Oil-based drilling fluid with high temperature and high pressure resistance

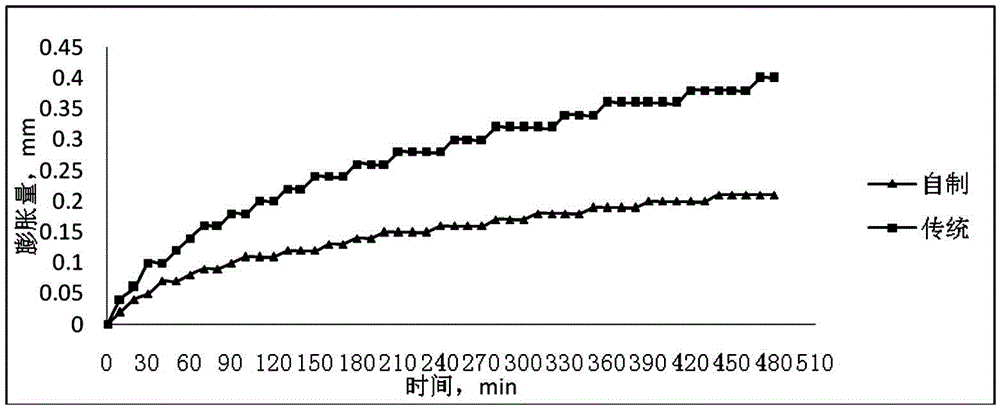

An oil-based drilling fluid, high temperature resistance technology, applied in the field of oil-based drilling fluid, can solve the problems of poor high temperature and high pressure resistance, environmental pollution, high toxicity, etc., achieve high viscosity and shear force, meet cuttings carry, low toxicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

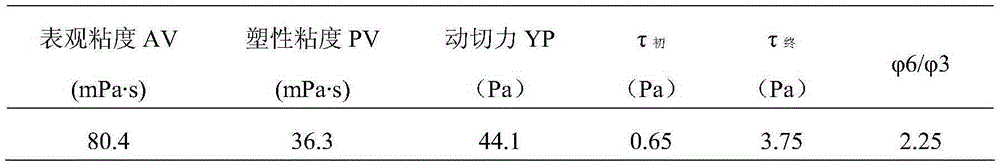

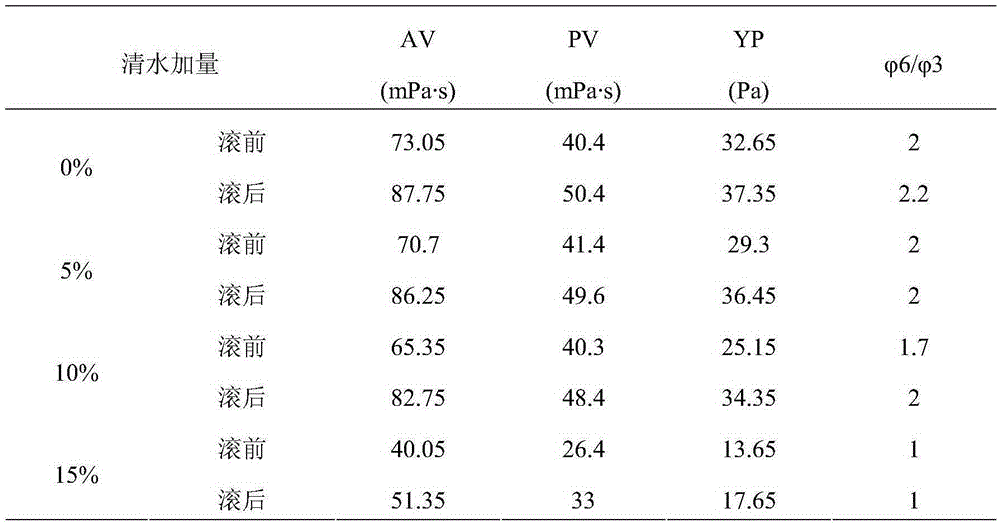

[0018] 1. Preparation method and basic rheological parameter measurement of resistant high temperature and high pressure oil-based drilling fluid

[0019] (1) The preparation method is as follows:

[0020] Calculated based on the amount added per 300g of No.5 white oil, the preferred mass parts of the above components are: 15g homemade organic soil HIS, 12g emulsifier, 12g fluid loss reducer, 3g wetting agent TWEEN-80, 4.5g Alkalinity regulator, 4.5g weighting agent.

[0021] 1) First, weigh out No. 5 white oil, emulsifier, homemade organic soil, fluid loss agent, wetting agent, alkalinity regulator and weighting agent according to the above-mentioned ratio.

[0022] 2) Add No. 5 white oil to the container (mud cup), heat to 180℃ at 10000r / min, add 180℃ oxidized asphalt powder and stir for 30min, cool to room temperature and then add dodecylbenzene sulfonic acid in order Sodium SDBS, homemade organic soil (HIS), wetting agent (TWEEN-80), alkalinity regulator (CaO) and weighting agent...

Embodiment 2

[0042] High temperature and high pressure resistant oil-based drilling fluid, which is prepared by mixing homemade organic soil, emulsifier, fluid loss agent, wetting agent, alkalinity regulator, and weighting agent in parts by weight. Calculated by the amount added in the oil, the mass parts of the above components are: 10g homemade organic soil HIS, 10g sodium dodecylbenzene sulfonate SDBS, 10g 180℃ oxidized asphalt powder, 2g TWEEN-80, 3gCaO, 3g recrystallized stone. Others are the same as in Example 1.

Embodiment 3

[0044] High temperature and high pressure resistant oil-based drilling fluid, which is prepared by mixing homemade organic soil, emulsifier, fluid loss agent, wetting agent, alkalinity regulator, and weighting agent in parts by weight. Calculated by the amount added in the oil, the mass parts of the above components are: 20g homemade organic soil HIS, 15g sodium dodecylbenzene sulfonate SDBS, 15g 180℃ oxidized asphalt powder, 5g TWEEN-80, 6gCaO, 6g recrystallized stone. Others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Plastic viscosity | aaaaa | aaaaa |

| Expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com