Fluorine-silicon modified acrylic resin as well as preparation method and application thereof

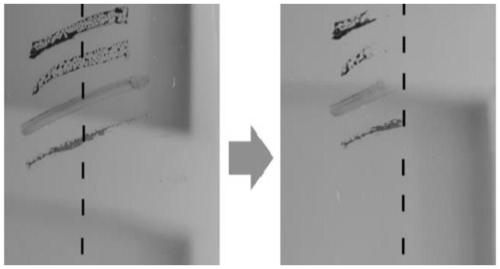

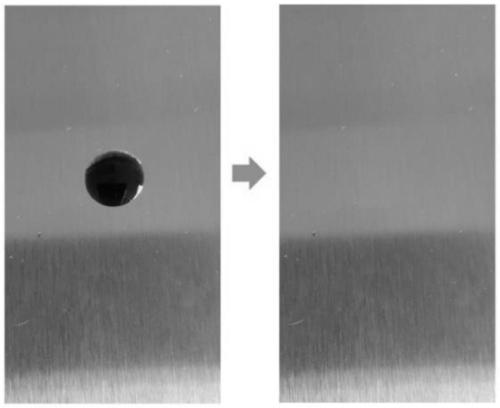

A technology of acrylic resin and fluorosilicone modification, which can be used in coatings, biocide-containing paints, antifouling/underwater coatings, etc., and can solve the problems of insufficient hydrophobic and oleophobic properties of resins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

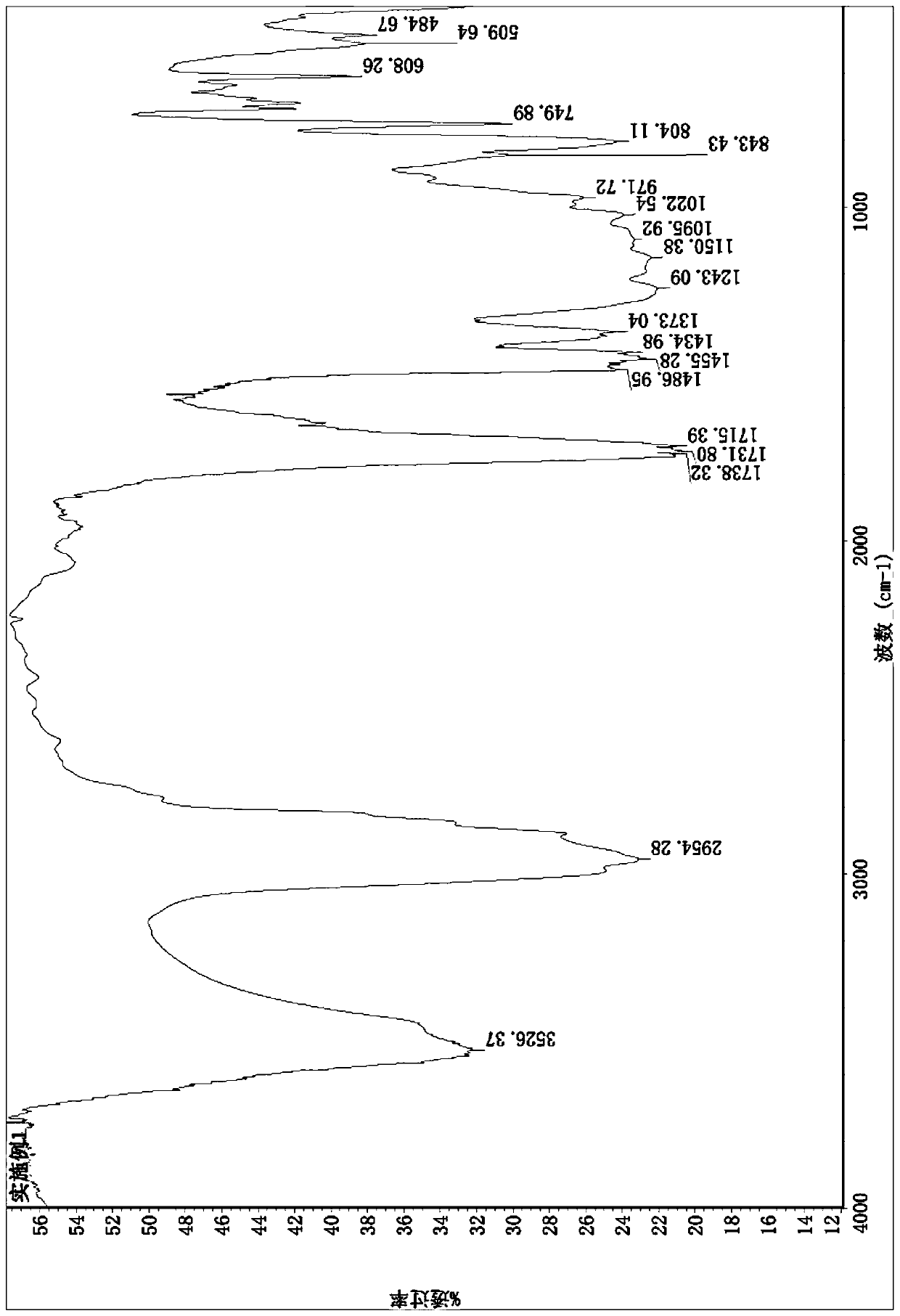

Embodiment 1

[0068] A fluorosilicone modified acrylic resin is composed of the following raw materials in mass percentage: 10% methyl methacrylate, 3% dicyclopentadienyl methacrylate, 5% hydroxyethyl methacrylate caprolactone, methacrylic acid 5% stearyl ester, 10% trifluoroethyl methacrylate, 5% heptadecanyl methacrylate, 2% acrylate-based monoblocked silicone oil (Mn=4000), 2% allyl double-blocked silicone oil ( Mn=3000) 10%, γ-methacryloxypropyltrimethoxysilane 0.5%, methacrylic acid 1%, methacrylate-2-hydroxyethyl 2%, acrylate-4-hydroxybutyl 3 %, glycidyl methacrylate 1%, trimethylolpropane trimethacrylate 1%, di-tert-amyl peroxide 1%, n-dodecyl mercaptan 0.5%, xylene 40%.

[0069] The fluorosilicon-modified acrylic resin of this example is prepared according to the following steps:

[0070] Add 40 parts of xylene, 20 parts of acrylate-based mono-capped silicone oil (Mn=4000) and 2 parts of di-tert-amyl peroxide into a four-necked flask equipped with a stirrer, a condenser, and a ther...

Embodiment 2

[0073] A fluorosilicone modified acrylic resin is composed of the following raw materials in mass percentage: 15% methyl methacrylate, 10% dicyclopentadienyl methacrylate, 5% hydroxyethyl methacrylate caprolactone, methacrylic acid 2% stearyl ester, 4% tetrafluoropropyl methacrylate, 1% heptadecanyl acrylate, 5% acrylate-based monoblocked silicone oil (Mn=2000), 5% allyl double-blocked silicone oil (Mn= 10000) 8%, γ-methacryloxypropyltriethoxysilane 2.5%, methacrylic acid 0.5%, methacrylate-2-hydroxyethyl 3%, acrylate-4-hydroxybutyl 2% , glycidyl methacrylate 0.5%, trimethylolpropane trimethacrylate 2%, di-tert-butyl peroxide 1%, cyclohexyl mercaptan 0.3%, xylene 20%, methyl isobutyl ketone 18.2%.

[0074] The fluorosilicon-modified acrylic resin of this example is prepared according to the following steps:

[0075] Add 38.2 parts of mixed solvents, 50 parts of acrylate-based mono-capped silicone oil (Mn=2000) and 2 parts of di-tert-butyl peroxide into a four-necked flask eq...

Embodiment 3

[0078] A fluorosilicon modified acrylic resin is composed of the following raw materials in mass percentage: 10% methyl methacrylate, 8% dicyclopentadienyl methacrylate, 4% hydroxyethyl methacrylate caprolactone, methacrylic acid 3% stearyl ester, 5% trifluoroethyl acrylate, 3% heptadecanyl methacrylate, 10% acrylate-based monoblocked silicone oil (Mn=300), 10% allyl double-blocked silicone oil (Mn= 2000) 2%, γ-methacrylic acid oxypropylmethyldimethoxysilane 1%, methacrylic acid 2%, methacrylate-2-hydroxyethyl 4%, acrylate-4-hydroxybutyl 1% , Glycidyl methacrylate 1.5%, trimethylolpropane trimethacrylate 1.5%, di-tert-amyl peroxide 2%, n-octyl mercaptan 0.3%, propylene glycol methyl ether acetate 41.7%.

[0079] The fluorosilicon-modified acrylic resin of this example is prepared according to the following steps:

[0080]Add 41.7 parts of propylene glycol methyl ether acetate, 100 parts of acrylate-based double-capped silicone oil (Mn=200) and 4 parts of di-tert-amyl peroxide...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com