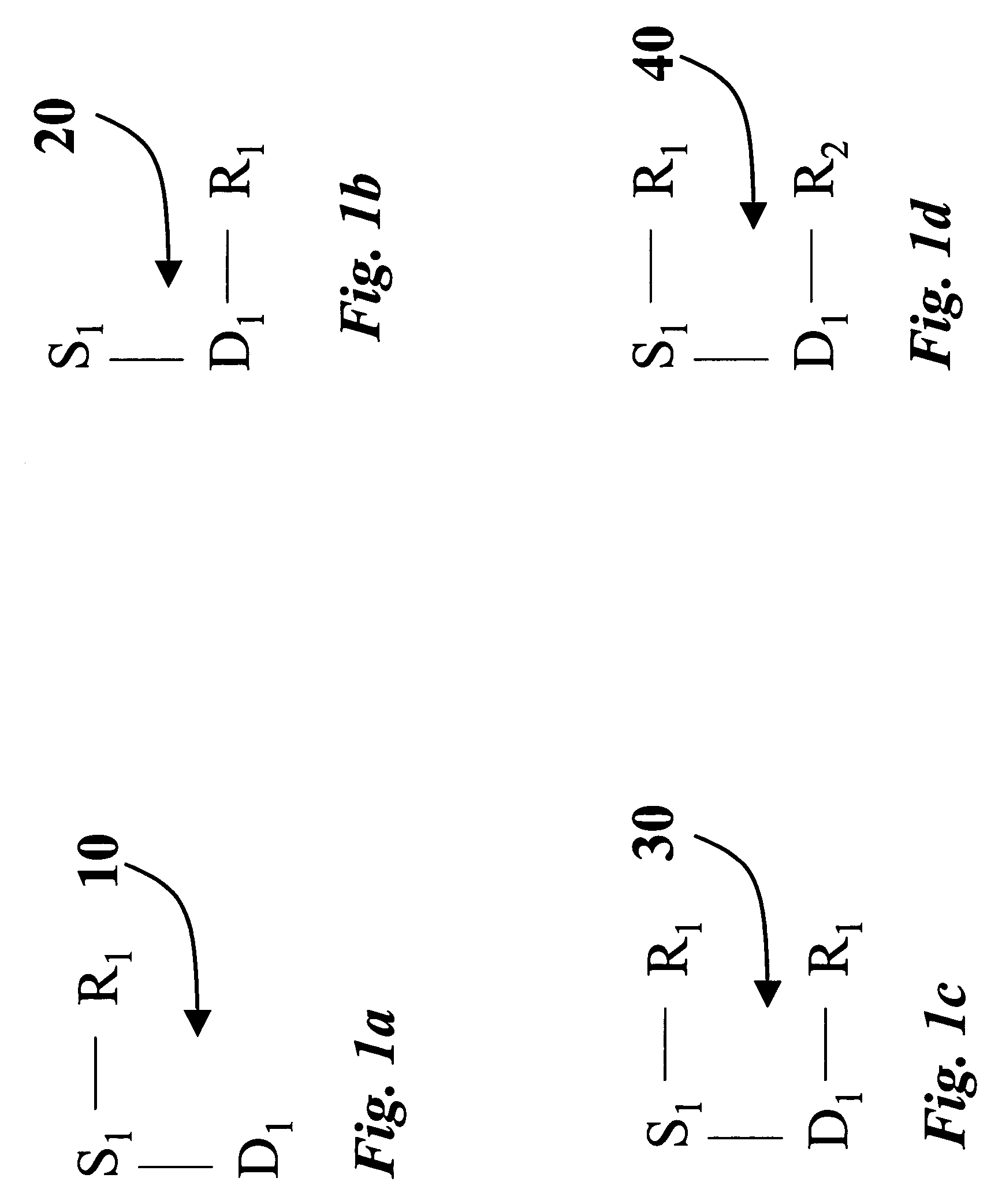

The present invention relates to amphipathic copolymeric binder particles that incorporate polymerizable crystallizable compounds chemically incorporated into a dispersible (D) portion and / or solvatable (S) portion of the copolymer. The invention also pertains to dry particulate electrophotographic toners incorporating an amphipathic copolymer comprising one or more polymerizable crystallizable compounds. Methods of making these dry electrophotographic toner particles, and methods of electrophotographically forming an image on a substrate using these toners, are also described.

Owner:SAMSUNG ELECTRONICS CO LTD

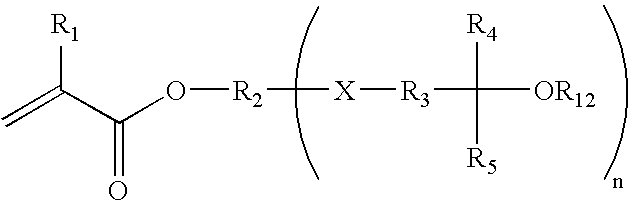

Photoresist composition

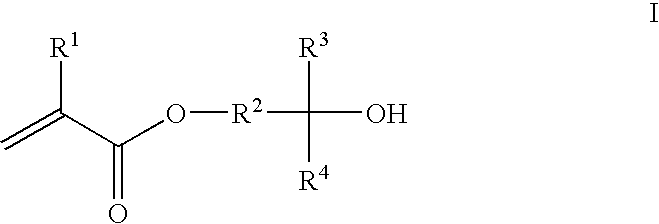

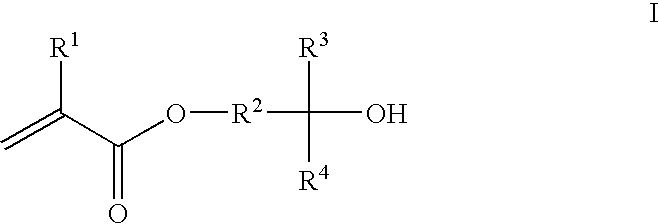

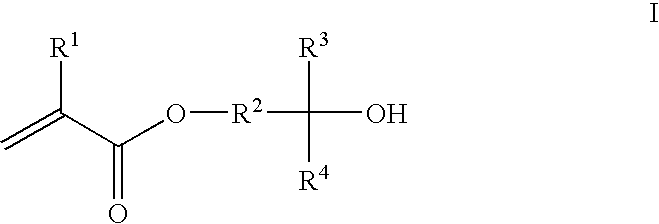

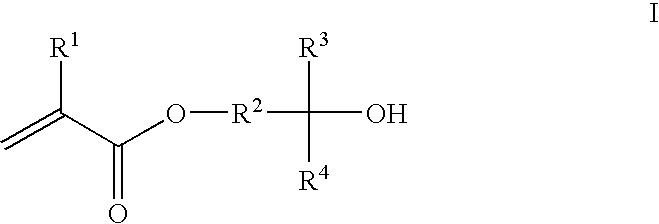

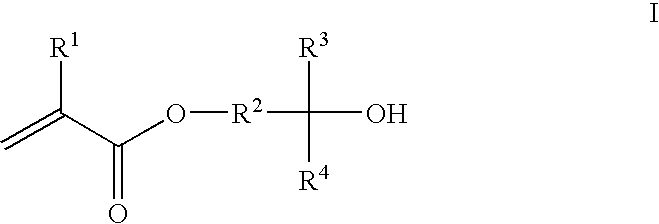

InactiveUS20050019696A1Amenable to free-radical copolymerizationReduce polydispersityPhotosensitive materialsRadiation applicationsResistMethacrylate

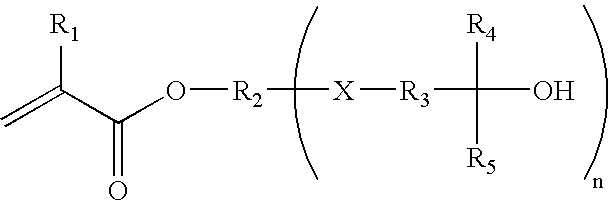

A photoresist composition is provided that includes a polymer having at least one acrylate or methacrylate monomer having a formula where R1 represents hydrogen (H), a linear or branched alkyl group of 1 to 20 carbons, or a semi- or perfluorinated linear or branched alkyl group of 1 to 20 carbons; and where R2 represents an unsubstituted aliphatic group or a substituted aliphatic group having zero or one trifluoromethyl(CF3) group attached to each carbon of the substituted aliphatic group, or a substituted or unsubstituted aromatic group; and where R3 represents hydrogen (H), methyl(CH3), trifluoromethyl(CF3), difluoromethyl(CHF2), fluoromethyl (CH2F), or a semi- or perfluorinated aliphatic chain; and where R4 represents trifluoromethyl(CF3), difluoromethyl(CHF2), fluoromethyl(CH2F), or a semi- or perfluorinated substituted or unsubstituted aliphatic group. A method of patterning a substrate using the photoresist composition is also provided herein.

Owner:GLOBALFOUNDRIES INC

Conjugated lipomers and uses thereof

ActiveUS9238716B2High transfection efficiencyDispersity of a polymer can be modifiedBiocidePowder deliveryPolymer scienceLipid Body

Owner:MASSACHUSETTS INST OF TECH

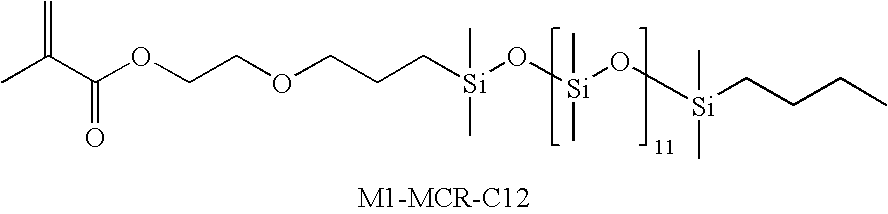

Fluorine-silicon modified acrylic resin as well as preparation method and application thereof

ActiveCN111393588AEasy to use in constructionHigh impact resistance self-healing functionAntifouling/underwater paintsPaints with biocidesMethacrylatePolymer science

The invention discloses fluorosilicone modified acrylic resin as well as a preparation method and an application thereof. The fluorine-silicon modified acrylic resin is prepared from the following components: methacrylate monomers, fluorine-containing acrylate monomers, acrylate-based silicone oil, allyl silicone oil, a polymerized active silane coupling agent, methacrylic acid, hydroxyl-containing active crosslinking monomers, glycidyl methacrylate, trimethylolpropane trimethacrylate, an initiator, a chain transfer agent and a solvent. The fluorine-containing acrylate monomer is composed of aC2-C3 short-chain fluorine-containing alkyl acrylate monomer and a C10-C12 long-chain fluorine-containing alkyl acrylate monomer. The fluorine-silicon modified acrylic resin prepared by the inventionhas the characteristic of high low viscosity, is convenient to construct and use, and reduces the generation of VOC. The coating prepared from the modified acrylic resin has the characteristics of high impact-resistant self-repairing function, icing prevention, low surface energy, hydrophobicity, oleophobicity, stain resistance, high and low temperature resistance and the like.

Owner:INST OF CHEM ENG GUANGDONG ACAD OF SCI

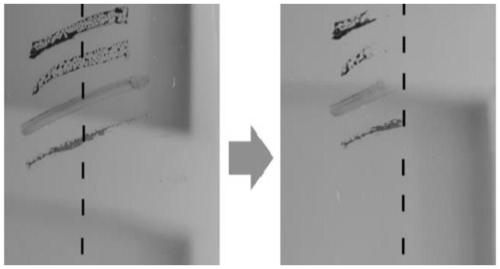

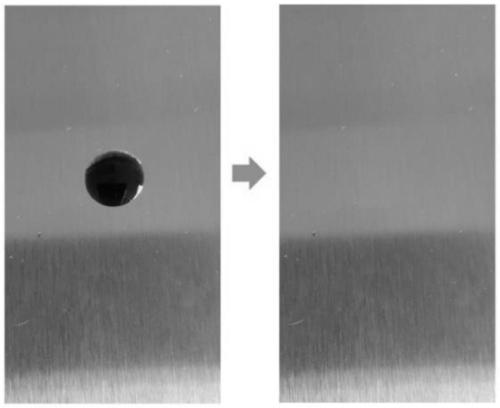

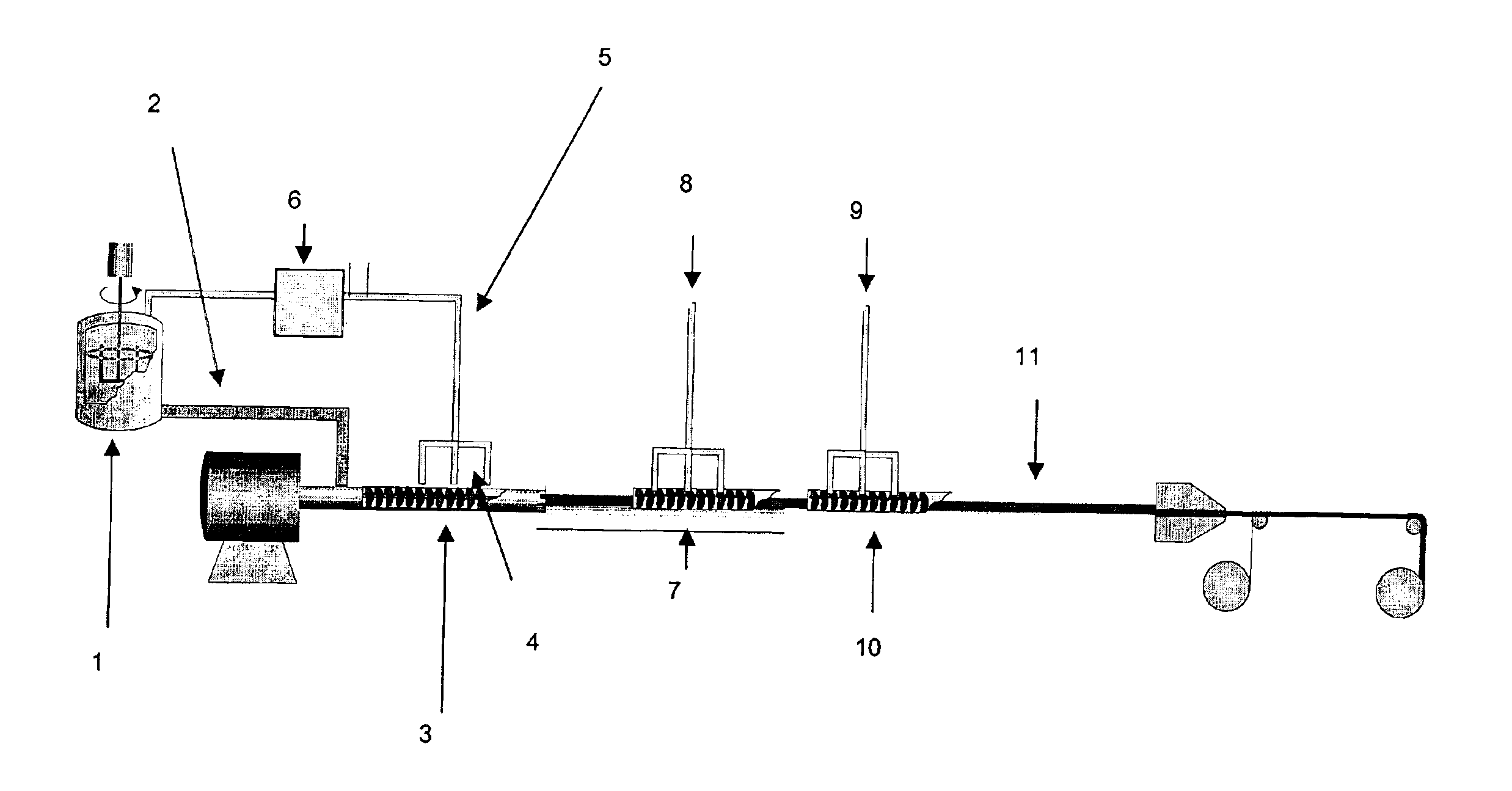

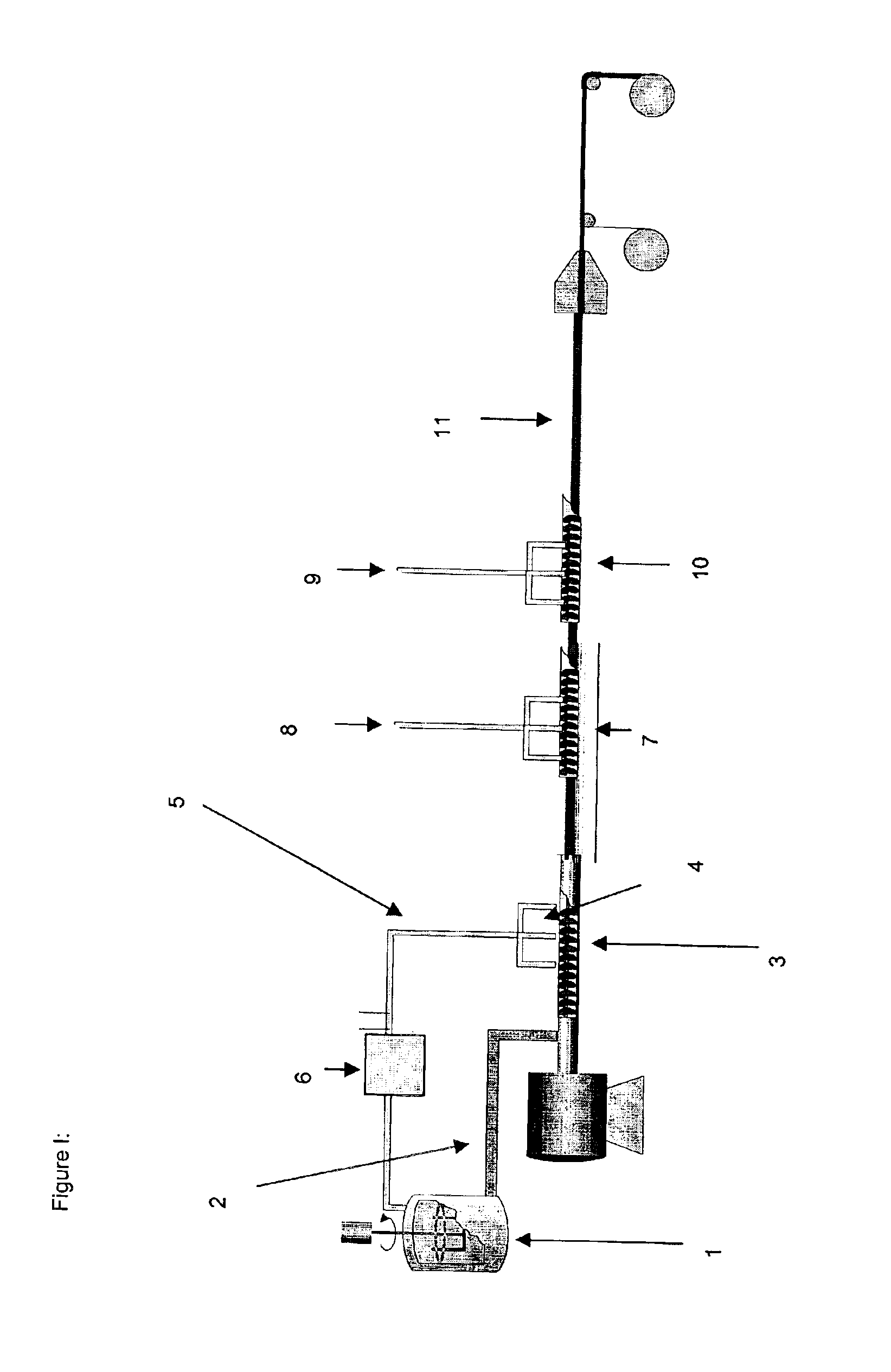

Continuous two-stage preparation of solvent-free polyacrylate hotmelt PSAs

ActiveUS6881442B2High molecular weightHigh throughputFilm/foil adhesivesOrganic dyesSolvent freeAntioxidant

In a continuous two-stage process for preparing solvent-free polyacrylate hotmelt pressure sensitive adhesives which is gentle on the polymer and redeploys the solvent used in the process the following steps are carried out:polymerizing a self-adhesive pressure sensitive adhesive in solution, the solvent having a low vapor pressure;continuously mixing the polymer solution with antioxidants and preheating the mixture under superatmospheric pressure without boiling it;concentrating the polymer solution to a residual solvent content of less than 0.1% by weight in a concentrating extruder under the effect of reduced pressure and elevated temperatures;condensing, collecting, and re-using the solvent stripped off in the extruder;compounding the abovementioned solvent-freed hotmelt pressure sensitive adhesive with tackifying resins, fillers, stabilizers, crosslinkers or other additives in a second extruder at a moderate melt temperature;transferring the blended solvent-free self-adhesive pressure sensitive adhesive to a downstream coating unit.

Owner:TESA SE

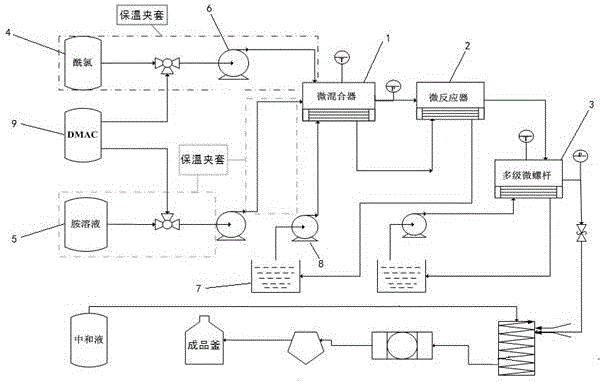

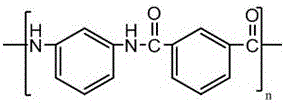

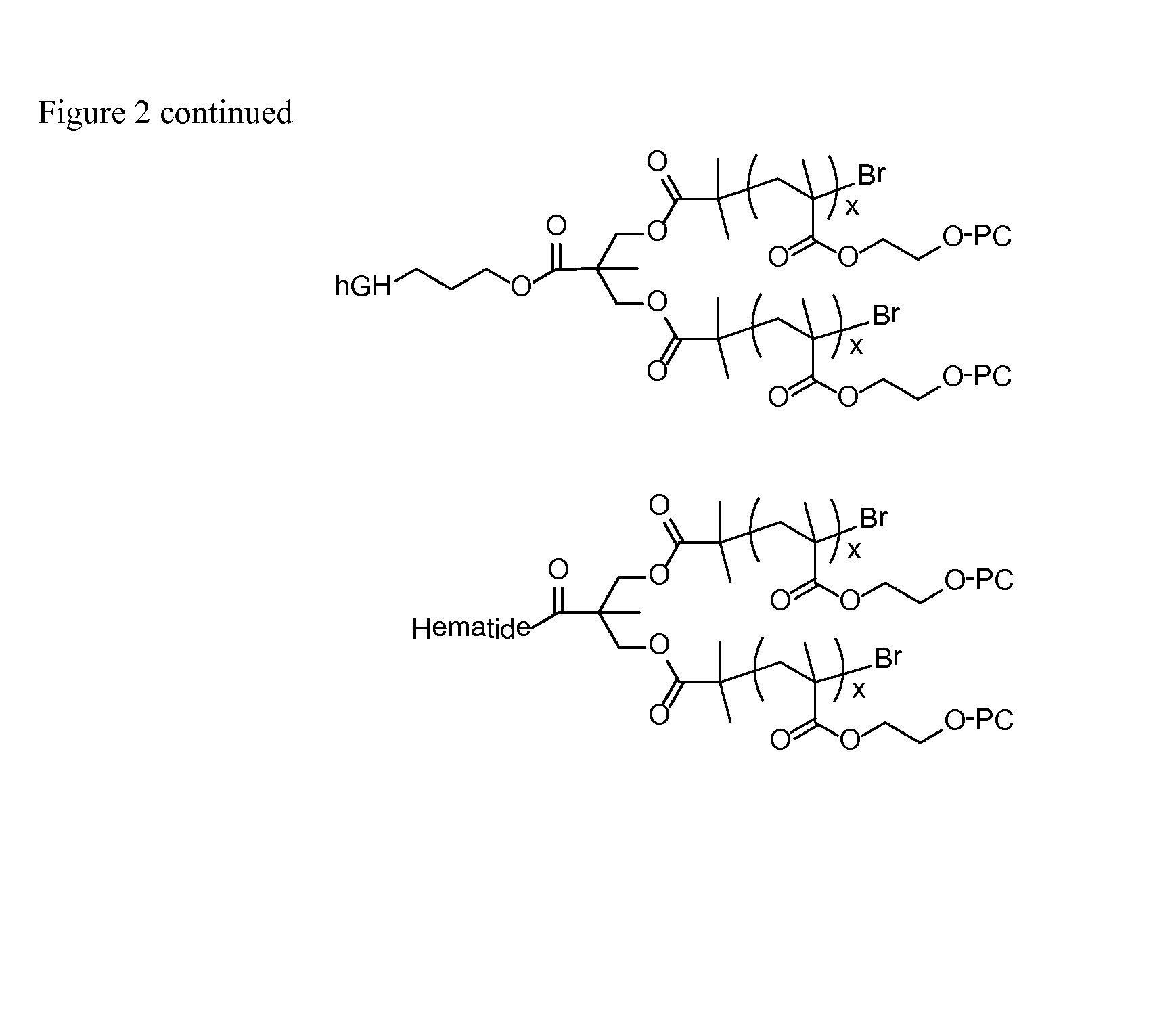

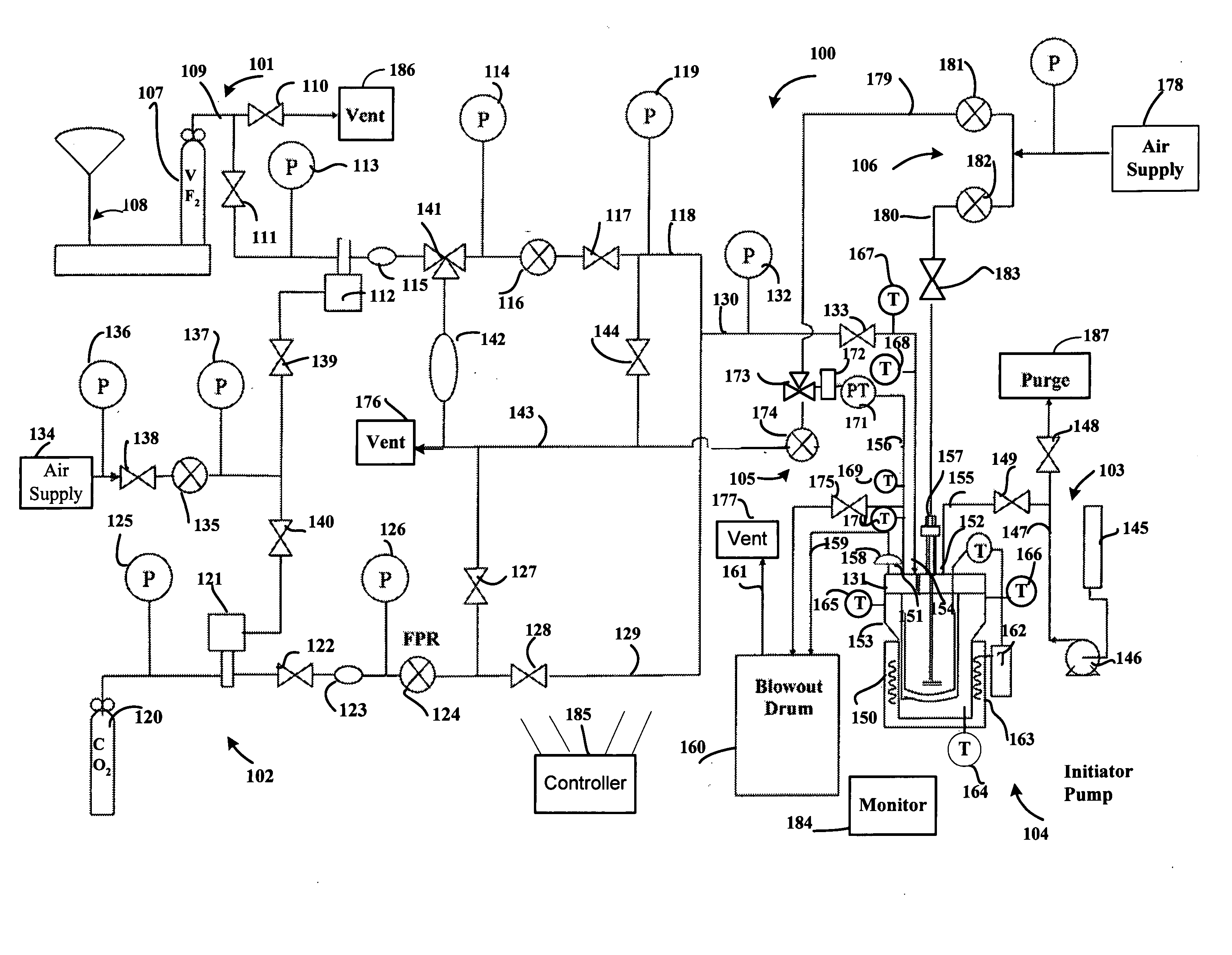

Continuous micro-reaction device and method for preparing meta-aramid resin and product

ActiveCN106478940AEasy transferReduce polydispersityChemical/physical/physico-chemical microreactorsMonocomponent polyamides artificial filamentAfter treatmentEngineering

A continuous micro-reaction device for preparing meta-aramid resin comprises a prepolymerization system, a polycondensation system, an after-treatment system and a heat exchange system, wherein the prepolymerization system, the polycondensation system and the after-treatment system are connected in sequence, and the heat exchange system is connected with the prepolymerization system and the polycondensation system to control temperatures of the prepolymerization system and the polycondensation system. The continuous micro-reaction device is characterized in that the prepolymerisation system comprises a raw material storage device, a micro-mixer and a micro-reactor which are connected in sequence; the polycondensation system comprises a multistage micro-screw device, and the micro-reactor is connected with multistage micro-screw device. The continuous micro-reaction device for preparing the meta-aramid resin improves the heat transfer effect at the polycondensation stage and the mass transfer effect at the polycondensation stage during preparation of the meta-aramid resin, and achieves the purpose of improving the performance of a meta-aramid resin product. The invention further provides a continuous micro-reaction method for preparing the meta-aramid resin and the product.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

High molecular weight zwitterion-containing polymers

InactiveUS20140024776A1Improve efficiencyMinimal number of production stepIn-vivo radioactive preparationsPharmaceutical non-active ingredientsPolymer scienceHigh molecular mass

Owner:KODIAK SCI

Polymerization of vinylidenefluoride (VF2) in a supercritical fluid medium

ActiveUS20060069223A1High molecular weightReduce polydispersityChemical recyclingBulk chemical productionPolymer scienceSolvent

Polymerization of fluoroolefin monomers proceeds in a supercritical carbon dioxide solvent at high monomer loading levels to provide a high molecular weight polymer with low polydispersity and / or a unimodal molecular weight distribution.

Owner:ARKEMA INC

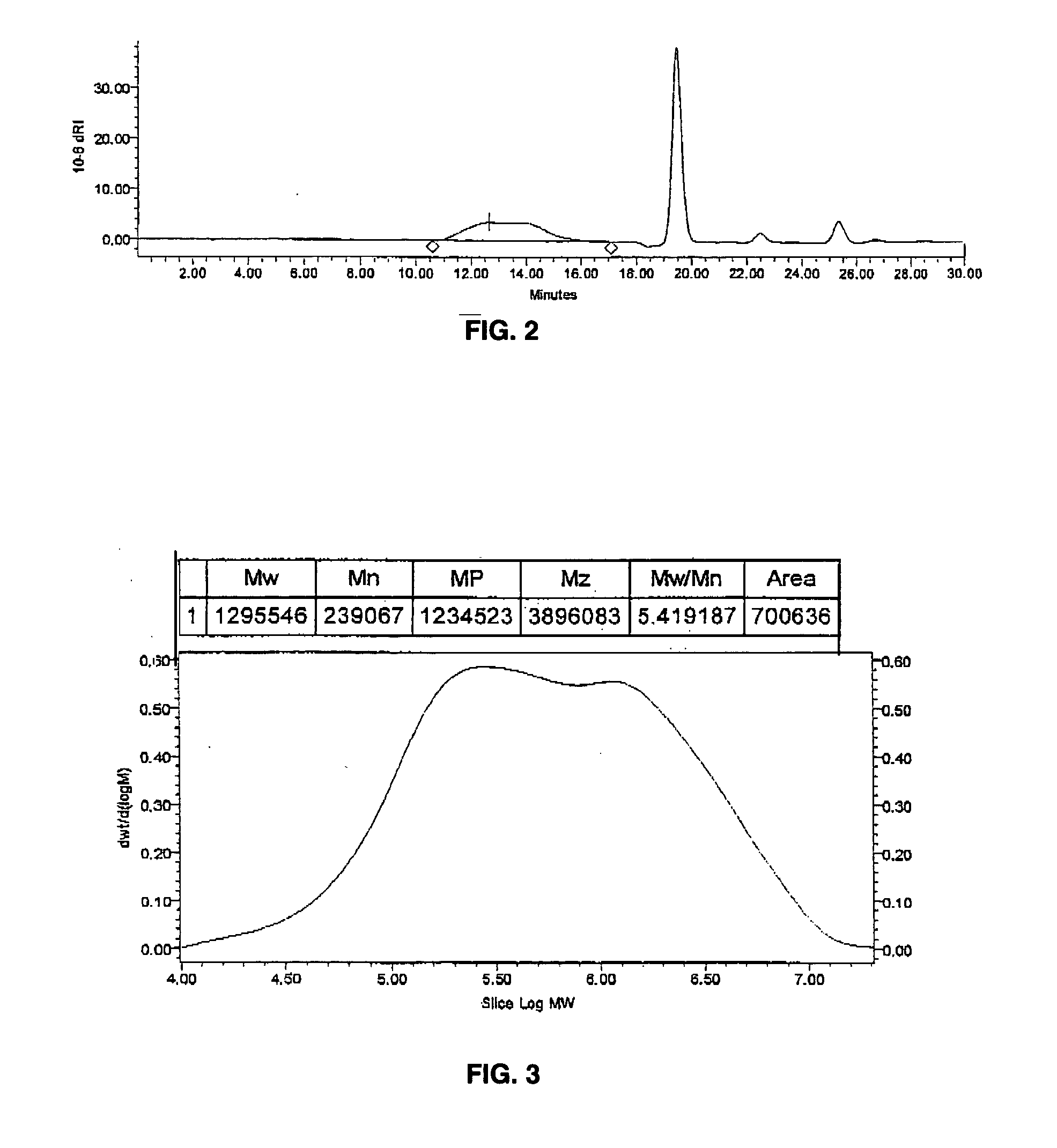

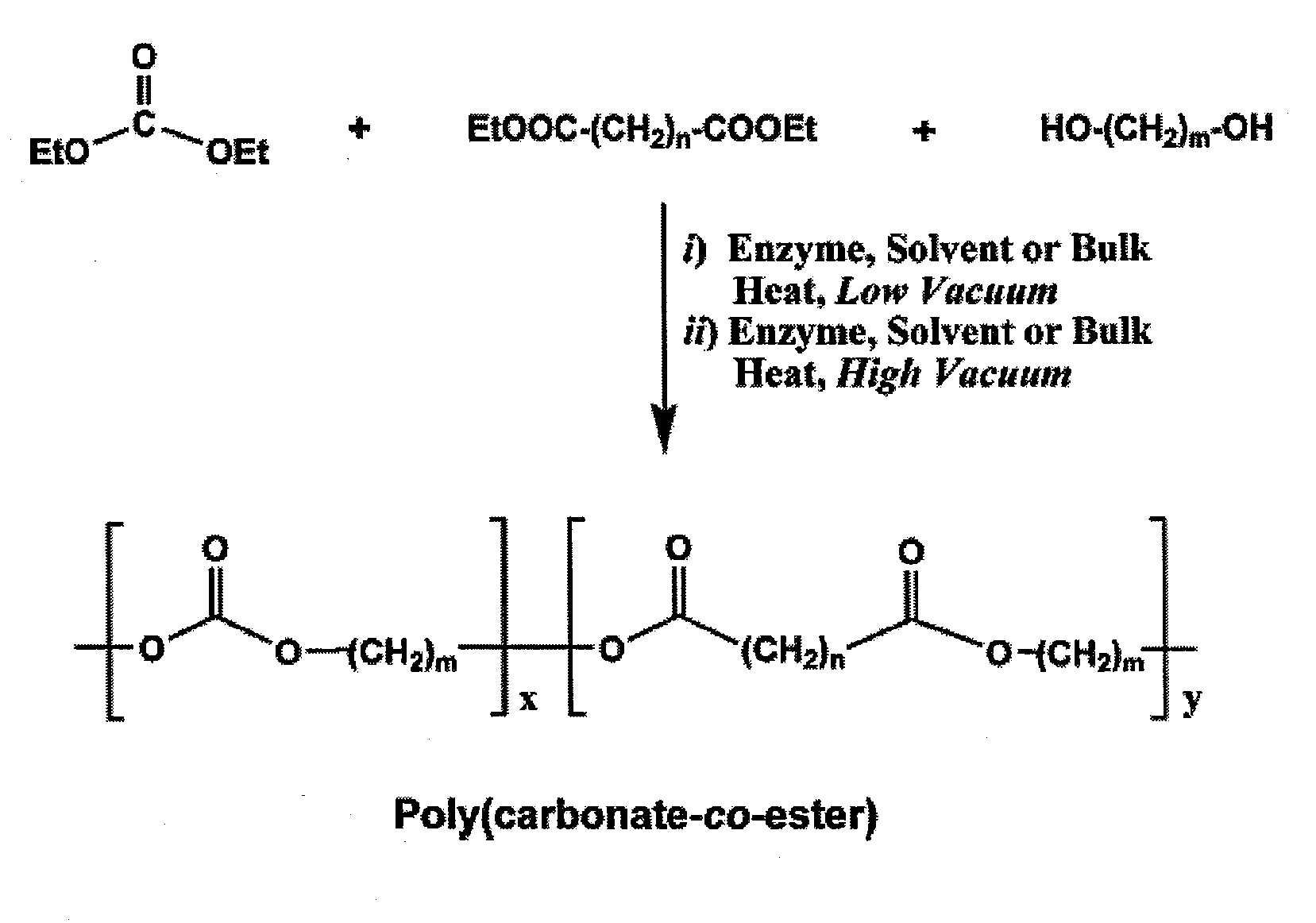

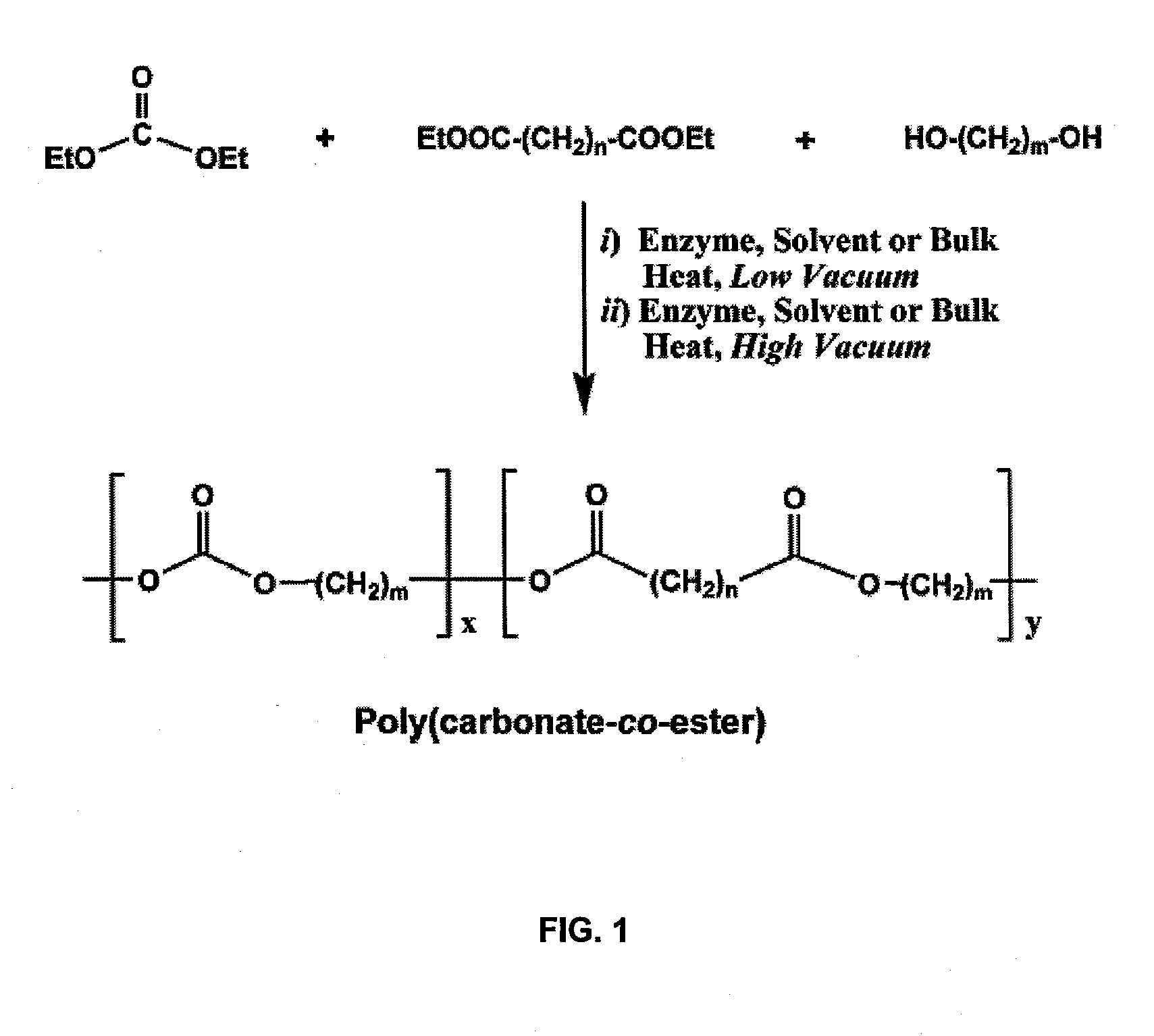

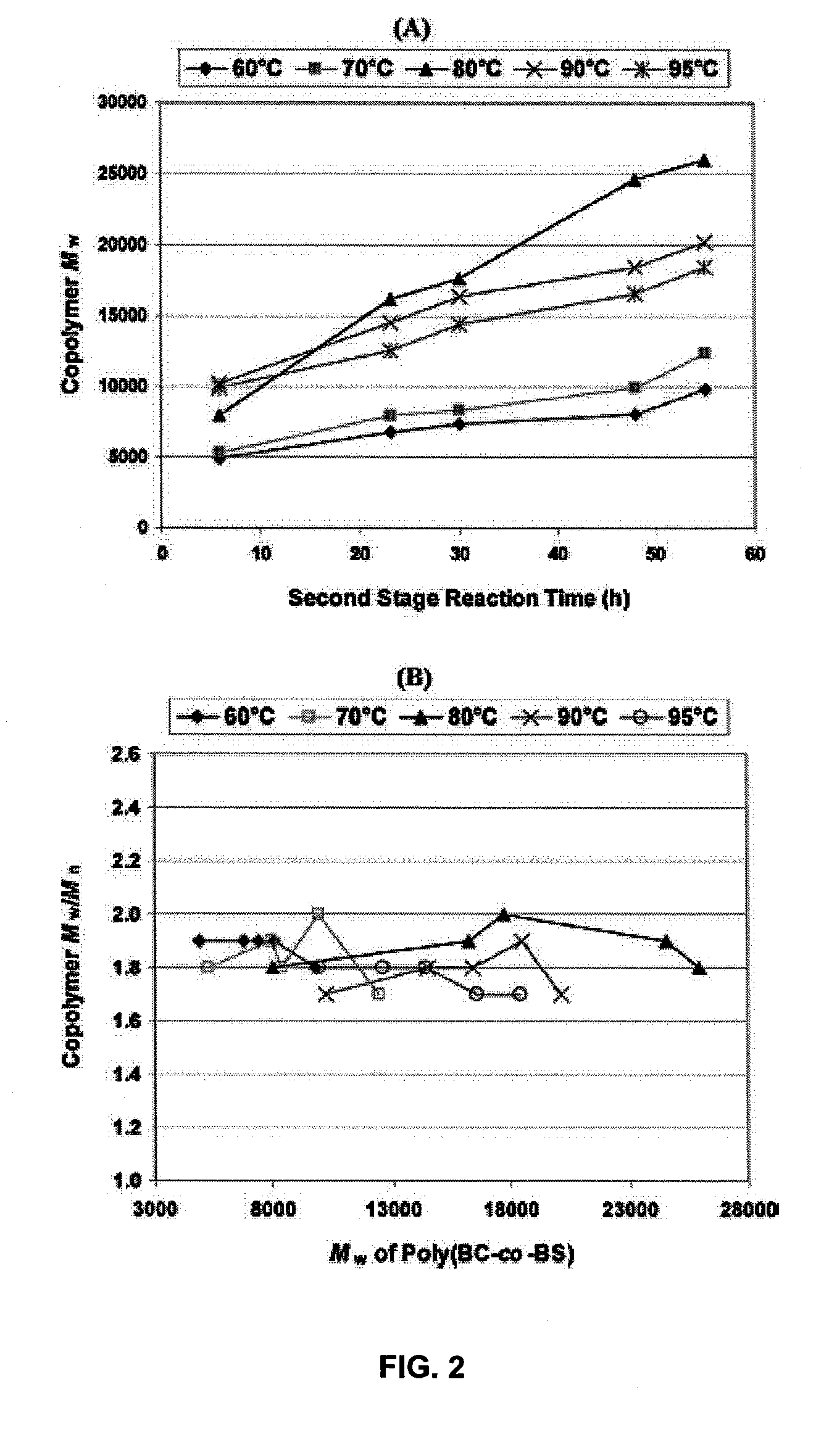

Enzyme-catalyzed polycarbonate and polycarbonate ester synthesis

InactiveUS20100041856A1Strong specificityEasy to controlFermentationTransesterificationPolycarbonate

An enzymatic process for preparing aliphatic polycarbonates via terpolymerization or transesterification using a dialkyl carbonate, an aliphatic diester, and an aliphatic diol or triol reactant. A catalyst having an enzyme capable of catalyzing an ester hydrolysis reaction in an aqueous environment is subsequently added to the reaction mixture. Next, polymerization of the reaction proceeds for an allotted time at a temperature≦100° C. Finally, the copolymer is isolated from an the catalyst via filtration.

Owner:POLYTECHNIC INST OF NEW YORK

Fluorinated photoresist materials with improved etch resistant properties

InactiveUS7217496B2Amenable to free-radical copolymerizationReduce polydispersityPhotosensitive materialsRadiation applicationsPhotoresistCarbonate

A photoresist composition including a polymer is disclosed, wherein the polymer includes at least one monomer having the formula:where R1 represents hydrogen (H), a linear, branched or cyclo alkyl group of 1 to 20 carbons, a semi- or perfluorinated linear, branched or cyclo alkyl group of 1 to 20 carbons or CN; R2 represents an alicyclic group of 5 or more carbon atoms; X represents a methylene, ether, ester, amide or carbonate linkage; R3 represents a linear or branched alkylene group or semi- or perfluorinated linear or branched alkylene group with 1 or more carbon atoms; R4 represents hydrogen (H), methyl (CH3), trifluoromethyl (CF3), difluoromethyl (CHF2), fluoromethyl (CH2F), or a semi- or perflourinated aliphatic group; R5 represents trifluoromethyl (CF3), difluoromethyl (CHF2), fluoromethyl (CH2F), or a semi- or perfluorinated substituted or unsubstituted aliphatic group; n represents an integer of 1 or more; and OR12 represents OH or at least one acid labile group selected from a tertiary alkyl carbonate, a tertiary alkyl ester, a tertiary alkyl ether, an acetal and a ketal. A method of patterning a substrate is also disclosed, wherein the method includes: applying the photoresist composition mentioned above to the substrate to form a film; patternwise exposing the film to an imaging radiation source; and developing areas of the film to form a patterned substrate.

Owner:GLOBALFOUNDRIES INC

Organosol liquid toner including amphipathic copolymeric binder having crosslinkable functionality

InactiveUS7052816B2Reduce polydispersityExceptional uniformityDevelopersAdditive ingredientOrganic chemistry

Liquid toner compositions having utility in electrographic applications. Organosol liquid toner compositions comprise binder particles dispersed in a nonaqueous liquid carrier, wherein the particles are derived from ingredients comprising one or more crosslinkable amphipathic copolymer(s). The organosol is easily combined with additional ingredients, such as one or more visual enhancement additives and other desired ingredients, and subjected to mixing processes to form a liquid toner composition. Methods of making and electrographically printing liquid toners derived from these organosols are also described.

Owner:S PRINTING SOLUTION CO LTD

Polymerization catalyst composition for ethylene oxide and proces for the production of poly(ethylene oxide) with the same

ActiveUS20060036066A1High yieldReduce polydispersityOrganic-compounds/hydrides/coordination-complexes catalystsCatalyst activation/preparationChemistryAlkali hydroxide

Provided are a polymerization catalyst composition for ethylene oxide which can give polyethylene oxide having a molecular weight lower than that of the prior art and a relatively narrow molecular weight distribution, and a process for the production of polyethylene oxide by the use of the catalyst composition. The catalyst composition makes it possible to produce polyethylene oxide having a molecular weight ranging from about 20,000 to 200,000 through direct polymerization in a high yield with economic advantage, and is characterized by comprising an organoaluminum compound and at least one member selected from among alkali metal alkoxides and alkali metal hydroxides. According to the process, polyethylene oxide having a molecular weight failing within the above range can be produced by the use of the catalyst composition under the same polymerication conditions as those of the prior art.

Owner:MEISEI CHEM WORKS

Organosol including amphipathic copolymeric binder made with Soluble High Tg Monomer and liquid toners for electrophotographic applications

ActiveUS7014973B2Easy transferAvoid resistanceDevelopersElectrographic processes using charge patternCopolymerMonomer

The invention provides liquid toner compositions in which the polymeric binder is chemically grown in the form of copolymeric binder particles dispersed in a liquid carrier. The polymeric binder includes one amphipathic copolymer that comprises the residue of a Soluble High Tg Monomer. The toners described herein exhibit surprisingly low fusion temperatures, yet are surprisingly resistant to blocking, are non-tacky and are resistant to marring and undesired erasure.

Owner:HEWLETT PACKARD DEV CO LP

Biocompatible compounds for sustained release pharmaceutical drug delivery systems

InactiveUS7687054B2Improving physical and degradation characteristicReduce molecular weightPowder deliveryDispersion deliverySulfurMedicine

Methods, compounds, and medicinal formulations utilizing biocompatible polymers for delivery of a drug, particularly for solubilizing, stabilizing and / or providing sustained release of drug from topical, implantable, and inhalation systems. Many of the methods, compounds, and medicinal formulations are particularly suitable for oral and / or nasal inhalation and use polymers of the formula —[X—R1—C(O)]— wherein each R1 is an independently selected organic group that links the —X— group to the carbonyl group, and each X is independently oxygen, sulfur, or catenary nitrogen.

Owner:3M INNOVATIVE PROPERTIES CO

Ethylene-C4-C20-alkene copolymers

Owner:CORNELL RES FOUNDATION INC

Derivatized polyhydroxystyrenes (DPHS) with a novolak type structure and blocked DPHS (BDPHS) and processes for preparing the same

ActiveUS20060099531A1Reduce polydispersityPhotomechanical apparatusPhotosensitive material auxillary/base layersVinyl etherDicarbonate

A process for preparing a blocked derivatized poly(4-hydroxystryrene)-DPHS having a novolak type structure which comprises the steps of (i) supplying a solution of methanol containing 4-hydroxyphenylmethylcarbinol, (ii) subjecting said solution to an acid catalyzed displacement reaction for a sufficient period of time and under suitable conditions of temperature and pressure to convert substantially all of said carbinol to 4-hydroxyphenylmethylcarbinol methyl ether in solution, (iii) polymerizing said ether containing solution in the presence of a suitable acid catalyst for a sufficient period of time and under suitable conditions of temperature and pressure to form a novolak type polymer; and (iv) reacting said polymer with a vinyl ether, a dialkyl dicarbonate, or a mixture of vinyl ether and a dialkyl dicarbonate to form the blocked DPHS. New compositions of matter which comprise the blocked derivatized poly(4-hydroxystyrene) prepared in the above manner and which have application in the electronic chemicals market such as in a photoresist composition and MEMS, and in other areas such as in varnishes, printing inks, epoxy resins, copying paper, tackifiers for rubber, crude oil separators, toner resins for photocopying, antireflective coatings, and the like.

Owner:DUPONT ELECTRONICS POLYMERS

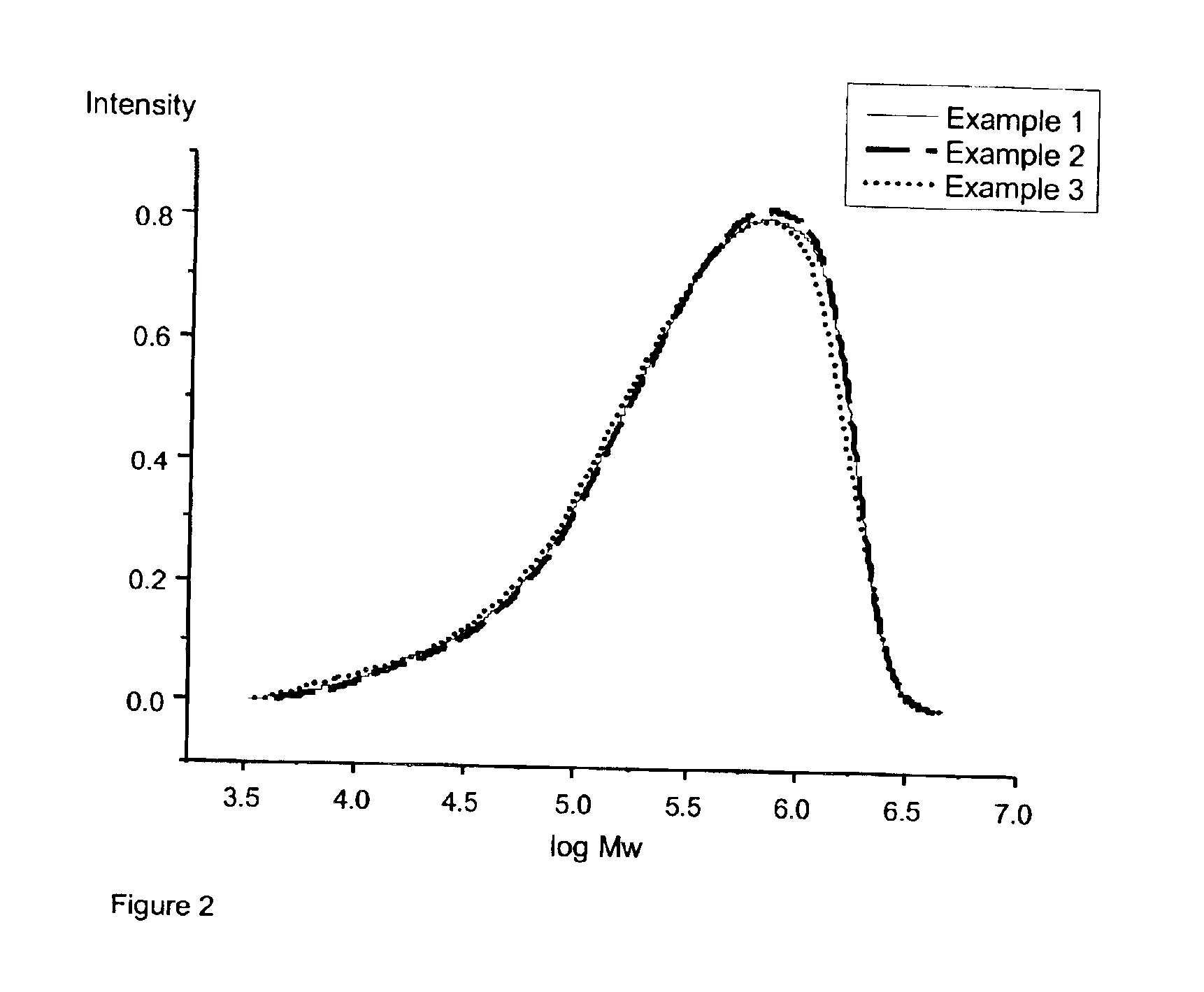

Low-polydispersity photoimageable polymers and photoresists and processes for microlithography

InactiveUS20050112495A1Reduce polydispersityEasy to produceSilver halide emulsionsCoatingsPhotoresistPolymer chemistry

The invention pertains to low polydispersity copolymers useful for photoimaging and photoresist compositions, and to the photoimaging processes which use these compositions. The low polydispersity copolymers of this invention are prepared using controlled radical polymerization (CRP) techniques, such as RAFT (reversible addition fragmentation chain transfer) polymerization.

Owner:COMMONWEALTH SCI & IND RES ORG

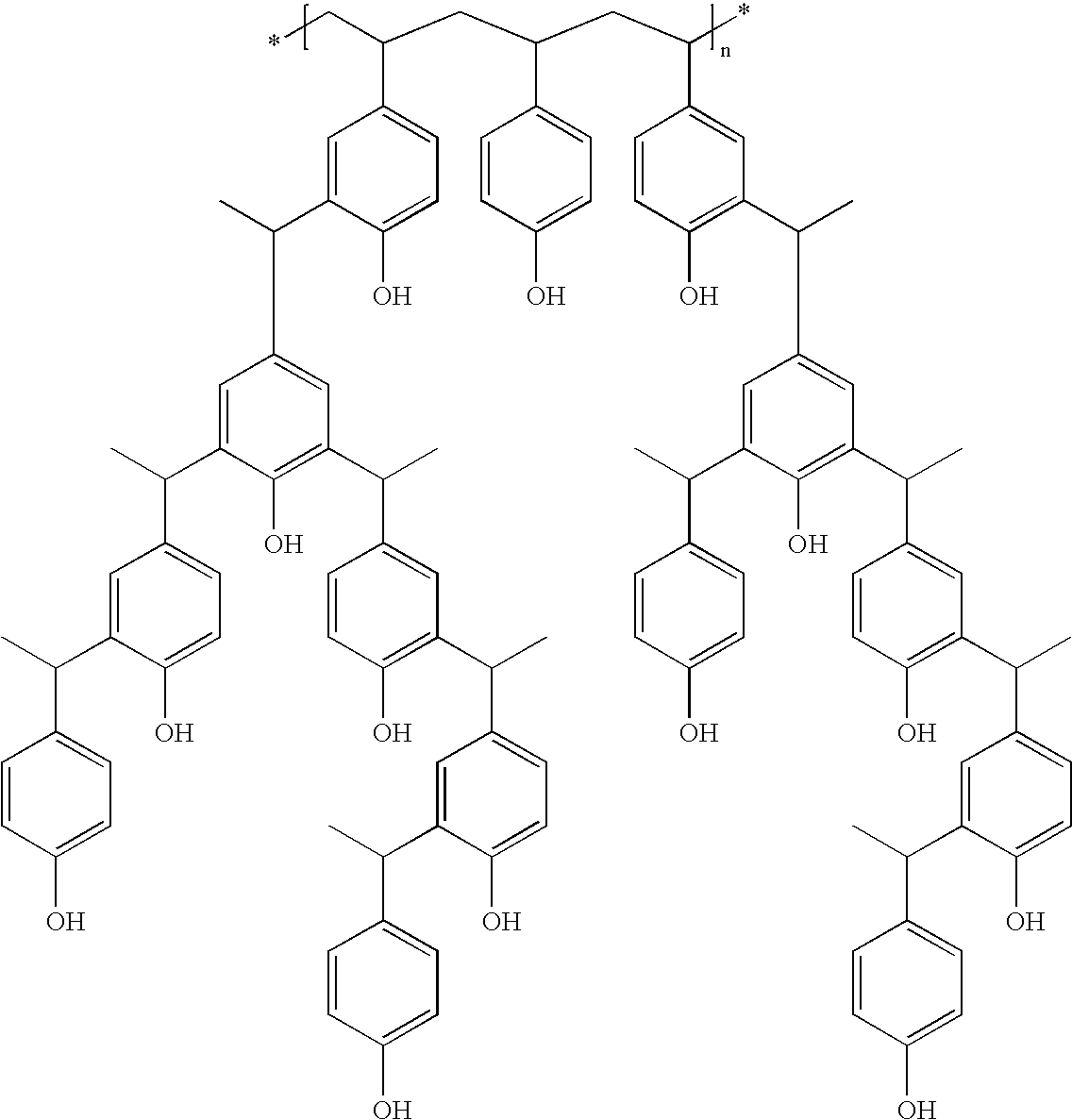

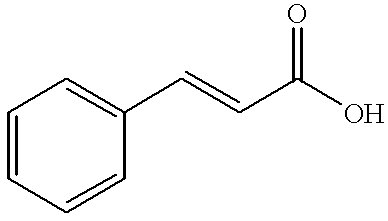

Process for reducing mono-functional and non-functional by-products during aralkylation of phenolics

Phenol aralkyistion polymers can be prepared by reaction among a phenolic monomer, at least one styrenic monomer and an aryl diolefin. A phenolic monomer can be initially aralkylated in the presence of an acid catalyst with a first portion of at least one styrenic monomer to obtain an aralkylated phenol. The aralkylated phenol thereafter can be reacted with an aryl diolefin to obtain a phenol aralkylation polymer. Optionally, (though preferably) the phenol aralkylation polymer is further aralkylated with a second portion of at least one styrenic monomer. By employing specific catalyst concentrations, reactant concentrations, reaction temperatures, and reaction times, the formation of mono-functional and non-functional by-products is substantially reduced.

Owner:GEORGIA PACIFIC CHEM LLC

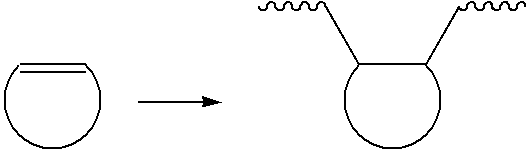

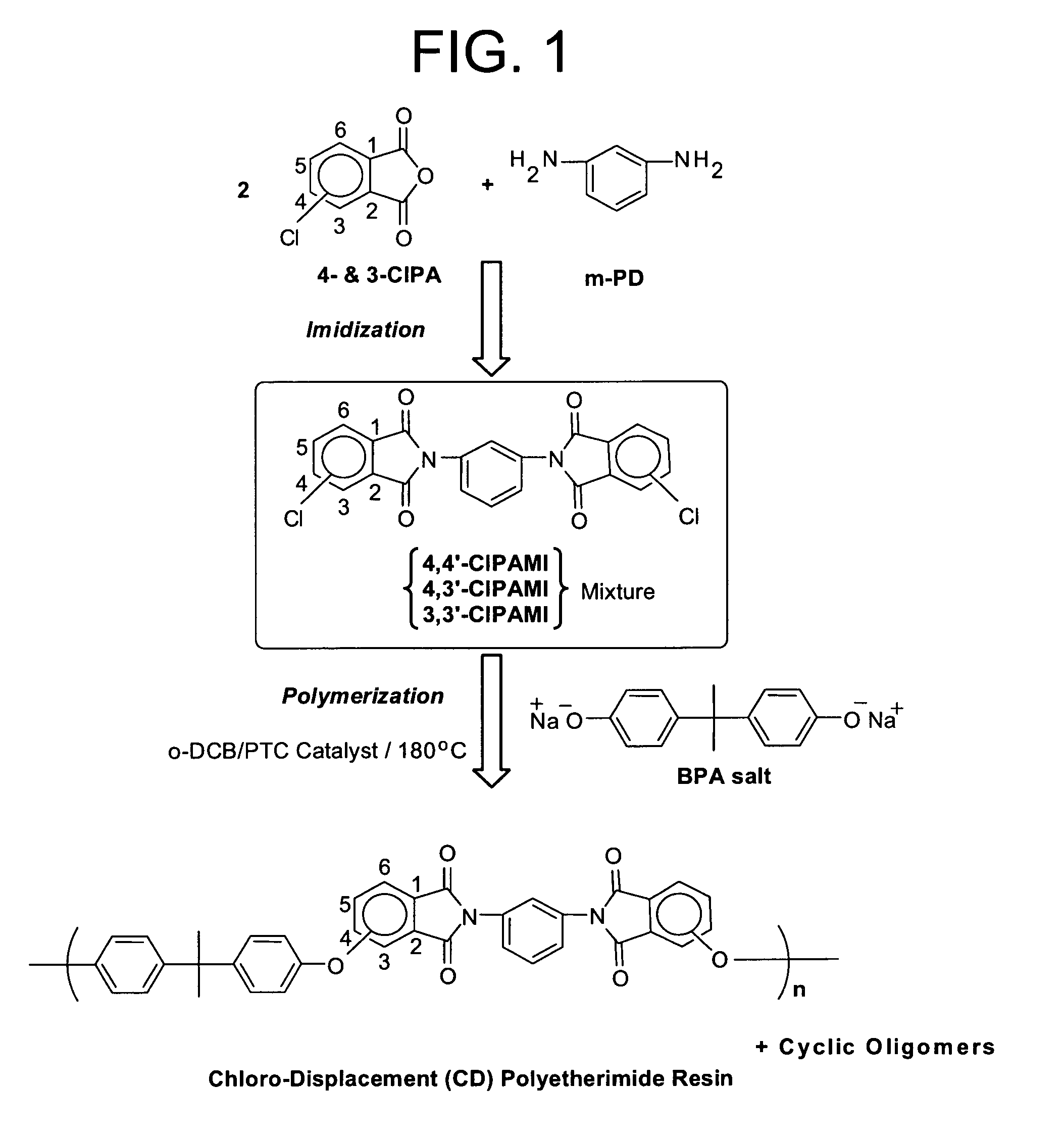

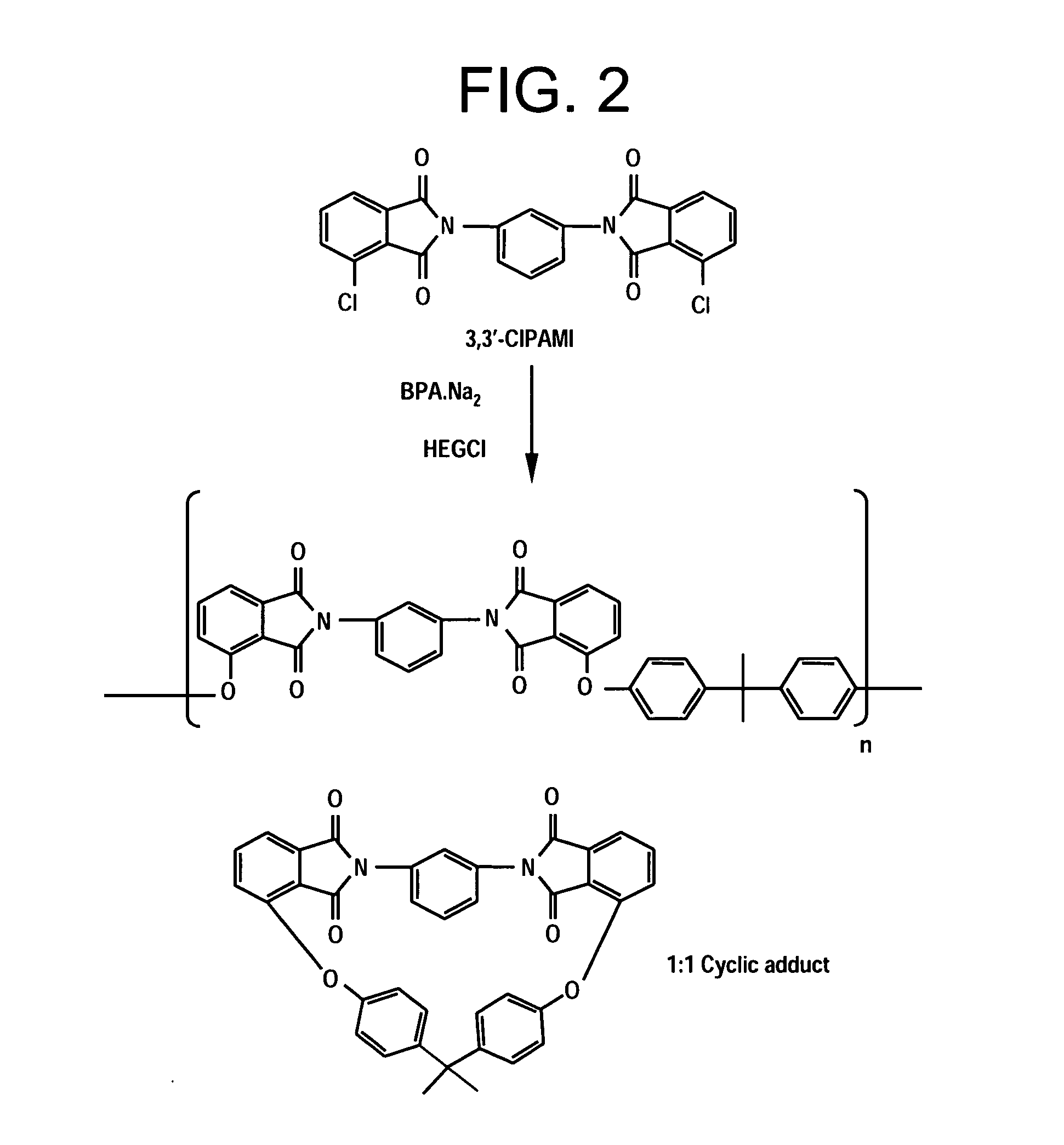

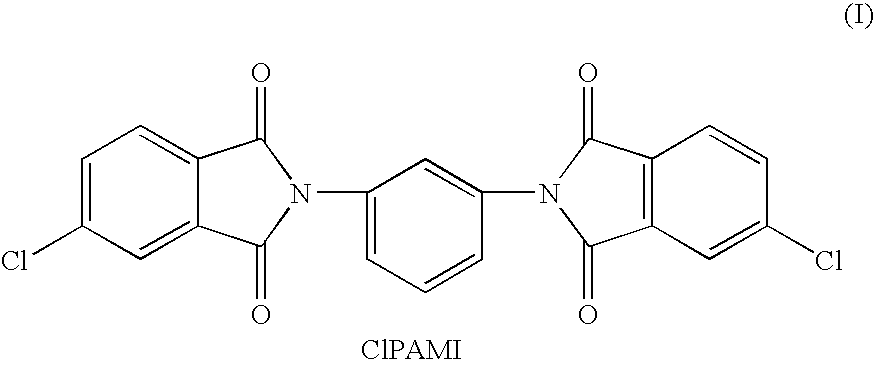

Process for fractionation/concentration to reduce the polydispersivity of polymers

InactiveUS20050049392A1Reduce polydispersityReduced polydispersivityNatural resin processPolyetherimideOligomer

Owner:SABIC GLOBAL TECH BV

Photoresist composition

InactiveUS7014980B2Amenable to free-radical copolymerizationReduce polydispersityPhotosensitive materialsRadiation applicationsMethacrylateHydrogen

A photoresist composition is provided that includes a polymer having at least one acrylate or methacrylate monomer having a formula where R1 represents hydrogen (H), a linear or branched alkyl group of 1 to 20 carbons, or a semi- or perfluorinated linear or branched alkyl group of 1 to 20 carbons; and where R2 represents an unsubstituted aliphatic group or a substituted aliphatic group having zero or one trifluoromethyl (CF3) group attached to each carbon of the substituted aliphatic group, or a substituted or unsubstituted aromatic group; and where R3 represents hydrogen (H), methyl (CH3), trifluoromethyl (CF3), difluoromethyl(CHF2), fluoromethyl (CH2F), or a semi- or perfluorinated aliphatic chain; and where R4 represents trifluoromethyl (CF3), difluoromethyl (CHF2), fluoromethyl (CH2F), or a semi- or perfluorinated substituted or unsubstituted aliphatic group. A method of patterning a substrate using the photoresist composition is also provided herein.

Owner:GLOBALFOUNDRIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com