Copper-sulfur separation inhibitor, lime-free copper-sulfur flotation separation method and application thereof

A copper-sulfur separation and separation method technology, applied in flotation, solid separation and other directions, can solve the problems of difficult filtration of concentrates, high environmental protection pressure, large fluctuations in addition amount, etc., to overcome the low grade of copper concentrates and ensure the quality and recovery rate, the effect of strong inhibition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

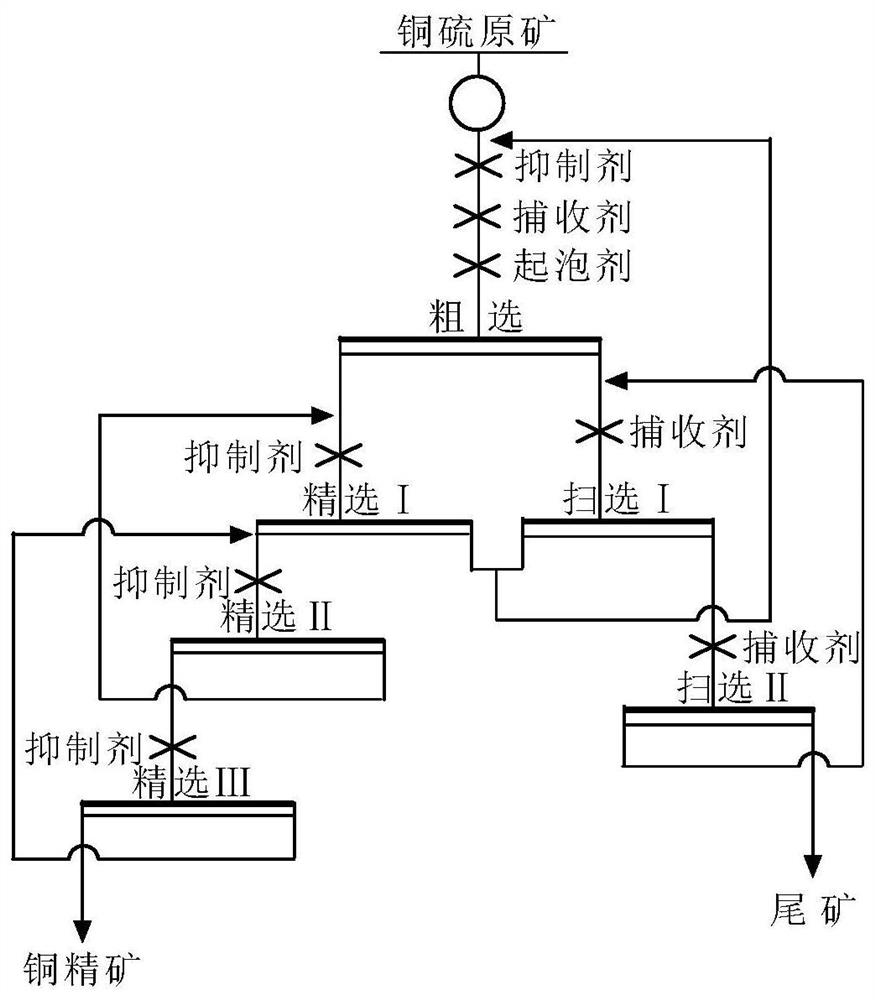

[0055] As a preferred embodiment of the present invention, the raw copper-sulfur ore is ground and then added with water to make a slurry.

[0056] Since the copper-sulfur raw ore is mostly lumpy or granular, which is not conducive to the subsequent flotation process, it needs to be ground.

[0057] As a preferred embodiment of the present invention, in step (a), the copper-sulfur raw ore is ground to a fineness of -0.074mm, accounting for 50-85%.

[0058] As a preferred embodiment of the present invention, in step (a), the mass concentration of the pulp is 30-45%.

[0059] If the mass concentration of the pulp is too low, it will easily cause a large consumption of chemicals and affect the recovery rate of copper concentrate; if the mass concentration of the pulp is too high, it will easily cause inclusions and affect the grade of the concentrate. Therefore, the mass concentration of the pulp needs to be controlled within a specific range. Typical but non-limiting mass conc...

Embodiment 1

[0088] This embodiment provides a copper-sulfur separation inhibitor, which includes the following raw materials: sodium carbonate, ammonium sulfate, calcium chloride and sodium hydroxide, and does not contain lime;

[0089] Wherein, the mass ratio of sodium carbonate, ammonium sulfate, calcium chloride and sodium hydroxide is 2:2:2:1.

Embodiment 2

[0091] This embodiment provides a copper-sulfur separation inhibitor, which includes the following raw materials: sodium carbonate, ammonium sulfate, calcium chloride and sodium hydroxide, and does not contain lime;

[0092] Wherein, the mass ratio of sodium carbonate, ammonium sulfate, calcium chloride and sodium hydroxide is 1:1:1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com