Water-based conductive ink and preparation method thereof

A conductive ink, water-based technology, applied in inks, household utensils, applications, etc., can solve the problems of poor stability and serious pollution of conductive inks, achieve low cost, weaken electromigration, and facilitate deposition and film formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

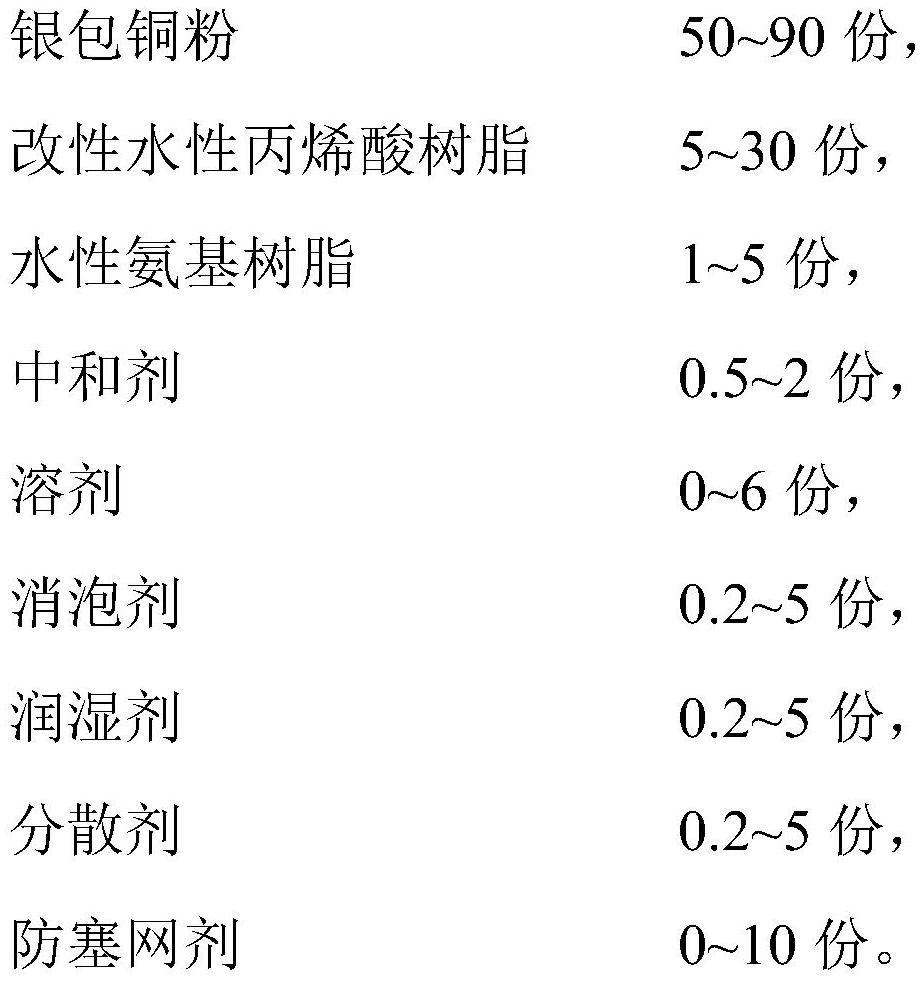

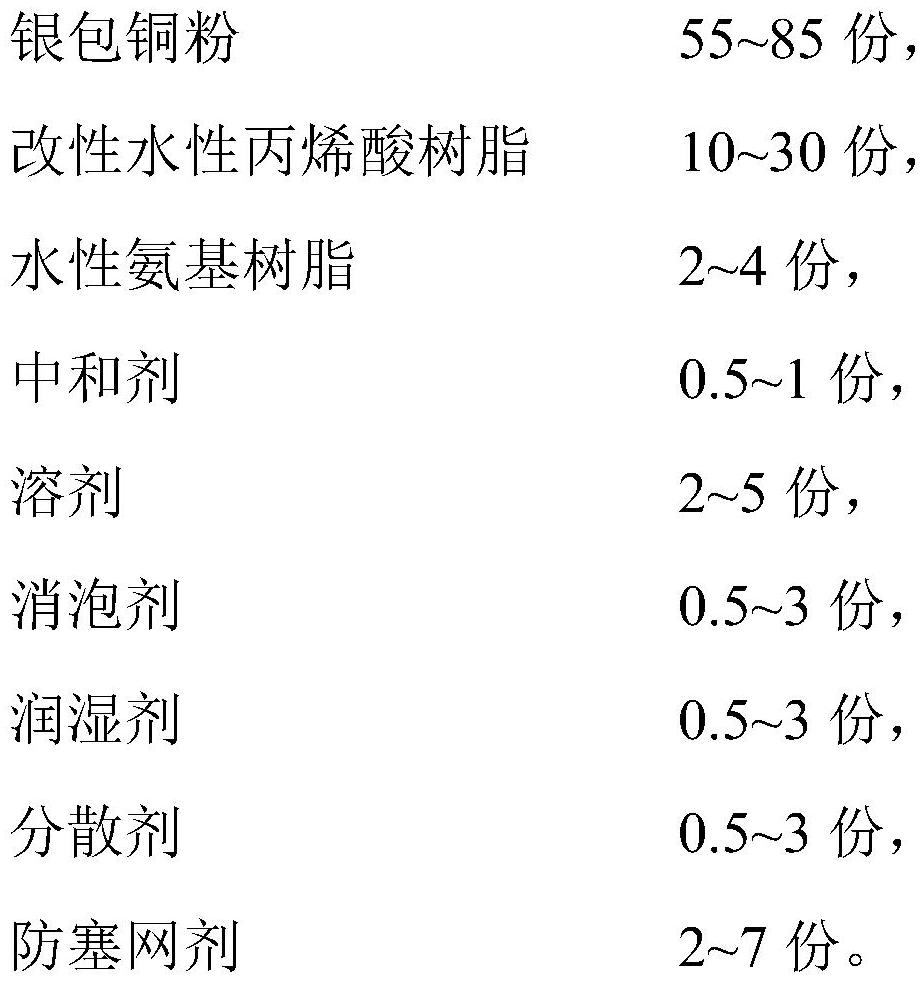

[0042] The second aspect of the embodiment of the present application provides a method for preparing the above-mentioned water-based conductive ink, comprising the following steps:

[0043] After mixing the silver-coated copper powder, modified water-based acrylic resin, water-based amino resin, neutralizer, solvent, defoamer, wetting agent, dispersant and anti-blocking agent in the formula, the gradient speed-up mixing process is carried out to obtain Water-based conductive ink.

[0044] The preparation method of the water-based conductive ink provided in the second aspect of the application, the silver-coated copper powder, modified water-based acrylic resin, water-based amino resin, neutralizer, solvent, defoamer, wetting agent, dispersant and After the anti-blocking agent is mixed, the raw material components are mixed evenly through the gradient speed-up mixing process, and then the water-based conductive ink is obtained. The process is simple, the preparation time is sh...

Embodiment 1

[0050] A water-based conductive ink, including components: silver-coated copper powder: 72 parts, epoxy resin modified water-based acrylic resin: 12 parts, water-based amino resin: 3.5 parts, neutralizer: 0.7 parts, solvent: 5.6 parts, disinfectant Foaming agent: 1 part, wetting agent: 1 part, dispersing agent: 1 part, anti-blocking agent: 3.2 parts.

[0051] Its preparation includes steps: after accurately weighing epoxy resin-modified water-based acrylic resin, water-based amino resin, neutralizer, solvent, defoamer, wetting agent, dispersant, and anti-blocking agent, add the mixture into the mixing tank according to the proportion , then place the mixing tank in a planetary mixer operated at room temperature at the following speeds: 500 rpm for 1 minute, then 750 rpm for 1 minute, then 900 rpm 1 minute, then stirred at 1100 rpm for 1 minute, and finally stirred at 1400 rpm for 1 minute, a total of 5 minutes, and the water-based conductive ink can be prepared after the stirr...

Embodiment 2

[0053] A water-based conductive ink, including components: silver-coated copper powder: 69 parts, epoxy resin modified water-based acrylic resin: 15 parts, water-based amino resin: 3.75 parts, neutralizer: 0.75 parts, solvent: 4 parts, disinfectant Foaming agent: 1.5 parts, wetting agent: 1 part, dispersing agent: 1 part, anti-blocking agent: 4 parts.

[0054] The preparation includes steps: after accurately weighing epoxy resin modified water-based acrylic resin, water-based amino resin, neutralizer, solvent, defoamer, wetting agent, dispersant, and anti-blocking agent, add them into the mixing tank according to the proportion , and then put the mixing tank into a planetary mixer, and the mixer was operated at room temperature at the following speed: 500 rpm for 1 minute, then 750 rpm for 1 minute, then 900 rpm for 1 minute minutes, then stirred at 1100 rpm for 1 minute, and finally at 1400 rpm for 1 minute, for a total of 5 minutes. After the stirring was completed, the wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com