Preparation method of hydrogenated nitrile rubber and degradation and hydrogenation method of butadiene type rubber

A technology of butadiene and rubber is applied in the field of preparation of hydrogenated butadiene rubber, and can solve the problems that hydrogenated nitrile rubber cannot be used at the same time and cannot be prepared.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0112] Under the Ar condition, add 60g of nitrile rubber (NBR; N41L) and 500mL of anhydrous chlorobenzene in a 1L stainless steel airtight container, add Jane's ruthenium catalyst (4ab, 4ab, The amount used is 0.04wt% of the mass of nitrile rubber), and the reaction is 12hr to obtain low molecular weight NBR. The degradation product is precipitated with methanol and dried; the degradation product M w =2.78E+05, M n =1.586E+5, the Mooney viscosity (ML(1+4); 100° C.) was 60.3, and the yield was >97%.

Embodiment 2

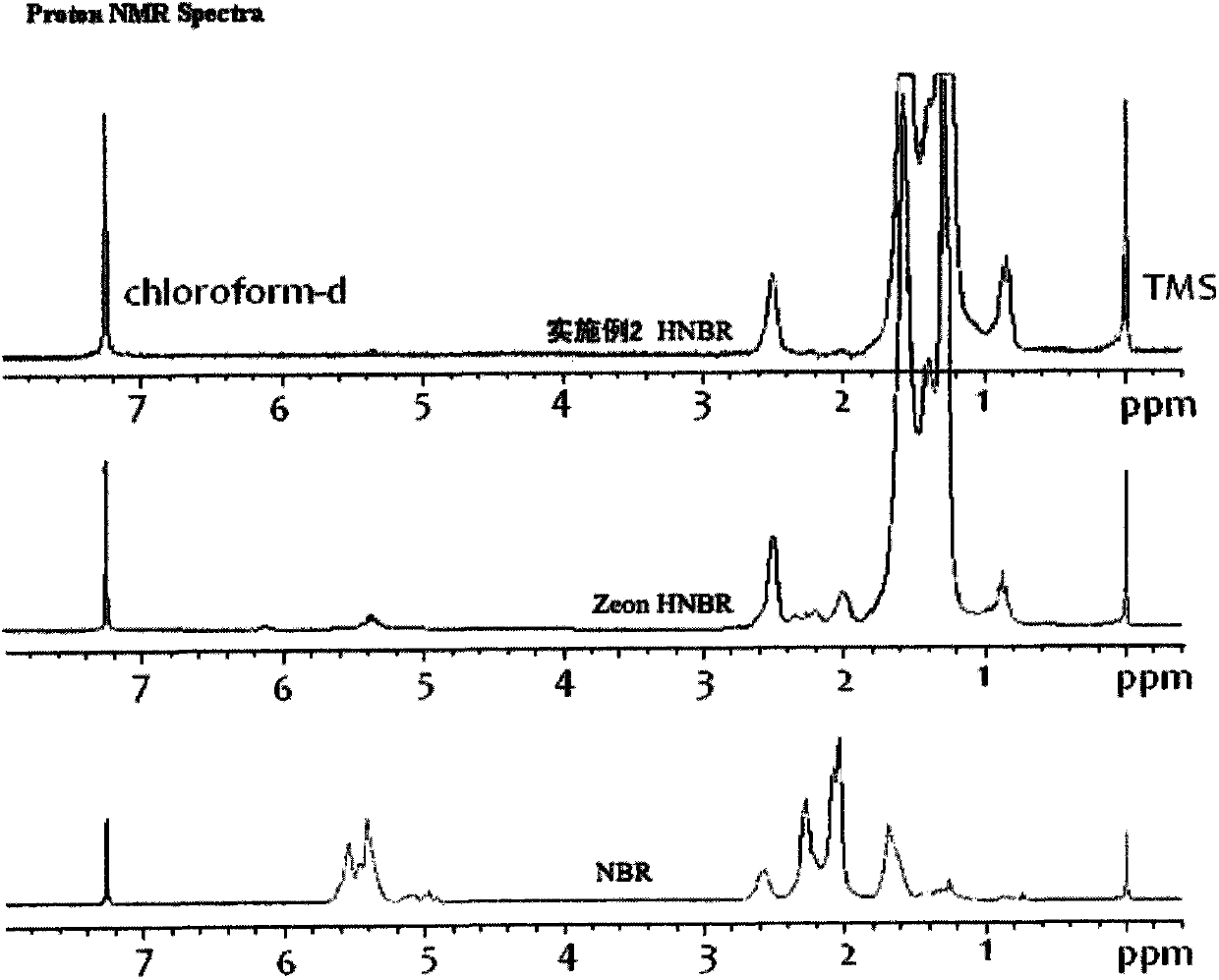

[0113] The preparation of embodiment 2 hydrogenated nitrile rubber (step-by-step method)

[0114] Under the Ar condition, add 60g of nitrile rubber (NBR; N41L) and 500mL of anhydrous chlorobenzene in a 1L stainless steel airtight container, add the Jane's ruthenium catalyst (4aa, Consumption is nitrile rubber 0.07wt%). Hydrogen gas was introduced until the pressure reached 5 MPa, then the temperature was raised to 130° C., and the reaction was carried out for 10 hours. HNBR with low molecular weight and high degree of hydrogenation is obtained. The HNBR product is precipitated with methanol and dried to obtain the product M w =1.60E+05, M n =1.12E+05, iodine value=12.6, hydrogenation degree>95%, yield>98%, molecular weight distribution dispersity 1.4.

Embodiment 3

[0115] The preparation of embodiment 3 hydrogenated nitrile rubber (one-step method)

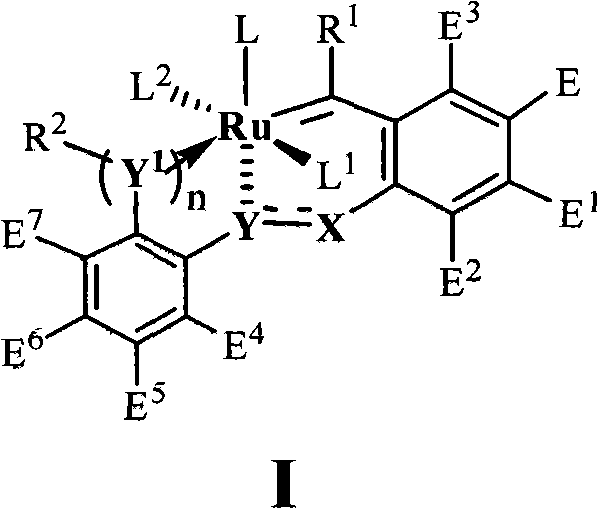

[0116] Under the condition of Ar, add 60g of nitrile rubber (NBR) and 500mL of anhydrous chlorobenzene into a 1L stainless steel airtight container, and after completely dissolving at 30°C, inject hydrogen until the pressure reaches 8.0MPa. Raise the temperature to 125°C, add the Jane's ruthenium catalyst (4aa, the amount is 0.1wt% of the nitrile rubber) in the general formula (I), and react for 15-10 hours until the hydrogenation reaction reaches 95-99%. HNBR with a high degree of hydrogenation is obtained. The degraded and hydrogenated HNBR product was precipitated with methanol and dried to obtain the product M w =1.80E+05, M n =1.07E+05, iodine value=3.1, hydrogenation degree>99%, yield>98%, molecular weight distribution dispersity 1.7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com