Preparation method of lead-acid battery pbo nano powder

A lead-acid battery, nano-powder technology, applied in nanotechnology, battery recycling, lead oxide and other directions, can solve the problems of difficult commercial production and application, high process cost, unsuitable for lead-acid battery recycling and manufacturing process, etc. Achieve the effect of reducing production cost, simplifying process and shortening production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

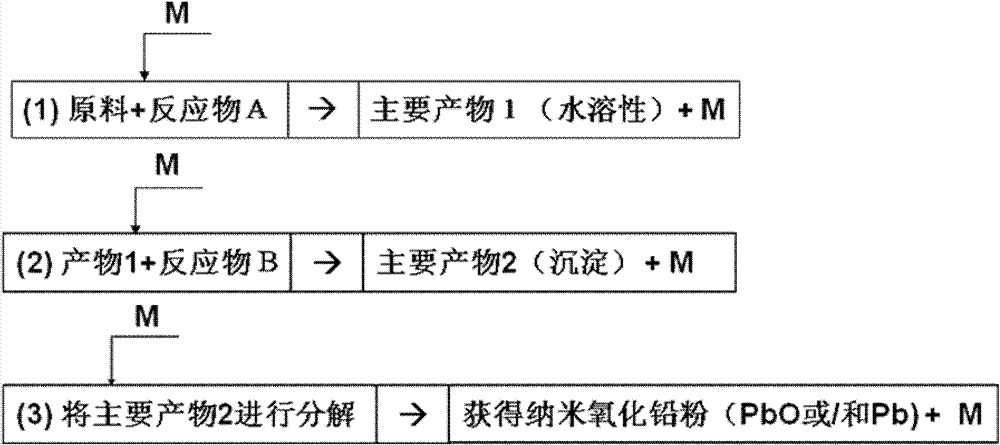

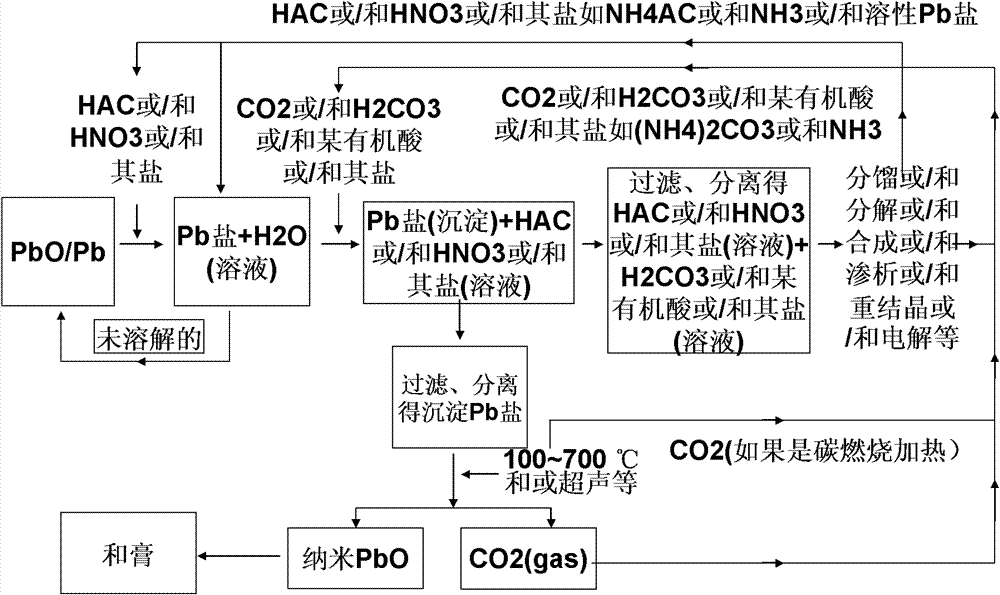

[0059] The preparation method of lead-acid accumulator lead oxide (PbO) nanopowder of the present invention, its schematic flow sheet, as specification attached Figure 5 As shown, the steps include:

[0060] (1) Mix 0.1kg of lead powder (containing about 0.457mol Pb) with 0.11kg or 1.1kg or 98kg of 50% acetic acid solution (containing about 0.457mol or 0.9mol or 9 or 457mol or 800mol of acetic acid) solution, and React at 25°C for 1 or 30 minutes while stirring to dissolve the lead powder in the solution; wherein, this step can be supplemented with ultrasound; the unreacted part of the lead powder can be taken out and mixed with the next batch of lead powder;

[0061](2) At room temperature (25°C), feed 0.02kg or 0.2kg or 20kg (about 0.457mol or 4.57mol or 457mol) of CO into the solution of dissolved lead salt (lead acetate) 2 ;

[0062] (3) Filter the solution system after the reaction to obtain the precipitate and the solution respectively. Thermally decompose the precip...

Embodiment 2

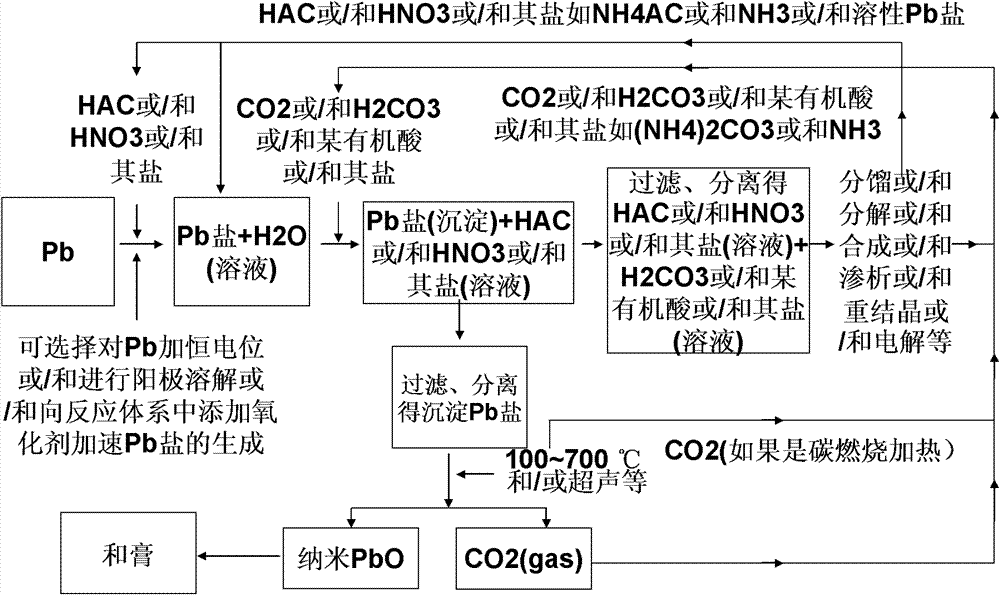

[0065] The preparation method of the lead oxide nanopowder of the present invention, its schematic flow sheet, as description attached Figure 6 As shown, the steps include:

[0066] (1) Mix 0.1kg of lead powder (containing about 0.457mol Pb) with 0.11kg or 1.1kg or 98kg of 50% acetic acid solution (containing about 0.9mol or 9mol or 90mol of acetic acid) and mix it under room temperature (25°C) React for 1 or 30 minutes while stirring to dissolve the lead powder in the solution; wherein, this step can be supplemented with ultrasound; the unreacted part of the lead powder can be taken out and mixed with the next batch of lead powder.

[0067] (2) Add 0.028kg or 0.28kg or 28kg (about 0.457mol or 4.57mol or 457mol) of urea to the solution of dissolved lead salt (lead acetate), heat (25-99°C) to decompose the urea and allow the reaction to occur.

[0068] (3) Filter the solution system after the reaction to obtain the precipitate and the solution respectively. Heat and decompos...

Embodiment 3

[0071] The preparation method of the lead oxide nanopowder of the present invention, its schematic flow sheet, as description attached Figure 7 As shown, the steps include:

[0072] (1) Mix 0.1kg of lead powder (about 0.457mol Pb) with 0.11kg or 1.1kg of acetic acid (25%) + sodium acetate (25%) solution (about 0.79mol or 7.9mol of acetate), and React at room temperature (25°C) for 1 or 30 minutes while stirring to dissolve the lead powder in the solution; wherein, this step can be supplemented with ultrasound; the unreacted part of the lead powder can be taken out and mixed with the next batch of lead powder .

[0073] (2) Add 0.038kg or 11.4kg (about 0.457mol or 13.71mol) of sodium bicarbonate to the solution of dissolved lead salt (lead acetate), heat (30-99°C) to decompose the sodium bicarbonate and allow the reaction to occur.

[0074] (3) Filter the solution system after the reaction to obtain the precipitate and the solution respectively. Heat and decompose the preci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com