Continuous micro-reaction device and method for preparing meta-aramid resin and product

A technology of micro-reaction devices and micro-reactors, which is applied in chemical instruments and methods, chemical/physical/physical-chemical reactors, textiles and papermaking, etc., can solve the problems of poor molecular weight distribution uniformity of polymers, and achieve the prevention of implosion and Formation of low-molecular-weight by-products, elevated temperature, and effects of low dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

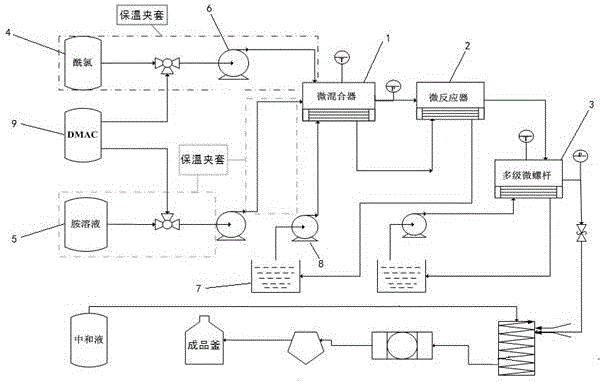

[0032] Combine below figure 1 The embodiments of the present invention will be described in detail.

[0033] The continuous micro-reaction device for preparing meta-aramid resin includes a prepolymerization system, a polycondensation system, a post-treatment system and a heat exchange system. The polycondensation system is connected to control the temperature of the prepolymerization system and the polycondensation system. The prepolymerization system includes a raw material storage device, a micromixer 1 and a microreactor 2 connected in sequence, and the polycondensation system includes a multistage microscrew device 3. The micro-reactor 2 is connected with the multi-edge micro-screw device 3 .

[0034] In the preparation process, the output of raw materials and the prepolymerization stage of the reaction are carried out in the prepolymerization system, and the polycondensation stage of the reaction is carried out in the polycondensation system. It is more than 1000 times ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com